ASTM D4385-95

(Practice)Standard Practice for Classifying Visual Defects in Thermosetting Reinforced Plastic Pultruded Products

Standard Practice for Classifying Visual Defects in Thermosetting Reinforced Plastic Pultruded Products

SCOPE

1.1 This practice covers acceptance criteria for visual acceptance of thermosetting reinforced plastic pultruded rods, bars, shapes, and sheets.

1.2 This practice presents definitions of possible defects to serve as a guide for contracts, drawings, product specifications, and final inspection.

1.3 This practice also categorizes different inspection requirements for three grades of product quality.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D 4385 – 95 An American National Standard

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Classifying Visual Defects in Thermosetting Reinforced

Plastic Pultruded Products

This standard is issued under the fixed designation D 4385; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope of the part shall be designated as critical areas. The areas of a

product that are critical structurally, aerodynamically, electri-

1.1 This practice covers acceptance criteria for visual ac-

cally, or for some other purpose shall be uniform and in

ceptance of thermosetting reinforced plastic pultruded rods,

accordance with the quality levels of Table 1 as stated on the

bars, shapes, and sheets.

product drawing. Critical areas may be designated on the

1.2 One objective of this practice is to present definitions of

product drawing by one of the following methods:

possible defects to serve as a guide for contracts, drawings,

3.4.1 Encircle critical areas,

product specifications, and final inspection.

3.4.2 Cross-hatch areas to designate areas of various levels,

1.3 This practice also categorizes different inspection re-

or

quirements for three grades of product quality.

3.4.3 Word description.

1.4 This standard does not purport to address all of the

3.5 Allowable Defects—Defects that by nature, number, or

safety concerns, if any, associated with its use. It is the

frequency of occurrence do not affect the serviceability of the

responsibility of the user of this standard to establish appro-

product. These allowable defects shall be fully described as to

priate safety and health practices and determine the applica-

type, size, number, extent allowed, and spacing. The appropri-

bility of regulatory limitations prior to use.

ate acceptance level (see Table 1) for defects in these areas

NOTE 1—There is no similar or equivalent ISO standard.

must be specified. Defects in excess of those listed as allowable

in the product specifications, drawings, or contracts for the

2. Referenced Documents

product shall be cause for rejection.

2.1 ASTM Standards:

3.6 Acceptable Defects—Unless otherwise specified, the

D 3647 Practice for Classifying Reinforced Plastic Pul-

following defects shall be acceptable in all instances:

truded Shapes According to Composition

3.6.1 Shrink-Mark—A dimple-like depression on the sur-

D 3917 Specification for Dimensional Tolerance of Ther-

face of a pultruded shape where it has retracted from the

mosetting Glass-Reinforced Plastic Pultruded Shapes

pultrusion die, and which has well-rounded edges. A shrink-

mark generally occurs on one surface of a part where there is

3. Acceptance Criteria

a boss, flange, rib, or other heavy section on the opposite

3.1 The method and frequency of sampling and the quality

surface. The shrink-mark may be caused by the difference in

level shall be agreed upon between the purchaser and the seller.

total shrinkage when there is a sudden change in section along

3.2 Dimensions and Tolerances—Pultruded shapes shall be

the surface of the part.

inspected for conformance with dimensions and tolerances

3.6.2 Resin Voids—Applicable to a number of mat- and

specified on the product drawing. Products with any dimen-

fabric-type reinforcement systems, particularly continuous

sions exceeding the specified limits shall be rejected.

strand mat used without a surfacing material or woven fabrics.

3.3 Punchability—Products 5 mm thick or thinner, having

The resin voids appear as multiple surface interruptions that

Reinforcement Material G and Reinforcement Type M in

conform to the pattern of the cloth weave or the continuous

accordance with Practice D 3647, shall be capable of being

strand mat fiber distribution. This is usually due to an insuffi-

punched, drilled, and riveted without causing splitting or

cient flow or shrinkage of the resin that fails to fill all of the

delamination when good commercial practices are employed

interstices of the fabric or mat reinforcement. These defects

(for example, proper backup, adequate hole spacing, etc.).

occur only on the surface layer of resin in contact with the

3.4 Critical Areas—Areas in which the presence of imper-

pultrusion die or mold.

fections is considered to be detrimental to the proper function

3.6.2.1 Pultrusions intended for chemical corrosion environ-

ments with pH below 5, or over 9, or for immersion applica-

This practice is under the jurisdiction of ASTM Committee D-20 on Plastics

tions, require a synthetic surface veil to ensure adequate resin

and is the direct responsibility of Subcommittee D20.18 on Reinforced Thermoset-

coverage. Any resin voids shall be repaired.

ting Plastics.

