ASTM D6689-01(2019)e1

(Guide)Standard Guide for Optimizing, Controlling, and Reporting Test Method Uncertainties from Multiple Workstations in the Same Laboratory Organization

Standard Guide for Optimizing, Controlling, and Reporting Test Method Uncertainties from Multiple Workstations in the Same Laboratory Organization

SIGNIFICANCE AND USE

4.1 Many analytical laboratories comply with accepted quality system requirements such as NELAC, Chapter 5,5 (see Note 2) and ISO/IEC 17025. When using standard test methods, their test results on the same sample should agree with those from other similar laboratories within the reproducibility estimates (R2) published in the standard. Reproducibility estimates are generated during the standardization process as part of the interlaboratory studies (ILS). Many laboratories participate in proficiency tests to confirm that they perform consistently over time. In both ILS and proficiency testing protocols, it is generally assumed that only one workstation is used to generate the data (see 6.5.1).

Note 2: NELAC, Chapter 5, allows the use of a Work Cell where multiple instruments/operators are treated as one unit: the performance of the Work Cell is tracked rather than each workstation independently. This guide is intended to go beyond the Work Cell to achieve the benefits of monitoring workstations independently.

4.2 Many laboratories have workloads or logistical requirements, or both, that dictate the use of multiple workstations. Some have multiple stations in the same area (central laboratory format). Others’ stations are scattered throughout a facility (at-line laboratory format). Often, analysis reports do not identify the workstation used for the testing, even if workstations differ in their testing uncertainties. Problems can arise if clients mistakenly attribute variation in report values to process rather then workstation variability. These problems can be minimized if the laboratory organization sets, complies with, and reports a unified set of measurement quality objectives throughout.

4.3 This guide can be used to harmonize calibration and control protocols for all workstations, thereby providing the same level of measurement traceability and control. It streamlines documentation and training requirements, thereby facilitating flexibility in personnel...

SCOPE

1.1 This guide describes a protocol for optimizing, controlling, and reporting test method uncertainties from multiple workstations in the same laboratory organization. It does not apply when different test methods, dissimilar instruments, or different parts of the same laboratory organization function independently to validate or verify the accuracy of a specific analytical measurement.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

´1

Designation: D6689 − 01 (Reapproved 2019)

Standard Guide for

Optimizing, Controlling, and Reporting Test Method

Uncertainties from Multiple Workstations in the Same

Laboratory Organization

This standard is issued under the fixed designation D6689; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

ε NOTE—Reapproved with editorial changes throughout in March 2019.

1. Scope E415 Test Method for Analysis of Carbon and Low-Alloy

Steel by Spark Atomic Emission Spectrometry

1.1 This guide describes a protocol for optimizing,

E1763 Guide for Interpretation and Use of Results from

controlling, and reporting test method uncertainties from mul-

Interlaboratory Testing of Chemical Analysis Methods

tiple workstations in the same laboratory organization. It does

(Withdrawn 2015)

not apply when different test methods, dissimilar instruments,

2.2 Other Documents:

or different parts of the same laboratory organization function

ISO/IEC 17025 General Requirements for the Competence

independently to validate or verify the accuracy of a specific

of Calibration and Testing Laboratories

analytical measurement.

MNL7-9TH ASTM Manual on Presentation of Data and

1.2 This standard does not purport to address all of the

ControlChartAnalysis,9thEdition,PreparedbyCommit-

safety concerns, if any, associated with its use. It is the

tee E11 on Quality and Statistics

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3. Terminology

mine the applicability of regulatory limitations prior to use.

3.1 Definitions—For definitions of terms used in this Guide,

1.3 This international standard was developed in accor-

refer to Terminologies E135 and D1129.

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

3.2 Definitions of Terms Specific to This Standard:

Development of International Standards, Guides and Recom-

3.2.1 laboratory organization, n—a business entity that

mendations issued by the World Trade Organization Technical

provides similar types of measurements from more than one

Barriers to Trade (TBT) Committee.

workstation located in one or more laboratories, all of which

operate under the same quality system.

2. Referenced Documents

NOTE1—KeyaspectsofaqualitysystemarecoveredinISO/IEC17025

2.1 ASTM Standards:

and include documenting procedures, application of statistical control to

D1129 Terminology Relating to Water measurement processes and participation in proficiency testing.

D6091 Practice for 99 %/95 % Interlaboratory Detection

3.2.2 maximum deviation, n—themaximumerrorassociated

Estimate (IDE) for Analytical Methods with Negligible

with a report value, at a specified confidence level, for a given

Calibration Error

concentration of a given element, determined by a specific

D6512 Practice for Interlaboratory Quantitation Estimate

method, throughout a laboratory organization.

