ASTM D3796-09

(Practice)Standard Practice for Calibration of Type S Pitot Tubes

Standard Practice for Calibration of Type S Pitot Tubes

SIGNIFICANCE AND USE

The Type S pitot tube (Fig. 1) is often used to measure the velocity of flowing gas streams in industrial smokestacks and ducts. Before a Type S pitot tube is used for this purpose, its coefficients must be determined by calibration against a standard pitot tube (2).

SCOPE

1.1 This practice covers the determination of Type S pitot tube coefficients in the gas velocity range from 305 to 1524 m/min or 5.08 to 25.4 m/s (1000 to 5000 ft/min). The method applies both to the calibration of isolated Type S pitot tubes (see 5.1), and pitobe assemblies.

1.2 This practice outlines procedures for obtaining Type S pitot tube coefficients by calibration at a single-velocity setting near the midpoint of the normal working range. Type S pitot coefficients obtained by this method will generally be valid to within ±3 % over the normal working range. If a more precise correlation between Type S pitot tube coefficient and velocity is desired, multivelocity calibration technique (Annex A1) should be used. The calibration coefficients determined for the Type S pitot tube by this practice do not apply in field use when the flow is nonaxial to the face of the tube.

1.3 This practice may be used for the calibration of thermal anemometers for gas velocities in excess of 3 m/s (10 ft/s).

1.4 The values stated in SI units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3796 − 09

StandardPractice for

1

Calibration of Type S Pitot Tubes

This standard is issued under the fixed designation D3796; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2 Definitions:

3.2.1 isolated Type S pitot tube—any Type S pitot tube that

1.1 This practice covers the determination of Type S pitot

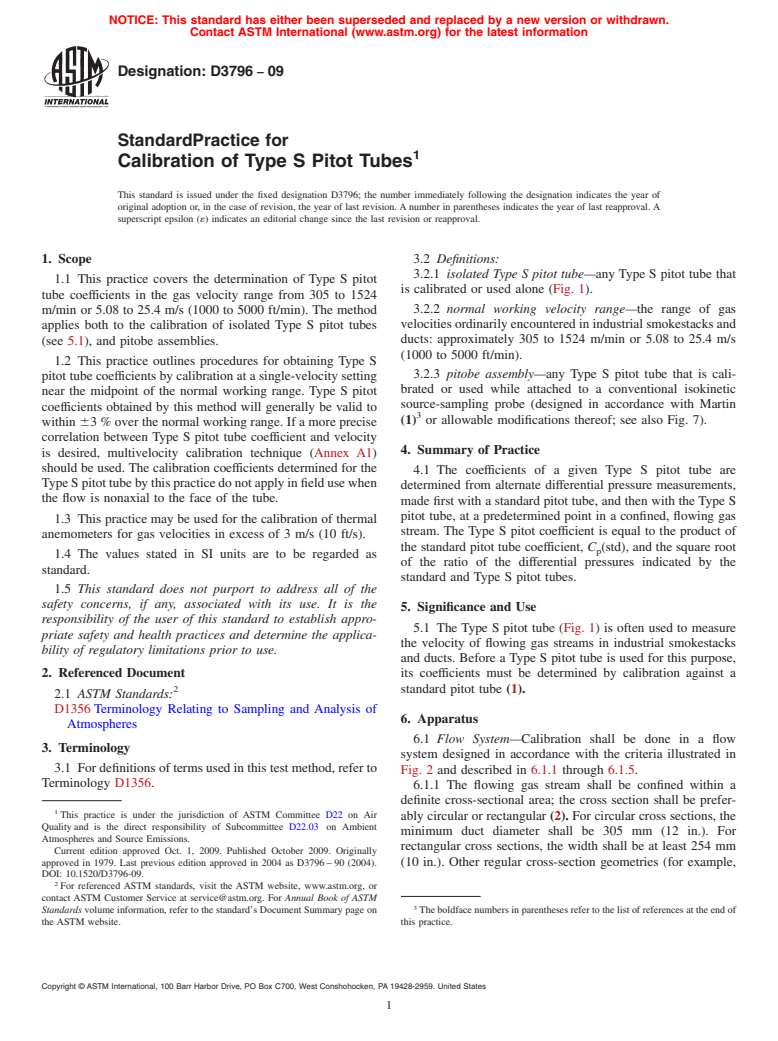

is calibrated or used alone (Fig. 1).

tube coefficients in the gas velocity range from 305 to 1524

3.2.2 normal working velocity range—the range of gas

m/min or 5.08 to 25.4 m/s (1000 to 5000 ft/min). The method

velocities ordinarily encountered in industrial smokestacks and

applies both to the calibration of isolated Type S pitot tubes

ducts: approximately 305 to 1524 m/min or 5.08 to 25.4 m/s

(see 5.1), and pitobe assemblies.

