ASTM D3835-02

(Test Method)Standard Test Method for Determination of Properties of Polymeric Materials by Means of a Capillary Rheometer

Standard Test Method for Determination of Properties of Polymeric Materials by Means of a Capillary Rheometer

SIGNIFICANCE AND USE

This test method is sensitive to polymer molecular weight and molecular weight distribution, polymer stability—both thermal and rheological, shear instability, and additives such as plasticizers, lubricants, moisture reinforcements, or inert fillers, or combination thereof.

The sensitivity of this test method makes the data useful for correlating with processing conditions and aids in predicting necessary changes in processing conditions. Unlike Test Method D 1238, which makes a one-point measure at a shear rate typically below processing conditions, this test method determines the shear sensitivity and flow characteristics at processing shear rates, and therefore can be used to compare materials of different compositions.

SCOPE

1.1 This test method covers measurement of the rheological properties of polymeric materials at various temperatures and shear rates common to processing equipment. It covers measurement of melt viscosity, sensitivity, or stability of melt viscosity with respect to temperature and polymer dwell time in the rheometer, die swell ratio (polymer memory), and shear sensitivity when extruding under constant rate or stress. The techniques described permit the characterization of materials that exhibit both stable and unstable melt viscosity properties.

1.2 This test method has been found useful for quality control tests on both reinforced and unreinforced thermoplastics, cure cycles of thermosetting materials, and other polymeric materials having a wide range of melt viscosities.

1.3 The values stated in SI units are to be regarded as standard. The inch-pound units given in parentheses are for information only.

Note 1—Although this test method and ISO 11443-1995, "Plastic—Determination of the Fluidity of Plastics Using Capillary and Slit-Die Rheometers" differ in approach or detail, the data obtained using ISO 11443, Method A is technically equivalent to this test method

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D3835–02

Standard Test Method for

Determination of Properties of Polymeric Materials by

1

Means of a Capillary Rheometer

This standard is issued under the fixed designation D3835; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* 2.2 ANSI Standard:

3

B46.1 Surface Texture

1.1 This test method covers measurement of the rheological

properties of polymeric materials at various temperatures and

3. Terminology

shear rates common to processing equipment. It covers mea-

3.1 Definitions of Terms Specific to This Standard:

surement of melt viscosity, sensitivity, or stability of melt

3.1.1 apparent values—viscosity, shear rate, and shear

viscosity with respect to temperature and polymer dwell time

stressvaluescalculatedassumingNewtonianbehaviorandthat

in the rheometer, die swell ratio (polymer memory), and shear

all pressure drops occur within the capillary.

sensitivity when extruding under constant rate or stress. The

3.1.2 critical shear rate—the shear rate corresponding to

techniques described permit the characterization of materials

the critical shear stress (1/s).

that exhibit both stable and unstable melt viscosity properties.

3.1.3 critical shear stress—the value of the shear stress at

1.2 This test method has been found useful for quality

which there is a discontinuity in the slope of log shear stress

control tests on both reinforced and unreinforced thermoplas-

versus log shear rate plot or periodic roughness of the polymer

tics, cure cycles of thermosetting materials, and other poly-

strand occurs as it exits the rheometer die (MPa).

meric materials having a wide range of melt viscosities.

3.1.4 delay time—the time delay between piston stop and

1.3 The values stated in SI units are to be regarded as

start when multiple data points are acquired from a single

standard. The inch-pound units given in parentheses are for

charge(s).

information only.

3.1.5 melt density—thedensityofthematerialinthemolten

NOTE 1—Although this test method and ISO 11443–1995, “Plastic—

form expressed in g/mL.

Determination of the Fluidity of Plastics Using Capillary and Slit-Die

3.1.6 melt time—the time interval between the completion

Rheometers” differ in approach or detail, the data obtained using ISO

of polymer charge and beginning of piston travel(s).

11443, Method A is technically equivalent to this test method

3.1.7 percent extrudate swell—the percentage change in the

1.4 This standard does not purport to address all of the

extrudate diameter relative to the die diameter.

safety concerns, if any, associated with its use. It is the

3.1.8 shear rate—rate of shear strain or velocity gradient in

responsibility of the user of this standard to establish appro-

the melt, usually expressed as reciprocal time such as

priate safety and health practices and determine the applica- −1 −1

second (s ).

bility of regulatory limitations prior to use.