E135 Terminology Relating to Analytical Chemistry for

3.2.3 measurement quality objectives, n—a model used by

Metals, Ores, and Related Materials

the laboratory organization to specify the maximum error

associated with a report value, at a specified confidence level.

1 3.2.4 workstation, n—a combination of people and equip-

This guide is under the jurisdiction ofASTM Committee D19 on Water and is

thedirectresponsibilityofSubcommitteeD19.02onQualitySystems,Specification, ment that executes a specific test method using a single

and Statistics.

specifiedmeasuringdevicetoquantifyoneormoreparameters,

Current edition approved March 15, 2019. Published April 2019. Originally

approved in 2001. Last previous edition approved in 2011 as D6689 – 01 (2011).

DOI: 10.1520/D6689-01R19E01.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D6689 − 01 (2019)

with each report value having an established estimated uncer- 4.6 The general principles of this protocol can be adapted to

taintythatcomplieswiththemeasurementqualityobjectivesof other types of measurements, such as mechanical testing and

the laboratory organization. on-line process control measurements such as temperature and

thickness gauging. In these areas, users will likely need to

establish their own models for defining measurement quality

4. Significance and Use

objectives. Proficiency testing may not be available or appli-

4.1 Many analytical laboratories comply with accepted

cable.

quality system requirements such as NELAC, Chapter 5, (see

4.7 It is especially important that users of this guide take

Note 2) and ISO/IEC 17025. When using standard test

responsibility for ensuring the accuracy of the measurements

methods, their test results on the same sample should agree

with those from other similar laboratories within the reproduc- madebytheworkstationstobeoperatedunderthisprotocol.In

addition to the checks mentioned in 6.2.3, laboratories are

ibility estimates (R2) published in the standard. Reproducibil-

ity estimates are generated during the standardization process encouraged to use other techniques, including, but not limited

to, analyzing some materials by independent methods, either

as part of the interlaboratory studies (ILS). Many laboratories

participate in proficiency tests to confirm that they perform within the same laboratory or in collaboration with other

equally competent laboratories. The risks associated with

consistently over time. In both ILS and proficiency testing

generating large volumes of data from carefully harmonized,

protocols, it is generally assumed that only one workstation is

but incorrectly calibrated multiple workstations are obvious

used to generate the data (see 6.5.1).

and must be avoided.

NOTE 2—NELAC, Chapter 5, allows the use of a Work Cell where

multiple instruments/operators are treated as one unit: the performance of

5. Summary

the Work Cell is tracked rather than each workstation independently. This

5.1 Identify the Test Method and establish the required

guide is intended to go beyond the Work Cell to achieve the benefits of

monitoring workstations independently. measurement quality objectives to be met throughout the

laboratory organization.

4.2 Many laboratories have workloads or logistical

requirements, or both, that dictate the use of multiple worksta-

5.2 Identify the workstations to be included in the protocol

tions. Some have multiple stations in the same area (central

and harmonize their experimental procedures, calibrations and

laboratory format). Others’ stations are scattered throughout a

control strategies to be identical, so they will be statistically

facility (at-line laboratory format). Often, analysis reports do

comparable.

not identify the workstation used for the testing, even if

5.3 Tabulate performance data for each workstation and

workstations differ in their testing uncertainties. Problems can

ensure that each workstation complies with the laboratory

arise if clients mistakenly attribute variation in report values to

organization’s measurement quality objectives.

processratherthenworkstationvariability.Theseproblemscan

5.4 Document items covered in 5.1 – 5.3.

be minimized if the laboratory organization sets, complies

with, and reports a unified set of measurement quality objec-

5.5 Establish and document a laboratory organization-wide

tives throughout.

Proficiency Test Policy that provides traceability to all work-

stations.

4.3 This guide can be used to harmonize calibration and

control protocols for all workstations, thereby providing the

5.6 Operate each workstation independently as described in

same level of measurement traceability and control. It stream-

its associated documentation. If any changes are made to any

lines documentation and training requirements, thereby facili-

workstation or its performance levels, document the changes

tating flexibility in personnel assignments. Finally, it offers an

and ensure compliance with the laboratory organization’s

opportunity to claim traceability of proficiency test measure-

measurement quality objectives.

ments to all included workstations, regardless on which work-

6. Procedure

station the proficiency test sample was tested. The potential

6.1 Identify the Test Method and establish the measurement

benefits of utilizing this protocol increase with the number of

workstations included in the laboratory organization. quality objectives to be met throughout the laboratory organi-

zation.

