ASTM F1374-92(2012)

(Test Method)Standard Test Method for Ionic/Organic Extractables of Internal Surfaces-IC/GC/FTIR for Gas Distribution System Components

Standard Test Method for Ionic/Organic Extractables of Internal Surfaces-IC/GC/FTIR for Gas Distribution System Components

SIGNIFICANCE AND USE

4.1 The purpose of this test method is to define a procedure for testing electropolished stainless steel components being considered for installation into a high-purity gas distribution system. Application of this test method is expected to yield comparable data among components tested for the purposes of qualification for this installation.

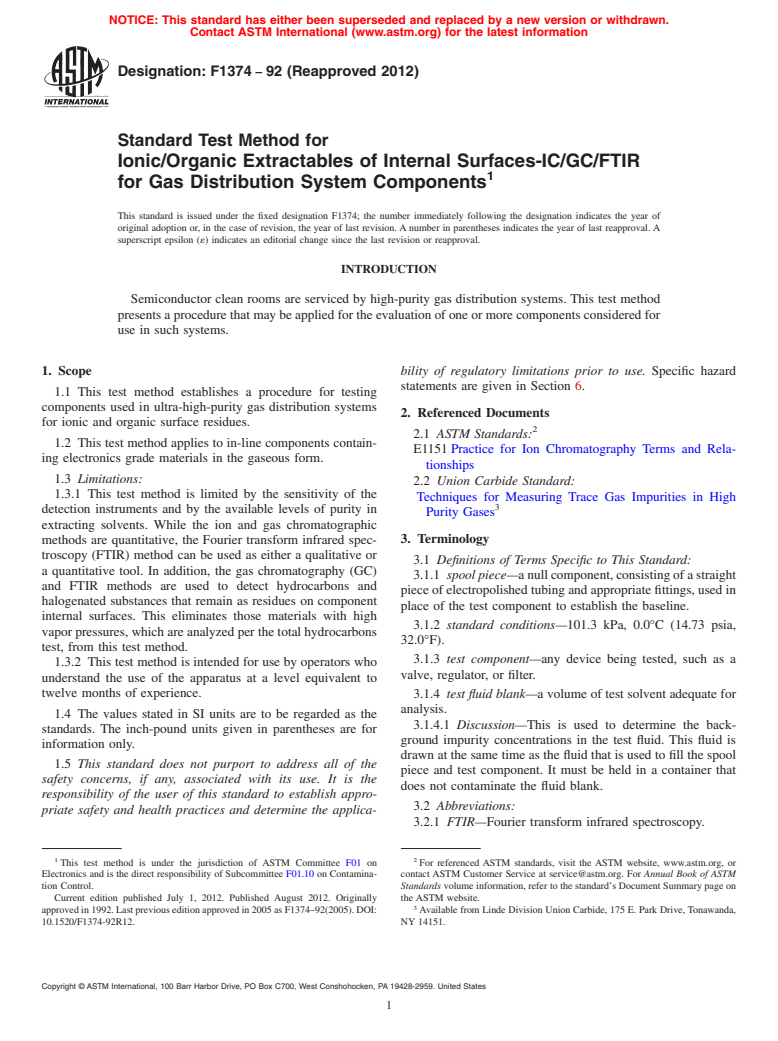

FIG. 1 Ionic/Organic Contribution Data Table Illustration

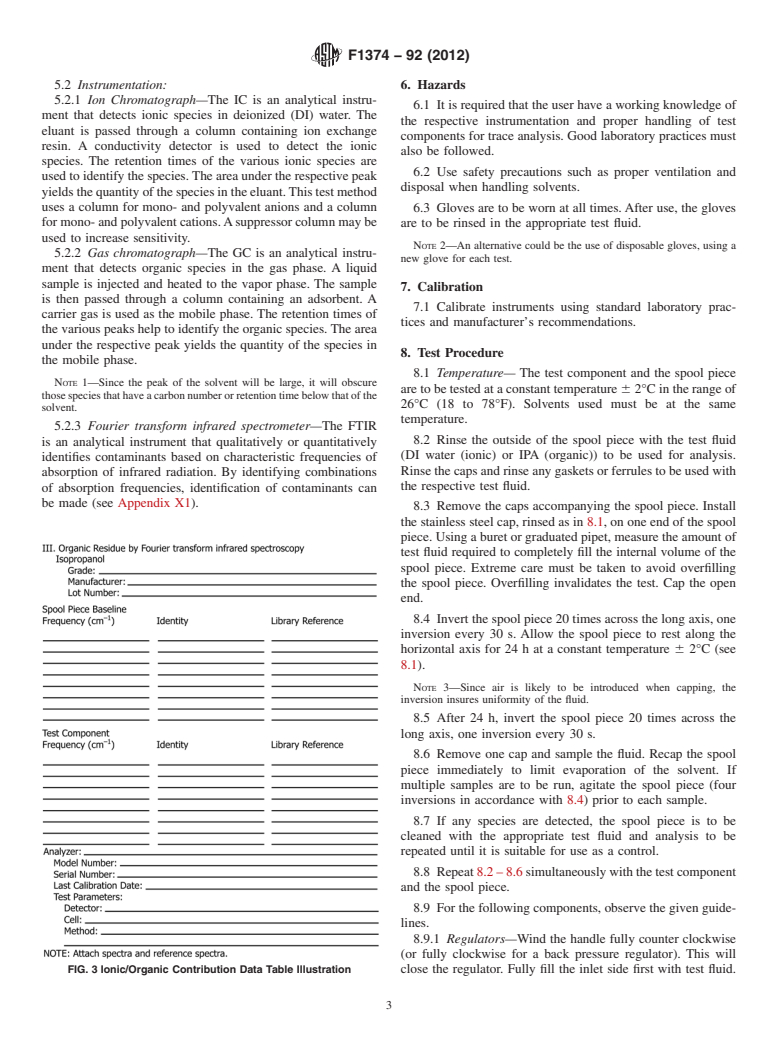

FIG. 2 Ionic/Organic Contribution Data Table Illustration

SCOPE

1.1 This test method establishes a procedure for testing components used in ultra-high-purity gas distribution systems for ionic and organic surface residues.

1.2 This test method applies to in-line components containing electronics grade materials in the gaseous form.

1.3 Limitations:

1.3.1 This test method is limited by the sensitivity of the detection instruments and by the available levels of purity in extracting solvents. While the ion and gas chromatographic methods are quantitative, the Fourier transform infrared spectroscopy (FTIR) method can be used as either a qualitative or a quantitative tool. In addition, the gas chromatography (GC) and FTIR methods are used to detect hydrocarbons and halogenated substances that remain as residues on component internal surfaces. This eliminates those materials with high vapor pressures, which are analyzed per the total hydrocarbons test, from this test method.

1.3.2 This test method is intended for use by operators who understand the use of the apparatus at a level equivalent to twelve months of experience.

1.4 The values stated in SI units are to be regarded as the standards. The inch-pound units given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1374 − 92 (Reapproved 2012)

Standard Test Method for

Ionic/Organic Extractables of Internal Surfaces-IC/GC/FTIR

