ASTM E415-14

(Test Method)Standard Test Method for Analysis of Carbon and Low-Alloy Steel by Spark Atomic Emission Spectrometry

Standard Test Method for Analysis of Carbon and Low-Alloy Steel by Spark Atomic Emission Spectrometry

SIGNIFICANCE AND USE

5.1 This test method for the spectrometric analysis of metals and alloys is primarily intended to test such materials for compliance with compositional specifications. It is assumed that all who use this test method will be analysts capable of performing common laboratory procedures skillfully and safely. It is expected that work will be performed in a properly equipped laboratory.

SCOPE

1.1 This test method covers the simultaneous determination of 20 alloying and residual elements in carbon and low-alloy steels by spark atomic emission vacuum spectrometry in the mass fraction ranges shown (Note 1).

Note 1—The mass fraction ranges of the elements listed have been established through cooperative testing2 of reference materials. Included, in addition to the original data of Test Method E415 – 71, are data from cooperative testing of a broader range of reference materials to expand the element mass fraction ranges.

1.2 This test method covers analysis of specimens having a diameter adequate to overlap and seal the bore of the spark stand opening. The specimen thickness can vary significantly according to the design of the spectrometer stand, but a thickness between 10 mm and 38 mm has been found to be most practical.

1.3 This test method covers the routine control analysis in iron and steelmaking operations and the analysis of processed material. It is designed for chill-cast, rolled, and forged specimens. Better performance is expected when reference materials and specimens are of similar metallurgical condition and composition. However, it is not required for all applications of this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E415 − 14

StandardTest Method for

Analysis of Carbon and Low-Alloy Steel by Spark Atomic

1

Emission Spectrometry

This standard is issued under the fixed designation E415; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

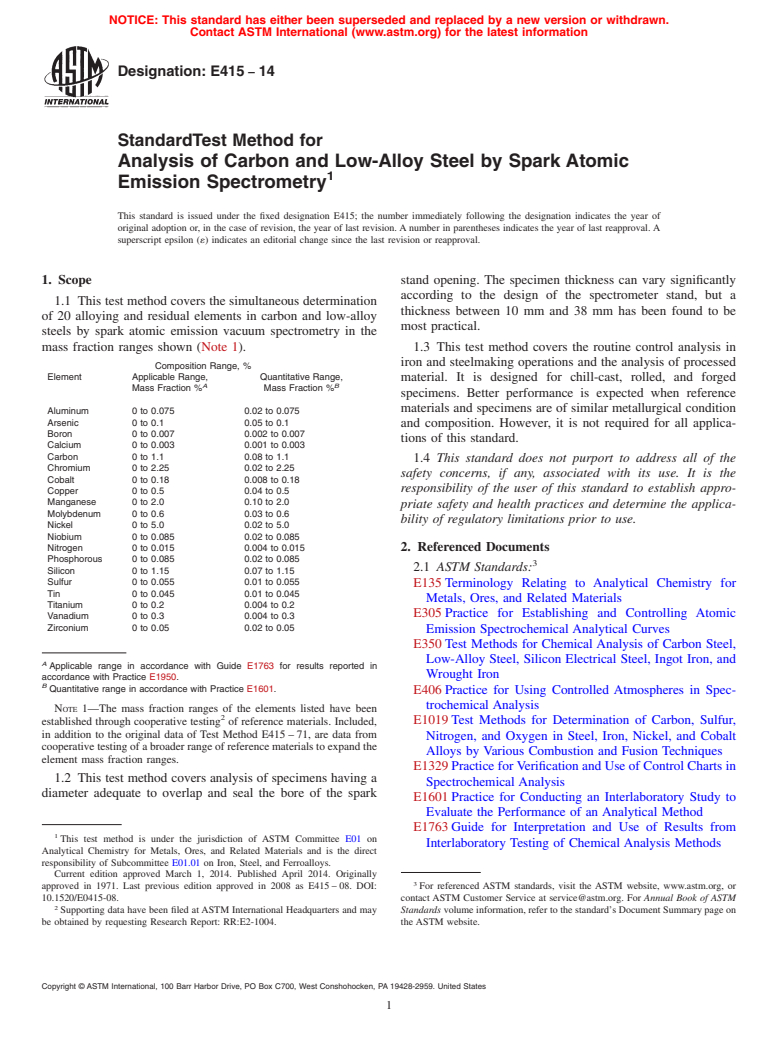

1. Scope stand opening. The specimen thickness can vary significantly

according to the design of the spectrometer stand, but a

1.1 This test method covers the simultaneous determination

thickness between 10 mm and 38 mm has been found to be

of 20 alloying and residual elements in carbon and low-alloy

most practical.

