ASTM D4576-01(2006)e1

(Test Method)Standard Test Method for Mold Growth Resistance of Wet Blue

Standard Test Method for Mold Growth Resistance of Wet Blue

SIGNIFICANCE AND USE

This test method provides a technique for evaluating mold growth resistance characteristics of wet blue, and should assist in the prediction of storage time before molding occurs.

The degree of correlation between this test and commercial quantities of wet blue in storage or shipment situations, or both, has not been fully determined.

SCOPE

1.1 This test method covers the determination of mold growth resistance of wet blue subject to storage and shipping requirements and intended for use in leather manufacturing. This test method may not be suitable to evaluate fungicides that are inactivated by proteins. This includes alkyldimethylbenzyl ammonium chlorides.

1.2 Conclusions about mold growth resistance are drawn from the results by comparing the test with a simultaneously run control of known resistance. Success or failure is determined by the amount of mold growth relative to the control.

1.3 To allow use of this test method by any laboratory, flexibility has been permitted in times, temperature, and humidity of incubation, inoculum, hide sampling area, and choice of control. These may be adjusted to fit local conditions but must be standardized.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

e1

Designation:D4576–01(Reapproved2006)

Standard Test Method for

Mold Growth Resistance of Wet Blue

This standard is issued under the fixed designation D 4576; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

e NOTE—Footnote 3 was revised in July 2008.

1. Scope 4. Significance and Use

1.1 This test method covers the determination of mold 4.1 This test method provides a technique for evaluating

growth resistance of wet blue subject to storage and shipping mold growth resistance characteristics of wet blue, and should

requirements and intended for use in leather manufacturing. assist in the prediction of storage time before molding occurs.

Thistestmethodmaynotbesuitabletoevaluatefungicidesthat 4.2 The degree of correlation between this test and commer-

are inactivated by proteins. This includes alkyldimethylbenzyl cial quantities of wet blue in storage or shipment situations, or

ammonium chlorides. both, has not been fully determined.

1.2 Conclusions about mold growth resistance are drawn

5. Interferences

from the results by comparing the test with a simultaneously

run control of known resistance. Success or failure is deter- 5.1 Acommon interference is contamination of plates, agar,

or samples by unwanted organisms that settle in from the

mined by the amount of mold growth relative to the control.

1.3 To allow use of this test method by any laboratory, environment.

5.2 Volatility and Leachability of Biocides—A “zone of

flexibility has been permitted in times, temperature, and

humidity of incubation, inoculum, hide sampling area, and inhibition” where no mold grows on the agar adjacent to the

specimen indicates that the fungicide may leach.

choice of control. These may be adjusted to fit local conditions

but must be standardized.

6. Apparatus

1.4 This standard does not purport to address all of the

6.1 Petri Dishes, 120 mm diameter. Sterile plastic dispos-

safety concerns, if any, associated with its use. It is the

able dishes are preferred.

responsibility of the user of this standard to establish appro-

6.2 Incubator, or location providing similar conditions be-

priate safety and health practices and determine the applica-

ing free of drafts, and capable of a constant (6 2°C) tempera-

bility of regulatory limitations prior to use.

ture within the 26 to 30°C range.

2. Terminology

6.3 Medicine droppers,disposableplastictypedelivering30

2.1 Definition of Term Specific to This Standard: to 35 drops per mL.

2.1.1 wet blue—hide or skin, or split of a hide or skin,

7. Reagents and Materials

tanned with basic chromium sulfate, containing approximately

7.1 Potato Dextrose Agar, a dehydrated plating medium

50 % moisture and having an acidic pH.

used in culturing yeasts and molds from dairy products.

3 6

3. Summary of Test Method

7.2 Inoculum, Aspergillus niger 1 3 10 spores per mL, or

other organism or a combination of organisms known to be

3.1 Wet blue test specimens are surrounded by but not

covered with agar, inoculated, and incubated. indigenous to the storage area of the wet blue.

3.2 After various incubation periods, mold growth is rated

8. Sampling, Test Specimen, and Test Units

as a percentage of the wet blue surface covered by mold.

8.1 Take test specimens from equivalent hide locations (for

3.3 Resistance to mold growth of the wet blue test specimen

example, butt area) for both test and control.

is determined by comparison with wet blue of known resis-

tance characteristics (the control), that is tested simultaneously.

