ASTM A778-01(2009)e1

(Specification)Standard Specification for Welded, Unannealed Austenitic Stainless Steel Tubular Products

Standard Specification for Welded, Unannealed Austenitic Stainless Steel Tubular Products

ABSTRACT

This specification covers straight seam and spiral butt seam welded unannealed austenitic stainless steel tubular products intended for low and moderate temperatures and corrosive service where treatment is not necessary for corrosion resistance. The tubular products shall be made from flat-rolled steel sheet, coil, or plate by a shielded arc-welding process. The welds shall be made by the manual or automatic electric-welding process. Injurious weld defects shall be repaired by removal to sound metal and rewelding. Transverse tension test and transverse-guided bend test shall be done to the welded joints. Finished products shall have smooth ends free or burrs and shall be free of injurious defects.

SCOPE

1.1 This specification covers straight seam and spiral butt seam welded unannealed austenitic stainless steel tubular products intended for low and moderate temperatures and corrosive service where heat treatment is not necessary for corrosion resistance. Table 1 lists the five grades covered by this specification. The user of this specification should be aware that a minimum amount of testing and examination is required of the basic product. The user requiring additional testing or examination is referred to the supplemental requirements or Ordering Information, or both. Users requiring a tubular product with post-weld heat treatment or with radiographic examination are referred to Specification A 312/A 312M, A 358/A 358M, or A 409/A 409M, as applicable.

1.2 This specification covers welded unannealed tubular products 3 in. (75 mm) through 48 in. (1200 mm) in outside diameter and in nominal wall thicknesses of 0.062 in. (1.5 mm) through 0.500 in. (12.5 mm) produced to this specification. Tubular products having other diameters or wall thickness, or both, may be furnished provided it complies with all other requirements of this specification.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:A778 −01(Reapproved 2009)

Standard Specification for

Welded, Unannealed Austenitic Stainless Steel Tubular

Products

This standard is issued under the fixed designation A778; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—The units statement in paragraph 1.3 was revised editorially in April 2009.

1. Scope Vessels and for General Applications

A262 Practices for Detecting Susceptibility to Intergranular

1.1 This specification covers straight seam and spiral butt

Attack in Austenitic Stainless Steels

seam welded unannealed austenitic stainless steel tubular

A312/A312M Specification for Seamless, Welded, and

products intended for low and moderate temperatures and

Heavily Cold Worked Austenitic Stainless Steel Pipes

corrosive service where heat treatment is not necessary for

A358/A358M Specification for Electric-Fusion-Welded

corrosion resistance. Table 1 lists the five grades covered by

Austenitic Chromium-Nickel Stainless Steel Pipe for

this specification. The user of this specification should be

High-Temperature Service and General Applications

aware that a minimum amount of testing and examination is

A370 Test Methods and Definitions for Mechanical Testing

required of the basic product. The user requiring additional

of Steel Products

testing or examination is referred to the supplemental require-

A409/A409M Specification for Welded Large Diameter

ments or Ordering Information, or both. Users requiring a

Austenitic Steel Pipe for Corrosive or High-Temperature

tubular product with post-weld heat treatment or with radio-

Service

graphic examination are referred to Specification A312/

A700 Practices for Packaging, Marking, and Loading Meth-

A312M, A358/A358M,or A409/A409M, as applicable.

ods for Steel Products for Shipment

1.2 This specification covers welded unannealed tubular

A941 TerminologyRelatingtoSteel,StainlessSteel,Related

products 3 in. (75 mm) through 48 in. (1200 mm) in outside

Alloys, and Ferroalloys

diameterandinnominalwallthicknessesof0.062in.(1.5mm)

A999/A999M Specification for General Requirements for

through 0.500 in. (12.5 mm) produced to this specification.

Alloy and Stainless Steel Pipe

Tubular products having other diameters or wall thickness, or

E340 Test Method for Macroetching Metals and Alloys

both, may be furnished provided it complies with all other

E527 Practice for Numbering Metals and Alloys in the

requirements of this specification.

Unified Numbering System (UNS)

1.3 The values stated in inch-pound units are to be regarded

2.2 AWS Standards:

as standard. The values given in parentheses are mathematical

A5.4 Corrosion—Resisting Chromium and Chromium-

conversions to SI units that are provided for information only

Nickel Steel Covered Welding Electrodes

and are not considered standard.