steels by spark atomic emission vacuum spectrometry in the

mass fraction ranges shown (Note 1). 1.3 This test method covers the routine control analysis in

iron and steelmaking operations and the analysis of processed

Composition Range, %

Element Applicable Range, Quantitative Range,

material. It is designed for chill-cast, rolled, and forged

A B

Mass Fraction % Mass Fraction %

specimens. Better performance is expected when reference

materials and specimens are of similar metallurgical condition

Aluminum 0 to 0.075 0.02 to 0.075

Arsenic 0 to 0.1 0.05 to 0.1

and composition. However, it is not required for all applica-

Boron 0 to 0.007 0.002 to 0.007

tions of this standard.

Calcium 0 to 0.003 0.001 to 0.003

Carbon 0 to 1.1 0.08 to 1.1

1.4 This standard does not purport to address all of the

Chromium 0 to 2.25 0.02 to 2.25

safety concerns, if any, associated with its use. It is the

Cobalt 0 to 0.18 0.008 to 0.18

responsibility of the user of this standard to establish appro-

Copper 0 to 0.5 0.04 to 0.5

Manganese 0 to 2.0 0.10 to 2.0

priate safety and health practices and determine the applica-

Molybdenum 0 to 0.6 0.03 to 0.6

bility of regulatory limitations prior to use.

Nickel 0 to 5.0 0.02 to 5.0

Niobium 0 to 0.085 0.02 to 0.085

Nitrogen 0 to 0.015 0.004 to 0.015 2. Referenced Documents

Phosphorous 0 to 0.085 0.02 to 0.085

3

2.1 ASTM Standards:

Silicon 0 to 1.15 0.07 to 1.15

Sulfur 0 to 0.055 0.01 to 0.055

E135 Terminology Relating to Analytical Chemistry for

Tin 0 to 0.045 0.01 to 0.045

Metals, Ores, and Related Materials

Titanium 0 to 0.2 0.004 to 0.2

E305 Practice for Establishing and Controlling Atomic

Vanadium 0 to 0.3 0.004 to 0.3

Zirconium 0 to 0.05 0.02 to 0.05

Emission Spectrochemical Analytical Curves

E350 Test Methods for Chemical Analysis of Carbon Steel,

Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and

A

Applicable range in accordance with Guide E1763 for results reported in

Wrought Iron

accordance with Practice E1950.

B

Quantitative range in accordance with Practice E1601.

E406 Practice for Using Controlled Atmospheres in Spec-

trochemical Analysis

NOTE 1—The mass fraction ranges of the elements listed have been

2

E1019 Test Methods for Determination of Carbon, Sulfur,

established through cooperative testing of reference materials. Included,

in addition to the original data of Test Method E415 – 71, are data from

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

cooperative testing of a broader range of reference materials to expand the

Alloys by Various Combustion and Fusion Techniques

element mass fraction ranges.

E1329 Practice for Verification and Use of Control Charts in

1.2 This test method covers analysis of specimens having a

Spectrochemical Analysis

diameter adequate to overlap and seal the bore of the spark

E1601 Practice for Conducting an Interlaboratory Study to

Evaluate the Performance of an Analytical Method

E1763 Guide for Interpretation and Use of Results from

1

This test method is under the jurisdiction of ASTM Committee E01 on

Interlaboratory Testing of Chemical Analysis Methods

Analytical Chemistry for Metals, Ores, and Related Materials and is the direct

responsibility of Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

Current edition approved March 1, 2014. Published April 2014. Originally

3

approved in 1971. Last previous edition approved in 2008 as E415 – 08. DOI: For referenced ASTM standards, visit the ASTM website, www.astm.org, or

