ASTM F2438-04(2022)

(Specification)Standard Specification for Oil Spill Response Boom Connection: Slide Connector

Standard Specification for Oil Spill Response Boom Connection: Slide Connector

SIGNIFICANCE AND USE

5.1 The general design geometry herein defined applies to both a separate adaptor accessory mating two booms of different geometry as well as boom end connectors (see Terminology F818).

5.2 Interconnectibility is intended to facilitate mating of oil spill response booms of various sizes, strengths, design, and manufacture.

5.3 The use of this general design geometry in no way guarantees the effective performance of the linked boom sections, since each boom’s design and the environmental conditions at each incident govern overall performance.

SCOPE

1.1 This specification covers design criteria requirements, design geometry, material characteristics, and desirable features for oil spill response boom slide connections. These criteria are intended to define minimum mating characteristics and are not intended to be restricted to a specific configuration.

1.2 The specification defines the geometry required to mate with typical Universal slide connectors or Specification F962 connectors with web thickness up to 0.3 in. Some very heavy-duty or PVC connectors may exceed this dimension and not be compatible.

1.3 The values stated in inch-pound units are to be regarded as standard. No other units of measurement are included in this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2438 −04 (Reapproved 2022)

Standard Specification for

Oil Spill Response Boom Connection: Slide Connector

This standard is issued under the fixed designation F2438; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope dance With Water Body Classifications

1.1 This specification covers design criteria requirements,

3. Material Characteristics

design geometry, material characteristics, and desirable fea-

3.1 End connector and locking pin materials shall be corro-

tures for oil spill response boom slide connections. These

sion resistant in seawater and such other environments as the

criteria are intended to define minimum mating characteristics

intended service may require. If dissimilar metals are used,

and are not intended to be restricted to a specific configuration.

care shall be used in design to avoid galvanic corrosion.

1.2 The specification defines the geometry required to mate

3.2 Any material is acceptable for construction of the boom

with typical Universal slide connectors or Specification F962

connector provided consideration is given to such factors as

connectors with web thickness up to 0.3 in. Some very

weight, mechanical strength, chemical resistance, flexibility,

heavy-duty or PVC connectors may exceed this dimension and

and conditions of the environment in which it is to be used.

not be compatible.

1.3 The values stated in inch-pound units are to be regarded

4. Design Requirements

as standard. No other units of measurement are included in this

4.1 The minimum tensile strength of a boom-to-boom

standard.

connection shall equal or exceed the minimum fabric tensile

1.4 This standard does not purport to address all of the

strength specified in Table 1 of Guide F1523/F1523M.

safety concerns, if any, associated with its use. It is the

4.2 The connector design shall ensure distribution or trans-

responsibility of the user of this standard to establish appro-

fer of the tension member loads from one boom section to the

priate safety, health, and environmental practices and deter-

next through or around the end connector in such a manner that

mine the applicability of regulatory limitations prior to use.

the integrity of the joint is not broken at the fabric connection

1.5 This international standard was developed in accor-

or any supplemental tension member connection(s).

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the 4.3 The connector opening shall be to the right when

Development of International Standards, Guides and Recom- looking at the top of the connector as shown in Fig. 1.

mendations issued by the World Trade Organization Technical

4.4 The connector or adapter shall not take more than 0.04

Barriers to Trade (TBT) Committee.

