ASTM E1623-00

(Test Method)Standard Test Method for Determination of Fire and Thermal Parameters of Materials, Products, and Systems Using an Intermediate Scale Calorimeter (ICAL)

Standard Test Method for Determination of Fire and Thermal Parameters of Materials, Products, and Systems Using an Intermediate Scale Calorimeter (ICAL)

SCOPE

1.1 This fire-test-response standard assesses the response of materials, products, and assemblies to controlled levels of radiant heat exposure with or without an external ignitor.

1.2 The fire-test-response characteristics determined by this test method include the ignitability, heat release rates, mass loss rates, visible smoke development, and gas release of materials, products, and assemblies under well ventilated conditions.

1.3 This test method is also suitable for determining many of the parameters or values needed as input for computer fire models. Examples of these values include effective heat of combustion, surface temperature, ignition temperature, and emissivity.

1.4 This test method is also intended to provide information about other fire parameters such as thermal conductivity, specific heat, radiative and convective heat transfer coefficients, flame radiation factor, air entrainment rates, flame temperatures, minimum surface temperatures for upward and downward flame spread, heat of gasification, nondimensional heat of gasification (1) and the Φ flame spread parameter (see Test Method E 1321). While some studies have indicated that this test method is suitable for determining these fire parameters, insufficient testing and research have been done to justify inclusion of the corresponding testing and calculating procedures.

1.5 The heat release rate is determined by the principle of oxygen consumption calorimetry, via measurement of the oxygen consumption as determined by the oxygen concentration and flow rate in the exhaust product stream (exhaust duct). The procedure is specified in 11.1. Smoke development is quantified by measuring the obscuration of light by the combustion product stream (exhaust duct).

1.6 Specimens are exposed to a constant heating flux in the range of 0 to 50 kW/m2 in a vertical orientation. Hot wires are used to ignite the combustible vapors from the specimen during the ignition and heat release tests. The assessment of the parameters associated with flame spread requires the use of line burners instead of hot wire ignitors.

1.6.1 Heat release measurements at low heat flux levels ( 10 kW/m2) require special considerations as described in Section A1.1.6.

1.7 This test method has been developed for evaluations, design, or research and development of materials, products, or assemblies, for mathematical fire modeling, or for research and development. The specimen shall be tested in thicknesses and configurations representative of actual end product or system uses.

1.8 Limitations of the test method are listed in Section .

1.9 The values stated in SI units are to be regarded as the standard.

1.10 This standard is used to measure and describe the response of materials, products, or assemblies to heat and flame under controlled conditions, but does not by itself incorporate all factors required for fire hazard or fire risk assessment of the materials, products, or assemblies under actual fire conditions.

1.11 Fire testing of products and materials is inherently hazardous, and adequate safeguards for personnel and property shall be employed in conducting these tests. This test method may involve hazardous materials, operations, and equipment. Specific information about hazard is given in Section 7.

1.12 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: E 1623 – 00 An American National Standard

Standard Test Method for

Determination of Fire and Thermal Parameters of Materials,

Products, and Systems Using an Intermediate Scale

Calorimeter (ICAL)

This standard is issued under the fixed designation E 1623; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 1.7 This test method has been developed for material,

product, or assembly evaluations, mathematical modeling,

1.1 This fire-test-response standard covers measuring the

design purposes, or research and development. The specimen

response of materials, products, and assemblies exposed to

shall be tested in thicknesses and configurations representative

controlled levels of radiant heating with or without an external

of actual end product or system uses.

ignitor.

1.8 Limitations of the test method are listed in Section 12.

1.2 This test method is used to determine the ignitability,

1.9 The values stated in SI units are to be regarded as the

heat release rates, mass loss rates, and visible smoke develop-

standard.

ment of materials, products, and assemblies under well venti-

1.10 This standard is used to measure and describe the

lated conditions.

response of materials, products, or assemblies to heat and

1.3 This test method is also used to determine many of the

flame under controlled conditions, but does not by itself

parameters or values needed in computer fire models. Ex-

incorporate all factors required for fire hazard or fire risk

amples of these values include effective heat of combustion,

assessment of the materials, products, or assemblies under

surface temperature, ignition temperature, gas concentrations,

actual fire conditions.

and emissivity.

