ASTM C877M-02(2009)

(Specification)Standard Specification for External Sealing Bands for Concrete Pipe, Manholes, and Precast Box Sections (Metric)

Standard Specification for External Sealing Bands for Concrete Pipe, Manholes, and Precast Box Sections (Metric)

ABSTRACT

This specification deals with the metric standard for three types of external sealing bands to be used in conjunction with concrete pipe, manholes, and precast box sections. The first type of bands shall be composed of rubber, mastic, and protective film elements, while the second type shall consist of a plastic film, reinforced, rubberized, asphalt, mastic coating with steel straps. The third type shall be composed of a backing band, an applied continuous butyl adhesive coating and an optional release element. All the elements of each type of sealing band shall have physical properties conforming with specified limits as determined through appropriate test methods herein provided.

SCOPE

1.1 This specification covers external sealing bands to be used in conjunction with concrete pipe as defined in Terminology C 822 and conforming to Specifications C 14M, C 76M, C 412M, C 478M, C 506M, C 507M, C 655M, C 985M, C 1417M, and C 1433M.

1.1.1 Type I, Rubber and Mastic Bands.

1.1.2 Type II, Plastic Film and Mesh Reinforced Mastic Bands.

1.1.3 Type III, Chemically Bonded Adhesive Butyl Bands.

1.2 This specification is the metric counterpart of Specification C 877.

Note 1—This specification covers only the design and material of the sealing bands. Sealing bands covered by this specification are adequate, when properly installed, for external hydrostatic pressures up to 90 kPa, (9.14 m) without leakage. The amount of infiltration or exfiltration flow in an installed pipeline is dependent upon many factors other than the sealing bands; allowable quantities and suitable testing of the installed pipeline and system must be covered by other specifications.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C877M −02 (Reapproved 2009)

Standard Specification for

External Sealing Bands for Concrete Pipe, Manholes, and

Precast Box Sections (Metric)

This standard is issued under the fixed designation C877M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope crete Manhole Sections (Metric)

C506M Specification for Reinforced ConcreteArch Culvert,

1.1 This specification covers external sealing bands to be

Storm Drain, and Sewer Pipe (Metric)

used in conjunction with concrete pipe as defined in Terminol-

C507M Specification for Reinforced Concrete Elliptical

ogy C822 and conforming to Specifications C14M, C76M,

Culvert, Storm Drain, and Sewer Pipe (Metric)

C412M, C478M, C506M, C507M, C655M, C985M, C1417M,

C655M Specification for Reinforced Concrete D-Load

and C1433M.

Culvert, Storm Drain, and Sewer Pipe (Metric)

1.1.1 Type I, Rubber and Mastic Bands.

1.1.2 Type II, Plastic Film and Mesh Reinforced Mastic

C681 Test Method for Volatility of Oil- and Resin-Based,

Bands.

Knife-Grade, Channel Glazing Compounds

1.1.3 Type III, Chemically Bonded Adhesive Butyl Bands.

C766 Test Method for Adhesion After Impact of Preformed

Tape Sealants (Withdrawn 1994)

1.2 This specification is the metric counterpart of Specifi-

C822 Terminology Relating to Concrete Pipe and Related

cation C877.

Products

NOTE 1—This specification covers only the design and material of the

C985M Specification for Nonreinforced Concrete Specified

sealing bands. Sealing bands covered by this specification are adequate,

Strength Culvert, Storm Drain, and Sewer Pipe (Metric)

when properly installed, for external hydrostatic pressures up to 90 kPa,

(9.14 m) without leakage.The amount of infiltration or exfiltration flow in

C1417M Specification for Manufacture of Reinforced Con-

aninstalledpipelineisdependentuponmanyfactorsotherthanthesealing

crete Sewer, Storm Drain, and Culvert Pipe for Direct

bands; allowable quantities and suitable testing of the installed pipeline

Design (Metric)

and system must be covered by other specifications.