Current edition approved June 15, 1995. Published August 1995. Originally 3.7 Repairable Defects—Repairable defects are those that

published as D 4385 – 84. Last previous edition D 4385 – 84a (1988).

can be repaired without affecting the serviceability of the

Annual Book of ASTM Standards, Vol 08.02.

D 4385

product unless otherwise specifically prohibited on product including the criteria for acceptance. Any excess of defects, as

specifications, drawings, or contracts. The specific repairable specified under the required level, shall be cause for rejection.

defects include blister, chips, die-parting line, gouges, groov- Unless otherwise specified, dimensions are surface dimensions.

ing, intermittent disfigurement, scale, scuffing, sluffing, stop

4.2 Acceptance Level I—Presence of any defects in excess

mark, wire brush surface, and resin voids (see 3.6.2). The

of those listed in Table 1, Level I, shall be cause for rejection.

repaired product must conform to the limits of Table 1. Other

4.3 Acceptance Level II—Presence of defects in excess of

defects may be repaired by mutual consent of the customer and

those listed in Table 1, Level II, shall be cause for rejection, if

the pultruder. Methods of repair shall be agreed upon between

defect is not repairable.

the purchaser and the seller and shall be fully described by the

4.4 Acceptance Level III—Presence of defects in excess of

product specification, drawings, or contracts.

those listed in Table 1, Level III, shall be cause for rejection, if

defect is not repairable.

4. Acceptance Levels

4.5 Acceptance Level IV—Any defect not specifically de-

4.1 Visual Inspection—Each sample selected in accordance

fined by size or shape in Levels I, II, or III that falls into a

with 3.1 shall be checked visually without the aid of magnifi-

category between Levels I, II, and III or beyond Level III and

cation. Defects shall be classified as to type and level, as shown

is considered acceptable, shall be designated as Level IV and

in Table 1. The quality level shall be determined by reference

shall be specified on the product specification or drawing. Any

to the product specification or drawing for the applicable

such defect shall be fully described as to size, shape, number,

acceptance level for allowable defects. The inspection shall be

extend, and spacing on the product drawing, product specifi-

concerned with those defects described by the product speci-

cation, or contracts for the products.

fications, drawings, or contracts for the pultruded products. If

none of these first three levels (Levels I, II, or III) is considered

5. Keywords

applicable, the level shall be Level IV, and allowable defects

must be specified on the product specification or drawing 5.1 pultrusion; structural shapes; visual