A product that meets the requirements of this method is Potato Dextrose Agar

stock no. 0013-01-4, available from Difco Labs, P.O. Box 1058A, Detroit,

This test method is under the jurisdiction ofASTM Committee D31 on Leather MI 28232.

and is the direct responsibility of Subcommittee D31.02 on Wet Blue. An inoculum that meets the requirements of this method is available as ATCC

Current edition approved Oct. 1, 2006. Published November 2006. Originally (AmericanTypeCultureCollection)16404,andisavailablefromseveralsourcesfor

approved in 1986. Last previous edition approved in 2001 as D 4576 - 01. laboratory supplies.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D4576–01 (2006)

8.2 If unable to test immediately, hold test specimens in

separate plastic bags and keep cool.

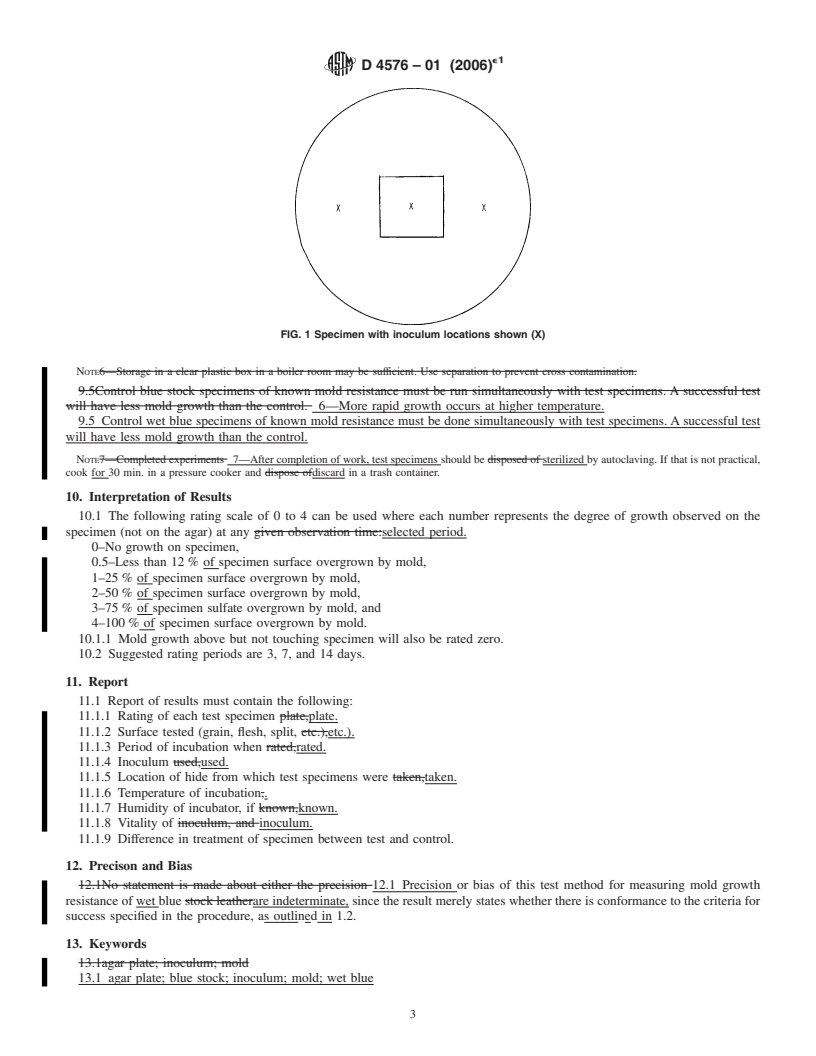

8.3 Test specimens should be a square, with a side of 25.4

mm (1 in.).

8.4 Use three test specimens for each test unit of wet blue

surface to be evaluated.

9. Procedure

9.1 Agar Preparation:

9.1.1 Agar Requirements—A split wet blue test specimen

requires about 25 mL solution and an unsplit wet blue test

specimenrequiresabout40mL.Calculatenumberofmillilitres

of agar required for tests to be performed, allowing 50 mL for

vitality check.

9.1.2 Weighout3.9gpotatodextroseagarforevery100mL

of agar required.

FIG. 1 Specimen with inoculum locations shown (X)

9.1.3 Pour a volume of water equivalent to total millilitre

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

e1

Designation:D4576–86(Reapproved1996) Designation:D4576–01(Reapproved2006)

Standard Test Method for

Mold Growth Resistance of Blue Stock (Leather)Wet Blue

This standard is issued under the fixed designation D 4576; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

e NOTE—Footnote 3 was revised in July 2008.

1. Scope

1.1 This test method covers the determination of mold growth resistance of blue stockwet blue subject to storage and shipping

requirements and intended for use in leather manufacturing. This test method may not be suitable to evaluate fungicides that are

inactivated by proteins. This includes alkyldimethylbenzyl ammonium chlorides.

