ASTM D7756-12

(Test Method)Standard Test Method for Residues in Liquefied Petroleum (LP) Gases by Gas Chromatography with Liquid, On-Column Injection

Standard Test Method for Residues in Liquefied Petroleum (LP) Gases by Gas Chromatography with Liquid, On-Column Injection

SIGNIFICANCE AND USE

5.1 Control over the residue content as specified in Specification D1835 is of considerable importance in end-use applications of LPG. Oily residue in LPG is contamination which can occur during production, transportation, or storage.

5.2 This test method is quicker and much more sensitive than manual methods, such as Test Method D2158, which is based on evaporation of large sample volumes followed by visual or gravimetric estimation of residue content.

5.3 This test method provides enhanced sensitivity in measurements of heavier (oily) residues, with a quantification limit of 10 mg/kg total residue.

5.4 This test method gives both quantitative results and information about contaminant composition such as boiling point range and fingerprint, which can be very useful in tracing the source of a particular contaminant.

SCOPE

1.1 This test method covers the determination, by gas chromatography, of soluble hydrocarbon materials, sometimes called “oily residue,” which can be present in Liquefied Petroleum (LP) Gases and which are substantially less volatile than the LPG product.

1.2 This test method quantifies, in the range of 10 to 600 mg/kg (ppm mass), the residue with a boiling point between 174°C and 522°C (C10 to C40) in LPG. Higher boiling materials, or materials that adhere permanently to the chromatographic column, will not be detected.

1.3 Units—The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D7756 −12

StandardTest Method for

Residues in Liquefied Petroleum (LP) Gases by Gas

1

Chromatography with Liquid, On-Column Injection

This standard is issued under the fixed designation D7756; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* Lighter Hydrocarbons to Gas-Volume, Liquid-Volume, or

Mass Basis

1.1 This test method covers the determination, by gas

D2598 Practice for Calculation of Certain Physical Proper-

chromatography, of soluble hydrocarbon materials, sometimes

ties of Liquefied Petroleum (LP) Gases from Composi-

called “oily residue,” which can be present in Liquefied

tional Analysis

Petroleum (LP) Gases and which are substantially less volatile

D3700 Practice for Obtaining LPG Samples Using a Float-

than the LPG product.

ing Piston Cylinder

1.2 This test method quantifies, in the range of 10 to 600

D6299 Practice for Applying Statistical Quality Assurance

mg/kg (ppm mass), the residue with a boiling point between

and Control Charting Techniques to Evaluate Analytical

174°C and 522°C (C to C ) in LPG. Higher boiling

10 40

Measurement System Performance

materials, or materials that adhere permanently to the chro-

D6667 Test Method for Determination of Total Volatile

matographic column, will not be detected.

Sulfur in Gaseous Hydrocarbons and Liquefied Petroleum

1.3 Units—The values stated in SI units are to be regarded Gases by Ultraviolet Fluorescence

E355 Practice for Gas ChromatographyTerms and Relation-

as standard. The values given in parentheses are for informa-

tion only. ships

E594 Practice for Testing Flame Ionization Detectors Used

1.4 This standard does not purport to address all of the

in Gas or Supercritical Fluid Chromatography

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

3. Terminology

priate safety and health practices and determine the applica-

3.1 Definitions of Terms Concerning Chromatography—

bility of regulatory limitations prior to use.

This test method makes reference to many common gas

chromatographicprocedures,terms,andrelationships.Detailed

2. Referenced Documents

definitions of these can be found in Practices E355 and E594.

2

2.1 ASTM Standards:

3.2 Definitions of Terms Concerning Liquefied Petroleum

D1265 Practice for Sampling Liquefied Petroleum (LP)

Gases—This test method makes reference to the definitions of

Gases, Manual Method

liquefied petroleum gases as described in Specification D1835.