A5.9 Corrosion–ResistingChromiumandChromium-Nickel

Steel Welding Rods and Bare Electrodes

2. Referenced Documents

2.3 SAE Standard:

2.1 ASTM Standards:

SAE J1086 Practice for Numbering Metals and Alloys

A240/A240M Specification for Chromium and Chromium-

(UNS)

Nickel Stainless Steel Plate, Sheet, and Strip for Pressure

3. Terminology

3.1 Definitions:

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee 3.2 The definitions in Specification A999/A999M and Ter-

A01.10 on Stainless and Alloy Steel Tubular Products.

minology A941 are applicable to this specification.

Current edition approved April 1, 2009. Published September 2009. Originally

approved in 1980. Last previous edition approved in 2001 as A778 – 01. DOI:

10.1520/A0778-01R09E01.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Welding Society (AWS), 550 NW LeJeune Rd.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Miami, FL 33126, http://www.aws.org.

Standards volume information, refer to the standard’s Document Summary page on Available from Society of Automotive Engineers (SAE), 400 Commonwealth

the ASTM website. Dr., Warrendale, PA 15096-0001, http://www.sae.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

A778−01 (2009)

TABLE 1 Chemical Requirements

Composition, %

Manga- Phos- Columbium

UNS Carbon Nitrogen,

Grade nese, phorus, Titanium Plus

A B Sulfur, Silicon,

Designation max max

Chromium Nickel

max max Tantalus

max max

TP 304L S30403 0.030 2.00 0.045 0.030 1.00 18.0–20.0 8.0–13.0 . . . 0.10

TP 316L S31603 0.030 2.00 0.045 0.030 1.00 16.0–18.0 10.0–14.0 2.00 . . 0.10

3.00

TP 317L S31703 0.030 2.00 0.045 0.030 1.00 18.0–20.0 11.0–15.0 3.0 . . 0.10

4.0

C

TP 321 S32100 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . .

D

TP 347 S34700 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . .

A

New designation established in accordance with Practice E527 and SAE J1086.

B

The carbon analysis shall be reported to the nearest 0.01 %, except for the low carbon (0.030) types, which shall be reported to the nearest 0.001 %.

C

The titanium content shall be not less than five times the carbon content and not more than 0.70 %.

D

The columbium plus tantalum content shall be not less than ten times the carbon content and not more than 1.10 %.

4. Ordering Information 6.3 Circumferentially welded joints of the same quality as

thelongitudinalorspiraljointsshallbepermittedbyagreement

4.1 Orders for material to this specification should include

between the manufacturer and the purchaser.

the following:

4.1.1 Quantity (feet, metres, or number of pieces),

6.4 All tubular products shall be furnished clean and free of

4.1.2 Name of material (welded unannealed austenitic stain-

scale.

less steel tubular products),

6.5 Welding:

4.1.3 Straight seam or spiral butt seam,

6.5.1 The welds shall be made by the manual or automatic

4.1.4 Grade (see Table 1),

electric-welding process.

4.1.5 Size (outside diameter and specified wall thickness)

6.5.2 The welded joints may show a reinforcing bead no

(see 10.3 and 10.4),

greater than ⁄16 in. (1.6 mm) on either surface of the tubular

4.1.6 Length (mill standard lengths, or specify cut lengths)

product. At no place shall the thickness of the weld section be

(see 10.1),

less than the minimum wall thickness permitted by the toler-

4.1.7 Optional requirements (Supplementary Requirements

ances of 10.4. The weld bead may be removed at the option of

S1 to S5),

the manufacturer or upon agreement between the manufacturer

4.1.8 Certification requirements,

and purchaser.

4.1.9 Specification designation, and

6.5.3 Injurious weld defects shall be repaired by removal to

4.1.10 Special requirements.

sound metal and rewelding.

