ASTM F154-02

(Guide)Standard Guide for Identification of Structures and Contaminants Seen on Specular Silicon Surfaces (Withdrawn 2003)

Standard Guide for Identification of Structures and Contaminants Seen on Specular Silicon Surfaces (Withdrawn 2003)

SCOPE

This standard was transferred to SEMI (www.semi.org) May 2003

1.1 The purpose of this guide is to list, illustrate, and provide reference for various characteristic features and contaminants that are seen on highly specular silicon wafers. Recommended practices for delineation and observation of these artifacts are referenced. The artifacts described in this guide are intended to parallel and support the content of the SEMI M18. These artifacts and common synonyms are arranged alphabetically in Tables 1 and 2 and illustrated in Figs. 1-68 .

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 154 – 02

Standard Guide for

Identification of Structures and Contaminants Seen on

1

Specular Silicon Surfaces

This standard is issued under the fixed designation F 154; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

A,B,C

TABLE 1 Wafer Structural Defects

1. Scope

Relevant

1.1 The purpose of this guide is to list, illustrate, and

Common Synonyms and Illustrating

Defect ASTM

Acronyms Figures

provide reference for various characteristic features and con-

Standard

taminants that are seen on highly specular silicon wafers.

Dislocation etch pit Etch Pit, Pit 1-5 F 1725

Recommended practices for delineation and observation of

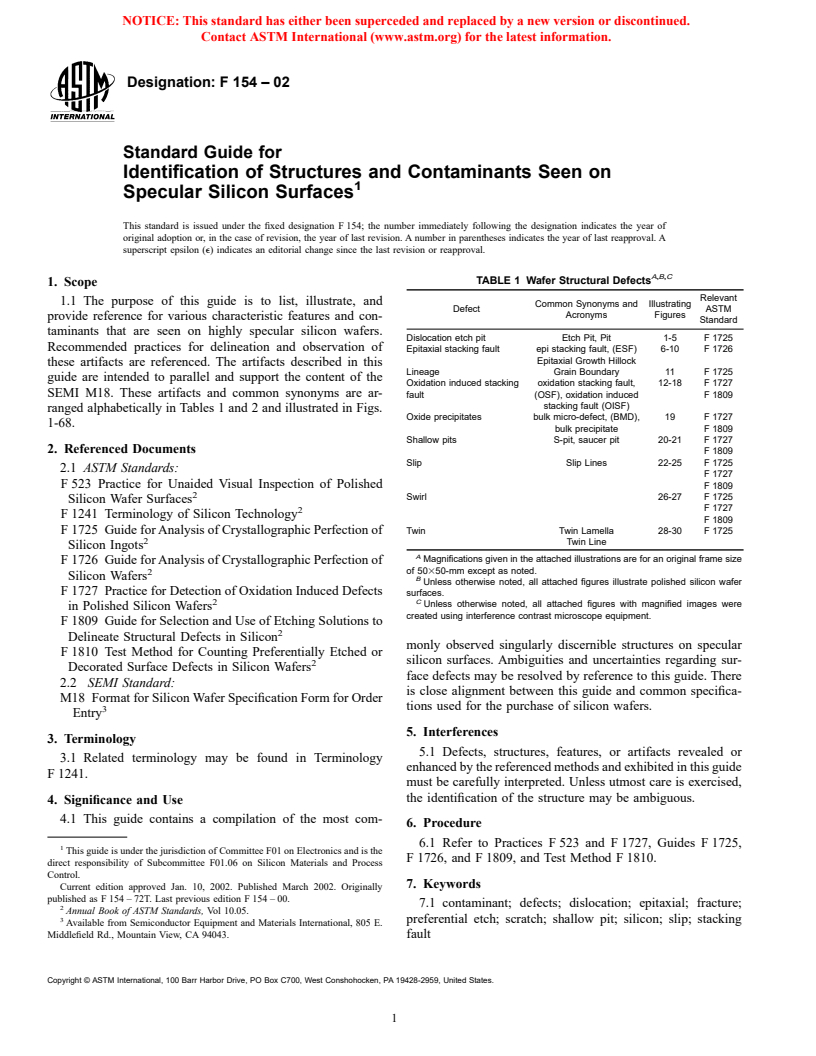

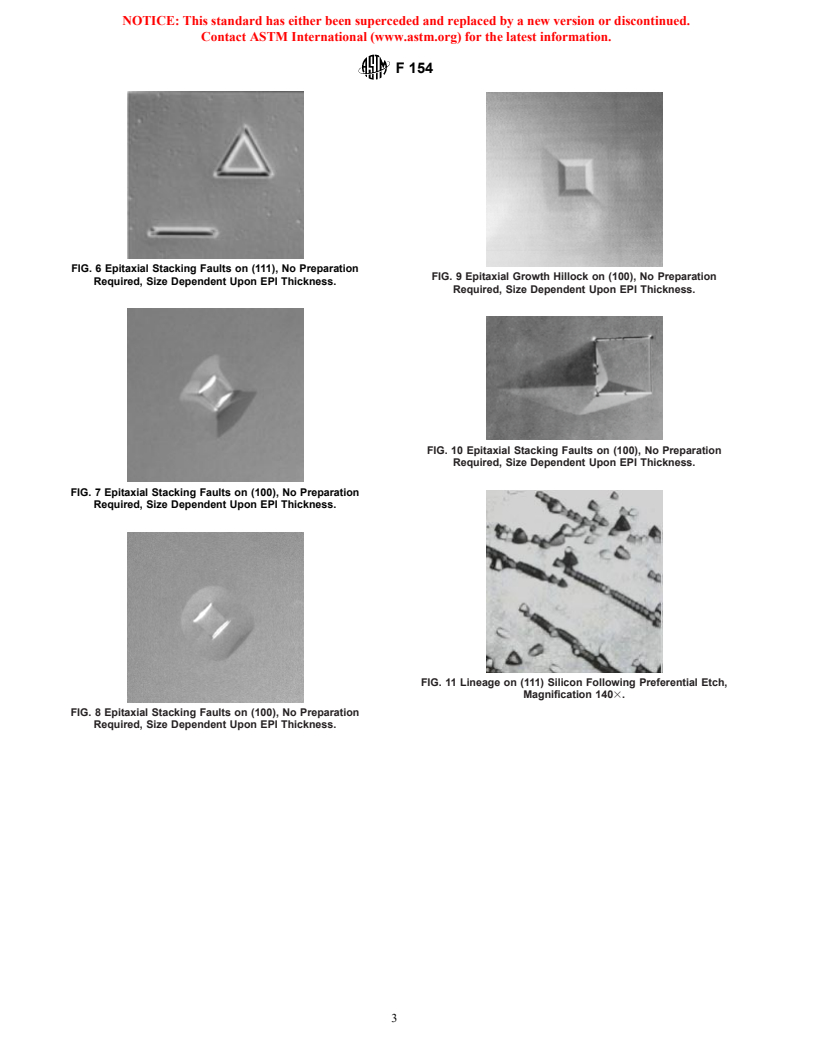

Epitaxial stacking fault epi stacking fault, (ESF) 6-10 F 1726

Epitaxial Growth Hillock

these artifacts are referenced. The artifacts described in this

Lineage Grain Boundary 11 F 1725

guide are intended to parallel and support the content of the

Oxidation induced stacking oxidation stacking fault, 12-18 F 1727

SEMI M18. These artifacts and common synonyms are ar-

fault (OSF), oxidation induced F 1809

stacking fault (OISF)

ranged alphabetically in Tables 1 and 2 and illustrated in Figs.

Oxide precipitates bulk micro-defect, (BMD), 19 F 1727

1-68.

bulk precipitate F 1809

Shallow pits S-pit, saucer pit 20-21 F 1727

2. Referenced Documents

F 1809

Slip Slip Lines 22-25 F 1725

2.1 ASTM Standards:

F 1727

F 523 Practice for Unaided Visual Inspection of Polished

F 1809

2

Swirl 26-27 F 1725

Silicon Wafer Surfaces

F 1727

2

F 1241 Terminology of Silicon Technology

F 1809

F 1725 Guide for Analysis of Crystallographic Perfection of Twin Twin Lamella 28-30 F 1725

2 Twin Line

Silicon Ingots

A

Magnifications given in the attached illustrations are for an original frame size