D1835 Specification for Liquefied Petroleum (LP) Gases

3.3 Definitions of Terms Specific to This Standard:

D2158 Test Method for Residues in Liquefied Petroleum

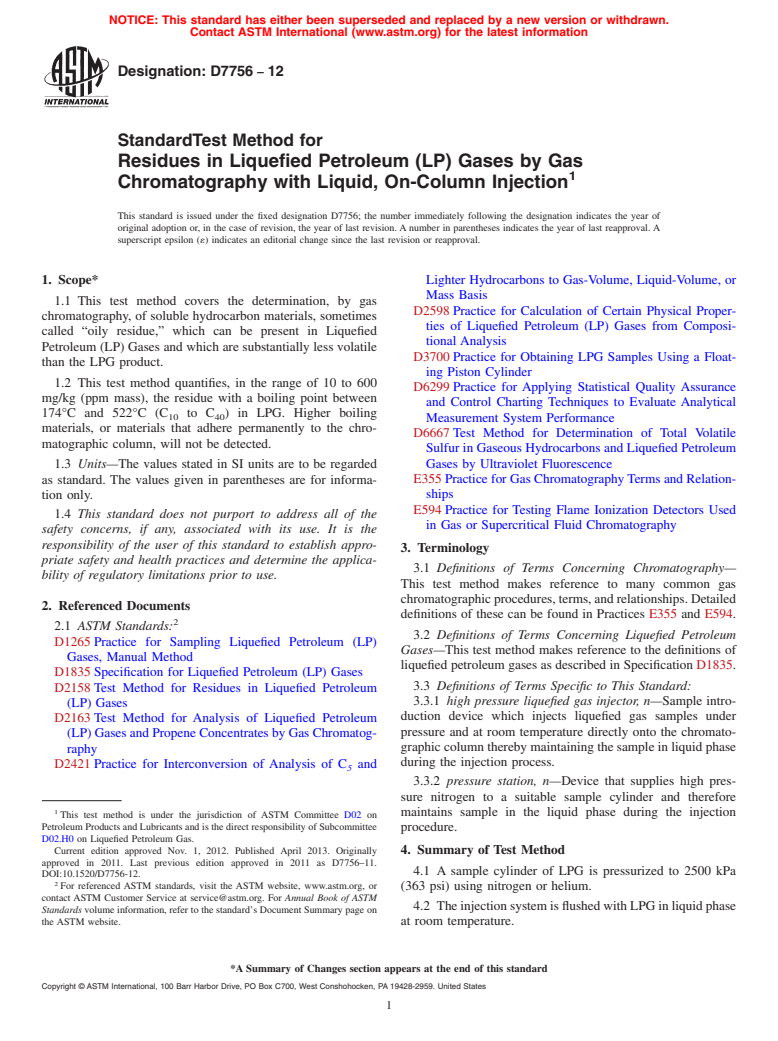

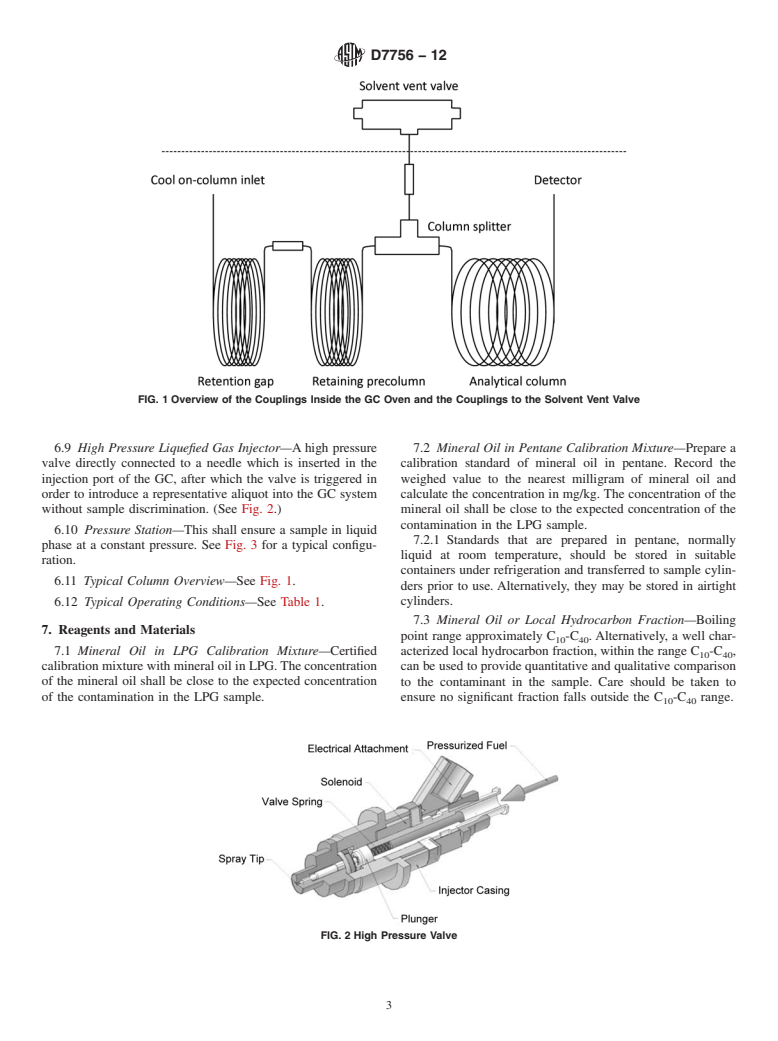

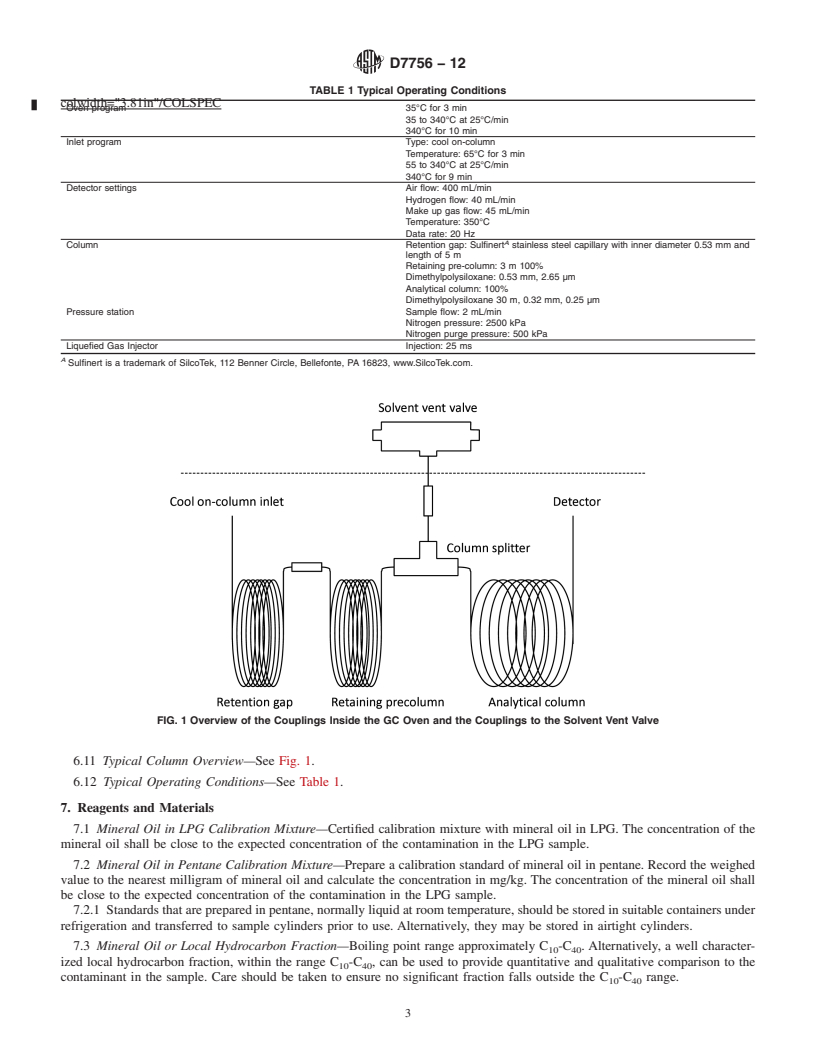

3.3.1 high pressure liquefied gas injector, n—Sample intro-

(LP) Gases

duction device which injects liquefied gas samples under

D2163 Test Method for Analysis of Liquefied Petroleum

pressure and at room temperature directly onto the chromato-

(LP) Gases and Propene Concentrates by Gas Chromatog-

graphic column thereby maintaining the sample in liquid phase

raphy

during the injection process.

D2421 Practice for Interconversion of Analysis of C and

5

3.3.2 pressure station, n—Device that supplies high pres-

sure nitrogen to a suitable sample cylinder and therefore

1

maintains sample in the liquid phase during the injection

This test method is under the jurisdiction of ASTM Committee D02 on

Petroleum Products and Lubricants and is the direct responsibility of Subcommittee

procedure.