C1433M Specification for Precast Reinforced Concrete

2. Referenced Documents Monolithic Box Sections for Culverts, Storm Drains, and

Sewers (Metric)

2.1 ASTM Standards:

D36 Test Method for Softening Point of Bitumen (Ring-and-

A167 Specification for Stainless and Heat-Resisting

Ball Apparatus)

Chromium-Nickel Steel Plate, Sheet, and Strip (With-

D217 Test Methods for Cone Penetration of Lubricating

drawn 2014)

C14M Specification for Nonreinforced Concrete Sewer, Grease

Storm Drain, and Culvert Pipe (Metric) D395 Test Methods for Rubber Property—Compression Set

C76M Specification for Reinforced Concrete Culvert, Storm

D412 Test Methods forVulcanized Rubber andThermoplas-

Drain, and Sewer Pipe (Metric)

tic Elastomers—Tension

C412M Specification for Concrete Drain Tile (Metric)

D471 Test Method for Rubber Property—Effect of Liquids

C478M Specification for Circular Precast Reinforced Con-

D570 Test Method for Water Absorption of Plastics

D573 Test Method for Rubber—Deterioration in an Air

Oven

This specification is under the jurisdiction of ASTM Committee C13 on

D624 Test Method for Tear Strength of Conventional Vul-

Concrete Pipe and is the direct responsibility of Subcommittee C13.08 on Joints for

canized Rubber and Thermoplastic Elastomers

Precast Concrete Structures.

Current edition approved Oct. 1, 2009. Published October 2009. Originally D882 Test Method for Tensile Properties of Thin Plastic

ε1

approved in 1980. Last previous edition approved in 2002 as C877M – 02 . DOI:

Sheeting

10.1520/C0877M-02R09.

D1171 Test Method for Rubber Deterioration—Surface

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Ozone Cracking Outdoors or Chamber (Triangular Speci-

Standards volume information, refer to the standard’s Document Summary page on

mens)

the ASTM website.

3 D1278 Test Methods for Rubber from Natural Sources—

The last approved version of this historical standard is referenced on

www.astm.org. Chemical Analysis

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C877M−02 (2009)

TABLE 1 Required Sealing Band Width

D1682 Test Method for Breaking Load and Elongation of

Textile Fabric (Withdrawn 1992) Equivalent Circular Pipe Sealing Band

Diameter, mm Width, mm

D1963 Test Method for Specific Gravity of Drying Oils,

450 to 825 180

Varnishes, Resins, and Related Materials at 25/25°C

900 to 1950 230

(Withdrawn 2004)

2100 to 2700 280

D2202 Test Method for Slump of Sealants 2850 to 3600 330

D2240 Test Method for Rubber Property—Durometer Hard-

ness

D3407 Test Methods for Joint Sealants, Hot-Poured, for andhaveathicknessbetweentheribsof1.6mm.Thethickness

of the ribs is not prohibited from varying from 3.2 mm at the

Concrete and Asphalt Pavements (Withdrawn 1996)

D3953 Specification for Strapping, Flat Steel and Seals base to 0.8 mm at the top.

5.1.3 Mastic Element—The mastic element shall contain

3. Terminology

rubber, reclaimed rubber and asphaltic derivatives, clay, and/or

resin and shall meet the physical requirements prescribed in

3.1 Definitions—Fordefinitionsoftermsrelatingtoconcrete

Section6.Themasticelementshallhaveathicknessof3.2mm

pipe, see Terminology C822.

and be free of porous areas, air pockets, and contamination by

4. Basis of Acceptance

foreign matter.

5.1.4 Protective Film—The protective film shall be water

4.1 The acceptability of the sealing bands shall be deter-

soluble, have a 0.025-mm thickness, and meet the physical

mined by the results of the physical tests prescribed in this

requirements prescribed in Section 6.

specification, if and when required, and by inspection to

determine whether the sealing bands conform to this specifi-

NOTE 2—The function of the film is to protect the mastic surface prior

cation as to design and freedom from defects.

to installation. It is intended to dissolve away in the presence of moisture

during installation and expose the mastic for sealing.

5. Materials and Manufacture for Sealing Bands

5.2 Type II Plastic Film and Mesh Reinforced Mastic

5.1 Type I, Rubber and Mastic Bands:

Bands:

