ASTM F2550-06

(Practice)Standard Practice for Locating Leaks in Sewer Pipes Using Electro-Scan--the Variation of Electric Current Flow Through the Pipe Wall

Standard Practice for Locating Leaks in Sewer Pipes Using Electro-Scan--the Variation of Electric Current Flow Through the Pipe Wall

SIGNIFICANCE AND USE

The testing of sewers for leaks is a regular practice necessary for the maintenance and optimal performance of sewer collection systems so remedial action can be prioritized, designed, and carried out to reduce infiltration and exfiltration.

This practice serves as a means to detect and locate all types of pipe defects that are potential sources of water leaks either into or out of electrically non-conducting pipes. Leaking joints and defective service connections are detected that often may not show as a defect when viewed from inside the pipe. The electro-scan data maybe processed and analyzed to provide some information on the size and type of pipe defect. (8.4.1)

This practice applies to mainline and lateral gravity flow storm sewers, sanitary sewers, and combined sewers fabricated from electrically non-conducting material with diameters between 3 and 60 in. (75 and 1500 mm). The pipes must be free of obstructions that prevent the sonde passing through the pipe.

SCOPE

1.1 This practice covers procedures for using the electro-scan method to detect and locate potential pipe leak defects that are potential sources of leaks in pipes fabricated from electrically nonconductive material such as plastic, clay, and concrete (reinforced and non-reinforced). The electro-scan method uses the variation of electric current flow through the pipe wall to locate defects that are potential water leakage paths either into or out of the pipe.

1.2 This practice applies to mainline and lateral gravity flow storm sewers, sanitary sewers, and combined sewers with diameters between 3 and 60 in. (75 and 1500 mm). The pipes must be free of obstructions that prevent the sonde passing through the pipe.

1.3 The use of the electro-scan requires access to sewers, filling sewers, and operations along roadways that are safety hazards. This standard does not describe the hazards likely to be encountered or the safety procedures that must be carried out when operating in these hazardous environments. () There are no safety hazards specifically associated with the use of an electro-scan apparatus that complies with the specifications provided in this standard. ( and .)

1.4 The use of electro-scan requires the insertion of various items into a sewer. There is always a risk that due to unknown structural conditions in the sewer such items may become lodged in the pipe or may cause the state of a sewer in poor structural condition to further deteriorate. This standard does not describe methods to assess the structural risk of a sewer.

1.5 The values stated in inch/pound units are to be regarded as the standard. The values in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and to determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2550 − 06

StandardPractice for

Locating Leaks in Sewer Pipes Using Electro-Scan--the

Variation of Electric Current Flow Through the Pipe Wall

This standard is issued under the fixed designation F2550; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Infiltration of groundwater into a sewer through defects in the pipe can considerably increase the

operation and capital costs of a sewer system. Exfiltration of sewage out of a sewer pipe may cause

degradation of aquifers and shoreline waters.Accurate location, measurement, and characterization of

all potential pipe leak defects are essential inputs for cost-effective design of pipe renewal or

remediation.Commonlyusedsewerleakassessmentmethodseitherdonotdetectasignificantnumber

of large potential pipe leak defects, particularly those caused by faulty joints or service connections,

2,3

or are too slow or costly or both for widespread application.

1. Scope There are no safety hazards specifically associated with the use

of an electro-scan apparatus that complies with the specifica-

1.1 This practice covers procedures for using the electro-

tions provided in this standard. (6.7 and 6.10.)

scan method to detect and locate potential pipe leak defects

that are potential sources of leaks in pipes fabricated from

1.4 The use of electro-scan requires the insertion of various

electrically nonconductive material such as plastic, clay, and

items into a sewer. There is always a risk that due to unknown

concrete (reinforced and non-reinforced). The electro-scan

structural conditions in the sewer such items may become

method uses the variation of electric current flow through the

lodged in the pipe or may cause the state of a sewer in poor

pipe wall to locate defects that are potential water leakage

structural condition to further deteriorate. This standard does

paths either into or out of the pipe.

not describe methods to assess the structural risk of a sewer.

1.2 This practice applies to mainline and lateral gravity flow

1.5 The values stated in inch/pound units are to be regarded

storm sewers, sanitary sewers, and combined sewers with

as the standard. The values in parentheses are for information

diameters between 3 and 60 in. (75 and 1500 mm). The pipes

only.

must be free of obstructions that prevent the sonde passing

through the pipe.