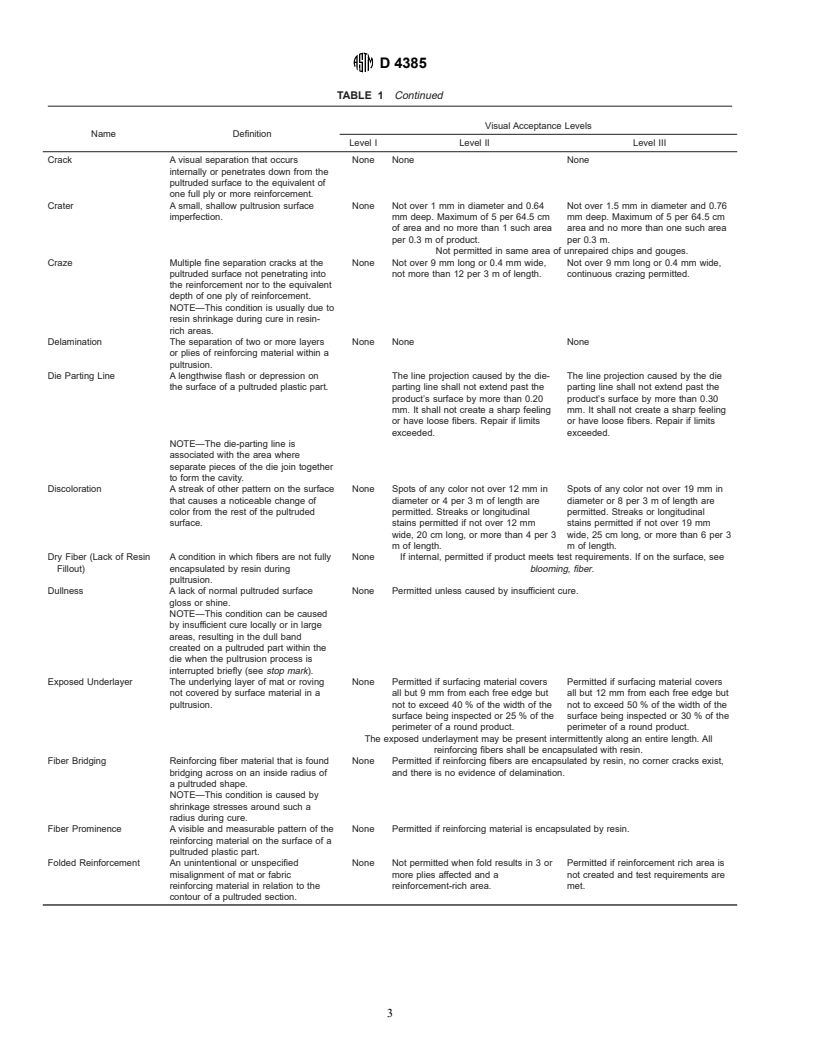

TABLE 1 Acceptance Criteria

Visual Acceptance Levels

Name Definition

Level I Level II Level III

Black Marking Black smudges on the surface of the None Permitted if not over 12 mm wide or 20 Permitted if not over 12 mm

pultruded product that cannot be cm long or more than 4 marks per 3 m

removed by cleaning, scrubbing, or of length.

wiping with solvent.

NOTE—Black marking results from

excessive pressures in the die when

the pultrusion is rubbing against soft or

unchromed die surfaces.

Blister A rounded elevation of the pultruded None Permitted if formed between surfacing Permitted if formed between surfacing

surface with boundaries that may be layer and balance of laminate, width is layer and balance of laminate, width is

more or less sharply defined. not greater than 75 % of surface no greater than 80 % of surface

NOTE—The rounded elevation width (but 10 cm max) and length is width (but 13 cm max) and length is

somewhat resembles in shape a blister not over 15 cm. No more than 1 per 3 not over 20 cm. No more than 2 per 3

on the surface of human skin. m of length. m of length.

Blisters may exist within the Product must meet test requirements and not exceed dimensional tolerances.

pultrusion as a hollow delaminated

area (gas-filled) under a raised portion Repair if limits exceeded.

of the surface.

Blooming, Fiber (Fiber A pultrusion surface condition None Permitted for rod and bar with all roving reinforcement. None permitted for a mat/

Show) exhibiting a fiber prominence or fiber roving profile unless the profile contains no surfacing veil by its specification.

show that usually has a white or

bleached color and a sparkling

appearance.

NOTE—The surface generally feels

rough when touched by the fingers and

is of superficial thickness easily

removed by buffing or light sanding.

Blooming, Undercure A dull and bleached surface color that None None None

is evident in pultruded material not

exposed to the weather.

Burn A discoloration, distortion, or None None None

destruction of the pultruded surface as

a result of thermal decomposition.

Chips (Gouges) Minor damage to the pultruded surface None Not over 6 mm long or wide or 0.64 Not over 10 mm wide or long or 0.64

that removes material but does not mm deep. Not more than 4 per3mof mm deep. Not more than 5 per3mof

cause a crack or craze. length. Repair if limits exceeded. length. Repair if limits exceeded.