10.1520/E0415-08. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

2

Supporting data have been filed at ASTM International Headquarters and may Standards volume information, refer to the standard’s Document Summary page on

be obtained by requesting Research Report: RR:E2-1004. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

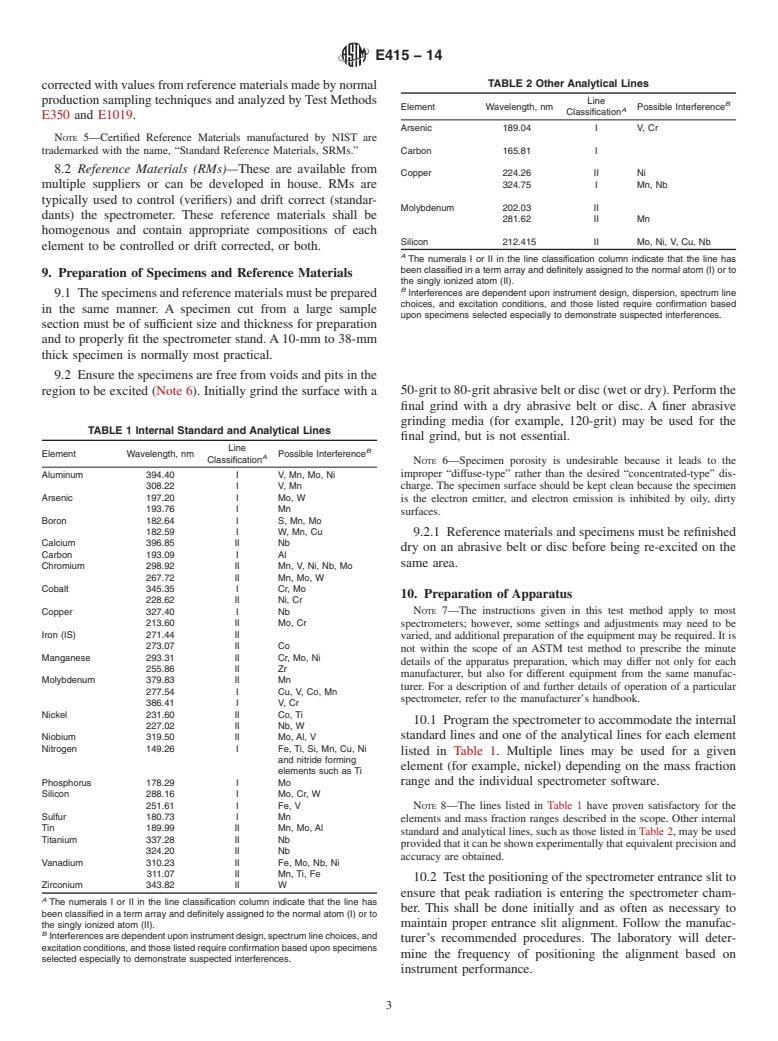

E415 − 14

E1806 Practice for Sampling Steel and Iron for Determina- shall be operat

...