1.11 This standard does not purport to address all of the

1.4 This test method was also designed to provide informa-

safety concerns, if any, associated with its use. It is the

tion about other fire parameters such as thermal conductivity,

responsibility of the user of this standard to establish appro-

specific heat, radiative and convective heat transfer coeffi-

priate safety and health practices and determine the applica-

cients, flame radiation factor, air entrainment rates, flame

bility of regulatory limitations prior to use. For specific hazard

temperatures, minimum surface temperatures for upward and

statements, see Section 7.

downward flame spread, heat of gasification, nondimensional

heat of gasification (1) and the F flame spread parameter (see

2. Referenced Documents

Test Method E 1321). While early studies indicate that it is

2.1 ASTM Standards:

appropriate to use this test method to determine these param-

D 2016 Test Methods for Moisture Content of Wood

eters, insufficient testing and research has been done to justify

D 3286 Test Method for Gross Calorific Value of Coal and

inclusion of testing and calculational procedures at this time.

Coke by the Isoperibol Bomb Calorimeter

1.5 The heat release rate is determined by measurement of

E 84 Test Method for Surface Burning Characteristics of

the oxygen consumption as determined by the oxygen concen-

Building Materials

tration and flow in the exhaust product stream as specified in

E 176 Terminology of Fire Standards

11.1. Smoke development is quantified by measuring the

E 177 Practice for Use of the Terms Precision and Bias in

obscuration of light by the combustion product stream.

ASTM Test Methods

1.6 Specimens are exposed to heating fluxes ranging from 0

2 E 662 Test Method for Specific Optical Density of Smoke

to 50 kW/m (heat release measurements at the low flux levels

Generated by Solid Materials

are limited by the exhaust hood size) in a vertical orientation.

E 691 Practice for Conducting an Interlaboratory Study to

Hot wires are used as the ignition source when the parameters

Determine the Precision of a Test Method

other than those connected to flame spread are being deter-

E 800 Guide for Measurement of Gases Present or Gener-

mined.

ated During Fires

This test method is under the jurisdiction of ASTM Committee E-5 on Fire

Standards and is the direct responsibility of Subcommittee E05.21 on Smoke and

Combustion Products. Discontinued; see 1988 Annual Book of ASTM Standards, Vol 04.09. Replaced

Current edition approved Oct. 10, 2000. Published January 2001. Originally by D 4442 and D 4444.

published as E 1623–94. Last previous edition E 1623–99. Annual Book of ASTM Standards, Vol 05.05.

2 5

The boldface numbers given in parentheses refer to the list of references at the Annual Book of ASTM Standards, Vol 04.07.

end of this standard. Annual Book of ASTM Standards, Vol 14.02.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

E 1623

E 906 Test Method for Heat and Visible Smoke Release 4. Summary of Test Method

Rates for Materials and Products

4.1 This is a test method designed to measure the rate of

E 1321 Test Method for Determining Material Ignition and

heat release from a specimen 1 m in a vertical orientation. The

Flame Spread Properties

specimen is exposed to a uniform heat flux from a gas fired

E 1354 Test Method for Heat and Visible Smoke Release

radiant panel up to 50 kW/m and ignited instantly. Heat

Rates for Materials and Products Using an Oxygen Con-

release measured by this test method is based on the observa-

sumption Calorimeter

tion that, generally, the net heat of combustion is directly

2.2 ASTM Proposal:

related to the amount of oxygen required for combustion (2, 3).

P147 Proposed Method for Room Fire Tests of Wall and

The primary measurements of oxygen concentrations and

Ceiling Materials and Assemblies

exhaust flow are made as specified by Huggett (3). Burning

2.3 ISO Standards:

may be either with or without a pilot ignition applied at the top

ISO 5657-1986(E) Fire Tests—Reaction to Fire—

and bottom of the specimen.

Ignitability of Building Materials

4.2 Additional measurements include the mass-loss rate of

ISO 5660-1 Fire Tests—Reaction to Fire—Rate of Heat

the specimen, surface temperature, the time to sustained

Release from Building Products

flaming and the specimen’s interior temperatures. The appara-

ISO 5725 Precision of Test Methods—Determination of

tus can be used to develop data relative to the other parameters

Repeatability and Reproducibility for a Standard Test

discussed in 1.2 and 1.3.

Method by Inter-Laboratory Tests

5. Significance and Use

ISO 9705 Full Scale Room Test for Surface Products

5.1 This test method is used primarily to determine the heat

3. Terminology

release rate of materials, products, and assemblies. Other

parameters are the effective heat of combustion, mass loss rate,

3.1 Definitions:

3.1.1 For definitions of terms used in this test method, refer the time to ignition, smoke and gas production, emissivity, and

surface temperature. These properties are determined on a

to Terminology E 176.

3.2 Definitions of Terms Specific to This Standard: specimen that may be an assembly of materials or products that

are tested in their end-use thickness. Therefore, the heat release

3.2.1 effective heat of combustion—the measured heat re-

lease divided by the mass loss for a specific time period. rate of a wall assembly, for instance, can be determined.