4.4 This guide can be used to identify and quantify benefits

6.1.1 Multi-element test methods can be handled

derived from corrective actions relating to under-performing

concurrently, if all elements are measured using common

workstations. It also provides means to track improved perfor-

technology, and the parameters that influence data quality are

mance after improvements have been made.

tabulated and evaluated for each element individually. An

4.5 It is a prerequisite that all users of this guide comply

example is Test Method E415 that covers the analysis of plain

with ISO/IEC 17025, especially including the use of docu-

carbon and low alloy steel by optical emission vacuum

mented procedures, the application of statistical control of

spectrometry. Workstations can be under manual or robotic

measurement processes, and participation in proficiency test-

control, as long as the estimated uncertainties are within the

ing.

specified measurement quality objectives. Avoid handling

multi-element test methods that concurrently use different

measurement technologies. Their procedures and error evalu-

ations are too diverse to be incorporated into one easy-to-

Available from The NELAC Institute (TNI), P.O. Box 2439, Weatherford, TX

76086, https://www.nelac-institute.org. manage package.

´1

D6689 − 01 (2019)

TABLE 1 Continued

6.1.2 Set the measurement quality objectives for the use of

Assumed

the Test Method throughout the laboratory organization, using

Std.

ERM True WS Av. UCL LCL

Dev.

customer requirements and available performance data. At the

Conc.

conclusion of this effort, the laboratory organization will know

648 0.25063 1 0.25174 0.25906 0.24442 0.00244

the maximum deviation allowable for any report value, at any 2 0.24891 0.25350 0.24432 0.00153

3 0.25123 0.25927 0.24319 0.00268

concentrationlevel,usingthemethodofchoice.Anexampleof

Cr 638 0.03746 1 0.03760 0.03886 0.03634 0.00042

a possible method for establishing measurement quality objec-

2 0.03745 0.03832 0.03658 0.00029

tives is given in Appendix X1. 3 0.03732 0.03813 0.03651 0.00027

648 0.23728 1 0.23190 0.23637 0.22743 0.00149

6.2 Identify the workstations to be included in the protocol 2 0.24012 0.24414 0.23610 0.00134

3 0.23982 0.24300 0.23664 0.00106

and harmonize their experimental procedures, calibrations and

Sn 638 0.00278 1 0.00255 0.00507 0.00003 0.00084

control strategies so that all performance data from all work-

2 0.00257 0.00296 0.00218 0.00013

stations are directly statistically comparable. 3 0.00322 0.00490 0.00154 0.00056

648 0.01424 1 0.01402 0.01600 0.01204 0.00066

6.2.1 For each workstation, list the parameters (personnel,

2 0.01412 0.01502 0.01322 0.00030

equipment, etc.) that significantly influence data quality. Each

3 0.01458 0.01668 0.01248 0.00070

Mo 638 0.06346 1 0.06253 0.06604 0.05902 0.00117

component of each workstation does not have to be identical

2 0.06398 0.06533 0.06263 0.00045

(such as from the same manufacturer or model number).

3 0.06387 0.06621 0.06153 0.00078

However, each workstation must perform the functions de-

648 0.08652 1 0.08539 0.08995 0.08083 0.00152

2 0.08722 0.08941 0.08503 0.00073

scribed in the test method.

3 0.08696 0.09011 0.08381 0.00105

6.2.2 Harmonize the experimental procedures associated

V 638 0.02107 1 0.02076 0.02184 0.01968 0.00036

2 0.02114 0.02219 0.02009 0.00035

with each workstation to ensure that all stations are capable of

3 0.02132 0.02231 0.02033 0.00033

generatingstatisticallycomparabledatathatcanbeexpectedto

648 0.06937 1 0.06892 0.07123 0.06661 0.00077

fall within the maximum allowable limits for the laboratory

2 0.06949 0.07219 0.06679 0.00090

3 0.06969 0.07233 0.06705 0.00088

organization. Ideally, all workstations within the laboratory

Ti 638 0.00224 1 0.00272 0.00296 0.00248 0.00008

organization will have essentially the same experimental pro-

2 0.00200 0.00200 0.00200 0.00000

cedures.

