ASTM D4097-01(2010)

(Specification)Standard Specification for Contact-Molded Glass-Fiber-Reinforced Thermoset Resin Corrosion-Resistant Tanks

Standard Specification for Contact-Molded Glass-Fiber-Reinforced Thermoset Resin Corrosion-Resistant Tanks

ABSTRACT

This specification covers cylindrical tanks fabricated by contact molding for above-ground vertical installation, to contain aggressive chemicals at essentially atmospheric pressure, and made of a commercial-grade polyester or vinyl ester, resin. This specification does not cover the design of vessels intended for pressure above hydrostatic, vacuum conditions, except as classified herein, or vessels intended for use with liquids heated above their flash points. The tanks are classified as type I and II according to the operating pressure or vacuum levels, and the safety factor required for external pressure. The tanks are further classified as grade 1 and 2 according to the generic types of thermoset resin. The resin used shall be a commercial grade, corrosion-resistant thermoset. The reinforcement should be a chopped-strand mat, a nonwoven biaxial or unidirectal fabric, a woven roving, or a surface mat. Materials shall be tested and the individual grades shall conform to specified values of design requirements such as straight shell, external pressure, top head, bottom head, open-top tanks, joints, fittings, hold-down lugs, and lifting lugs; laminate construction requirements such as structural tank, joints, and fittings and accessories; and other requirements such as physical properties, chemical resistance of resin, glass content, tensile strength, flexural properties and degree of cure. The dimensions and tolerances, as well as the workmanship, finish and appearance are also detailed.

SCOPE

1.1 This specification covers cylindrical tanks fabricated by contact molding for above-ground vertical installation, to contain aggressive chemicals at essentially atmospheric pressure, and made of a commercial-grade polyester or vinyl ester, resin. Included are requirements for materials, properties, design, construction, dimensions, tolerances, workmanship, and appearance.

1.2 This specification does not cover the design of vessels intended for pressure above hydrostatic, vacuum conditions, except as classified herein, or vessels intended for use with liquids heated above their flash points.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are provided for information purposes only.

Note 1—Special design consideration should be given to vessels subject to superimposed mechanical forces, such as earthquakes, wind load, or agitation, to vessels subject to service temperature in excess of 180°F (82°C), and to vessels with unsupported bottoms.

Note 2—There is no known ISO equivalent to this standard.

1.4 The following safety hazards caveat pertains only to the test method portion, Section 11, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4097 −01 (Reapproved 2010) An American National Standard

Standard Specification for

Contact-Molded Glass-Fiber-Reinforced Thermoset Resin

Corrosion-Resistant Tanks

This standard is issued under the fixed designation D4097; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope C581 Practice for Determining Chemical Resistance of

Thermosetting Resins Used in Glass-Fiber-Reinforced

1.1 This specification covers cylindrical tanks fabricated by

Structures Intended for Liquid Service

contact molding for above-ground vertical installation, to

C582 Specification for Contact-Molded ReinforcedThermo-

contain aggressive chemicals at essentially atmospheric

setting Plastic (RTP) Laminates for Corrosion-Resistant

pressure, and made of a commercial-grade polyester or vinyl

Equipment

ester,resin.Includedarerequirementsformaterials,properties,

D618 Practice for Conditioning Plastics for Testing

design, construction, dimensions, tolerances, workmanship,

D638 Test Method for Tensile Properties of Plastics

and appearance.

D790 Test Methods for Flexural Properties of Unreinforced

1.2 This specification does not cover the design of vessels

and Reinforced Plastics and Electrical Insulating Materi-

intended for pressure above hydrostatic, vacuum conditions,

als

except as classified herein, or vessels intended for use with

D883 Terminology Relating to Plastics

liquids heated above their flash points.

D2150 Specification for Woven Roving Glass Fabric for

Polyester-Glass Laminates (Withdrawn 1987)

1.3 The values stated in inch-pound units are to be regarded

as standard. The values given in parentheses are provided for D2583 Test Method for Indentation Hardness of Rigid Plas-

tics by Means of a Barcol Impressor

information purposes only.

D2584 Test Method for Ignition Loss of Cured Reinforced

NOTE 1—Special design consideration should be given to vessels

Resins

subject to superimposed mechanical forces, such as earthquakes, wind

D2996 Specification for Filament-Wound “Fiberglass’’

load, or agitation, to vessels subject to service temperature in excess of

180°F (82°C), and to vessels with unsupported bottoms. (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

NOTE 2—There is no known ISO equivalent to this standard.