(1000 to 5000 ft/min).

1.2 This practice outlines procedures for obtaining Type S

3.2.3 pitobe assembly—any Type S pitot tube that is cali-

pitot tube coefficients by calibration at a single-velocity setting

brated or used while attached to a conventional isokinetic

near the midpoint of the normal working range. Type S pitot

source-sampling probe (designed in accordance with Martin

coefficients obtained by this method will generally be valid to

3

(1) or allowable modifications thereof; see also Fig. 7).

within 63 % over the normal working range. If a more precise

correlation between Type S pitot tube coefficient and velocity

4. Summary of Practice

is desired, multivelocity calibration technique (Annex A1)

should be used. The calibration coefficients determined for the

4.1 The coefficients of a given Type S pitot tube are

TypeSpitottubebythispracticedonotapplyinfieldusewhen

determined from alternate differential pressure measurements,

the flow is nonaxial to the face of the tube.

made first with a standard pitot tube, and then with the Type S

pitot tube, at a predetermined point in a confined, flowing gas

1.3 This practice may be used for the calibration of thermal

stream. The Type S pitot coefficient is equal to the product of

anemometers for gas velocities in excess of 3 m/s (10 ft/s).

the standard pitot tube coefficient, C (std), and the square root

p

1.4 The values stated in SI units are to be regarded as

of the ratio of the differential pressures indicated by the

standard.

standard and Type S pitot tubes.

1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

5. Significance and Use

responsibility of the user of this standard to establish appro-

5.1 The Type S pitot tube (Fig. 1) is often used to measure

priate safety and health practices and determine the applica-

the velocity of flowing gas streams in industrial smokestacks

bility of regulatory limitations prior to use.

and ducts. Before a Type S pitot tube is used for this purpose,

2. Referenced Document its coefficients must be determined by calibration against a

2

standard pitot tube (1).

2.1 ASTM Standards:

D1356 Terminology Relating to Sampling and Analysis of

6. Apparatus

Atmospheres

6.1 Flow System—Calibration shall be done in a flow

3. Terminology

system designed in accordance with the criteria illustrated in

3.1 For definitions of terms used in this test method, refer to

Fig. 2 and described in 6.1.1 through 6.1.5.

Terminology D1356.

6.1.1 The flowing gas stream shall be confined within a

definite cross-sectional area; the cross section shall be prefer-

1

This practice is under the jurisdiction of ASTM Committee D22 on Air

ably circular or rectangular (2). For circular cross sections, the

Quality and is the direct responsibility of Subcommittee D22.03 on Ambient

minimum duct diameter shall be 305 mm (12 in.). For

Atmospheres and Source Emissions.

rectangular cross sections, the width shall be at least 254 mm

Current edition approved Oct. 1, 2009. Published October 2009. Originally

approved in 1979. Last previous edition approved in 2004 as D3796 – 90 (2004). (10 in.). Other regular cross-section geometries (for example,

DOI: 10.1520/D3796-09.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to the list of references at the end of

the ASTM website. this practice.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