for Gas Distribution System Components

This standard is issued under the fixed designation F1374; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Semiconductor clean rooms are serviced by high-purity gas distribution systems. This test method

presentsaprocedurethatmaybeappliedfortheevaluationofoneormorecomponentsconsideredfor

use in such systems.

1. Scope bility of regulatory limitations prior to use. Specific hazard

statements are given in Section 6.

1.1 This test method establishes a procedure for testing

components used in ultra-high-purity gas distribution systems

2. Referenced Documents

for ionic and organic surface residues.

2.1 ASTM Standards:

1.2 This test method applies to in-line components contain-

E1151Practice for Ion Chromatography Terms and Rela-

ing electronics grade materials in the gaseous form.

tionships

1.3 Limitations:

2.2 Union Carbide Standard:

1.3.1 This test method is limited by the sensitivity of the

Techniques for Measuring Trace Gas Impurities in High

detection instruments and by the available levels of purity in

Purity Gases

extracting solvents. While the ion and gas chromatographic

3. Terminology

methods are quantitative, the Fourier transform infrared spec-

troscopy (FTIR) method can be used as either a qualitative or

3.1 Definitions of Terms Specific to This Standard:

a quantitative tool. In addition, the gas chromatography (GC)

3.1.1 spool piece—anullcomponent,consistingofastraight

and FTIR methods are used to detect hydrocarbons and

pieceofelectropolishedtubingandappropriatefittings,usedin

halogenated substances that remain as residues on component

place of the test component to establish the baseline.

internal surfaces. This eliminates those materials with high

3.1.2 standard conditions—101.3 kPa, 0.0°C (14.73 psia,

vaporpressures,whichareanalyzedperthetotalhydrocarbons

32.0°F).

test, from this test method.

3.1.3 test component—any device being tested, such as a

1.3.2 This test method is intended for use by operators who

valve, regulator, or filter.

understand the use of the apparatus at a level equivalent to

twelve months of experience.

3.1.4 test fluid blank—a volume of test solvent adequate for

analysis.