D2997 Specification for Centrifugally Cast “Fiberglass”

1.4 The following safety hazards caveat pertains only to the

(Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

test method portion, Section 11, of this specification: This D3892 Practice for Packaging/Packing of Plastics

standarddoesnotpurporttoaddressallofthesafetyconcerns,

D4024 Specification for Machine Made “Fiberglass” (Glass-

ifany,associatedwithitsuse.Itistheresponsibilityoftheuser Fiber-Reinforced Thermosetting Resin) Flanges

of this standard to establish appropriate safety and health

D5421 Specification for Contact Molded “Fiberglass”

practices and determine the applicability of regulatory limita- (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

tions prior to use.

F412 Terminology Relating to Plastic Piping Systems

2.2 ANSI Standards:

2. Referenced Documents

B 16.1 Cast Iron Pipe Flanges and Flanged Fittings, Class

25, 125, 250, and 800

2.1 ASTM Standards:

B 16.5 Steel Pipe Flanges, Flanged Valves and Fittings

3. Terminology

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced 3.1 Definitions—Definitions are in accordance with Termi-

Plastic Piping Systems and Chemical Equipment.

nologies D883 and F412, unless otherwise indicated.

Current edition approved Jan. 1, 2010. Published January 2010. Originally

approved in 1982. Last previous edition approved in 2001 as D4097 - 01. DOI:

10.1520/D4097-01R10.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or The last approved version of this historical standard is referenced on

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM www.astm.org.

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4097−01 (2010)

3.2 Definitions of Terms Specific to This Standard: 5.1.1.4 Ultraviolet absorbers may be added for improved

3.2.1 contact molding—includes the “hand lay-up” or a weather resistance if agreed upon between the fabricator and

the purchaser.

combination of the “hand lay-up” and the “spray-up” manu-

facturing processes. 5.1.1.5 Antimony compounds or other fire-retardant agents

may be added to halogenated resins for improved fire

4. Classification resistance, if agreed upon between the fabricator and the

purchaser.

4.1 Tanks meeting this specification are classified according

to type. It is the responsibility of the purchaser to specify the

NOTE 6—Because the addition of fire-retardant agents may interfere

with visual inspection of laminate quality, they should not be used in the

requirement for Type II tanks, the operating pressure or

inner surface (7.1.1) or interior layer (7.1.2), unless their functional

vacuum levels, and the safety factor required for external

advantages would outweigh the loss of visual inspection.

pressure.Absence of a designation of type required shall imply

5.2 Reinforcement:

that Type I is adequate.

5.2.1 Chopped-Strand Mat—Chopped-strand mat shall be

4.1.1 Type I—Atmospheric pressure tanks vented directly to

constructed from chopped commercial-grade E-type glass

the atmosphere, designed for pressure no greater or lower than

strands bonded together using a binder. The strands should be

atmospheric.

treated with a sizing that is chemically compatible with the

4.1.2 Type II—Atmospheric pressure tanks vented directly

resin system used.

into a fume conservation system, and designed to withstand,

thespecifiedpositiveandnegativepressurenottoexceed14in.

NOTE 7—The selection of the particular chopped-strand mat is depen-

of water (355.6 mm) when all tie-down lugs are properly

dent upon the performance characteristics required of the finished product

secured, in accordance with the fabricator’s recommendations and upon the processing techniques to be used.

for flat-bottom tanks.

5.2.2 Nonwoven Biaxial or Unidirectal Fabric—These

4.2 Tanks meeting this specification are classified according products shall be a commercial grade of E-type glass fiber with

a sizing that is chemically compatible with the resin system

to type as follows:

4.2.1 Grade 1—Tanks manufactured with a single generic used.

type of thermoset resin throughout. 5.2.3 Woven Roving—Woven roving shall be in accordance

with Specification D2150.

4.2.2 Grade 2—Tanks manufactured with different generic

types of thermoset resin in the barrier and the structural

5.2.4 Surface Mat—The reinforcement used for the inner

portion. surface (7.1.1) shall be either a commercial-grade chemical

resistant glass surface mat or an organic-fiber surface mat. In

NOTE 3—The external corrosive environment due to spillage or

environments that attack glass, the use of an organic-fiber

corrosivevaporsshouldbeconsideredwhenspecifyingGrade2tanks(see

surface mat is required.

7.1.3.3).

5. Materials and Manufacture 6. Design Requirements

5.1 Resin—The resin used shall be a commercial grade, 6.1 StraightShell—Theminimumrequiredwallthicknessof

corrosion-resistant thermoset that has either been evaluated in the cylindrical straight shell at any fluid level shall be deter-

a laminate by test in accordance with 11.3, or that has been mined by the following equation, but shall not be less than ⁄16

determined by previous documented service to be acceptable in.:

for the service conditions. Where service conditions have not

t 5 PD/2S 5 0.036 γ HD/2S or 0.2489 γ HD/2S

~ !