1.2 Conclusions about mold growth resistance are drawn from the results by comparing the test with a simultaneously run

control of known resistance. Success or failure is determined by the amount of mold growth relative to the control.

1.3 To allow use of this test method by any laboratory, flexibility has been permitted in times, temperature, and humidity of

incubation, inoculum, hide sampling area, and choice of control. These may be adjusted to fit local conditions but must be

standardized.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Terminology

2.1 Definition of Term Specific to This Standard:

2.1.1 blue stockwet blue—hide or skin, or split of a hide or skin, tanned with basic chromium sulfate, containing approximately

50 % moisture and having an acidic pH.

3. Summary of Test Method

3.1Blue stock3.1 Wet blue test specimens are surrounded by but not covered with agar, inoculated, and incubated.

3.2 After various incubation periods, mold growth is rated as a percentage of the wet blue stock covered. surface covered by

mold.

3.3 Resistance to mold growth of the subjectwet blue stock test specimen is determined by comparison with blue stockwet blue

of known resistance characteristics (the control), that is tested simultaneously.

4. Significance and Use

4.1 This test method provides a technique for evaluating mold growth resistance characteristics of blue stockwet blue, and

should assist in the prediction of storage time before molding occurs.

4.2 The degree of correlation between this test and blue stock in commercial quantitiescommercial quantities of wet blue in

storage or shipment situations, or both, has not been fully determined.

5. Interferences

5.1 A common interference is contamination of plates, agar, or samples by unwanted organisms that settle in from the

environment.

5.2 Volatility and Leachability of Biocides—A“zone of inhibition” where no mold grows on the agar adjacent to the specimen

indicates that the fungicide may leach.

6. Apparatus

6.1 Petri Dishes—120, 120 mm diameter. Sterile plastic disposable dishes are preferred.

6.2 Incubator, or other location, location providing similar conditions being free of drafts, and capable of a constant (6 2°C)

This test method is under the jurisdiction of ASTM Committee D31 on Leather and is the direct responsibility of Subcommittee D31.02 on Blue Stock.

Current edition approved June 9, 1986. Published July 1986.

This test method is under the jurisdiction of ASTM Committee D31 on Leather and is the direct responsibility of Subcommittee D31.02 on Wet Blue.

Current edition approved Oct. 1, 2006. Published November 2006. Originally approved in 1986. Last previous edition approved in 2001 as D 4576 - 01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D4576–01 (2006)

temperature within the 26 to 30°C range, range.

6.3 Medicine droppers, disposable plastic type delivering 30 to 35 drops per mL.

7. Reagents and Materials

7.1 Potato Dextrose Agar, a dehydrated plating medium used in culturing yeasts and molds from dairy products.

3 6

7.2 Inoculum, Aspergillus niger 1 3 10 spores per mL, or other organism or a combination of organisms known to be

indigenous to the storage area orof the blue stock. wet blue.

8. Sampling, Test Specimen, and Test Units

8.1 Take test specimens from equivalent hide locations (for example, butt area) for both test and control.

8.2 If unable to test immediately, hold test specimens in separate plastic bags and keep cool.

8.3Cut test specimens one in. square.

8.4Use three test specimens for each test unit or blue stock surface to be evaluated.

8.3 Test specimens should be a square, with a side of 25.4 mm (1 in.).

8.4 Use three test specimens for each test unit of wet blue surface to be evaluated.

9. Procedure

9.1 Agar Preparation:

9.1.1 Agar Requirements—A split wet blue stock sampletest specimen requires about 25 mL solution and an unsplit wet blue

stock test specimen requires about 40 mL. Calculate number of mLmillilitres of agar required for tests to be performed, allowing

50 mL for vitality check.

9.1.2 Weigh out 3.9 g potato dextrose agar for every 100 mL of agar required.

9.1.3Addmillilitre9.1.3 Pouravolumeofwaterequivalenttototalmillilitresofagarrequirementsolutiontobeaker.Bringwater

to boiling on hot plate equipped with magnetic stirrer mechanism. While stirring, slowly add dry agar.

9.1.4 Boil agar for 20 min.

NOTE 1—Pressure cooking for 20 min. is preferable to open boiling.

9.1.5 Cover with aluminum foil to prevent contamination and cool to 50°C before pouring.

NOTE 2—This temperature is critical, as 50°C allows some water of condensation to develop on petri dish cover providing humidity for growth of

fung

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.