1.4 The values stated in SI units are to be regarded as the

3.1.4.1 Discussion—This is used to determine the back-

standards. The inch-pound units given in parentheses are for

ground impurity concentrations in the test fluid. This fluid is

information only.

drawn at the same time as the fluid that is used to fill the spool

1.5 This standard does not purport to address all of the

piece and test component. It must be held in a container that

safety concerns, if any, associated with its use. It is the

does not contaminate the fluid blank.

responsibility of the user of this standard to establish appro-

3.2 Abbreviations:

priate safety and health practices and determine the applica-

3.2.1 FTIR—Fourier transform infrared spectroscopy.

1 2

This test method is under the jurisdiction of ASTM Committee F01 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Electronics and is the direct responsibility of Subcommittee F01.10 on Contamina- contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

tion Control. Standards volume information, refer to the standard’s Document Summary page on

Current edition published July 1, 2012. Published August 2012. Originally the ASTM website.

approvedin1992.Lastpreviouseditionapprovedin2005asF1374–92(2005).DOI: Available from Linde Division Union Carbide, 175 E. Park Drive,Tonawanda,

10.1520/F1374-92R12. NY 14151.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1374 − 92 (2012)

3.2.2 GC—gas chromatography.

3.2.3 IC—ion chromatography.

3.2.4 IPA—isopropanol (2-propanol).

3.2.5 MS—mass spectrometry.

3.2.6 ppbv—parts per billion by volume (such as nL/L).

3.2.7 ppbw—parts per billion by weight (such as ng/g).

3.2.8 ppmv—parts per million by volume (such as µL/L).

3.2.9 ppmw—parts per million by weight (such as µg/g).

3.2.10 psid—pounds per square inch differential.

3.2.11 scfm—standard cubic feet per minute.

3.2.12 slpm—standard litre per minute. The gas volumetric

flow rate measured in litres per minute at 0.0°C (32°F) and

101.3 kPa (1 atm).

4. Significance and Use

4.1 The purpose of this test method is to define a procedure

FIG. 2 Ionic/Organic Contribution Data Table Illustration

for testing electropolished stainless steel components being

considered for installation into a high-purity gas distribution

system. Application of this test method is expected to yield

comparable data among components tested for the purposes of

qualification for this installation.

5. Apparatus

5.1 Materials:

5.1.1 Test Fluid—Thepurityoffluidusedfortheextractions

will determine the detection limit of the test. Therefore,

extremely high purity fluids are required. At least 18.0 MΩ

water [corrected for 18°C (64°F)] must be used for the ionic

extractables determination. Total oxidizable carbon must be

lessthan50ppbw.Thewatermustbefilteredthrougha0.2-µm

(or finer) filter. Electronics grade (or better) IPA is to be used

for the organic extractables determination.

5.1.2 Spool Piece— a straight run of electropolished 316-L

stainless steel tubing with no restrictions. The length of the

spool piece shall be approximately 200 mm. The spool piece

should be the same diameter as the test component.

5.1.3 Caps—usedtosealtheendsofthetestcomponentand

spool piece are to be of 316-L stainless steel. For stub end

components, 316-L stainless steel compression fittings with

nylon or polytetraflouroethylene ferrules are to be used. For

face seal fittings, stainless steel gaskets must be used.

5.1.4 Gloves—made of powder free latex or natural rubber

FIG. 1 Ionic/Organic Contribution Data Table Illustration and resistant to the test fluids used in this test method.

F1374 − 92 (2012)

5.2 Instrumentation: 6. Hazards

5.2.1 Ion Chromatograph—The IC is an analytical instru-

6.1 It is required that the user have a working knowledge of

ment that detects ionic species in deionized (DI) water. The

the respective instrumentation and proper handling of test

eluant is passed through a column containing ion exchange

components for trace analysis. Good laboratory practices must

resin. A conductivity detector is used to detect the ionic

also be followed.

species. The retention times of the various ionic species are

6.2 Use safety precautions such as proper ventilation and

usedtoidentifythespecies.Theareaundertherespectivepeak

disposal when handling solvents.

yieldsthequantityofthespeciesintheeluant.Thistestmethod

uses a column for mono- and polyvalent anions and a column

6.3 Gloves are to be worn at all times.After use, the gloves

formono-andpolyvalentcations.Asuppressorcolumnmaybe are to be rinsed in the appropriate test fluid.

used to increase sensitivity.

NOTE 2—An alternative could be the use of disposable gloves, using a

5.2.2 Gas chromatograph—The GC is an analytical instru-

new glove for each test.

ment that detects organic species in the gas phase. A liquid

sample is injected and heated to the vapor phase. The sample

7. Calibration

is then passed through a column containing an adsorbent. A

7.1 Calibrate instruments using standard laboratory prac-

carrier gas is used as the mobile phase. The retention times of

tices and manufacturer’s recommendations.

the various peaks help to identify the organic species.The area

under the respective peak yields the quantity of the species in

8. Test Procedure

the mobile phase.

8.1 Temperature— The test component and the sp

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.