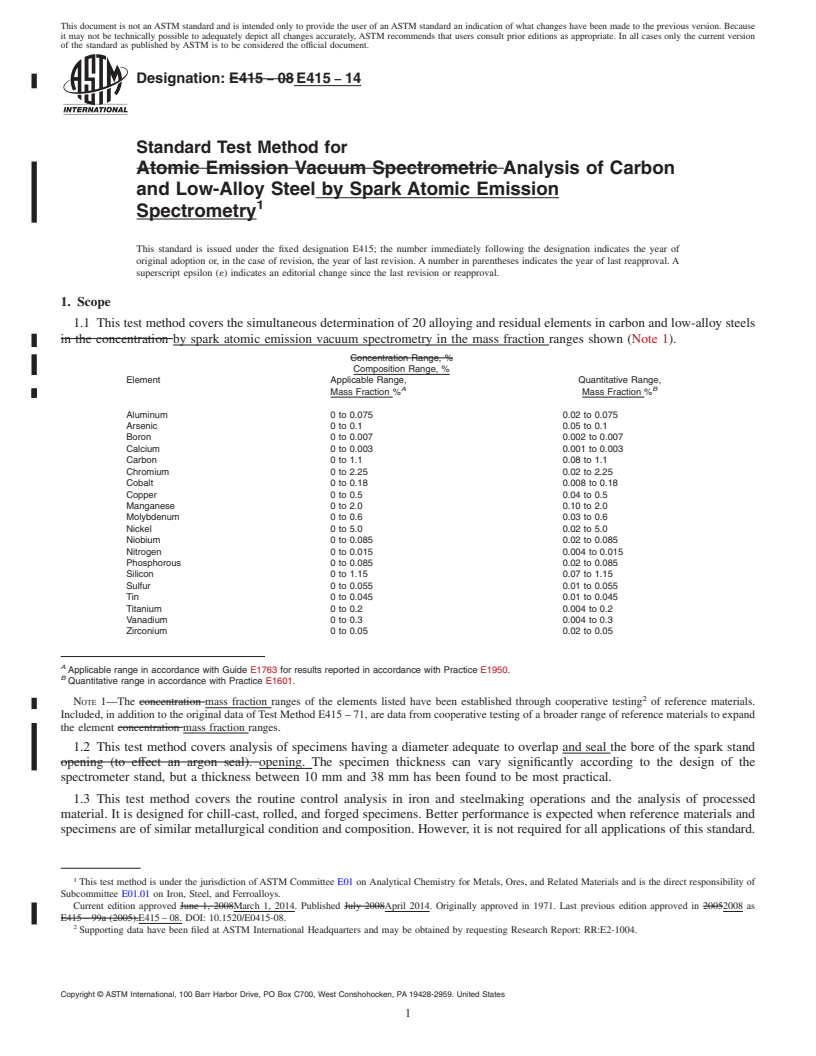

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E415 − 08 E415 − 14

Standard Test Method for

Atomic Emission Vacuum Spectrometric Analysis of Carbon

and Low-Alloy Steel by Spark Atomic Emission

1

Spectrometry

This standard is issued under the fixed designation E415; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the simultaneous determination of 20 alloying and residual elements in carbon and low-alloy steels

in the concentration by spark atomic emission vacuum spectrometry in the mass fraction ranges shown (Note 1).

Concentration Range, %

Composition Range, %

Element Applicable Range, Quantitative Range,

A B

Mass Fraction % Mass Fraction %

Aluminum 0 to 0.075 0.02 to 0.075

Arsenic 0 to 0.1 0.05 to 0.1

Boron 0 to 0.007 0.002 to 0.007

Calcium 0 to 0.003 0.001 to 0.003

Carbon 0 to 1.1 0.08 to 1.1

Chromium 0 to 2.25 0.02 to 2.25

Cobalt 0 to 0.18 0.008 to 0.18

Copper 0 to 0.5 0.04 to 0.5

Manganese 0 to 2.0 0.10 to 2.0

Molybdenum 0 to 0.6 0.03 to 0.6

Nickel 0 to 5.0 0.02 to 5.0

Niobium 0 to 0.085 0.02 to 0.085

Nitrogen 0 to 0.015 0.004 to 0.015

Phosphorous 0 to 0.085 0.02 to 0.085

Silicon 0 to 1.15 0.07 to 1.15

Sulfur 0 to 0.055 0.01 to 0.055

Tin 0 to 0.045 0.01 to 0.045

Titanium 0 to 0.2 0.004 to 0.2

Vanadium 0 to 0.3 0.004 to 0.3

Zirconium 0 to 0.05 0.02 to 0.05

A

Applicable range in accordance with Guide E1763 for results reported in accordance with Practice E1950.

B

Quantitative range in accordance with Practice E1601.

2

NOTE 1—The concentration mass fraction ranges of the elements listed have been established through cooperative testing of reference materials.

Included, in addition to the original data of Test Method E415 – 71, are data from cooperative testing of a broader range of reference materials to expand

the element concentration mass fraction ranges.

1.2 This test method covers analysis of specimens having a diameter adequate to overlap and seal the bore of the spark stand

opening (to effect an argon seal). opening. The specimen thickness can vary significantly according to the design of the

spectrometer stand, but a thickness between 10 mm and 38 mm has been found to be most practical.

1.3 This test method covers the routine control analysis in iron and steelmaking operations and the analysis of processed

material. It is designed for chill-cast, rolled, and forged specimens. Better performance is expected when reference materials and

specimens are of similar metallurgical condition and composition. However, it is not required for all applications of this standard.