D02.H0 on Liquefied Petroleum Gas.

Current edition approved Nov. 1, 2012. Published April 2013. Originally

4. Summary of Test Method

approved in 2011. Last previous edition approved in 2011 as D7756–11.

4.1 A sample cylinder of LPG is pressurized to 2500 kPa

DOI:10.1520/D7756-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

(363 psi) using nitrogen or helium.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2 TheinjectionsystemisflushedwithLPGinliquidphase

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. at room temperature.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7756−12

4.3 After flushing, the injection device is routed to the GC point range and fingerprint, which can be very useful in tracing

injector port and LPG (25 milliseconds activation time equiva- the source of a particular contaminant.

lent to 30 µL) is introduced via a high pressure valve and

need

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D7756 − 11 D7756 − 12

Standard Test Method for

Residues in Liquefied Petroleum (LP) Gases by Gas

1

Chromatography with Liquid, On-Column Injection

This standard is issued under the fixed designation D7756; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This test method covers the determination, by gas chromatography, of soluble hydrocarbon materials, sometimes called

“oily residue,” which can be present in Liquefied Petroleum (LP) Gases and which are substantially less volatile than the LPG

product.

1.2 This test method quantifies, in the range of 10 to 600 mg/kg (ppm mass), the residue with a boiling point between 174°C

and 522°C (C to C ) in LPG. Higher boiling materials, or materials that adhere permanently to the chromatographic column,

10 40

will not be detected.

1.3 Units—The values stated in SI units are to be regarded as standard. The values given in parentheses are for information only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1265 Practice for Sampling Liquefied Petroleum (LP) Gases, Manual Method

D1835 Specification for Liquefied Petroleum (LP) Gases

D2158 Test Method for Residues in Liquefied Petroleum (LP) Gases

D2163 Test Method for Analysis of Liquefied Petroleum (LP) Gases and Propene Concentrates by Gas Chromatography

D2421 Practice for Interconversion of Analysis of C and Lighter Hydrocarbons to Gas-Volume, Liquid-Volume, or Mass Basis

5

D2598 Practice for Calculation of Certain Physical Properties of Liquefied Petroleum (LP) Gases from Compositional Analysis

D3700 Practice for Obtaining LPG Samples Using a Floating Piston Cylinder

D6299 Practice for Applying Statistical Quality Assurance and Control Charting Techniques to Evaluate Analytical Measure-

ment System Performance

D6667 Test Method for Determination of Total Volatile Sulfur in Gaseous Hydrocarbons and Liquefied Petroleum Gases by

Ultraviolet Fluorescence

E355 Practice for Gas Chromatography Terms and Relationships

E594 Practice for Testing Flame Ionization Detectors Used in Gas or Supercritical Fluid Chromatography

3. Terminology

3.1 Definitions of Terms Concerning Chromatography—This test method makes reference to many common gas chromato-

graphic procedures, terms, and relationships. Detailed definitions of these can be found in Practices E355 and E594.

3.2 Definitions of Terms Concerning Liquefied Petroleum Gases—This test method makes reference to the definitions of

liquefied petroleum gases as described in Specification D1835.

3.3 Definitions of Terms Specific to This Standard:

1

This test method is under the jurisdiction of ASTM Committee D02 on Petroleum Products and Lubricants and is the direct responsibility of Subcommittee D02.H0 on

Liquefied Petroleum Gas.

Current edition approved Oct. 1, 2011Nov. 1, 2012. Published November 2011April 2013. DOI:10.1520/D7756-11Originally approved in 2011. Last previous edition

approved in 2011 as D7756–11. DOI:10.1520/D7756-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D7756 − 12

3.3.1 high pressure liquefied gas injector, n—Sample introduction device which injects liquefied gas samples under pressure and

at room temperature directly onto the chromatographic column thereby maintaining the sample in liquid phase during the injection

process.

3.3.2 pressure station, n—Device that supplies high pressure nitrogen to a suitable sample cylinder and therefore maintains

sample in the liquid phase during the injection procedure.

4. Summary of Test Method

4.1 A sample cylinder of LPG is pressurized to 2500 kPa (363 psi) using nitrogen or helium.

4.2 The injection system is flus

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.