F 1726 Guide for Analysis of Crystallographic Perfection of

2 of 50350-mm except as noted.

Silicon Wafers

B

Unless otherwise noted, all attached figures illustrate polished silicon wafer

F 1727 Practice for Detection of Oxidation Induced Defects

surfaces.

C

2

Unless otherwise noted, all attached figures with magnified images were

in Polished Silicon Wafers

created using interference contrast microscope equipment.

F 1809 Guide for Selection and Use of Etching Solutions to

2

Delineate Structural Defects in Silicon

monly observed singularly discernible structures on specular

F 1810 Test Method for Counting Preferentially Etched or

silicon surfaces. Ambiguities and uncertainties regarding sur-

2

Decorated Surface Defects in Silicon Wafers

face defects may be resolved by reference to this guide. There

2.2 SEMI Standard:

is close alignment between this guide and common specifica-

M18 Format for Silicon Wafer Specification Form for Order

tions used for the purchase of silicon wafers.

3

Entry

5. Interferences

3. Terminology

5.1 Defects, structures, features, or artifacts revealed or

3.1 Related terminology may be found in Terminology

enhanced by the referenced methods and exhibited in this guide

F 1241.

must be carefully interpreted. Unless utmost care is exercised,

the identification of the structure may be ambiguous.

4. Significance and Use

4.1 This guide contains a compilation of the most com-

6. Procedure

6.1 Refer to Practices F 523 and F 1727, Guides F 1725,

1

This guide is under the jurisdiction of Committee F01 on Electronics and is the

F 1726, and F 1809, and Test Method F 1810.

direct responsibility of Subcommittee F01.06 on Silicon Materials and Process

Control.

7. Keywords

Current edition approved Jan. 10, 2002. Published March 2002. Originally

published as F 154 – 72T. Last previous edition F 154 – 00.

7.1 contaminant; defects; dislocation; epitaxial; fracture;

2

Annual Book of ASTM Standards, Vol 10.05.

3 preferential etch; scratch; shallow pit; silicon; slip; stacking

Available from Semiconductor Equipment and Materials International, 805 E.

Middlefield Rd., Mountain View, CA 94043. fault

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 154

TABLE 2 Polished Surface Visual Characteristics

Relevant

Common Synonyms and Illustrating

Defect ASTM

Acronyms Figure

Standards

Area contamination Contamination, foreign 31-32 F 523

matter, residue

Crack Cleavage, fracture 33-38 F 523

Crater Slurry ring 39 F 523

Crow’s feet Contact damage 40 F 523

Dimple Depression 41-42 F 523

Dopant striation ring Striation 43 F 523

Edge chip Chip

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.