5.2 Representative joints and other characteristics of an

3.2.2 emissivity—the ratio of the power per unit area radi-

assembly shall be included in a specimen when these details

ated from a material’s surface to that radiated from a black

are part of normal design.

body at the same temperature.

5.3 This test method is applicable to end-use products not

3.2.3 heat release rate—the heat evolved from the speci-

men, per unit of time and area. having an ideally planar external surface. The radiant flux field

shall be adjusted to be that which is desired at the average

3.2.4 heating flux—the incident flux imposed externally

from the heater on the specimen at the initiation of the test. distance of the surface from the radiant panel.

5.4 In this procedure, the specimens are subjected to one or

3.2.4.1 Discussion—the specimen, once ignited, is also

heated by its own flame. more specific sets of laboratory conditions. If different test

conditions are substituted or the end use conditions are

3.2.5 ignitability—the propensity to ignition, as measured

by the time to sustained flaming, in seconds, at a specified changed, it may not be possible by or from this test to predict

changes in the fire test response characteristics measured.

heating flux.

3.2.6 net heat of combustion—the oxygen bomb (see Test Therefore, the results are valid only for the fire test exposure

conditions described in this procedure.

Method D 3286) value for the heat of combustion, corrected

for gaseous state of product water. 5.5 Test Limitations:

5.5.1 The test results have limited validity if the specimen

3.2.7 orientation—the plane in which the exposed face of

the specimen is located during testing, either vertical or melts sufficiently to overflow the drip tray, or explosive

spalling occurs.

horizontal facing up.

3.2.8 oxygen consumption principle—the expression of the 5.5.2 Exercise caution in interpreting results of specimens

that sag, deform, or delaminate during a test. Report observa-

relationship between the mass of oxygen consumed during

tions of such behavior.

combustion and the heat released.

3.2.9 smoke obscuration—reduction of light transmission

6. Apparatus

by smoke, as measured by light attenuation.

6.1 General:

3.2.10 sustained flaming—existence of flame on or over

6.1.1 Where dimensions are stated in the following descrip-

most of the specimen surface for periods of at least 5 s.

tion, they shall be considered mandatory and shall be followed

3.2.10.1 Discussion—Flaming of less than 4 s duration is

within nominal tolerance of 65 mm on the radiant panel and

identified as flashing or transitory flaming.

specimen holder assemblies. An exception to this tolerance is

the placement of the screen in front of the ceramic burner that

shall be 60.5 mm. The tolerances permitted in the exhaust

Discontinued; see 1983 Annual Book of ASTM Standards, Vol 04.07.

system (see Proposal P147) for the proposed room fire test

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036. method or the ISO 9705 standard are permissible.