1.6 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.3 The use of the electro-scan requires access to sewers,

responsibility of the user of this standard to establish appro-

filling sewers, and operations along roadways that are safety

priate safety and health practices and to determine the

hazards. This standard does not describe the hazards likely to

applicability of regulatory limitations prior to use.

be encountered or the safety procedures that must be carried

out when operating in these hazardous environments. (7.1.3)

2. Terminology

2.1 Definitions of Terms Specific to This Standard:

This practice is under the jurisdiction ofASTM Committee F36 on Technology

and Underground Utilities and is the direct responsibility of Subcommittee F36.20 2.1.1 lateral, n—sewer pipe connecting the common sewer

on Inspection and Renewal of Water and Wastewater Infrastructure.

collection system to the user.

Current edition approved Feb. 1, 2006. Published February 2006. DOI: 10.1520/

F2550-06.

2.1.2 mainline, n—pipe that is part of the common sewer

Water Environmental Research Foundation (WERF), An Examination of

collection system.

Innovative Methods Used in the Inspection of Wastewater Systems.December,2004.

Harris, R.J et al, Sewer Leak Detection—Electro-Scan Adds a New Dimension:

2.1.3 maintenance hole, n—(MH) vertical shafts intersect-

Case Study, City of Redding, California, ASCE. August, 2004.

ing a sewer that allows entry to the sewer for cleaning,

The sole source of supply of the electro-scan methodapparatus known to the

inspection and maintenance.

committee at this time is Metrotech Corporation. If you are aware of alternative

manufacturers, please provide this information to ASTM International Headquar-

2.1.4 owner, n—entity holding legal rights to, and respon-

ters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. sible for the operation and maintenance of the sewer pipe.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2550 − 06

2.1.5 sliding pipe plug, n—device that blocks the flow 4.1.6 Permission to use water from fire hydrants at the work

through a pipe and at the same time can be pulled through the site, or other suitable designated sources within a reasonable

pipe. distancefromtheworkareas,whichisnecessaryforcontracted

work performance;

2.1.6 sonde, n—electro-scan electrode placed in a pipe.

4.1.7 Authorizationtoperformworkthatmustbeperformed

3. Significance and Use during nighttime hours, weekends, or holidays; and

4.1.8 Traffic control by uniformed officers or contract per-

3.1 The testing of sewers for leaks is a regular practice

sonnel when the safety of workers or the public requires such

necessary for the maintenance and optimal performance of

protection.

sewer collection systems so remedial action can be prioritized,

designed, and carried out to reduce infiltration and exfiltration.