5.1.1 Sealing bands shall be composed of rubber, mastic,

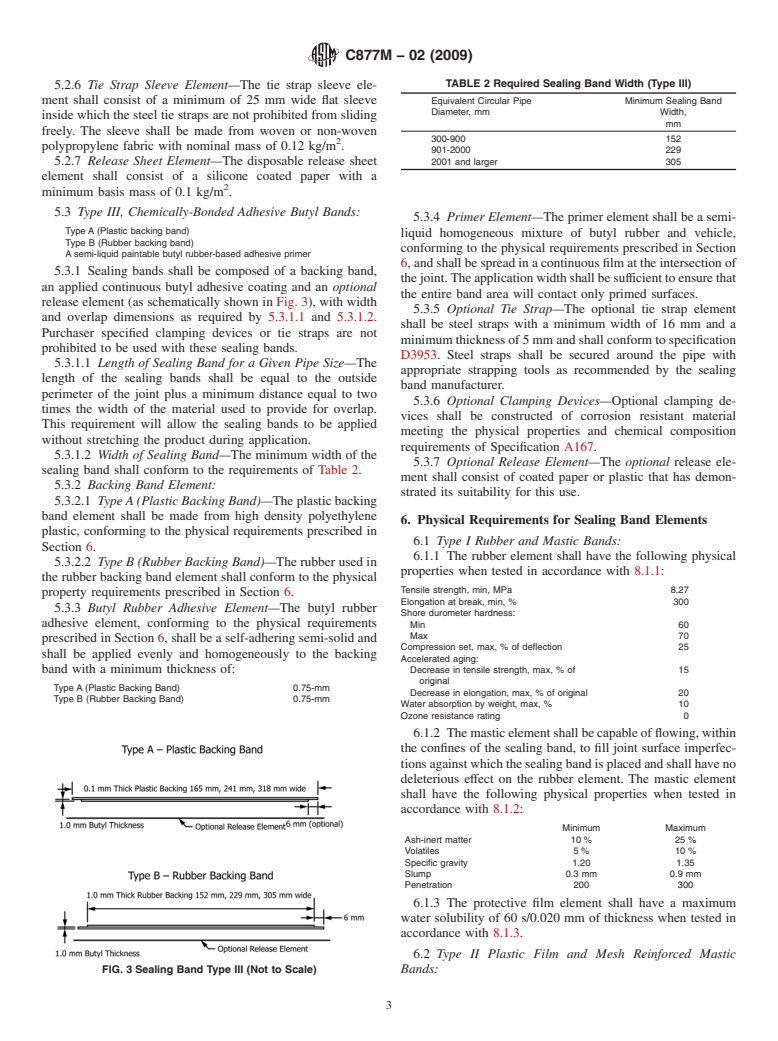

5.2.1 Sealing bands shall be composed of a plastic film,

and protective film elements as schematically shown in Fig. 1

reinforced, rubberized, asphalt, mastic coating with steel straps

and with dimensions as required in the following:

as schematically shown in Fig. 2 with dimensions as required

5.1.1.1 Length of Sealing Band—For a given pipe size, the

in the following:

length of the sealing band as furnished shall be such that after

5.2.1.1 Length of Sealing Band for a Given Pipe Size—The

being stretched longitudinally 8 to 12 % as part of the

length of the sealing band shall be equal to the outside

installation procedure, the sealing band will encircle the

perimeter of the joint plus 200 mm to provide for overlap.

outside perimeter of the pipe and overlap by an amount equal

5.2.1.2 Width of Sealing Band—The width of the sealing

to, but not less than, the width of the sealing band. Sealing

band shall conform to the requirements of Table 1.

bands may be furnished in the required length or multiples

5.2.2 Plastic Film Element—The plastic film element shall

thereof.

beanextendedpolymerwhichprovidesexternalreinforcement

5.1.1.2 Width of Sealing Band—The width of the sealing

and shall meet the physical requirements prescribed in Section

band shall conform to the requirements of Table 1.

6.

5.1.2 Rubber Element—The rubber element shall be ex-

5.2.3 Mesh Reinforcement Element—The mesh reinforce-

truded or molded from a high-grade rubber compound and

ment shall consist of a woven plastic mesh and shall meet the

shall be cured in such a manner that any cross section will be

physical requirements prescribed in Section 6.

dense, homogeneous, and free of porosity, blisters, pitting, and

5.2.4 Rubberized Asphalt Mastic Element—The rubberized,

other imperfections. The basic polymer shall be natural,

asphalt, mastic element shall be a self adhering composition

synthetic, or a blend of both and shall meet the physical

and shall meet the requirements prescribed in Section 6.

requirements prescribed in Section 6. The rubber element shall

5.2.5 Tie Strap Element—Thetiestrapelementshallbesteel

have ribs with a height of 4.8 mm, spaced 19 to 32 mm apart,

straps with a minimum width of 15 mm and a minimum

thickness of 0.50 mm and shall conform to Specification

D3953. Steel straps shall be secured around the pipe with

appropriate strapping tools as recommended by the sealing

band manufacturer.

FIG. 1 Sealing Band Type I Schematic (Not to Scale) FIG. 2 Sealing Band Type II (Not to Scale)

C877M−02 (2009)

TABLE 2 Required Sealing Band Width (Type III)

5.2.6 Tie Strap Sleeve Element—The tie strap sleeve ele-

ment shall consist of a minimum of 25 mm wide flat sleeve Equivalent Circular Pipe Minimum Sealing Band

Diameter, mm Width,

inside which the steel tie straps are not prohibited from sliding

mm

freely. The sleeve shall be made from woven or non-woven

300-900 152

polypropylene fabric with nominal mass of 0.12 kg/m .