5. Significance and Use

6.5.4 The alloy content (chromium, nickel, molybdenum,

columbium, and carbon) of the filler metal shall conform to

5.1 It is anticipated that the ASTM Subcommittees A01.06,

that required for the plate or the welding electrodes as shown

A01.10, A01.17, A01.22, and A01.28 will use the standard

in Table II of Specification AWS A5.4 or in Table I of

composition limits listed in this specification for the grades

Specification AWS A5.9, except that when welding on Type

identifiedbythecorrespondingUNSdesignationintheproduct

321 base metal, the deposited weld metal may correspond to

specification unless there is a specific technical justification for

Type 347.

doing otherwise. The compositions in this specification shall

not be considered as chemical requirements for any particular

7. Mechanical Test Requirements

product until adopted by the subcommittee overseeing that

product.

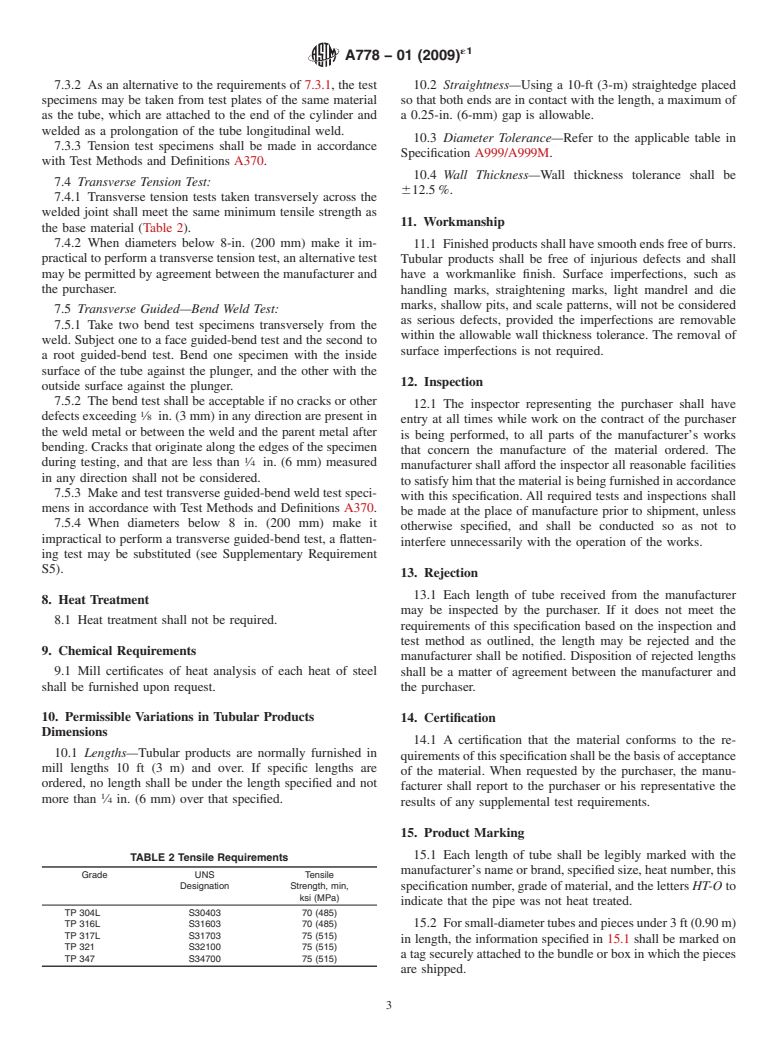

7.1 Each lot shall be subjected to one transverse tension test

and two transverse guided bend tests.

6. Manufacture

NOTE 1—The term lot applies to all pipe of the same grade, of the same

6.1 The tubular products shall be made from flat-rolled steel

thickness, produced from the same heat with the same weld procedure.

sheet, coil, or plate by a shielded arc-welding process. The

7.2 The maximum lot size shall be in accordance with the

material used for manufacture shall conform to the require-

following table:

mentsofoneofthegradesofSpecificationA240/A240Mlisted

Diameter Range Lot Size (lengths)

in Table 1. At the manufacturer’s option, filler metal may be

up to 3 in. exclusive 400

used.