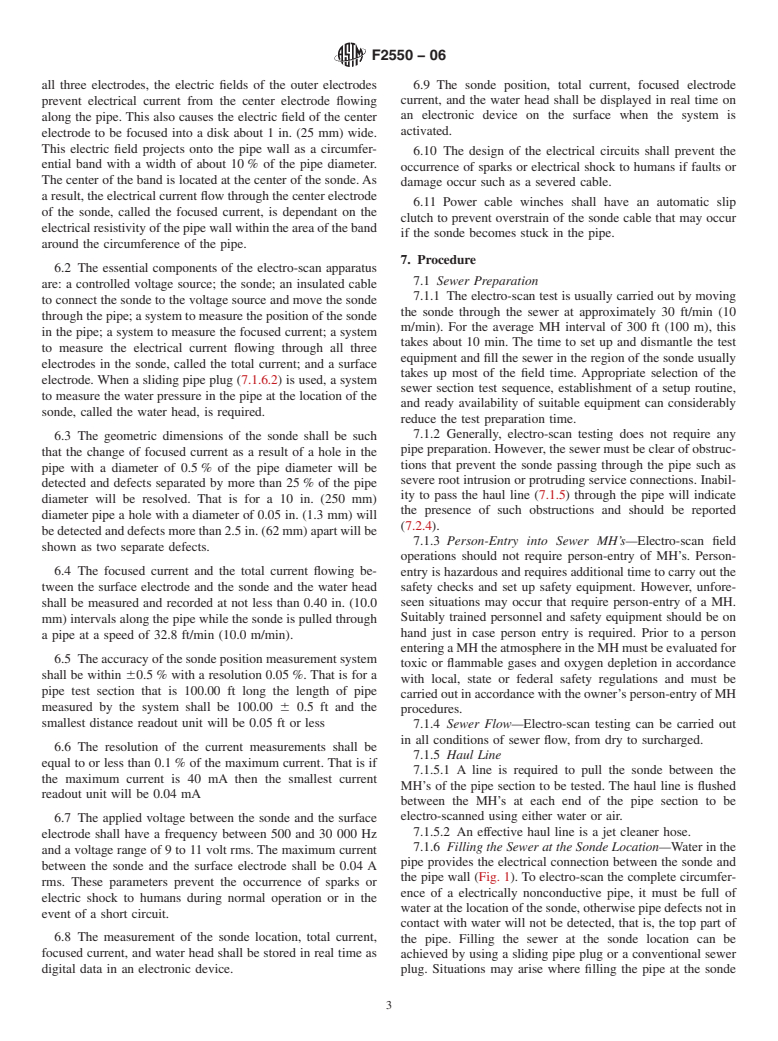

5. Electro-scan: Principle of Operation

3.2 This practice serves as a means to detect and locate all

5.1 Most sewer pipe materials such as clay, plastic,

types of pipe defects that are potential sources of water leaks

concrete, reinforced concrete, and brick are poor conductors of

either into or out of electrically non-conducting pipes. Leaking

electrical current.Adefect in the pipe wall that leaks water will

joints and defective service connections are detected that often

also leak electrical current, whether or not water infiltration or

may not show as a defect when viewed from inside the pipe.

exfiltration is occurring at the time of the test.

The electro-scan data maybe processed and analyzed to pro-

5.2 The electro-scan test is carried out by applying an

vide some information on the size and type of pipe defect.

electrical potential of 9 to11 Volts rms with a frequency of 500

(8.4.1)

Hz to 30 kHz between an electrode in the electrically noncon-

3.3 This practice applies to mainline and lateral gravity flow

ductive pipe and an electrode on the surface, which is usually

storm sewers, sanitary sewers, and combined sewers fabricated

a metal stake pushed into the ground. A simplified electrical

from electrically non-conducting material with diameters be-

circuit for this procedure is shown in Fig. 1. The water in the

tween 3 and 60 in. (75 and 1500 mm). The pipes must be free

pipeisatalevelthatensuresthatthepipeisfullattheelectrode

of obstructions that prevent the sonde passing through the pipe.

location. Provided electrical current is prevented from flowing

along the inside of the pipe, the electrical resistance of the

4. Contract Responsibilities

current path between the electrode in the pipe and the surface

4.1 Apartfromtheprovisionsgenerallyincludedinatesting

electrode is very low except through the electrically noncon-

services contract, electro-scan testing contracts should define

ductive pipe wall. The high electrical resistance of the pipe

or affix responsibility for or make provisions for the following

wallallowsonlyaverysmallelectricalcurrenttoflowbetween

items:

the two electrodes unless there is a defect in the pipe such as

4.1.1 Access to the site of work is to be provided to the

a crack, defective joint, or faulty service connection. The

extent that the owner is legally able to so provide or, if not so

greater the electric current flow through the pipe defect, the

able, a written release from responsibility for the performance

larger the size of the defect.

of work at sites where access cannot be made available;

6. Apparatus

4.1.2 Clearances of blockages or obstructions in the sewer

system; 6.1 The electro-scan method requires a means of preventing

4.1.3 Locationandexposureofallmaintenanceholes(MH); the electric current from the electrode in the electrically

4.1.4 MH numbering system for all areas of the project and

nonconductive pipe from traveling along the inside of the pipe

MH invert elevations and depths; before reaching the ground electrode. Such a means is a

4.1.5 Shutdown or manual operation of certain pump sta-

three-electrode array, known as a sonde. The sonde is con-

tions if such becomes necessary for performance of the work; structed in such a way that when equal voltages are applied to

FIG. 1 Electro-scan Electrical Schematic

F2550 − 06

all three electrodes, the electric fields of the outer electrodes 6.9 The sonde position, total current, focused electrode

prevent electrical current from the center electrode flowing current, and the water head shall be displayed in real time on

an electronic device on the surface when the system is

along the pipe. This also causes the electric field of the center

activated.

electrode to be focused into a disk about 1 in. (25 mm) wide.

This electric field projects onto the pipe wall as a circumfer-

6.10 The design of the electrical circuits shall prevent the

ential band with a width of about 10 % of the pipe diameter.

occurrence of sparks or electrical shock to humans if faults or

The center of the band is located at the center of the sonde.As

damage occur such as a severed cable.

a result, the electrical current flow through the center electrode

6.11 Power cable winches shall have an automatic slip

of the sonde, called the focused current, is dependant on the

clutch to prevent overstrain of the sonde cable that may occur

electrical resistivity of the pipe wall within the area of the band

if the sonde becomes stuck in the pipe.

around the circumference of the pipe.