901-2000 229

2001 and larger 305

5.2.7 Release Sheet Element—The disposable release sheet

element shall consist of a silicone coated paper with a

minimum basis mass of 0.1 kg/m .

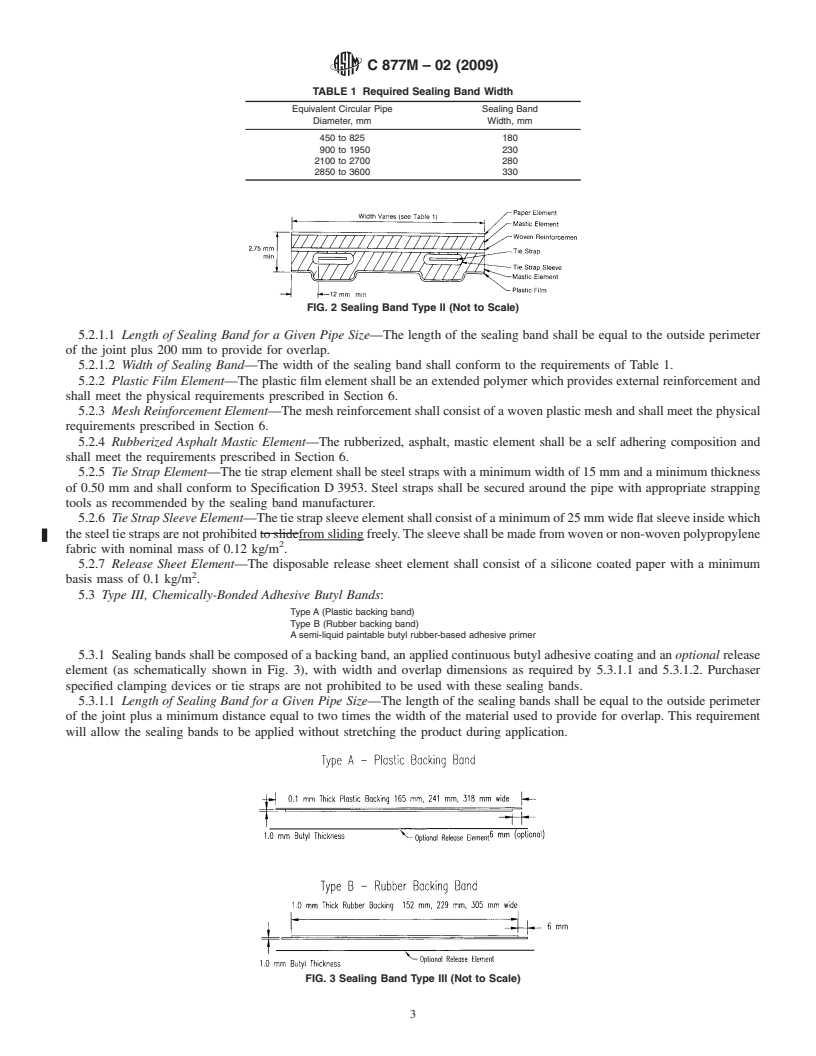

5.3 Type III, Chemically-Bonded Adhesive Butyl Bands:

5.3.4 Primer Element—The primer element shall be a semi-

Type A (Plastic backing band)

liquid homogeneous mixture of butyl rubber and vehicle,

Type B (Rubber backing band)

conforming to the physical requirements prescribed in Section

A semi-liquid paintable butyl rubber-based adhesive primer

6, and shall be spread in a continuous film at the intersection of

5.3.1 Sealing bands shall be composed of a backing band,

thejoint.Theapplicationwidthshallbesufficienttoensurethat

an applied continuous butyl adhesive coating and an optional

the entire band area will contact only primed surfaces.

release element (as schematically shown in Fig. 3), with width

5.3.5 Optional Tie Strap—The optional tie strap element

and overlap dimensions as required by 5.3.1.1 and 5.3.1.2.

shall be steel straps with a minimum width of 16 mm and a

Purchaser specified clamping devices or tie straps are not

minimumthicknessof5mmandshallconformtospecification

prohibited to be used with these sealing bands.

