ASTM D2569-97

(Test Method)Standard Test Method for Distillation of Pitch

Standard Test Method for Distillation of Pitch

SCOPE

1.1 This test method covers a distillation test for pitch applicable whenever the amount of distillate below 270°C is less than 2.0% by this test method.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: D 2569 – 97

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

1

Distillation of Pitch

This standard is issued under the fixed designation D 2569; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

Diameter of bulb, outside, mm 86.0 6 1.5

Diameter of neck, inside, mm 22.0 6 1.0

1.1 This test method covers a distillation test for pitch

Diameter of tubulature, inside, mm 10.06 0.5

Height of flask, outside, mm 131.0 6 1.5

applicable whenever the amount of distillate below 270°C is

Vertical distance, bottom of bulb, 93.0 6 1.5

less than 2.0 % by this test method.

outside, to horizontal tangent at

tubulature, inside, mm

1.2 The values stated in SI units are to be regarded as the

Length of tubulature, mm 220 6 5

standard. The values given in parentheses are for information

Angle of tubulature, ° 1.0 to 1.5

only. Thickness of tubulature wall, mm 75 6 2

1.3 This standard does not purport to address all of the

5.2 Condenser Tube— A tapered glass condenser, as shown

safety concerns, if any, associated with its use. It is the

in Fig. 2, having the following dimensions:

responsibility of the user of this standard to establish appro-

Outside diameter of small end, mm 12.5 6 1.5

priate safety and health practices and determine the applica-

Outside diameter of large end, mm 28.5 6 3.0

Length, mm 360 6 4

bility of regulatory limitations prior to use.

Length of tapered part, mm 100 6 5

4

2. Referenced Documents

5.3 Source of Heat—Electric heater, 750-W, with variable

transformer control as shown in Fig. 2, with a direct-reading

2.1 ASTM Standards:

2 voltmeter (120 V) or ammeter (5 A). Transformer settings shall

D 140 Practice for Sampling Bituminous Materials

3

be reproducible within 2 % on the percent input dial. The

E 1 Specification for ASTM Thermometers

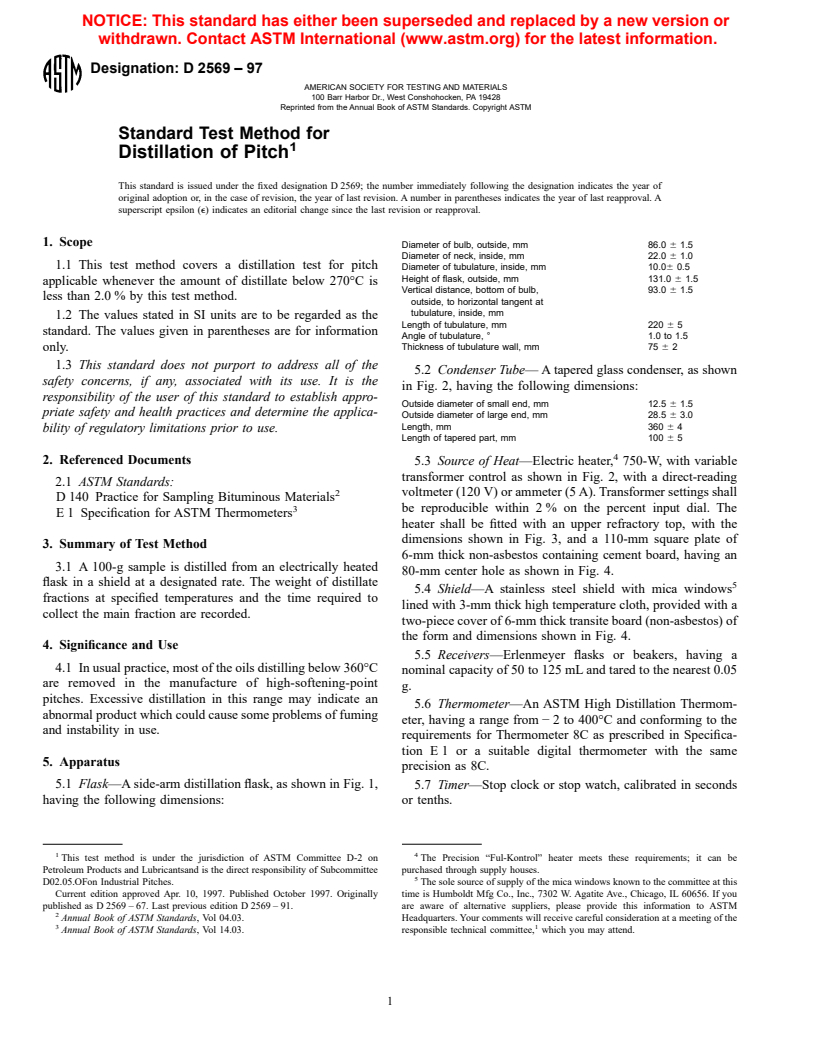

heater shall be fitted with an upper refractory top, with the

dimensions shown in Fig. 3, and a 110-mm square plate of

3. Summary of Test Method

6-mm thick non-asbestos containing cement board, having an

3.1 A 100-g sample is distilled from an electrically heated

80-mm center hole as shown in Fig. 4.

flask in a shield at a designated rate. The weight of distillate

5

5.4 Shield—A stainless steel shield with mica windows

fractions at specified temperatures and the time required to

lined with 3-mm thick high temperature cloth, provided with a

collect the main fraction are recorded.

two-piece cover of 6-mm thick transite board (non-asbestos) of

the form and dimensions shown in Fig. 4.