3–8 in. exclusive 300

8–14 in. exclusive 200

6.2 Tubular products 14 in. (350 mm) in diameter and

14 in. and over 100

smaller shall have a single longitudinal weld or a spiral butt

7.3 Specimen Preparation:

weld seam. Tubular products of larger diameter may have a

maximum of three longitudinal welds. All weld tests, exami- 7.3.1 Transverse tension and bend test specimens shall be

nations, inspections, or treatments are to be performed on each takenfromtheendofalengthandshallbeflattenedcoldbefore

weld seam. final machining to size.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

An American National Standard Designation: A 778 – 01 (Reapproved 2009)

Designation:A 778–00

Standard Specification for

Welded, Unannealed Austenitic Stainless Steel Tubular

Products

This standard is issued under the fixed designation A 778; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—The units statement in paragraph 1.3 was revised editorially in April 2009.

1. Scope

1.1 This specification covers straight seam and spiral butt seam welded unannealed austenitic stainless steel tubular products

intended for low and moderate temperatures and corrosive service where heat treatment is not necessary for corrosion resistance.

Table 1 lists the five grades covered by this specification. The user of this specification should be aware that a minimum amount

of testing and examination is required of the basic product. The user requiring additional testing or examination is referred to the

supplemental requirements or Ordering Information, or both. Users requiring a tubular product with post-weld heat treatment or

with radiographic examination are referred to Specification A 312/A 312M, A 358/A 358M, or A 409/A 409M, as applicable.

1.2 This specification covers welded unannealed tubular products 3 in. (75 mm) through 48 in. (1200 mm) in outside diameter

andinnominalwallthicknessesof0.062in.(1.5mm)through0.500in.(12.5mm)producedtothisspecification.Tubularproducts

having other diameters or wall thickness, or both, may be furnished provided it complies with all other requirements of this

specification.

1.3The values stated in inch-pound units are to be regarded as the standard.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 ASTM Standards:

A 240/A 240M Specification for Heat-Resisting Chromium and Chromium-Nickel Stainless Steel Plate, Sheet, and Strip for

Pressure Vessels and for General Applications

A 262 Practices for Detecting Susceptibility to Intergranular Attack in Austenitic Stainless Steels

A 312/A 312M Specification for Seamless andWeldedAustenitic Stainless Steel Pipes Specification for Seamless,Welded, and

Heavily Cold Worked Austenitic Stainless Steel Pipes

A 358/A 358M Specification for Electric-Fusion-Welded Austenitic Chromium-Nickel AlloyStainless Steel Pipe for High-

Temperature Service and General Applications

A 370 Test Methods and Definitions for Mechanical Testing of Steel Products

A 409/A 409M Specification for Welded Large Diameter Austenitic Steel Pipe for Corrosive or High-Temperature Service

A 700 Practices for Packaging, Marking, and Loading Methods for Steel Products for Domestic Shipment

A 941 Terminology Relating to Steel, Stainless Steel, Related Alloys, and Ferroalloys

A 999/A 999M Specification for General Requirements for Alloy and Stainless Steel Pipe

E 340 Test Method for Macroetching Metals and Alloys

E527Practice for Numbering Metals and Alloys (UNS) Test Method for Macroetching Metals and Alloys

E 527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

2.2 AWS Standards:

A5.4 Corrosion—Resisting Chromium and Chromium-Nickel Steel Covered Welding Electrodes

A5.9 Corrosion–Resisting Chromium and Chromium-Nickel Steel Welding Rods and Bare Electrodes

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel, Stainless Steel,Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.10 on Stainless and Alloy Steel Tubular Products .

Current edition approved May 10, 2000. Published July 2000. Originally published as A778–80. Last previous edition A778–98.

Current edition approved April 1, 2009. Published September 2009. Originally approved in 1980. Last previous edition approved in 2001 as A 778 – 01.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

, Vol 01.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Annual Book of ASTM Standards, Vol 01.01.

Available from American Welding Society (AWS), 550 NW LeJeune Rd., Miami, FL 33126, http://www.aws.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

A 778 – 01 (2009)

TABLE 1 Chemical Requirements

Composition, %

Manga- Phos- Columbium

UNS Carbon Nitrogen,

Grade nese, phorus, Titanium Plus

A B

Sulfur, Silicon,

Designation max max

Chromium Nickel

max max Tantalus

max max

TP 304L S30403 0.030 2.00 0.045 0.030 1.00 18.0–20.0 8.0–13.0 . . . 0.10

TP 316L S31603 0.030 2.00 0.045 0.030 1.00 16.0–18.0 10.0–14.0 2.00 . . 0.10

3.00

TP 317L S31703 0.030 2.00 0.045 0.030 1.00 18.0–20.0 11.0–15.0 3.0 . . 0.10

4.0

C

TP 321 S32100 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . .

D

TP 347 S34700 0.08 2.00 0.045 0.030 1.00 17.0–19.0 9.0–12.0 . . .

A

New designation established in accordance with Practice E 527 and SAE J1086, Practice for Numbering Metals and Alloys (UNS).

B

The carbon analysis shall be reported to the nearest 0.01 %, except for the low carbon (0.030) types, which shall be reported to the nearest 0.001 %.

C

The titanium content shall be not less than five times the carbon content and not more than 0.70 %.

D

The columbium plus tantalum content shall be not less than ten times the carbon content and not more than 1.10 %.

2.3 SAE Standard:

SAE J1086 Practice for Numbering Metals and Alloys (UNS)

3. Terminology

3.1 Definitions:

3.2 The definitions in Specification A 999/A 999M and Terminology A 941are applicable to this specification.

4. Ordering Information

4.1 Orders for material to this specification should include the following:

4.1.1 Quantity (feet, metres, or number of pieces),

4.1.2 Name of material (welded unannealed austenitic stainless steel tubular products),

4.1.3 Straight seam or spiral butt seam,

4.1.4 Grade (see Table 1),

4.1.5 Size (outside diameter and specified wall thickness) (see 10.3 and 10.4),

4.1.6 Length (mill standard lengths, or specify cut lengths) (see 10.1),

4.1.7 Optional requirements (Supplementary Requirements S1 to S5),

4.1.8 Certification requirements,

4.1.9 Specification designation, and

4.1.10 Special requirements.

5. Significance and Use

5.1 It is anticipated that the ASTM Subcommittees A01.06, A01.10, A01.17, A01.22, and A01.28 will use the standard

composition limits listed in this specification for the grades identified by the corresponding UNS designation in the product

specification unless there is a specific technical justification for doing otherwise. The compositions in this specification shall not

be considered as chemical requirements for any particular product until adopted by the subcommittee overseeing that product.

6. Manufacture

6.1 The tubular products shall be made from flat-rolled steel sheet, coil, or plate by a shielded arc-welding process.The material

used for manufacture shall conform to the requirements of one of the grades of SpecificationA 240/A 240M listed in Table 1.At

the manufacturer’s option, filler metal may be used.

6.2 Tubular products 14 in. (350 mm) in diameter and smaller shall have a single longitudinal weld or a spiral butt weld seam.

Tubular products of larger diameter may have a maximum of three longitudinal welds. All weld tests, examinations, inspections,

or treatments are to be performed on each weld seam.

6.3 Circumferentially welded joints of the same quality as the longitudinal or spiral joints shall be permitted by agreement

between the manufacturer and the purchaser.

6.4 All tubular products shall be furnished clean and free of scale.

6.5 Welding:

6.5.1 The welds shall be made by the manual or automatic electric-welding process.

6.5.2 The welded joints may show a reinforcing bead no greater than ⁄16 in. (1.6 mm) on either surface of the tubular product.

At no place shall the thickness of the weld section be less than the minimum wall thickness permitted by the tolerances of 10.4.

The weld bead may be removed at the option of the manufacturer or upon agreement between the manufacturer and purchaser.

Annual Book of ASTM Standards, Vol 01.05.

Available from Society of Automotive Engineers (SAE), 400 Commonwealth Dr., Warrendale, PA 15096-0001, http://www.sae.org.

´1

A 778 – 01 (2009)

6.5.3 Injurious weld defects shall be repaired by removal to sound metal and rewelding.

6.5.4 The alloy content (chromium, nickel, molybdenum, columbium, and carbon) of the filler metal shall conform to that

required for the plate or the welding electrodes as shown inTable II of SpecificationAWSA5.4 or inTable I of SpecificationAWS

A5.9, except that when welding on Type 321 base metal, the deposited weld metal may correspond to Type 347.

7. Heat Treatment

7.1Heat treatment shall not be required.

8.Chemical Requirements Chemical Requirements

8.1Mill certificates of heat analysis of each heat of steel shall be furnished upon request.