D3953. Steel straps shall be secured around the pipe with

5.3.1.1 Length of Sealing Band for a Given Pipe Size—The

appropriate strapping tools as recommended by the sealing

length of the sealing bands shall be equal to the outside

band manufacturer.

perimeter of the joint plus a minimum distance equal to two

5.3.6 Optional Clamping Devices—Optional clamping de-

times the width of the material used to provide for overlap.

vices shall be constructed of corrosion resistant material

This requirement will allow the sealing bands to be applied

meeting the physical properties and chemical composition

without stretching the product during application.

requirements of Specification A167.

5.3.1.2 Width of Sealing Band—The minimum width of the

5.3.7 Optional Release Element—The optional release ele-

sealing band shall conform to the requirements of Table 2.

ment shall consist of coated paper or plastic that has demon-

5.3.2 Backing Band Element:

strated its suitability for this use.

5.3.2.1 Type A (Plastic Backing Band)—The plastic backing

band element shall be made from high density polyethylene

6. Physical Requirements for Sealing Band Elements

plastic, conforming to the physical requirements prescribed in

6.1 Type I Rubber and Mastic Bands:

Section 6.

6.1.1 The rubber element shall have the following physical

5.3.2.2 Type B (Rubber Backing Band)—The rubber used in

properties when tested in accordance with 8.1.1:

the rubber backing band element shall conform to the physical

Tensile strength, min, MPa 8.27

property requirements prescribed in Section 6.

Elongation at break, min, % 300

5.3.3 Butyl Rubber Adhesive Element—The butyl rubber

Shore durometer hardness:

adhesive element, conforming to the physical requirements

Min 60

Max 70

prescribed in Section 6, shall be a self-adhering semi-solid and

Compression set, max, % of deflection 25

shall be applied evenly and homogeneously to the backing

Accelerated aging:

band with a minimum thickness of: Decrease in tensile strength, max, % of 15

original

Type A (Plastic Backing Band) 0.75-mm

Decrease in elongation, max, % of original 20

Type B (Rubber Backing Band) 0.75-mm

Water absorption by weight, max, % 10

Ozone resistance rating 0

6.1.2 Themasticelementshallbecapableofflowing,within

the confines of the sealing band, to fill joint surface imperfec-

tionsagainstwhichthesealingbandisplacedandshallhaveno

deleterious effect on the rubber element. The mastic element

shall have the following physical properties when tested in

accordance with 8.1.2:

Minimum Maximum

Ash-inert matter 10 % 25 %

Volatiles 5 % 10 %

Specific gravity 1.20 1.35

Slump 0.3 mm 0.9 mm

Penetration 200 300

6.1.3 The protective film element shall have a maximum

water solubility of 60 s/0.020 mm of thickness when tested in

accordance with 8.1.3.

6.2 Type II Plastic Film and Mesh Reinforced Mastic

FIG. 3Sealing Band Type III (Not to Scale) Bands:

C877M−02 (2009)

6.2.1 The plastic film element shall have the following 7.1.4 The sealing band shall be manufactured to RMA

physical properties when tested in accordance with 8.2.1: (Rubber Manufacturers Association) commercial tolerances.

7.1.5 The mastic element shall have a minimum thickness

Tensile strength, min, MPa 27.6

Elongation at break, min,% 100

of 3.2 mm.

Tear resistance, min, MPa 10.4

7.2 Type II Plastic Film and Mesh Reinforced Mastic

Water absorption, max, % 0.01

Bands:

6.2.2 Thereinforcingmeshelementshallhavethefollowing

7.2.1 The thickness of plastic film and mesh reinforced

physical properties when tested in accordance with 8.2.2:

mastic bands shall be a minimum of 2.75 mm when measured

Tensile strength, min, N/mm

away from the tie straps.

warp 13

fill 13

7.3 Type III, Chemically-Bonded Adhesive Butyl Bands:

Elongation at break, min, %

warp 20

Type A (Plastic backing band)

fill 20

Type B (Rubber backing band)

6.2.3 The rubberized asphalt mastic layer shall have the

7.3.1 Type A:

following physical properties when tested in accordance with

7.3.1.1 The bonded adhesive butyl material shall

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C877M–01 Designation: C 877M – 02 (Reapproved 2009)

Standard Specification for

External Sealing Bands for Concrete Pipe, Manholes, and

Precast Box Sections [Metric](Metric)

This standard is issued under the fixed designation C 877M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers external sealing bands to be used in conjunction with concrete pipe as defined in Terminology

C 822 and conforming to Specifications C14M, C76M, C412M, C478M, C506M, C507M, C655M, C985M, C1417M, and

C1433Mand conforming to Specifications C 14M, C 76M, C 412M, C 478M, C 506M, C 507M, C 655M, C 985M, C 1417M, and

C 1433M.

