ASTM F897-02

(Test Method)Standard Test Method for Measuring Fretting Corrosion of Osteosynthesis Plates and Screws

Standard Test Method for Measuring Fretting Corrosion of Osteosynthesis Plates and Screws

SCOPE

1.1 This test method provides a screening test for determining the amount of metal loss from plates and screws used for osteosynthesis (internal fixation of broken bones) due to fretting corrosion in the contact area between the screw head and the plate hole countersink area. The implants are used in the form they would be used clinically. The machine described generates a relative motion between plates and screws which simulates one type of motion pattern that can occur when these devices are used clinically.

1.2 Since the environmental and stress conditions used in this test method may not be identical to those experienced by bone plates in the human body, this test method may produce fretting corrosion rates that are lower or higher than those experienced in practice. The recommended axial load of 400 N was selected as being in a range where the amount of fretting corrosion is not sensitive to small changes in axial load (1). The combination of the recommended load and angular displacement are such that a measurable amount of fretting corrosion of surgical alloys occurs in a comparatively short period of time (7 to 14 days). (1-3)

1.3 The device is designed so as to facilitate sterilization of the test specimens and test chambers to permit testing with proteinaceous solutions that would become contaminated with microbial growth in nonsterile conditions.

1.4 The specimens used can be standard osteosynthesis implants or can be materials fabricated into the appropriate shapes.

1.5 This test method may be used for testing the fretting corrosion of metal plates and screws of similar or different alloy compositions, or it may be used for testing the fretting corrosion of metal-nonmetal combinations. This test method may also be used for wear or degradation studies of nonmetallic materials. This test method may be used as a screening test to rank the corrosivities of saline or proteinaceous solutions, or to rank metal-to-metal couples for resistance to fretting corrosion, or to study other material combinations.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.7 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of whoever uses this standard to consult and establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F897–02

Standard Test Method for

Measuring Fretting Corrosion of Osteosynthesis Plates and

1

Screws

This standard is issued under the fixed designation F 897; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope test to rank the corrosivities of saline or proteinaceous solu-

tions, or to rank metal-to-metal couples for resistance to

1.1 This test method provides a screening test for determin-

fretting corrosion, or to study other material combinations.

ing the amount of metal loss from plates and screws used for

1.6 The values stated in SI units are to be regarded as the

osteosynthesis (internal fixation of broken bones) due to

standard. The values given in parentheses are for information

fretting corrosion in the contact area between the screw head

only.

and the plate hole countersink area. The implants are used in

1.7 This standard may involve hazardous materials, opera-

the form they would be used clinically. The machine described

tions, and equipment. This standard does not purport to

generates a relative motion between plates and screws which

address all of the safety concerns associated with its use. It is

simulates one type of motion pattern that can occur when these

the responsibility of whoever uses this standard to consult and

devices are used clinically.

establish appropriate safety and health practices and deter-

1.2 Since the environmental and stress conditions used in

mine the applicability of regulatory limitations prior to use.

this test method may not be identical to those experienced by

bone plates in the human body, this test method may produce

2. Referenced Documents

fretting corrosion rates that are lower or higher than those

2.1 ASTM Standards:

experienced in practice.The recommended axial load of 400 N

3

D 1886 Test Methods for Nickel in Water

was selected as being in a range where the amount of fretting

2 F 86 Practice for Surface Preparation and Marking of Me-

corrosion is not sensitive to small changes in axial load (1).

4

tallic Surgical Implants

The combination of the recommended load and angular dis-

F 382 Specification and Test Method for Metallic Bone

placement are such that a measurable amount of fretting

4

Plates

corrosion of surgical alloys occurs in a comparatively short

F 543 Specification and Test Methods for Metallic Medical

period of time (7 to 14 days). (1-3)

4

Bone Screws

1.3 The device is designed so as to facilitate sterilization of

G 1 Practice for Preparing, Cleaning, and Evaluating Cor-

the test specimens and test chambers to permit testing with

5

rosion Test Specimens

proteinaceous solutions that would become contaminated with

microbial growth in nonsterile conditions.