H H H

been evaluated, a suitable resin may also be selected by

where:

agreement between fabricator and purchaser.

5.1.1 The resin shall contain no pigment, dyes, colorants, or t = wall thickness, in. (mm),

filler, except as follows: S = allowable hoop tensile stress (not to exceed ⁄10 of the

H

ultimate hoop strength), psi (kPa) (see 11.8),

5.1.1.1 A thixotropic agent that does not interfere with

P = pressure, psi (kPa),

visual inspection of laminate quality, or with the required

H = fluid head, in. (mm),

corrosion resistance of the laminate, may be added for viscos-

γ = specific gravity of fluid, and

ity control.

D = inside diameter of tank, in. (mm).

NOTE 4—The addition of a thixotropic agent may reduce the resistance

NOTE8—Theuseofanacceptedanalyticaltechnique,suchaslaminated

ofmanyresinsystemstocertaincorrosivechemicalenvironments.Itisthe

plate theory (LPT), for design and analysis of composite vessels may

responsibility of the fabricator, using a thixotropic agent in the resin

predict stresses, strains, and strength on a ply-by-ply basis, given some

required for 7.1.1 and 7.1.2, to ascertain its compatibility with the

basic lamina properties.

corrosive environment when this has been reported by the purchaser.

NOTE 9—The calculation is suitable for the shell design of elevated

dished-bottom tanks that are mounted or supported below the tangent of

5.1.1.2 Resinpastesusedtofillcrevicesbeforeoverlayshall

the dished-bottom head. Special consideration must be given to the

not be subject to the limitation of 5.1.1.

loading on the straight shell at the support when tank has mounting

5.1.1.3 Resin may contain pigment, dyes, or colorants when

supports located above the tangent line.

agreed upon between fabricator and purchaser.

NOTE10—TableX2.1,AppendixX2,illustratesminimumstraight-shell

wall thicknesses.

NOTE5—Theadditionofpigment,dyes,orcolorantsmayinterferewith

visual inspection of laminate quality. 6.2 Design for External Pressure:

D4097−01 (2010)

6.2.1 Cylindrical Shells—For cylindrical shells, compute

0.5

the value 1.73 (D /t) . If the result is less than L/D of the

o o

cylinder, compute P as follows:

a

2.5

P 5 2.6 E/F D /L t/D

~ ! ~ !

~ !

a o o

If the result is greater than L/D of the cylinder, compute P

o a

as follows:

2.5

2.6~E/F!~D /L!~t/D !

o o

P 5

0.5

a

L/D 2 0.45 t/D

~ ! ~ !

o o

where:

D = outside diameter, in.,

o

E = hoop tensile modulus of the filament wound structural

t

laminate, psi (kPa),

F = design factor = 5,

L = design length, in. (mm), of a vessel section, taken as

the largest of the following: (a) the distance between

head tangent lines plus one-third the depth of each

FIG. 1 Jointed Head Detail

formed head, if there are no stiffening rings (excluding (Sketch A)

conical heads and sections); (b) the distance between

cone-to-cylinder junctions for vessels with a cone or

where:

conical heads if there are no stiffening rings; (c) the

D = shell outside diameter, in. (mm),

greatest center-to-center distance between any two

o

E = hoop tensile modulus, psi (kPa),

adjacent stiffening rings; (d) the distance from the

h

F = design factor = 5,

center of the first stiffening ring to the formed head

4 4

I = moment of inertia, in. (mm ), of stiffener for the

tangentlineplusone-thirdthedepthoftheformedhead s

effective length of shell, L ,

s

(excluding conical heads and sections), all measured

L = one-half of the distance from the centerline of the

s

parallel to the axis of the vessel; (e) the distance from

stiffening ring to the next line of support on one side,

the first stiffening ring in the cylinder to the cone-to-

plus one-half of the centerline distance to the next line

cylinder junction,

of support on the other side of the stiffening ring, both

P = allowable external pressure, psi (kPa), and

a

measured parallel to the axis of the cylinder, in.Aline

t = wall thickness, in. (mm) (nominal).

of support is the following: (a) a stiffening ring that

6.2.2 Torispherical Heads—For torispherical heads, com-

meets the requirements of this paragraph; (b )a

pute the allowable external pressure, P , as follows:

a

circumferentiallineonaheadatone-thirdthedepthof

P 5 0.36~E/F! t/R the head from the head tangent line; (c) a cone-to-

~ !

a o

cylinder junction,

where:

P = actual external pressure, psi (kPa).