1.1.1 Type I, Rubber and Mastic Bands.

1.1.2 Type II, Plastic Film and Mesh Reinforced Mastic Bands.

1.1.3 Type III, Chemically Bonded Adhesive Butyl Bands.

1.2 This specification is the metric counterpart of Specification C 877.

NOTE 1—This specification covers only the design and material of the sealing bands. Sealing bands covered by this specification are adequate, when

properly installed, for external hydrostatic pressures up to 90 kPa, (9.14 m) without leakage. The amount of infiltration or exfiltration flow in an installed

pipeline is dependent upon many factors other than the sealing bands; allowable quantities and suitable testing of the installed pipeline and system must

be covered by other specifications.

2. Referenced Documents

2.1 ASTM Standards:

A 167 Specification for Stainless and Heat-Resisting Chromium-Nickel Steel Plate, Sheet, and Strip

C 14M Specification for RNonreinforced Concrete Sewer, Storm Drain, and Culvert Pipe [Metric]

C 76M Specification for Reinforced Concrete Culvert, Storm Drain, and Sewer Pipe [Metric]

C 412M Specification for Concrete Drain Tile [Metric]

C 478M Specification for Precast Reinforced concreteConcrete Manhole Sections [Metric] (Metric)

C 506M Specification for Reinforced Concrete Arch Culvert, Storm Drain, and Sewer Pipe [Metric] (Metric)

C 507M Specification for Reinforced Concrete Elliptical Culvert, Storm Drain, and Sewer Pipe [Metric] (Metric)

C 655M Specification for Reinforced Concrete D-Load Culvert, Storm Drain, and Sewer Pipe [Metric] (Metric)

C 681 Test Method for Volatility of Oil- and Resin-Based, Knife-Grade, Channel Glazing Compounds

C 766 Test Method for Adhesion After Impact of Preformed Tape Sealants

C 822 Terminology Relating to Concrete Pipe and Related Products

C 985M Specification for Nonreinforced Concrete Specified Strength Culvert, Storm Drain, and Sewer Pipe [Metric]

C 1417M Specification for Manufacture of Reinforced Concrete Sewer, Storm Drain, and Culvert Pipe for Direct Design

[Metric]

C 1433M Specification for Precast Reinforced Concrete Box Sections for Culvert, Storm Drain, and Sewers [Metric]

D5Test Method for Penetration of Bituminous Materials Specification for Precast Reinforced Concrete Monolithic Box Sections

for Culverts, Storm Drains, and Sewers (Metric)

D36 Test Method for Softening Point of Bitumen (Ring-and-Ball Apparatus)

D 217 Test Methods for Cone Penetration of Lubricating Grease

D 395 Test Methods for Rubber Property—Compression Set

D 412 Test Methods for Vulcanized Rubber and Thermoplastic Rubbers and Thermoplastic Elastomers-Tension Test Methods

for Vulcanized Rubber and Thermoplastic ElastomersTension

This specification is under the jurisdiction of ASTM Committee C13 on Concrete Pipe and is the direct responsibility of Subcommittee C13.08 on Rubber Gaskets.

Current edition approved June 10, 2001. Published August 2001. Originally published as C877M–80. Last previous edition C877M–00.

This specification is under the jurisdiction of ASTM Committee C08 on Refractories and is the direct responsibility of Subcommittee C08.00 on .

´1

Current edition approved Oct. 1, 2009. Published October 2009. Originally approved in 1980. Last previous edition approved in 2002 as C 877M – 02 .

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 01.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Withdrawn.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 877M – 02 (2009)

D 471 Test Method for Rubber Property-Effect of Liquids

D 570 Test Method for Water Absorption of Plastics

D 573 Test Method for Rubber-Deterioration in an Air Oven

D 624 Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers

D 882 Test Method for Tensile Properties of Thin Plastic Sheeting

D 1171 Test Method for Rubber Deterioration-Surface Ozone Cracking Outdoors or Chamber (Triangular Specimens)

D 1278 Test Methods for Rubber from Natural Sources—Chemical Analysis

D 1682 Test Methods for Breaking Load and Elongation of Textile Fabrics NO TITLE

D 1963 Test Method for Specific Gravity of Drying Oils, Varnishes, Resins, and Related Materials at 25/25°C25/25C

D 2202 Test Method for Slump of Sealants

D 2240 Test Method for Rubber Property—Durometer Hardness

D 3407 Test Methods of Testing for Joint Sealants, Hot-Poured, for Concrete and Asphalt Pavements

D 3953 Specification for Strapping, Flat Steel and Seals

3. Terminology

3.1 Definitions—For definitions of terms relating to concrete pipe, see Terminology C 822.

4. Basis of Acceptance

4.1 The acceptability of the sealing bands shall be determined by the results of the physical tests prescribed in this specification,

if and when required, and by inspection to determine whether the sealing bands conform to this specification as to design and

freedom from defects.