3 0.00200 0.00200 0.00200 0.00000

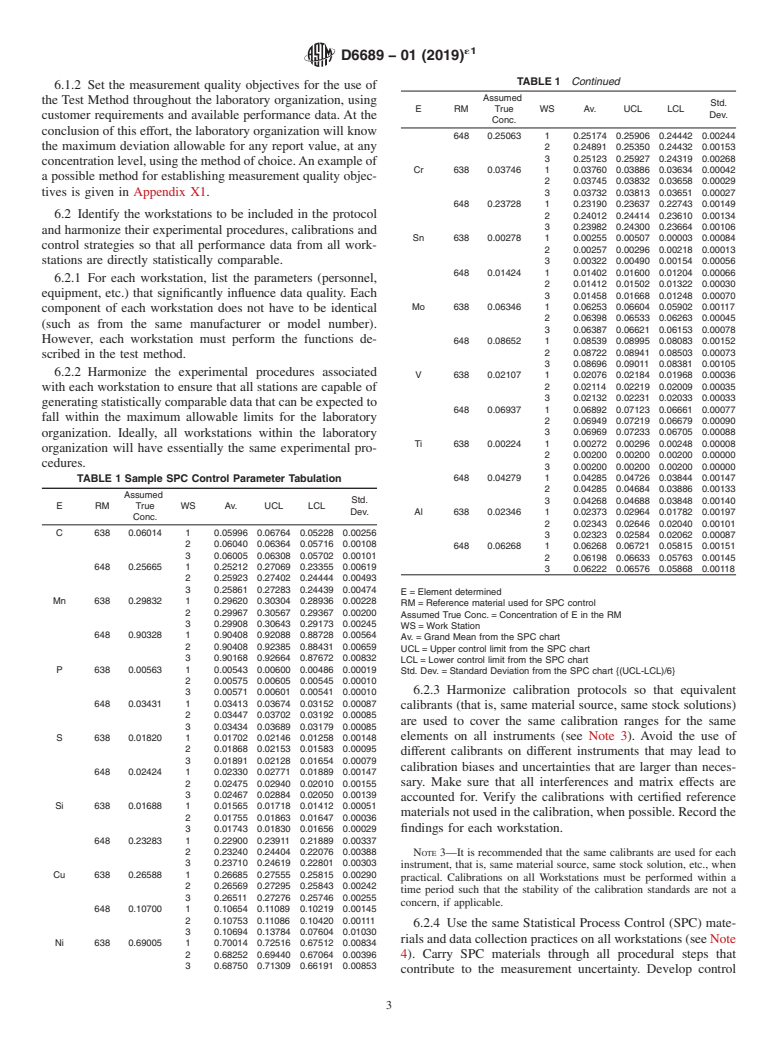

TABLE 1 Sample SPC Control Parameter Tabulation 648 0.04279 1 0.04285 0.04726 0.03844 0.00147

2 0.04285 0.04684 0.03886 0.00133

Assumed

Std. 3 0.04268 0.04688 0.03848 0.00140

ERM True WS Av. UCL LCL

Dev. Al 638 0.02346 1 0.02373 0.02964 0.01782 0.00197

Conc.

2 0.02343 0.02646 0.02040 0.00101

C 638 0.06014 1 0.05996 0.06764 0.05228 0.00256

3 0.02323 0.02584 0.02062 0.00087

2 0.06040 0.06364 0.05716 0.00108

648 0.06268 1 0.06268 0.06721 0.05815 0.00151

3 0.06005 0.06308 0.05702 0.00101

2 0.06198 0.06633 0.05763 0.00145

648 0.25665 1 0.25212 0.27069 0.23355 0.00619

3 0.06222 0.06576 0.05868 0.00118

2 0.25923 0.27402 0.24444 0.00493

3 0.25861 0.27283 0.24439 0.00474

E = Element determined

Mn 638 0.29832 1 0.29620 0.30304 0.28936 0.00228

RM = Reference material used for SPC control

2 0.29967 0.30567 0.29367 0.00200

Assumed True Conc. = Concentration of E in the RM

3 0.29908 0.30643 0.29173 0.00245

WS = Work Station

648 0.90328 1 0.90408 0.92088 0.88728 0.00564

Av. = Grand Mean from the SPC chart

2 0.90408 0.92385 0.88431 0.00659

UCL = Upper control limit from the SPC chart

3 0.90168 0.92664 0.87672 0.00832

LCL = Lower control limit from the SPC chart

P 638 0.00563 1 0.00543 0.00600 0.00486 0.00019

Std. Dev. = Standard Deviation from the SPC chart {(UCL-LCL)/6}

2 0.00575 0.00605 0.00545 0.00010

6.2.3 Harmonize calibration protocols so that equivalent

3 0.00571 0.00601 0.00541 0.00010

648 0.03431 1 0.03413 0.03674 0.03152 0.00087

calibrants (that is, same material

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.