ASTM G73-04

(Practice)Standard Practice for Liquid Impingement Erosion Testing

Standard Practice for Liquid Impingement Erosion Testing

SCOPE

1.1 This practice covers tests in which solid specimens are eroded or otherwise damaged by repeated discrete impacts of liquid drops or jets. Among the collateral forms of damage considered are degradation of optical properties of window materials, and penetration, separation, or destruction of coatings. The objective of the tests may be to determine the resistance to erosion or other damage of the materials or coatings under test, or to investigate the damage mechanisms and the effect of test variables. Because of the specialized nature of these tests and the desire in many cases to simulate to some degree the expected service environment, the promulgation of a method is not deemed practicable. This practice gives guidance in setting up a test, and specifies test and analysis procedures and reporting requirements that can be followed even with quite widely differing materials, test facilities, and test conditions. It also provides a standardized scale of erosion resistance numbers applicable to metals and other structural materials. It serves, to some degree, as a tutorial on liquid impingement erosion.

1.2 The values stated in SI units are to be regarded as standard. The inch-pound units in parentheses are provided for information.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:G73–04

Standard Practice for

1

Liquid Impingement Erosion Testing

ThisstandardisissuedunderthefixeddesignationG73;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E140 Hardness Conversion Tables for Metals Relationship

Among Brinell Hardness, Vickers Hardness, Rockwell

1.1 This practice covers tests in which solid specimens are

Hardness, Superficial Hardness, Knoop Hardness, and

eroded or otherwise damaged by repeated discrete impacts of

Scleroscope Hardness

liquid drops or jets. Among the collateral forms of damage

E177 Practice for Use of the Terms Precision and Bias in

considered are degradation of optical properties of window

ASTM Test Methods

materials, and penetration, separation, or destruction of coat-

E179 Guide for Selection of Geometric Conditions for

ings. The objective of the tests may be to determine the

MeasurementofReflectionandTransmissionPropertiesof

resistance to erosion or other damage of the materials or

Materials

coatings under test, or to investigate the damage mechanisms

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

and the effect of test variables. Because of the specialized

sion Test Specimens

natureofthesetestsandthedesireinmanycasestosimulateto

G32 Test Method for Cavitation Erosion Using Vibratory

some degree the expected service environment, the promulga-

Apparatus

tion of a method is not deemed practicable.This practice gives

G40 Terminology Relating to Wear and Erosion

guidance in setting up a test, and specifies test and analysis

G134 Test Method for Erosion of Solid Materials by a

procedures and reporting requirements that can be followed

Cavitating Liquid Jet

even with quite widely differing materials, test facilities, and

3

2.2 Military Standards:

test conditions. It also provides a standardized scale of erosion

MIL-C-83231 Coatings, Polyurethane, Rain Erosion Resis-

resistance numbers applicable to metals and other structural

tance for Exterior Aircraft and Missile Plastic Parts

materials. It serves, to some degree, as a tutorial on liquid

MIL-P-8184 Plastic Sheet, Acrylic, Modified

impingement erosion.