5. Materials and Manufacture for Sealing Bands

5.1 Type I, Rubber and Mastic Bands:

5.1.1 Sealingbandsshallbecomposedofrubber,mastic,andprotectivefilmelementsasschematicallyshowninFig.1andwith

dimensions as required in the following:

5.1.1.1 Length of Sealing Band—For a given pipe size, the length of the sealing band as furnished shall be such that after being

stretched longitudinally 8 to 12 % as part of the installation procedure, the sealing band will encircle the outside perimeter of the

pipe and overlap by an amount equal to, but not less than, the width of the sealing band. Sealing bands may be furnished in the

required length or multiples thereof.

5.1.1.2 Width of Sealing Band—The width of the sealing band shall conform to the requirements of Table 1.

5.1.2 Rubber Element—Therubberelementshallbeextrudedormoldedfromahigh-graderubbercompoundandshallbecured

in such a manner that any cross section will be dense, homogeneous, and free of porosity, blisters, pitting, and other imperfections.

The basic polymer shall be natural, synthetic, or a blend of both and shall meet the physical requirements prescribed in Section

6. The rubber element shall have ribs with a height of 4.8 mm, spaced 19 to 32 mm apart, and have a thickness between the ribs

of 1.6 mm. The thickness of the ribs is not prohibited to varyfrom varying from 3.2 mm at the base to 0.8 mm at the top.

5.1.3 Mastic Element—The mastic element shall contain rubber, reclaimed rubber and asphaltic derivatives, clay, asbestos,

and/or resin and shall meet the physical requirements prescribed in Section 6. The mastic element shall have a thickness of 3.2

mm and be free of porous areas, air pockets, and contamination by foreign matter.

5.1.4 Protective Film—The protective film shall be water soluble, have a 0.025-mm thickness, and meet the physical

requirements prescribed in Section 6.

NOTE 2—The function of the film is to protect the mastic surface prior to installation. It is intended to dissolve away in the presence of moisture during

installation and expose the mastic for sealing.

5.2 Type II Plastic Film and Mesh Reinforced Mastic Bands:

5.2.1 Sealing bands shall be composed of a plastic film, reinforced, rubberized, asphalt, mastic coating with steel straps as

schematically shown in Fig. 2 with dimensions as required in the following:

FIG. 1 Sealing Band Type I Schematic (Not to Scale)

C 877M – 02 (2009)

TABLE 1 Required Sealing Band Width

Equivalent Circular Pipe Sealing Band

Diameter, mm Width, mm

450 to 825 180

900 to 1950 230

2100 to 2700 280

2850 to 3600 330

FIG. 2 Sealing Band Type II (Not to Scale)

5.2.1.1 Length of Sealing Band for a Given Pipe Size—The length of the sealing band shall be equal to the outside perimeter

of the joint plus 200 mm to provide for overlap.

5.2.1.2 Width of Sealing Band—The width of the sealing band shall conform to the requirements of Table 1.

5.2.2 Plastic Film Element—The plastic film element shall be an extended polymer which provides external reinforcement and

shall meet the physical requirements prescribed in Section 6.

5.2.3 Mesh Reinforcement Element—The mesh reinforcement shall consist of a woven plastic mesh and shall meet the physical

requirements prescribed in Section 6.

5.2.4 Rubberized Asphalt Mastic Element—The rubberized, asphalt, mastic element shall be a self adhering composition and

shall meet the requirements prescribed in Section 6.

5.2.5 Tie Strap Element—The tie strap element shall be steel straps with a minimum width of 15 mm and a minimum thickness

of 0.50 mm and shall conform to Specification D 3953. Steel straps shall be secured around the pipe with appropriate strapping

tools as recommended by the sealing band manufacturer.

5.2.6 Tie Strap Sleeve Element—Thetiestrapsleeveelementshallconsistofaminimumof25mmwideflatsleeveinsidewhich

thesteeltiestrapsarenotprohibitedtoslidefromslidingfreely.Thesleeveshallbemadefromwovenornon-wovenpolypropylene

fabric with nominal mass of 0.12 kg/m .