4. Significance and Use

5.5 Receivers—Erlenmeyer flasks or beakers, having a

4.1 In usual practice, most of the oils distilling below 360°C

nominal capacity of 50 to 125 mL and tared to the nearest 0.05

are removed in the manufacture of high-softening-point

g.

pitches. Excessive distillation in this range may indicate an

5.6 Thermometer—An ASTM High Distillation Thermom-

abnormal product which could cause some problems of fuming

eter, having a range from − 2 to 400°C and conforming to the

and instability in use.

requirements for Thermometer 8C as prescribed in Specifica-

tion E 1 or a suitable digital thermometer with the same

5. Apparatus

precision as 8C.

5.1 Flask—A side-arm distillation flask, as shown in Fig. 1, 5.7 Timer—Stop clock or stop watch, calibrated in seconds

having the following dimensions: or tenths.

1 4

This test method is under the jurisdiction of ASTM Committee D-2 on The Precision “Ful-Kontrol” heater meets these requirements; it can be

Petroleum Products and Lubricantsand is the direct responsibility of Subcommittee purchased through supply houses.

5

D02.05.OFon Industrial Pitches. The sole source of supply of the mica windows known to the committee at this

Current edition approved Apr. 10, 1997. Published October 1997. Originally time is Humboldt Mfg Co., Inc., 7302 W. Agatite Ave., Chicago, IL 60656. If you

published as D 2569 – 67. Last previous edition D 2569 – 91. are aware of alternative suppliers, please provide this information to ASTM

2

Annual Book of ASTM Standards, Vol 04.03. Headquarters. Your comments will receive careful consideration at a meeting of the

3 1

Annual Book of ASTM Standards, Vol 14.03. responsible technical committee, which you may attend.

1

---------------------- Page: 1 ----------------------

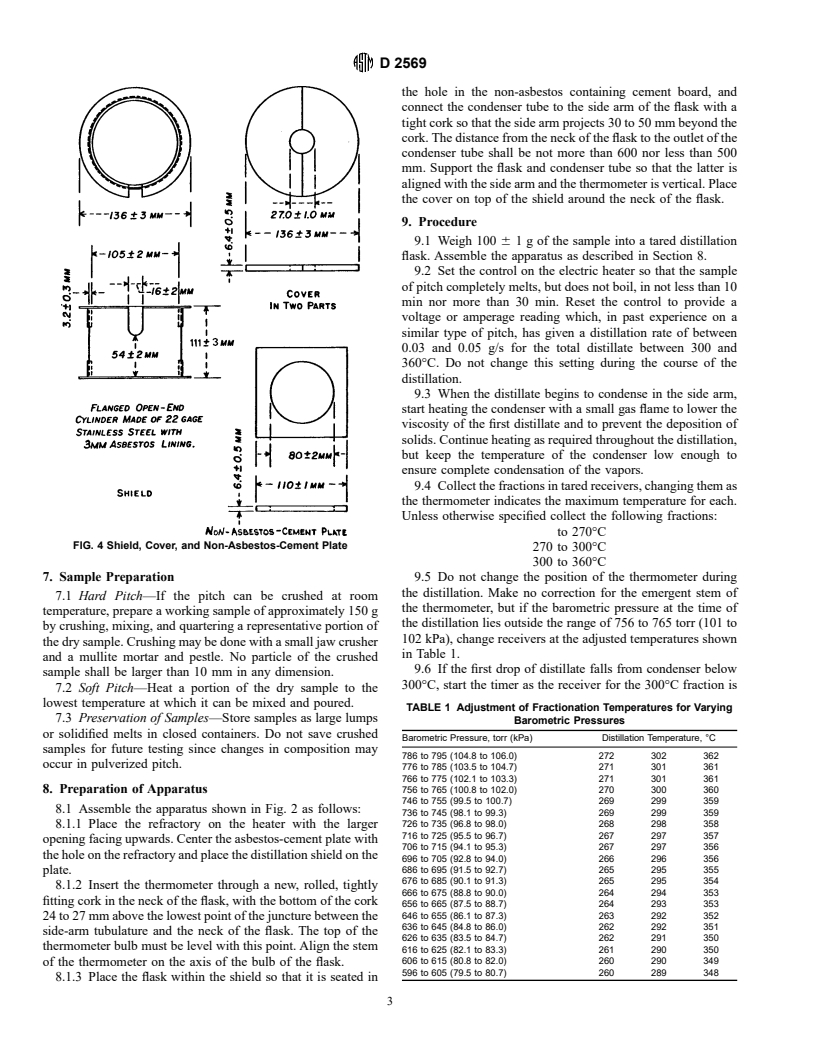

D 2569

FIG. 1 Distillation Flask

FIG. 2 Apparatus Assembly for Pitch Distillation

FIG. 3 Upper Part of Electric Heater

6. Sampling air-dry a representative portion.

6.1 Samples from bulk shipments shall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.