1

This test method is under the jurisdiction of ASTM Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials and is the direct responsibility of

Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

Current edition approved June 1, 2008March 1, 2014. Published July 2008April 2014. Originally approved in 1971. Last previous edition approved in 20052008 as

E415 – 99a (2005).E415 – 08. DOI: 10.1520/E0415-08.

2

Supporting data have been filed at ASTM International Headquarters and may be obtained by requesting Research Report: RR:E2-1004.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

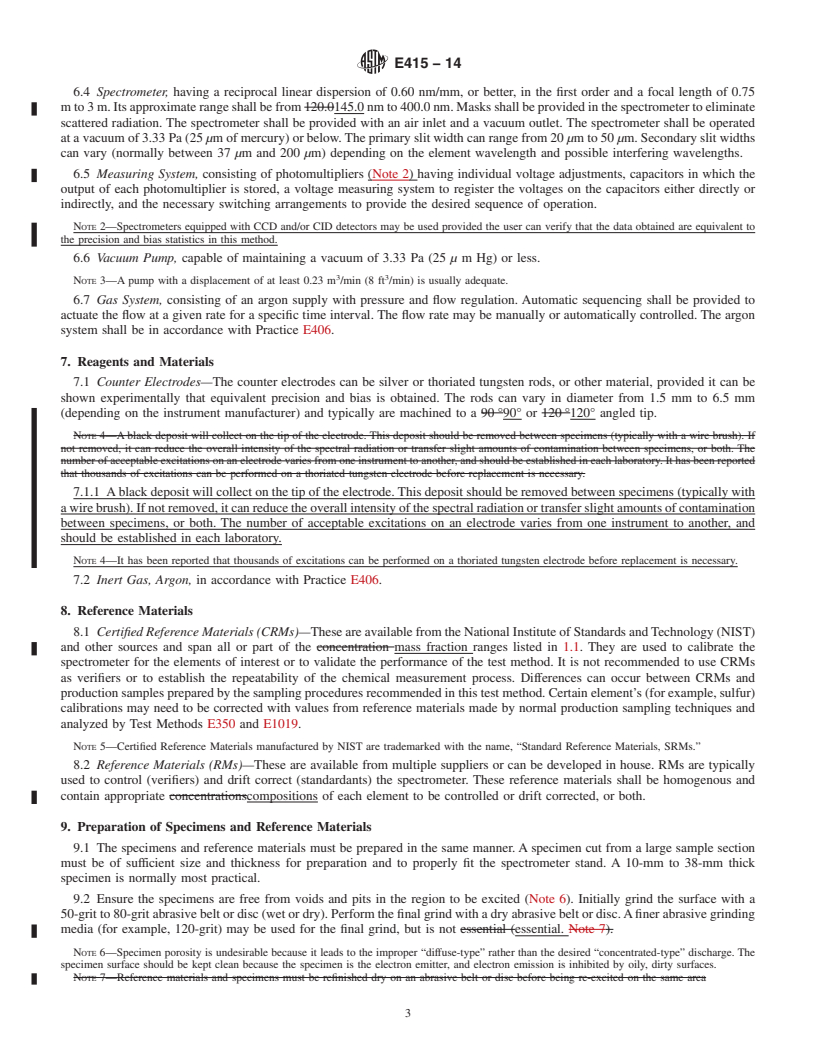

E415 − 14

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

3

2.1 ASTM Standards:

E135 Terminology Relating to Analytical Chemistry for Metals, Ores, and Related Materials

E158 Practice for Fundamental Calculations to Convert Intensities into Concentrations in Optical Emission Spectrochemical

4

Analysis (Withdrawn 2004)

E305 Practice for Establishing and Controlling Atomic Emission Spectrochemical Analytical Curves

E350 Test Methods for Chemical Analysis of Carbon Steel, Low-Alloy Steel, Silicon Electrical Steel, Ingot Iron, and Wrought

Iron

E406 Practice for Using Controlled Atmospheres in Spectrochemical Analysis

E1019 Test Methods for Determination of Carbon, Sulfur, Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt Alloys by

Various Combustion and Fusion Techniques

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.