5.2.7 Release Sheet Element—The disposable release sheet element shall consist of a silicone coated paper with a minimum

basis mass of 0.1 kg/m .

5.3 Type III, Chemically-Bonded Adhesive Butyl Bands:

Type A (Plastic backing band)

Type B (Rubber backing band)

A semi-liquid paintable butyl rubber-based adhesive primer

5.3.1 Sealing bands shall be composed of a backing band, an applied continuous butyl adhesive coating and an optional release

element (as schematically shown in Fig. 3), with width and overlap dimensions as required by 5.3.1.1 and 5.3.1.2. Purchaser

specified clamping devices or tie straps are not prohibited to be used with these sealing bands.

5.3.1.1 Length of Sealing Band for a Given Pipe Size—The length of the sealing bands shall be equal to the outside perimeter

of the joint plus a minimum distance equal to two times the width of the material used to provide for overlap. This requirement

will allow the sealing bands to be applied without stretching the product during application.

FIG. 3 Sealing Band Type III (Not to Scale)

C 877M – 02 (2009)

5.3.1.2 Width of Sealing Band—The minimum width of the sealing band shall conform to the requirements of Table 2.

5.3.2 Backing Band Element:

5.3.2.1 TypeA(Plastic Backing Band)—Theplasticbackingbandelementshallbemadefromhighdensitypolyethyleneplastic,

conforming to the physical requirements prescribed in Section 6.

5.3.2.2 Type B (Rubber Backing Band)—The rubber used in the rubber backing band element shall conform to the physical

property requirements prescribed in Section 6.

5.3.3 Butyl Rubber Adhesive Element—The butyl rubber adhesive element, conforming to the physical requirements prescribed

in Section 6, shall be a self-adhering semi-solid and shall be applied evenly and homogeneously to the backing band with a

minimum thickness of:

Type A (Plastic Backing Band) 0.75-mm

Type B (Rubber Backing Band) 0.75-mm

5.3.4 Primer Element—The primer element shall be a semi-liquid homogeneous mixture of butyl rubber and vehicle,

conforming to the physical requirements prescribed in Section 6, and shall be spread in a continuous film at the intersection of the

joint. The application width shall be sufficient to ensure that the entire band area will contact only primed surfaces.

5.3.5 Optional Tie Strap—The optional tie strap element shall be steel straps with a minimum width of 16 mm and a minimum

thickness of 5 mm and shall conform to specification D 3953. Steel straps shall be secured around the pipe with appropriate

strapping tools as recommended by the sealing band manufacturer.

5.3.6 Optional Clamping Devices—Optional clamping devices shall be constructed of corrosion resistant material meeting the

physical properties and chemical composition requirements of Specification A 167.

5.3.7 Optional Release Element—The optional release element shall consist of coated paper or plastic that has demonstrated

its suitability for this use.

6. Physical Requirements for Sealing Band Elements

6.1 Type I Rubber and Mastic Bands:

6.1.1 The rubber element shall have the following physical properties when tested in accordance with 8.1.1:

Tensile strength, min, MPa 8.27

Elongation at break, min, % 300

Shore durometer hardness:

Min 60

Max 70

Compression set, max, % of deflection 25

Accelerated aging:

Decrease in tensile strength, max, % of 15

original

Decrease in elongation, max, % of original 20

Water absorption by weight, max, % 10

Ozone resistance rating 0

6.1.2 The mastic element shall be capable of flowing, within the confines of the sealing band, to fill joint surface imperfections

against which the sealing band is placed and shall have no deleterious effect on the rubber element. The mastic element shall have

the following physical properties when tested in accordance with 8.1.2:

Minimum Maximum

Ash-inert matter 10 % 25 %

Volatiles 5 % 10 %

Specific gravity 1.20 1.35

Slump 0.3 mm 0.9 mm

Penetration 200 300

6.1.3 The protective film element shall have a maximum water solubility of 60 s/0.020 mm of thickness when tested in

accordance with 8.1.3.

6.2 Type II Plastic Film and Mesh Reinforced Mastic Bands:

6.2.1 The plastic film element shall have the following physical properties when tested in accordance with 8.2.1:

TABLE 2 Required Sealing Band Width (Type III)

Equivalent Circular Pipe Minimum Sealing Band Width,

Diameter, mm mm

300-900 152

901-2000 229

2001 and larger 305

C 877M – 02 (2009)

Tensile strength, min, MPa 27.6

Elongation at br

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.