ASTM D2851-98(2015)

(Specification)Standard Specification for Liquid Optical Adhesive

Standard Specification for Liquid Optical Adhesive

ABSTRACT

This specification covers liquid optical adhesive for use in bonding glass to glass or other transparent adherends. The adhesive shall be in liquid form and free of solvent in order to avoid bubble formation in the adhesive layer. Each component shall be completely reactive. The adhesive may be heat-, catalyst-, or radiation-cured. Voltatility, color, viscosity, foreign particle content, refractive index, stability, light transmission, glass doublet preparation, environmental test, and bond strength tests shall be performed in accordance with the specified requirements.

SCOPE

1.1 This specification covers liquid optical adhesive for use in bonding glass to glass or other transparent adherends.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information purposes only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 6, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in 6.1.1.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D2851 −98(Reapproved 2015)

Standard Specification for

Liquid Optical Adhesive

This standard is issued under the fixed designation D2851; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Bond strength data may be suitable for specification

acceptance, service evaluation, manufacturing control,

1.1 This specification covers liquid optical adhesive for use

research, and development. Bond strength tests are not consid-

in bonding glass to glass or other transparent adherends.

ered significant for applications differing widely from the test

1.2 The values stated in SI units are to be regarded as

in rate and type of loading.

standard. The values given in parentheses are provided for

information purposes only.

5. General Requirements

1.3 The following precautionary caveat pertains only to the

5.1 The adhesive shall be in liquid form and free of solvent

test method portion, Section 6, of this specification: This

in order to avoid bubble formation in the adhesive layer. Each

standard does not purport to address all of the safety concerns,

component shall be completely reactive (without residual

if any, associated with its use. It is the responsibility of the user

volatile products). The adhesive may be heat-, catalyst-, or

of this standard to establish appropriate safety and health

radiation-cured.

practices and determine the applicability of regulatory limita-

5.1.1 Volatility—Volatile content of the adhesive shall not

tions prior to use. Specific precautionary statements are given

exceed 0.5%, unless otherwise agreed upon between the

in 6.1.1.

manufacturer and the purchaser.

2. Referenced Documents

5.1.2 Viscosity—The viscosity of the adhesive shall be

within a well-defined range as agreed upon between the

2.1 ASTM Standards:

manufacturer and the purchaser.

D542Test Method for Index of Refraction of Transparent

5.1.3 Color—The color of the adhesive shall not exceed the

Organic Plastics

color of a platinum-cobalt standard solution No. 300.

D897Test Method forTensile Properties ofAdhesive Bonds

5.1.4 Cleanliness—Thenumberandsizeofforeignparticles

D904Practice for Exposure of Adhesive Specimens to

foundin100mLoftheadhesiveshallnotexceed5particlesin

Artificial Light

the size range from 10 to 100 µm (0.1 mm), and none larger

D907Terminology of Adhesives

than 100 µm. The number and size of foreign particles in the

D1084Test Methods for Viscosity of Adhesives

catalyst required to cure 100 mL of the adhesive shall not

E308PracticeforComputingtheColorsofObjectsbyUsing

exceed 2 particles in the size range from 10 to 100 µm, and

the CIE System

none larger than 100 µm.

3. Terminology

5.1.5 Refractive Index—The refractive index of the cured

3.1 Definitions—Many terms in this specification are de- adhesive shall be within a well-defined range as agreed upon

fined in Terminology D907. between the manufacturer and the purchaser.

5.1.6 Stability—The liquid adhesive shall not change in

4. Significance and Use

viscosity by greater than 20% of its original viscosity nor

4.1 The bond strength tests provide reasonably accurate

show any formation of solids, when tested as described in 6.6.

information with regard to the bond strength of the adhesives.

