ASTM A778-01

(Specification)Standard Specification for Welded, Unannealed Austenitic Stainless Steel Tubular Products

Standard Specification for Welded, Unannealed Austenitic Stainless Steel Tubular Products

ABSTRACT

This specification covers straight seam and spiral butt seam welded unannealed austenitic stainless steel tubular products intended for low and moderate temperatures and corrosive service where treatment is not necessary for corrosion resistance. The tubular products shall be made from flat-rolled steel sheet, coil, or plate by a shielded arc-welding process. The welds shall be made by the manual or automatic electric-welding process. Injurious weld defects shall be repaired by removal to sound metal and rewelding. Transverse tension test and transverse-guided bend test shall be done to the welded joints. Finished products shall have smooth ends free or burrs and shall be free of injurious defects.

SCOPE

1.1 This specification covers straight seam and spiral butt seam welded unannealed austenitic stainless steel tubular products intended for low and moderate temperatures and corrosive service where heat treatment is not necessary for corrosion resistance. lists the five grades covered by this specification. The user of this specification should be aware that a minimum amount of testing and examination is required of the basic product. The user requiring additional testing or examination is referred to the supplemental requirements or Ordering Information, or both. Users requiring a tubular product with post-weld heat treatment or with radiographic examination are referred to Specification A312/A312M, A358/A358M, or A409/A409M, as applicable.

1.2 This specification covers welded unannealed tubular products 3 in. (75 mm) through 48 in. (1200 mm) in outside diameter and in nominal wall thicknesses of 0.062 in. (1.5 mm) through 0.500 in. (12.5 mm) produced to this specification. Tubular products having other diameters or wall thickness, or both, may be furnished provided it complies with all other requirements of this specification.

1.3 The values stated in inch-pound units are to be regarded as the standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A 778 – 01

Standard Specification for

Welded, Unannealed Austenitic Stainless Steel Tubular

1

Products

This standard is issued under the fixed designation A 778; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope A 370 Test Methods and Definitions for MechanicalTesting

2

of Steel Products

1.1 This specification covers straight seam and spiral butt

A 409/A 409M Specification for Welded Large Diameter

seam welded unannealed austenitic stainless steel tubular

Austenitic Steel Pipe for Corrosive or High-Temperature

products intended for low and moderate temperatures and

3

Service

corrosive service where heat treatment is not necessary for

A 700 Practices for Packaging, Marking, and Loading

corrosion resistance. Table 1 lists the five grades covered by

4

Methods for Steel Products for Domestic Shipment

this specification. The user of this specification should be

A 941 Terminology Relating to Steel, Related Alloys, and

aware that a minimum amount of testing and examination is

3

Ferroalloys

required of the basic product. The user requiring additional

A 999/A 999M Specification for General Requirements for

testing or examination is referred to the supplemental require-

3

Alloy and Stainless Steel Pipe

ments or Ordering Information, or both. Users requiring a

5

E 340 Test Method for Macroetching Metals and Alloys

tubular product with post-weld heat treatment or with radio-

3

E 527 Practice for Numbering Metals and Alloys (UNS)

graphic examination are referred to Specification A 312/

2.2 AWS Standards:

A 312M, A 358/A 358M,or A 409/A 409M, as applicable.

A 5.4 Corrosion—Resisting Chromium and Chromium-

1.2 This specification covers welded unannealed tubular

6

Nickel Steel Covered Welding Electrodes

products 3 in. (75 mm) through 48 in. (1200 mm) in outside

A 5.9 Corrosion–Resisting Chromium and Chromium-

diameter and in nominal wall thicknesses of 0.062 in. (1.5 mm)

6

Nickel Steel Welding Rods and Bare Electrodes

through 0.500 in. (12.5 mm) produced to this specification.

2.3 SAE Standard:

Tubular products having other diameters or wall thickness, or

SAE J1086 Practice for Numbering Metals and Alloys

both, may be furnished provided it complies with all other

7

(UNS)

requirements of this specification.

1.3 The values stated in inch-pound units are to be regarded

3. Terminology

as the standard.

3.1 Definitions:

2. Referenced Documents 3.2 The definitions in Specification A 999/A 999M and

Terminology A 941 are applicable to this specification.