R = outside crown radius of head, in. (mm).

o

Typical half-round stiffener sizes and dimensions for differ-

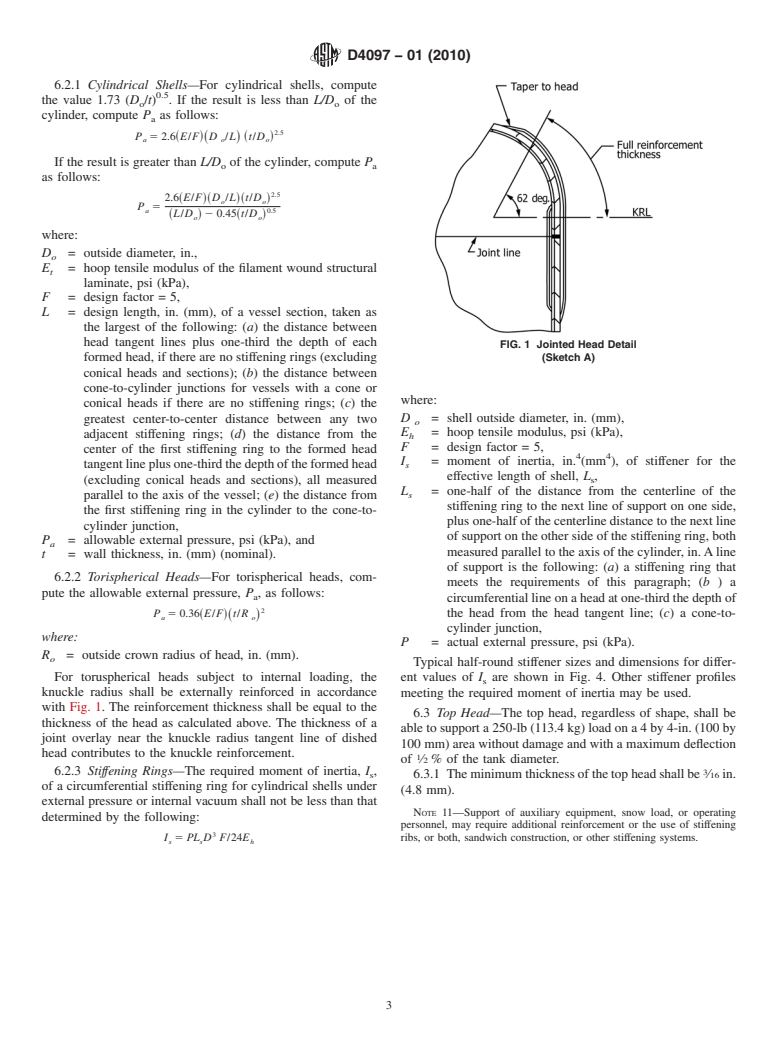

For toruspherical heads subject to internal loading, the ent values of I are shown in Fig. 4. Other stiffener profiles

s

knuckle radius shall be externally reinforced in accordance

meeting the required moment of inertia may be used.

with Fig. 1. The reinforcement thickness shall be equal to the

6.3 Top Head—The top head, regardless of shape, shall be

thickness of the head as calculated above. The thickness of a

able to support a 250-lb (113.4 kg) load ona4by 4-in. (100 by

joint overlay near the knuckle radius tangent line of dished

100 mm) area without damage and with a maximum deflection

head contributes to the knuckle reinforcement.

of ⁄2 % of the tank diameter.

6.2.3 Stiffening Rings—The required moment of inertia, I , 3

s

6.3.1 Theminimumthicknessofthetopheadshallbe ⁄16in.

of a circumferential stiffening ring for cylindrical shells under

(4.8 mm).

external pressure or internal vacuum shall not be less than that

NOTE 11—Support of auxiliary equipment, snow load, or operating

determined by the following:

personnel, may require additional reinforcement or the use of stiffening

I 5 PL D F/24E ribs, or both, sandwich construction, or other stiffening systems.

s s h

D4097−01 (2010)

6.4 Bottom Head: 6.4.4 The tank bottom shall not have variations from a

6.4.1 The minimum thickness for a fully supported flat- nominally flat plane that would prevent uniform contact of the

bottom head shall be as follows: entire bottom surface with a properly prepared support surface

⁄16 in. (4.8 mm) for 2 to 6-ft (0.6 to 1.8-m) diameter, whenthetankisfilledwithliquid.Thebottomlaminatesurface

⁄4 in. (6.4 mm) for over 6 to 12-ft (1.8 to 3.7-m) diameter, and shall be a hand-work finish and shall have no excessive

⁄8 in. (9.5 mm) for over 12-ft (3.7-m) diameter. laminate projections that would prevent uniform contact with a

6.4.2 Bottom heads may be molded integrally with the properly prepared flat support surface when the tank is filled

straight-shell, or may be molded separately with a straight with liquid.

flange length for subsequent joining t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.