3. Summary of Test Method

1.4 The specimens used can be standard osteosynthesis

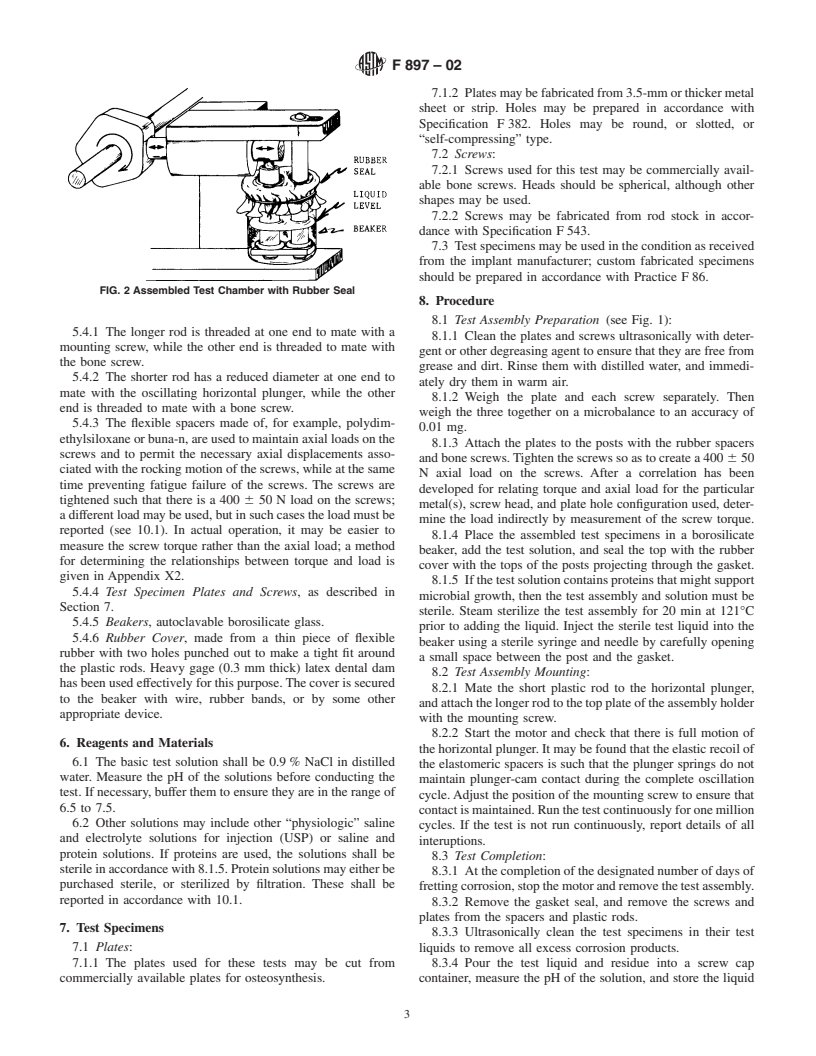

3.1 A two-hole plate is attached to two plastic rods with

implants or can be materials fabricated into the appropriate

bone screws, with flexible spacers between the plate and the

shapes.

rods, placed in a glass beaker, and the beaker sealed with a

1.5 This test method may be used for testing the fretting

flexible rubber cover. This assembly is steam sterilized, and

corrosion of metal plates and screws of similar or different

then a sterile solution is injected through the rubber cover into

alloy compositions, or it may be used for testing the fretting

the beaker. This assembly is then mounted in the fretting

corrosion of metal-nonmetal combinations. This test method

apparatus which, when set in motion, produces a rocking

may also be used for wear or degradation studies of nonme-

motion and, therefore, a small cyclic displacement between the

tallic materials. This test method may be used as a screening

mating surfaces of the plate and screws.The amount of fretting

corrosion is determined at the end of the test by measurement

of the weight loss of the plates and screws and by chemical

1

This test method is under the jurisdiction ofASTM Committee F04 on Medical

analysis of the solutions.

and Surgical Materials and Devices and is the direct responsibility of Subcommittee

F04.15 on Material Test Methods.

Current edition approved Dec. 10, 2002. Published February 2003. Originally

e1

3

approved in 1984. Last previous edition approved in 1984 as F 897 – 84 (1997) .

Annual Book of ASTM Standards, Vol 11.01.

2 4

The boldface numbers in parentheses refer to the list of references at the end of Annual Book of ASTM Standards, Vol 13.01.

5

this standard. Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.