5.1.7 Light Transmission—Visible light transmission

through a bonded glass doublet (two glass disks bonded as

This specification is under the jurisdiction of ASTM Committee D14 on described in 6.8) shall not be less than 98.5% of the total light

Adhesives and is the direct responsibility of Subcommittee D14.60 on Adhesive

transmitted through a single glass disk. There shall be no

Material Classification System.

change in light transmission of a glass doublet after the

Current edition approved April 1, 2015. Published April 2015. Originally

environmental test (see 6.9).

approved in 1970. Last previous edition approved in 2009 as D2851–98(2009).

DOI: 10.1520/D2851-98R15.

5.1.8 Environmental Test—Separation within the adhesive

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

layer or from either glass surface of the glass doublet shall not

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

exceed 1.0 mm in depth nor extend beyond 180° of the

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. periphery of the adhesive layer (see 6.9).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2851−98 (2015)

5.1.9 Bond Strength—Thetensilestrengthofabondedglass

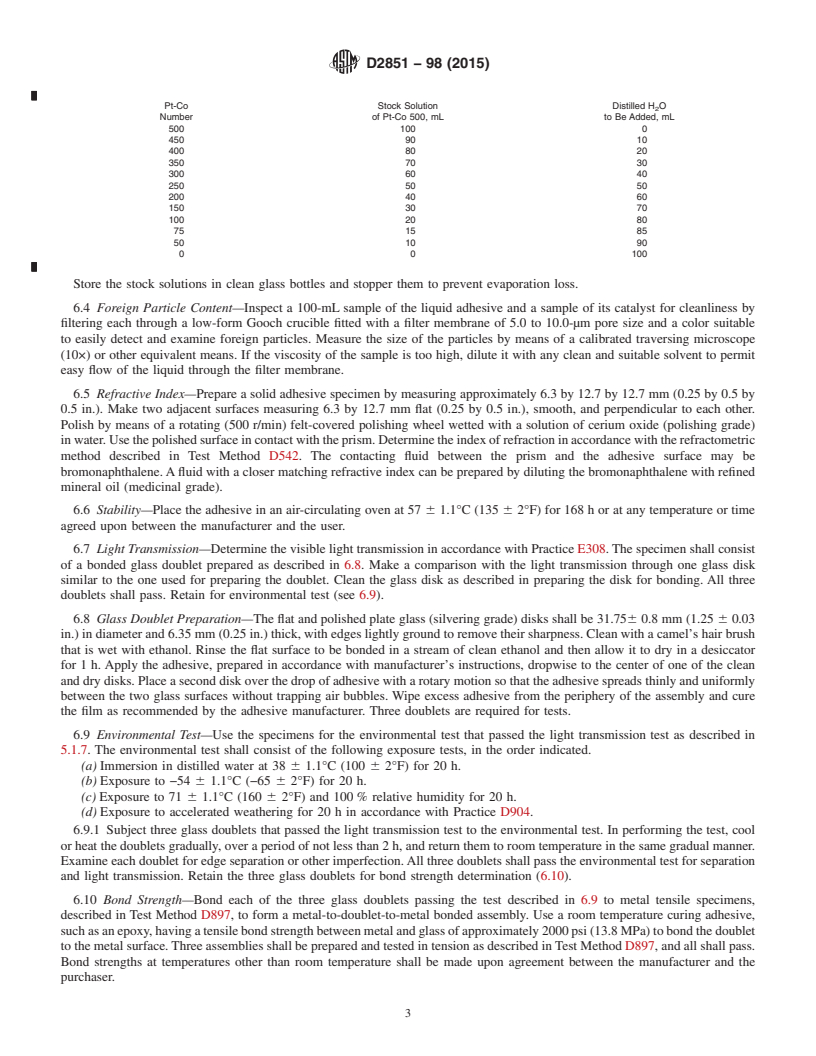

Pt-Co Stock Solution Distilled H O

Number of Pt-Co 500, mL to Be Added, mL

doubletafterbeingsubjectedtotheenvironmentaltest(see6.9)

500 100 0

shall be greater than 200 psi (1.38 MPa) or any value agreed

450 90 10

upon between the manufacturer and the purchaser.