D 4385

TABLE 1 Continued

Visual Acceptance Levels

Name Definition

Level I Level II Level III

Crack A visual separation that occurs None None None

internally or penetrates down from the

pultruded surface to the equivalent of

one full ply or more reinforcement.

Crater A small, shallow pultrusion surface None Not over 1 mm in diameter and 0.64 Not over 1.5 mm in diameter and 0.76

imperfection. mm deep. Maximum of 5 per 64.5 cm mm deep. Maximum of 5 per 64.5 cm

of area and no more than 1 such area area and no more than one such area

per 0.3 m of product. per 0.3 m.

Not permitted in same area of unrepaired chips and gouges.

Craze Multiple fine separation cracks at the None Not over 9 mm long or 0.4 mm wide, Not over 9 mm long or 0.4 mm wide,

pultruded surface not penetrating into not more than 12 per3mof length. continuous crazing permitted.

the reinforcement nor to the equivalent

depth of one ply of reinforcement.

NOTE—This condition is usually due to

resin shrinkage during cure in resin-

rich areas.

Delamination The separation of two or more layers None None None

or plies of reinforcing material within a

pultrusion.

Die Parting Line A lengthwise flash or depression on The line projection caused by the die- The line projection caused by the die

the surface of a pultruded plastic part. parting line shall not extend past the parting line shall not extend past the

product’s surface by more than 0.20 product’s surface by more than 0.30

mm. It shall not create a sharp feeling mm. It shall not create a sharp feeling

or have loose fibers. Repair if limits or have loose fibers. Repair if limits

exceeded. exceeded.

NOTE—The die-parting line is

associated with the area where

separate pieces of the die join together

to form the cavity.

Discoloration A streak of other pattern on the surface None Spots of any color not over 12 mm in Spots of any color not over 19 mm in

that causes a noticeable change of diameter or 4 per3mof length are diameter or 8 per3mof length are

color from the rest of the pultruded permitted. Streaks or longitudinal permitted. Streaks or longitudinal

surface. stains permitted if not over 12 mm stains permitted if not over 19 mm

wide, 20 cm long, or more than 4 per 3 wide, 25 cm long, or more than 6 per 3

m of length. m of length.

Dry Fiber (Lack of Resin A condition in which fibers are not fully None If internal, permitted if product meets test requirements. If on the surface, see

Fillout) encapsulated by resin during blooming, fiber.

pultrusion.

Dullness A lack of normal pultruded surface None Permitted unless caused by insufficient cure.

gloss or shine.

NOTE—This condition can be caused

by insufficient cure locally or in large

areas, resulting in the dull band

created on a pultruded part within the

die when the pultrusion process is

interrupted briefly (see stop mark).

Exposed Underlayer The underlying layer of mat or roving None Permitted if surfacing material covers Permitted if surfacing material covers

not covered by surface material in a all but 9 mm from each free edge but all but 12 mm from each free edge but

pultrusion. not to exceed 40 % of the width of the not to exceed 50 % of the width of the

surface being inspected or 25 % of the surface being inspected or 30 % of the

perimeter of a round product. perimeter of a round product.

The exposed underlayment may be present intermittently along an entire length. All

reinforcing fibers shall be encapsulated with resin.

Fiber Bridging Reinforcing fiber material that is found None Permitted if reinforcing fibers are encapsulated by resin, no corner cracks exist,

bridging across on an inside radius of and there is no evidence of delamination.

a pultruded shape.

NOTE—This condition is caused by

shrinkage stresses around such a

radius during cure.

Fiber Prominence A visible and measurable pattern of the None Permitted if reinforcing material is encapsulated by resin.

reinforcing material on the surface of a

pultruded plastic part.

Folded Reinforcement An unintentional or unspecified None Not permitted when fold results in 3 or Permitted if reinforcement rich area is

misalignment of mat or fabric more plies affected and a not created and test requirements are

reinforcing material in relation to the reinforcement-rich area. met.

contour of a pultruded section.

D 4385

TABLE 1 Continued

Visual Acceptance Levels

Name Definition

Level I Level II Level III

NOTE—Such folds may or may not

affect the surface appearance of the

pultrusion and are chiefly visible in a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.