3.1.9 shear stress—force per area, usually expressed in

pascals (Pa).

2. Referenced Documents

3.1.10 swell ratio—the ratio of the diameter of the extruded

2

2.1 ASTM Standards:

strand to the diameter of the capillary (die).

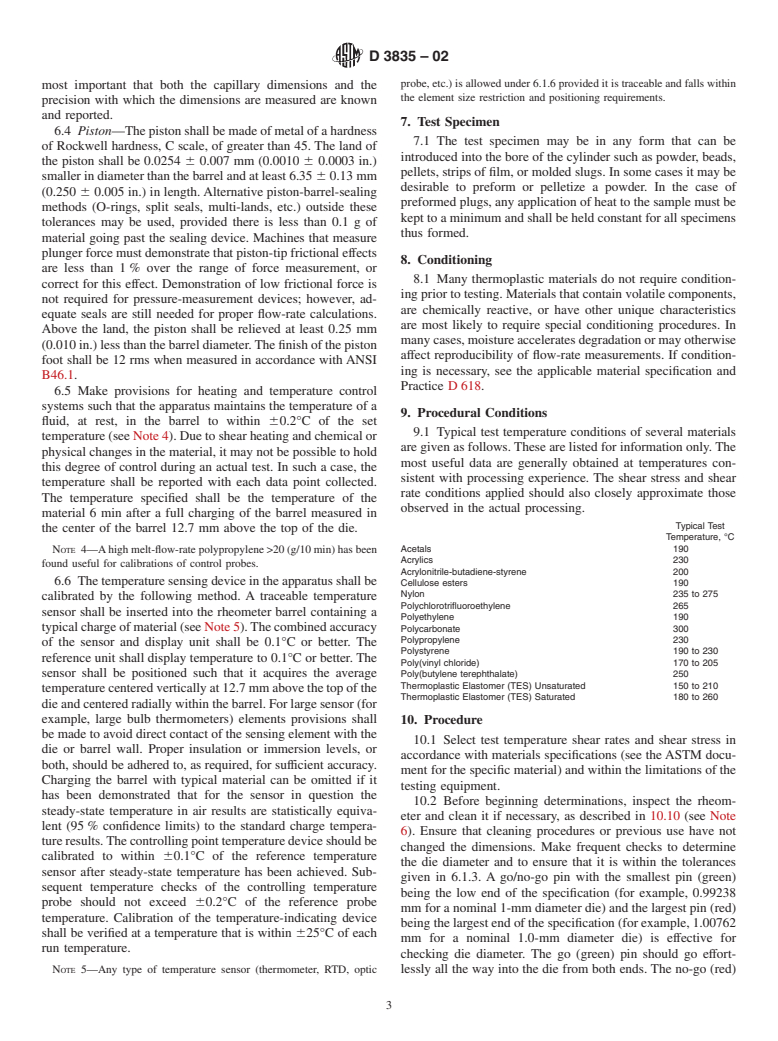

D618 Practice for Conditioning Plastics for Testing

3.1.11 viscosity—ratioofshearstresstoshearrateatagiven

D1238 TestMethodforMeltFlowRatesofThermoplastics

shear rate or shear stress. It is usually expressed in pascal

by Extrusion Plastometer

seconds (Pa·s).

E691 Practice for Conducting an Interlaboratory Study to

3.1.11.1 Viscosity determined on molten polymers is some-

Determine the Precision of a Test Method

times referred to as melt viscosity.

3.1.11.2 Viscosity determined on materials exhibiting non-

Newtonian flow behavior is referred to as apparent viscosity

1

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics

unless corrections are made as specified in Section 11.

and is the direct responsibility of Subcommittee D20.30 on Thermal Properties

(Section D20.30.08).

3.1.12 zero shear viscosity, h —thelimitingviscosityasthe

0

Current edition approved November 10, 2002. Published January 2003. Origi-

shear rate falls to zero.

nally approved in 1979. Last previous edition approved in 1996 as D3835–96.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM Internatio

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.