2.1 ASTM Standards:

A 240 Specification for Heat-Resisting Chromium and

4. Ordering Information

Chromium-Nickel Stainless Steel Plate, Sheet, and Strip

2 4.1 Orders for material to this specification should include

for Pressure Vessels

the following:

A 262 Practices for Detecting Susceptibility to Intergranu-

2 4.1.1 Quantity (feet, metres, or number of pieces),

lar Attack in Austenitic Stainless Steels

4.1.2 Name of material (welded unannealed austenitic stain-

A 312/A 312M Specification for Seamless and Welded

3 less steel tubular products),

Austenitic Stainless Steel Pipes

4.1.3 Straight seam or spiral butt seam,

A 358/A 358M Specification for Electric-Fusion-Welded

4.1.4 Grade (see Table 1),

Austenitic Chromium-Nickel Alloy Steel Pipe for High-

3

4.1.5 Size (outside diameter and specified wall thickness)

Temperature Service

(see 10.3 and 10.4),

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

4

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee Annual Book of ASTM Standards, Vol 01.05.

5

A01.10 on Stainless and Alloy Steel Tubular Products. Annual Book of ASTM Standards, Vol 03.01.

6

Current edition approved March 10, 2001. Published June 2001. Originally Available from American Welding Society, 2501 N.W. 7th St., Miami, FL

published as A 778 – 80. Last previous edition A 778 – 00. 33125.

2 7

Annual Book of ASTM Standards, Vol 01.03. Available from Society of Automotive Engineers, 400 Commonwealth Drive,

3

Annual Book of ASTM Standards, Vol 01.01. Warrendale, PA 15096.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A778–01

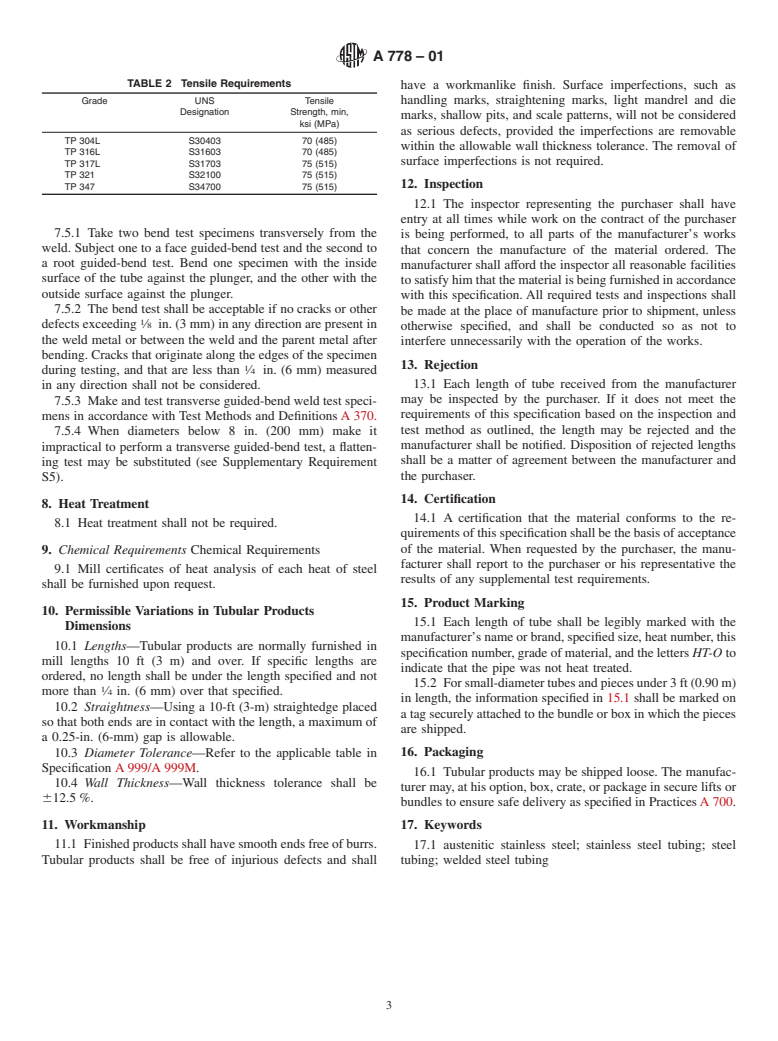

TABLE 1 Chemical Requirements

Composition, %

Manga- Phos- Columbium

UNS Carbon Nitrogen,

Grade nese, phorus, Titanium Plus

A B

Sulfur, Silicon,

Designation max max

Chromium Nickel

max max Tantalus

max max

TP 304L S30403 0.030 2.00 0.045 0.030 1.00 18.0–20.0 8.0–13.0 . . . 0.10

TP 316L S31603 0.030 2.00 0.045 0.030 1.00 16.0–18.0 10.0–14.0 2.00 . . 0.10

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.