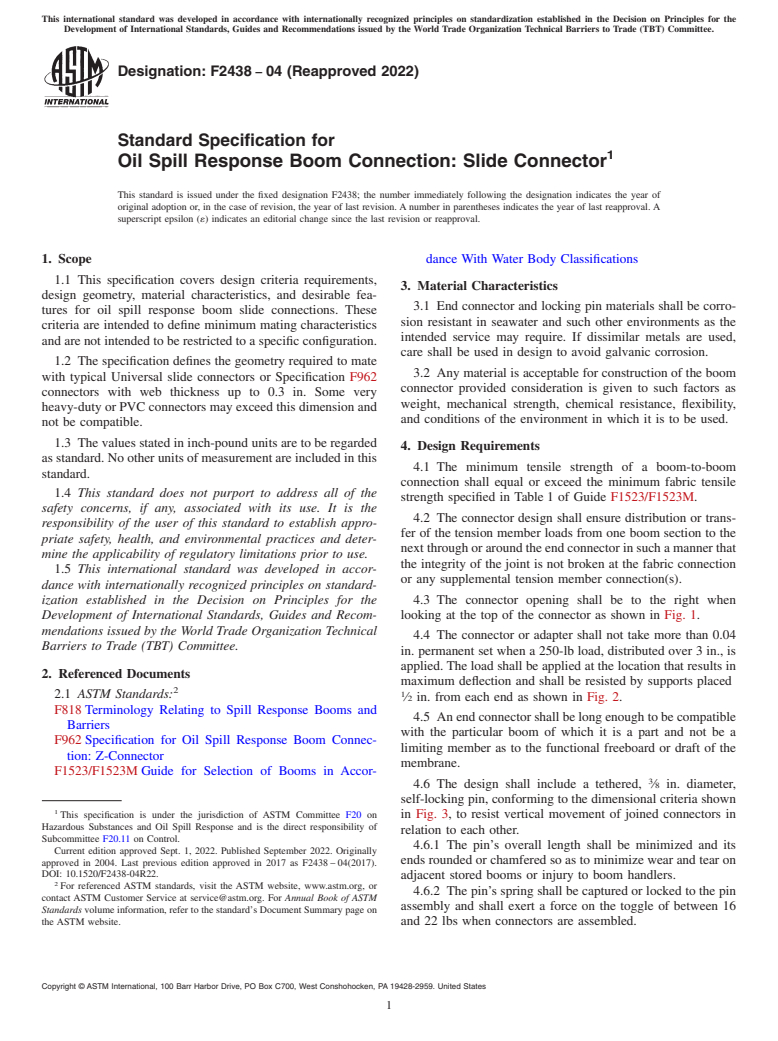

in. permanent set when a 250-lb load, distributed over 3 in., is

applied. The load shall be applied at the location that results in

2. Referenced Documents

maximum deflection and shall be resisted by supports placed

2.1 ASTM Standards:

⁄2 in. from each end as shown in Fig. 2.

F818 Terminology Relating to Spill Response Booms and

4.5 An end connector shall be long enough to be compatible

Barriers

with the particular boom of which it is a part and not be a

F962 Specification for Oil Spill Response Boom Connec-

limiting member as to the functional freeboard or draft of the

tion: Z-Connector

membrane.

F1523/F1523M Guide for Selection of Booms in Accor-

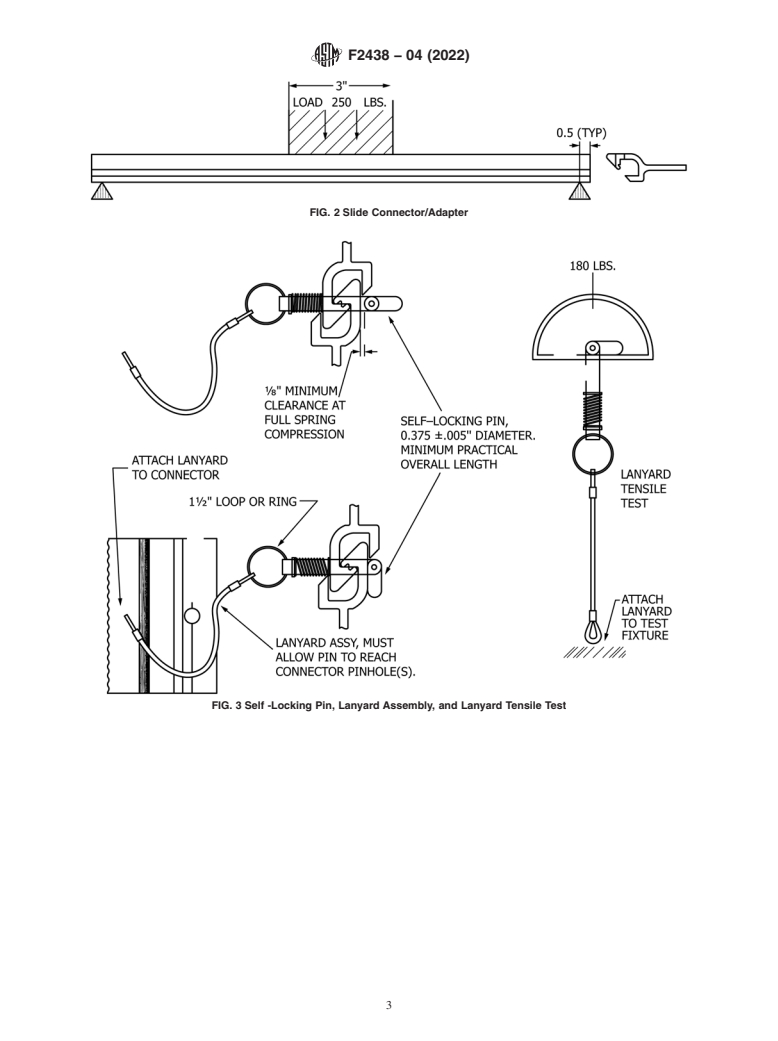

4.6 The design shall include a tethered, ⁄8 in. diameter,

self-locking pin, conforming to the dimensional criteria shown

This specification is under the jurisdiction of ASTM Committee F20 on

in Fig. 3, to resist vertical movement of joined connectors in

Hazardous Substances and Oil Spill Response and is the direct responsibility of

relation to each other.

Subcommittee F20.11 on Control.

4.6.1 The pin’s overall length shall be minimized and its

Current edition approved Sept. 1, 2022. Published September 2022. Originally

ends rounded or chamfered so as to minimize wear and tear on

approved in 2004. Last previous edition approved in 2017 as F2438 – 04(2017).

DOI: 10.1520/F2438-04R22.

adjacent stored booms or injury to boom handlers.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.6.2 The pin’s spring shall be captured or locked to the pin

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

assembly and shall exert a force on the toggle of between 16

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. and 22 lbs when connectors are assembled.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

---

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.