400 80 20

350 70 30

300 60 40

6. Test Methods

250 50 50

6.1 Volatility: 200 40 60

150 30 70

6.1.1 Thoroughly clean three petri dish bottoms, 95-mm

100 20 80

outsidediameter,bywashingwithdetergentandascrubbrush.

75 15 85

Rinse with warm running tap water. Place petri dishes in an 50 10 90

0 0 100

air-circulatingovenfor30minat65 62°C(150 64°F).Raise

Store the stock solutions in clean glass bottles and stopper

temperature to 110 6 2°C (230 6 4°F) for 1 h. Remove petri

them to prevent evaporation loss.

dishes from oven and place in a desiccator. After petri dishes

have cooled to room temperature, approximately 2 h, weigh

6.4 Foreign Particle Content—Inspect a 100-mL sample of

each dish to the nearest 0.1 mg. (Warning—In addition to

the liquid adhesive and a sample of its catalyst for cleanliness

other precautions, do not handle petri dishes with bare hands.

byfilteringeachthroughalow-formGoochcruciblefittedwith

Use tongs.)

a filter membrane of 5.0 to 10.0-µm pore size and a color

6.1.2 Replaceeachpetridishintheovenat110 62°C(230

suitabletoeasilydetectandexamineforeignparticles.Measure

6 4°F) for 1 h. Repeat cool-down procedure. Reweigh each

the size of the particles by means of a calibrated traversing

petridishtothenearest0.1mg.Ifweightagreestowithin 60.2

microscope(10×)orotherequivalentmeans.Iftheviscosityof

mg of initial weight, proceed to 6.1.3. If weight exceeds this

the sample is too high, dilute it with any clean and suitable

60.2-mgrange,repeatprocessuntilaconstantweightforeach

solvent to permit easy flow of the liquid through the filter

petri dish is obtained.

membrane.

6.1.3 Toeachpetridishaddapproximately10gofadhesive,

6.5 Refractive Index—Prepare a solid adhesive specimen by

and mix with catalyst or any component

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D2851 − 98 (Reapproved 2009) D2851 − 98 (Reapproved 2015)

Standard Specification for

Liquid Optical Adhesive

This standard is issued under the fixed designation D2851; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers liquid optical adhesive for use in bonding glass to glass or other transparent adherends.

1.2 The values stated in SI units are to be regarded as standard. The values given in parentheses are provided for information

purposes only.

1.3 The following precautionary caveat pertains only to the test method portion, Section 6, of this specification:This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to

use.Specific precautionary statements are given in 6.1.1.

2. Referenced Documents

2.1 ASTM Standards:

D542 Test Method for Index of Refraction of Transparent Organic Plastics

D897 Test Method for Tensile Properties of Adhesive Bonds

D904 Practice for Exposure of Adhesive Specimens to Artificial Light

D907 Terminology of Adhesives

D1084 Test Methods for Viscosity of Adhesives

E308 Practice for Computing the Colors of Objects by Using the CIE System

3. Terminology

3.1 Definitions—Many terms in this specification are defined in Terminology D907.

4. Significance and Use

4.1 The bond strength tests provide reasonably accurate information with regard to the bond strength of the adhesives. Bond

strength data may be suitable for specification acceptance, service evaluation, manufacturing control, research, and development.

Bond strength tests are not considered significant for applications differing widely from the test in rate and type of loading.

5. General Requirements

5.1 The adhesive shall be in liquid form and free of solvent in order to avoid bubble formation in the adhesive layer. Each

component shall be completely reactive (without residual volatile products). The adhesive may be heat-, catalyst-, or

radiation-cured.

5.1.1 Volatility—Volatile content of the adhesive shall not exceed 0.5 %, unless otherwise agreed upon between the

manufacturer and the purchaser.

5.1.2 Viscosity—The viscosity of the adhesive shall be within a well-defined range as agreed upon between the manufacturer

and the purchaser.