E 1623

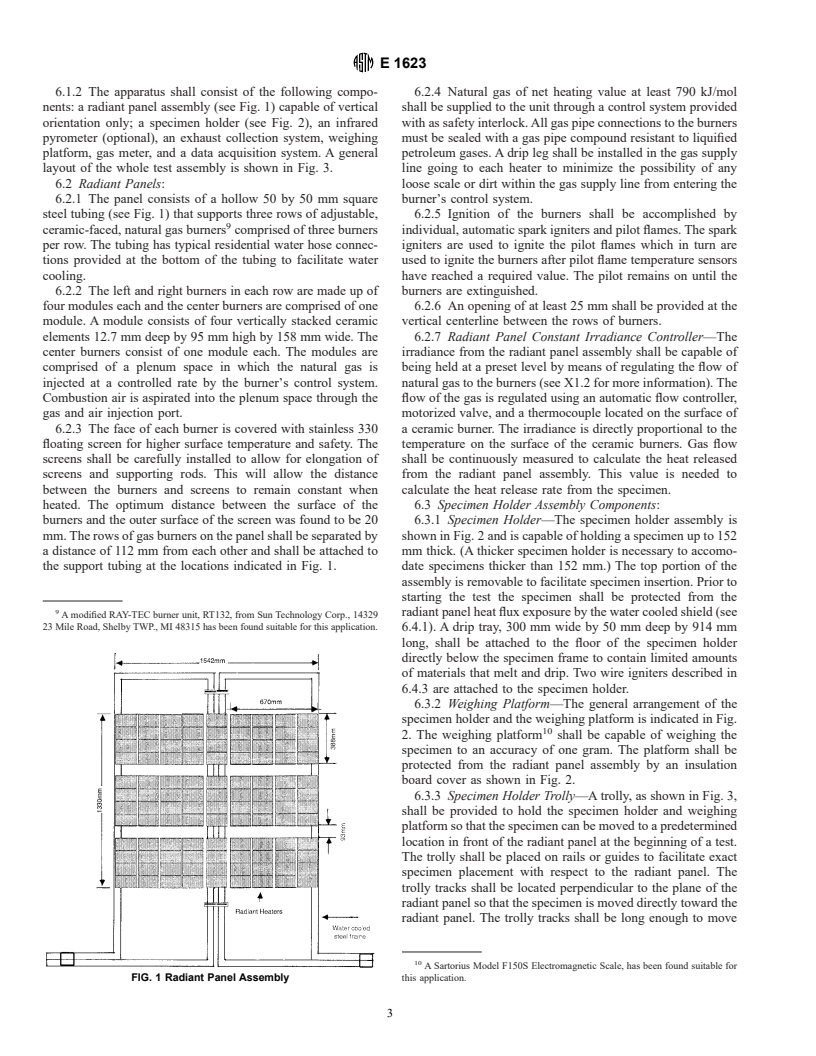

6.1.2 The apparatus shall consist of the following compo- 6.2.4 Natural gas of net heating value at least 790 kJ/mol

nents: a radiant panel assembly (see Fig. 1) capable of vertical shall be supplied to the unit through a control system provided

orientation only; a specimen holder (see Fig. 2), an infrared with as safety interlock. All gas pipe connections to the burners

pyrometer (optional), an exhaust collection system, weighing must be sealed with a gas pipe compound resistant to liquified

platform, gas meter, and a data acquisition system. A general petroleum gases. A drip leg shall be installed in the gas supply

layout of the whole test assembly is shown in Fig. 3. line going to each heater to minimize the possibility of any

6.2 Radiant Panels: loose scale or dirt within the gas supply line from entering the

6.2.1 The panel consists of a hollow 50 by 50 mm square burner’s control system.

steel tubing (see Fig. 1) that supports three rows of adjustable, 6.2.5 Ignition of the burners shall be accomplished by

ceramic-faced, natural gas burners comprised of three burners individual, automatic spark igniters and pilot flames. The spark

per row. The tubing has typical residential water hose connec- igniters are used to ignite the pilot flames which in turn are

tions provided at the bottom of the tubing to facilitate water used to ignite the burners after pilot flame temperature sensors

cooling. have reached a required value. The pilot remains on until the

6.2.2 The left and right burners in each row are made up of burners are extinguished.

four modules each and the center burners are comprised of one 6.2.6 An opening of at least 25 mm shall be provided at the

module. A module consists of four vertically stacked ceramic vertical centerline between the rows of burners.

elements 12.7 mm deep by 95 mm high by 158 mm wide. The 6.2.7 Radiant Panel Constant Irradiance Controller—The

center burners consist of one module each. The modules are irradiance from the radiant panel assembly shall be capable of

comprised of a plenum space in which the natural gas is being held at a preset level by means of regulating the flow of

injected at a controlled rate by the burner’s control system. natural gas to the burners (see X1.2 for more information). The

Combustion air is aspirated into the plenum space through the flow of the gas is regulated using an automatic flow controller,

gas and air injection port. motorized valve, and a thermocouple located on the surface of

6.2.3 The face of each burner is covered with stainless 330 a ceramic burner. The irradiance is directly proportional to the

floating screen for higher surface temperature and safety. The temperature on the surface of the ceramic burners. Gas flow

screens shall be carefully installed to allow for elongation of shall be continuously measured to calculate the heat released

screens and supporting rods. This will allow the distance from the radiant panel assembly. This value is needed to

between the burners and screens to remain constant when calculate the heat release rate from the specimen.

heated. The optimum distance between the surface of the 6.3 Specimen Holder Assembly Components:

burners and the outer surface of the screen was found to be 20 6.3.1 Specimen Holder—The specimen holder assembly is

mm. The rows of gas burners on the panel shall be separated by shown in Fig. 2 and is capable of holding a specimen up to 152

a distance of 112 mm from each other and shall be attached to mm thick. (A thicker specimen holder is necessary to accomo-

the support tubing at the locations indicated in Fig. 1. date specimens thicker than 152 mm.) The top portion of the

assembly is removable to facilitate specimen insertion. Prior to

starting the test the specimen shall be protected from the

radiant panel heat flux exposure by the water cooled shield (see

A modified RAY-TEC burner unit, RT132, from Sun Technology Corp., 14329

23 Mile Road, Shelby TWP., MI 48315 has been found suitable for this application.

6.4.1). A drip tray, 300 mm wide by 50 mm deep by 914 mm

long, shall be attached to the floor of the specimen holder

directly below the specimen frame to contain limited amo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.