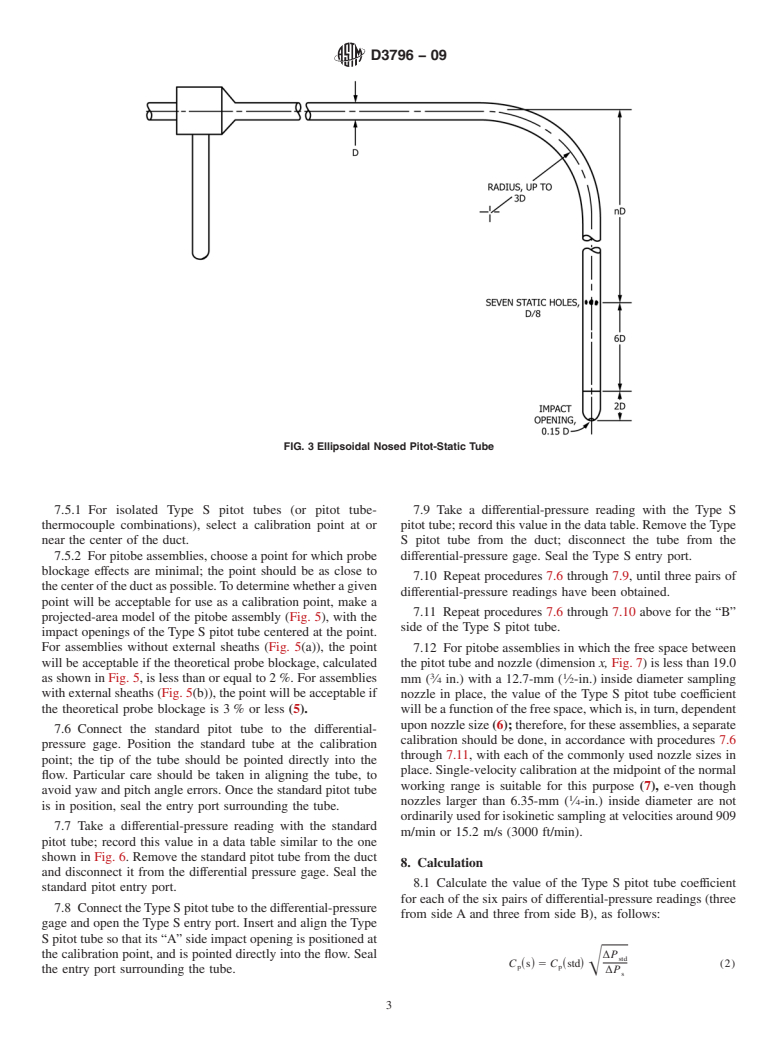

D3796 − 09

FIG. 1 Isolated Type-S Pitot Tube

FIG. 2 Pitot Tube Calibration System

he

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D3796–90 (Reapproved 2004) Designation: D3796 – 09

Standard Practice for

1

Calibration of Type S Pitot Tubes

This standard is issued under the fixed designation D3796; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice covers the determination of Type S pitot tube coefficients in the gas velocity range from 305 to 1524 m/min

or 5.08 to 25.4 m/s [1000(1000 to 5000 ft/min].ft/min). The method applies both to the calibration of isolated Type S pitot tubes

(see 5.1), and pitobe assemblies.

1.2 This practice outlines procedures for obtaining Type S pitot tube coefficients by calibration at a single-velocity setting near

themidpointofthenormalworkingrange.TypeSpitotcoefficientsobtainedbythismethodwillgenerallybevalidtowithin 63%

over the normal working range. If a more precise correlation between Type S pitot tube coefficient and velocity is desired,

multivelocity calibration technique (Annex A1) should be used.

1.3This practice may be used for the calibration of thermal anemometers for gas velocities in excess of 3 m/s [10 ft/s].

1.4) should be used. The calibration coeffıcients determined for the Type S pitot tube by this practice do not apply in field use

when the flow is nonaxial to the face of the tube.

1.3 This practice may be used for the calibration of thermal anemometers for gas velocities in excess of 3 m/s (10 ft/s).

1.4 The values stated in SI units are to be regarded as standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Document

2

2.1 ASTM Standards:

D1356 Terminology Relating to Sampling and Analysis of Atmospheres

3. Terminology

3.1 For definitions of terms used in this test method, refer to Terminology D1356.

3.2 Definitions:

3.2.1 isolated Type S pitot tube—any Type S pitot tube that is calibrated or used alone (Fig. 1).

3.2.2 normal working velocity range—the range of gas velocities ordinarily encountered in industrial smokestacks and ducts:

approximately 305 to 1524 m/min or 5.08 to 25.4 m/s [1000(1000 to 5000 ft/min]. ft/min).

3.2.3 pitobe assembly—any Type S pitot tube that is calibrated or used while attached to a conventional isokinetic

3

source-sampling probe (designed in accordance with Martin (1) or allowable modifications thereof; see also Fig. 7).

4. Summary of Practice

4.1 The coefficients of a given Type S pitot tube are determined from alternate differential pressure measurements, made first

with a standard pitot tube, and then with the Type S pitot tube, at a predetermined point in a confined, flowing gas stream. The

Type S pitot coefficient is equal to the product of the standard pitot tube coefficient, C (std), and the square root of the ratio of

p

the differential pressures indicated by the standard and Type S pitot tubes.

5. Significance and Use

5.1 The Type S pitot tube (Fig. 1) is often used to measure the velocity of flowing gas streams in industrial smokestacks and

ducts. Before aType S pitot tube is used for this purpose, its coefficients must be determined by calibration against a standard pitot

tube (2).

1

This practice is under the jurisdiction of ASTM Committee D22 on Air Quality and is the direct responsibility of Subcommittee D22.01 on Quality Control.

Current edition approved Oct. 1, 2004.2009. Published December 2004.October 2009. Originally approved in 1979. Last previous edition approved in 19982004 as

D3796 - 90 (1998).(2004). DOI: 10.1520/D3796-90R04.10.1520/D3796-09.

2

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The boldface numbers in parentheses refer to the list of references at the end of this practice.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D3796 – 09

FIG. 1 Isolated Type-S Pitot Tube

6. Apparatus

6.1 Flow System—Calibration shall be done in a flow system designed

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.