9.Mechanical Requirements

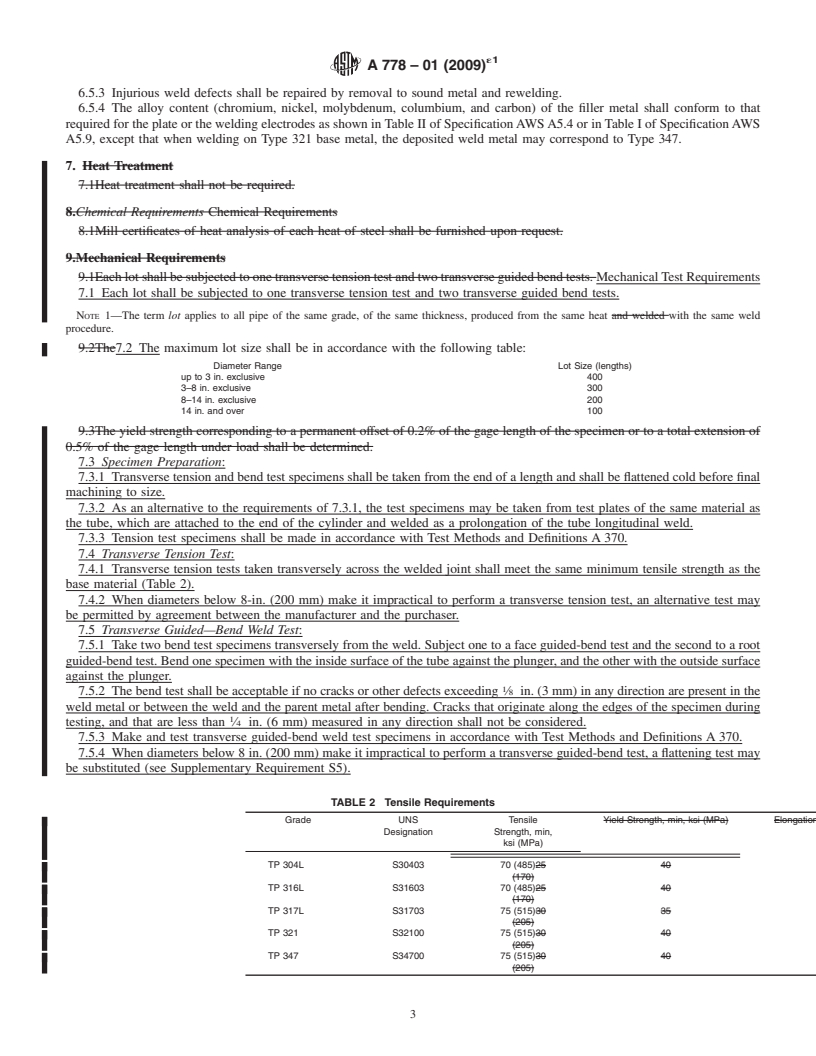

9.1Eachlotshallbesubjectedtoonetransversetensiontestandtwotransverseguidedbendtests.MechanicalTestRequirements

7.1 Each lot shall be subjected to one transverse tension test and two transverse guided bend tests.

NOTE 1—The term lot applies to all pipe of the same grade, of the same thickness, produced from the same heat and welded with the same weld

procedure.

9.2The7.2 The maximum lot size shall be in accordance with the following table:

Diameter Range Lot Size (lengths)

up to 3 in. exclusive 400

3–8 in. exclusive 300

8–14 in. exclusive 200

14 in. and over 100

9.3The yield strength corresponding to a permanent offset of 0.2% of the gage length of the specimen or to a total extension of

0.5% of the gage length under load shall be determined.

7.3 Specimen Preparation:

7.3.1 Transverse tension and bend test specimens shall be taken from the end of a length and shall be flattened cold before final

machining to size.

7.3.2 As an alternative to the requirements of 7.3.1, the test specimens may be taken from test plates of the same material as

the tube, which are attached to the end of the cylinder and welded as a prolongation of the tube longitudinal weld.

7.3.3 Tension test specimens shall be made in accordance with Test Methods and Definitions A 370.

7.4 Transverse Tension Test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.