7. Procedure

6.2 The essential components of the electro-scan apparatus

7.1 Sewer Preparation

are: a controlled voltage source; the sonde; an insulated cable

7.1.1 The electro-scan test is usually carried out by moving

to connect the sonde to the voltage source and move the sonde

the sonde through the sewer at approximately 30 ft/min (10

through the pipe; a system to measure the position of the sonde

m/min). For the average MH interval of 300 ft (100 m), this

in the pipe; a system to measure the focused current; a system

takes about 10 min. The time to set up and dismantle the test

to measure the electrical current flowing through all three

equipment and fill the sewer in the region of the sonde usually

electrodes in the sonde, called the total current; and a surface

takes up most of the field time. Appropriate selection of the

electrode. When a sliding pipe plug (7.1.6.2) is used, a system

sewer section test sequence, establishment of a setup routine,

to measure the water pressure in the pipe at the location of the

and ready availability of suitable equipment can considerably

sonde, called the water head, is required.

reduce the test preparation time.

7.1.2 Generally, electro-scan testing does not require any

6.3 The geometric dimensions of the sonde shall be such

pipe preparation. However, the sewer must be clear of obstruc-

that the change of focused current as a result of a hole in the

tions that prevent the sonde passing through the pipe such as

pipe with a diameter of 0.5 % of the pipe diameter will be

severe root intrusion or protruding service connections. Inabil-

detected and defects separated by more than 25 % of the pipe

ity to pass the haul line (7.1.5) through the pipe will indicate

diameter will be resolved. That is for a 10 in. (250 mm)

the presence of such obstructions and should be reported

diameter pipe a hole with a diameter of 0.05 in. (1.3 mm) will

(7.2.4).

be detected and defects more than 2.5 in. (62 mm) apart will be

7.1.3 Person-Entry into Sewer MH’s—Electro-scan field

shown as two separate defects.

operations should not require person-entry of MH’s. Person-

6.4 The focused current and the total current flowing be-

entry is hazardous and requires additional time to carry out the

tween the surface electrode and the sonde and the water head safety checks and set up safety equipment. However, unfore-

shall be measured and recorded at not less than 0.40 in. (10.0 seen situations may occur that require person-entry of a MH.

Suitably trained personnel and safety equipment should be on

mm) intervals along the pipe while the sonde is pulled through

hand just in case person entry is required. Prior to a person

a pipe at a speed of 32.8 ft/min (10.0 m/min).

enteringaMHtheatmosphereintheMHmustbeevaluatedfor

6.5 The accuracy of the sonde position measurement system

toxic or flammable gases and oxygen depletion in accordance

shall be within 60.5 % with a resolution 0.05 %. That is for a

with local, state or federal safety regulations and must be

pipe test section that is 100.00 ft long the length of pipe

carried out in accordance with the owner’s person-entry of MH

measured by the system shall be 100.00 6 0.5 ft and the

procedures.

smallest distance readout unit will be 0.05 ft or less

7.1.4 Sewer Flow—Electro-scan testing can be carried out

in all conditions of sewer flow, from dry to surcharged.

6.6 The resolution of the current measurements shall be

7.1.5 Haul Line

equal to or less than 0.1 % of the maximum current. That is if

7.1.5.1 A line is required to pull the sonde between the

the maximum current is 40 mA then the smallest current

MH’s of the pipe section to be tested. The haul line is flushed

readout unit will be 0.04 mA

between the MH’s at each end of the pipe section to be

electro-scanned using either water or air.

6.7 The applied voltage between the sonde and the surface

7.1.5.2 An effective haul line is a jet cleaner hose.

electrode shall have a frequency between 500 and 30 000 Hz

7.1.6 Filling the Sewer at the Sonde Location—Water in the

and a voltage range of 9 to 11 volt rms. The maximum current

pipe provides the electrical connection between the sonde and

between the sonde and the surface electrode shall be 0.04 A

the pipe wall (Fig. 1). To electro-scan the complete circumfer-

rms. These parameters prevent the occurrence of sparks or

ence of a electrically nonconductive pipe, it must be full of

electric shock to humans during normal operation or in the

water at the location of the sonde, otherwise pipe defects not in

event of a short circuit.

contact with water will not b

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.