1.2 The values stated in SI units are to be regarded as

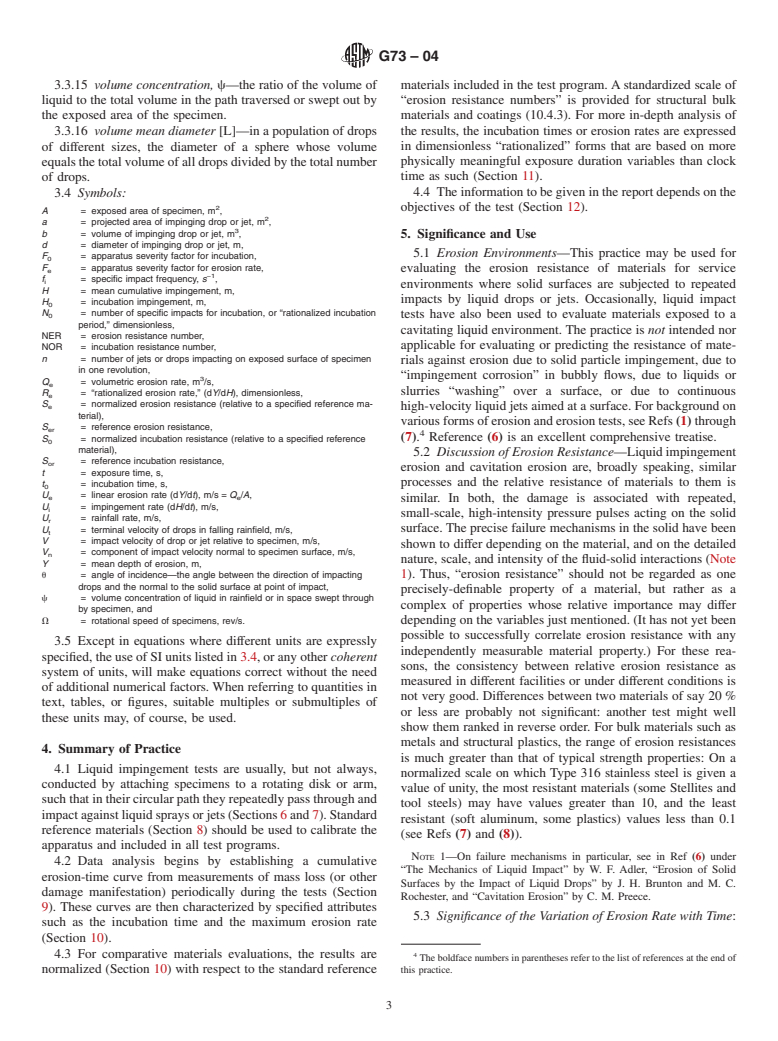

3. Terminology

standard.The inch-pound units in parentheses are provided for

3.1 See Terminology G40 for definitions of terms that are

information.

not defined below in either 3.2 or 3.3. 3.2 quotes definitions,

1.3 This standard does not purport to address all of the

takenfromTerminologyG40,forimportanttermsrelatedtothe

safety concerns, if any, associated with its use. It is the

title, Scope, or Summary of this practice. 3.3 gives definitions

responsibility of the user of this standard to establish appro-

of terms specific to this practice that are not in Terminology

priate safety and health practices and determine the applica-

G40.

bility of regulatory limitations prior to use.

3.2 Definitions—All definitions listed below are quoted

2. Referenced Documents from Terminology G40–02G40.

2

3.2.1 cumulative erosion-time curve, n—in cavitation and

2.1 ASTM Standards:

impingement erosion, a plot of cumulative erosion versus

D1003 Test Method for Haze and Luminous Transmittance

cumulative exposure duration, usually determined by periodic

of Transparent Plastics

interruption of the test and weighing of the specimen. This is

E92 Test Method for Vickers Hardness of Metallic Materi-

the primary record of an erosion test. Most other characteris-

als

tics, such as the incubation period, maximum erosion rate,

terminal erosion rate, and erosion rate-time curve, are derived

1

This practice is under the jurisdiction of ASTM Committee G02 on Wear and

from it.

Erosion and is the direct responsibility of Subcommittee G02.10 on Erosion by

3.2.2 damage, n—in cavitation or impingement, any effect

Solids and Liquids.

on a solid body resulting from its exposure to these phenom-

Current edition approved Nov 1, 2004. Published November 2004. Originally

approved in 1982. Last previous edition approved in 1998 as G73–98. DOI: ena.This may include loss of material, surface deformation, or

10.1520/G0073-04.

anyotherchangesinmicrostructure,properties,orappearance.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

the ASTM website. Robbins Ave., Philadelphia, PA 19111-5098.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

--------------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.