5.1.3 Color—The color of the adhesive shall not exceed the color of a platinum-cobalt standard solution No. 300.

This specification is under the jurisdiction of ASTM Committee D14 on Adhesives and is the direct responsibility of Subcommittee D14.60 on Adhesive Material

Classification System.

Current edition approved Nov. 1, 2009April 1, 2015. Published November 2009April 2015. Originally approved in 1970. Last previous edition approved in 20042009 as

D2851 – 98 (2004).(2009). DOI: 10.1520/D2851-98R09.10.1520/D2851-98R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D2851 − 98 (2015)

5.1.4 Cleanliness—The number and size of foreign particles found in 100 mL of the adhesive shall not exceed 5 particles in the

size range from 10 to 100 μm (0.1 mm), and none larger than 100 μm. The number and size of foreign particles in the catalyst

required to cure 100 mL of the adhesive shall not exceed 2 particles in the size range from 10 to 100 μm, and none larger than

100 μm.

5.1.5 Refractive Index—The refractive index of the cured adhesive shall be within a well-defined range as agreed upon between

the manufacturer and the purchaser.

5.1.6 Stability—The liquid adhesive shall not change in viscosity by greater than 20 % of its original viscosity nor show any

formation of solids, when tested as described in 6.6.

5.1.7 Light Transmission—Visible light transmission through a bonded glass doublet (two glass disks bonded as described in

6.8) shall not be less than 98.5 % of the total light transmitted through a single glass disk. There shall be no change in light

transmission of a glass doublet after the environmental test (see 6.9).

5.1.8 Environmental Test—Separation within the adhesive layer or from either glass surface of the glass doublet shall not exceed

1.0 mm in depth nor extend beyond 180° of the periphery of the adhesive layer (see 6.9).

5.1.9 Bond Strength—The tensile strength of a bonded glass doublet after being subjected to the environmental test (see 6.9)

shall be greater than 200 psi (1.38 MPa) or any value agreed upon between the manufacturer and the purchaser.

6. Test Methods

6.1 Volatility:

6.1.1 Thoroughly clean three petri dish bottoms, 95-mm outside diameter, by washing with detergent and a scrub brush. Rinse

with warm running tap water. Place petri dishes in an air-circulating oven for 30 min at 65 6 2°C (150 6 4°F). Raise temperature

to 110 6 2°C (230 6 4°F) for 1 h. Remove petri dishes from oven and place in a desiccator. After petri dishes have cooled to room

temperature, approximately 2 h, weigh each dish to the nearest 0.1 mg. (Warning—In addition to other precautions, do not handle

petri dishes with bare hands. Use tongs.)

6.1.2 Replace each petri dish in the oven at 110 6 2°C (230 6 4°F) for 1 h. Repeat cool-down procedure. Reweigh each petri

dish to the nearest 0.1 mg. If weight agrees to within 60.2 mg of initial weight, proceed to 6.1.3. If weight exceeds this 60.2-mg

range, repeat process until a constant weight for each petri dish is obtained.

6.1.3 To each petri dish add approximately 10 g of adhesive, and mix with catalyst or any component part required for curing.

Weigh each dish to the nearest 0.1 mg. Cure the adhesive by following the procedure described by the manufacturer. Then place

each sample in an oven at 105 6 2°C (220 6 4°F) to a constant weight (same procedure as in 5.1.1 but at 105°C). Reweigh each

sample to the nearest 0.1 mg and calculate the percent volatile matter as follows.

Volatile matter,%5 @~A 2 B!/A# 3100 (1)

where:

A = weight of original sample, and

B = weight of cured adhesive taken to constant weight.

where:

A = weight of original sample, and

B = weight of cured adhesive taken to constant weight.

6.2 Viscosity—Measure the viscosity of the adhesive in accordance with Test Methods D1084. (Brookfield, Method B, or any

other suitable viscometer may be used.)

6.3 Color—Determine the color of the adh

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.