ASTM C1249-06a(2010)

(Guide)Standard Guide for Secondary Seal for Sealed Insulating Glass Units for Structural Sealant Glazing Applications

Standard Guide for Secondary Seal for Sealed Insulating Glass Units for Structural Sealant Glazing Applications

SIGNIFICANCE AND USE

It should be realized that the design of an IG unit edge seal for use in SSG systems is a collaborative effort of at least the IG unit fabricator, sealant manufacturer, and design professional, among others.

This guide provides information on silicone sealants that are used for the secondary seal of IG units that are glazed into SSG systems.

Information is also provided on the other major components of the IG unit edge seal, compatibility of components, durability, and quality assurance (QA).

SCOPE

1.1 This guide covers design and fabrication considerations for the edge seal of conventionally sealed insulating glass units, herein referred to as IG units. The IG units described are used in structural silicone sealant glazing systems, herein referred to as SSG systems. SSG systems typically are either two or four sided, glazed with a structural sealant. Other conditions such as one, three, five, six sided may be used.

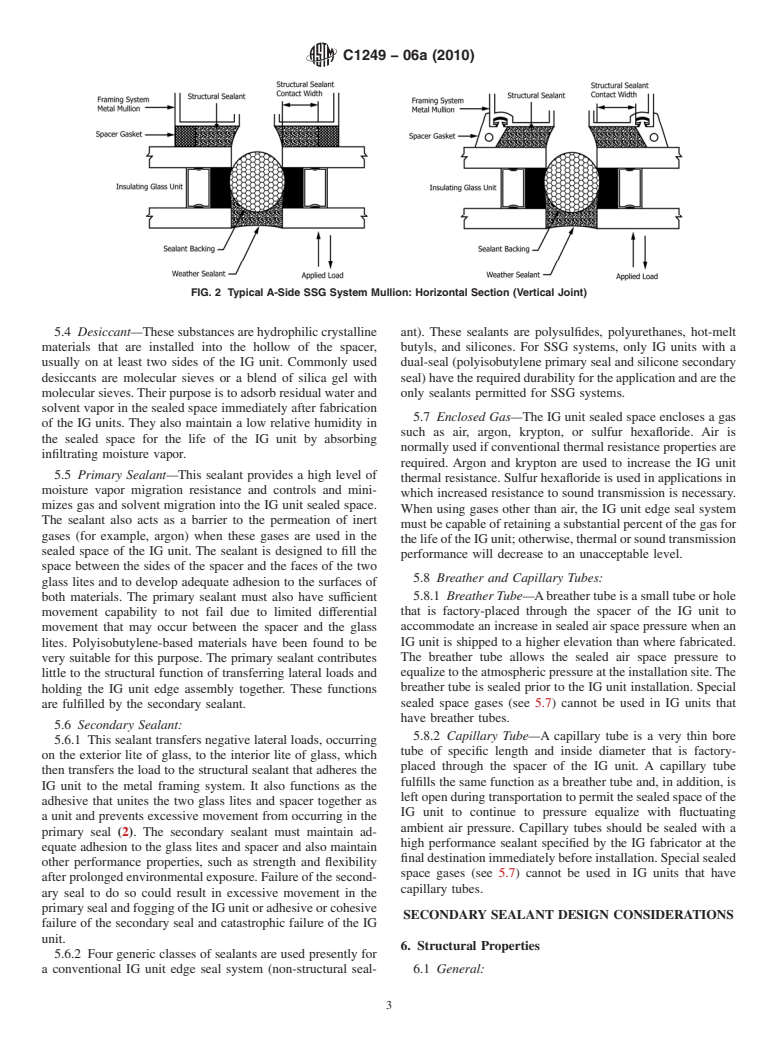

1.2 This guides does not cover the IG units of other than conventional edge seal design (Fig. 1); however, the information contained herein may be of benefit to the designers of such IG units.

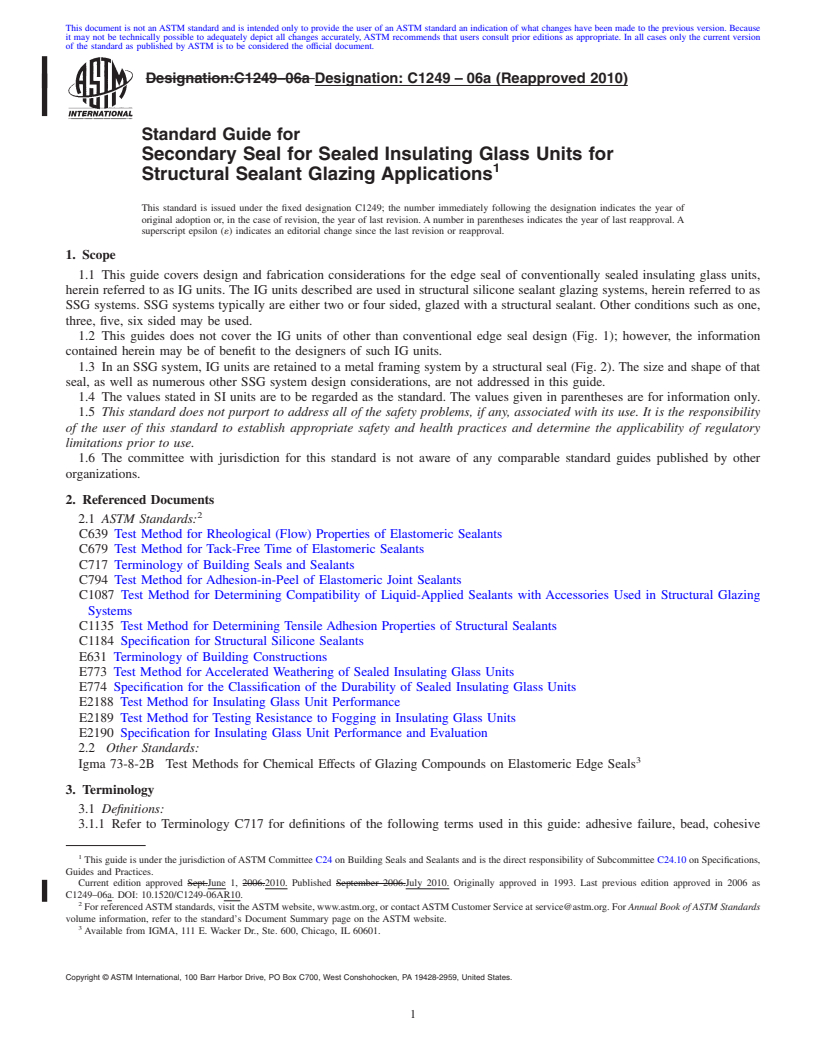

1.3 In an SSG system, IG units are retained to a metal framing system by a structural seal (Fig. 2). The size and shape of that seal, as well as numerous other SSG system design considerations, are not addressed in this guide.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.6 The committee with jurisdiction for this standard is not aware of any comparable standard guides published by other organizations.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C1249 − 06a (Reapproved 2010)

Standard Guide for

Secondary Seal for Sealed Insulating Glass Units for

Structural Sealant Glazing Applications

This standard is issued under the fixed designation C1249; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Elastomeric Sealants

C679Test Method for Tack-Free Time of Elastomeric Seal-

1.1 This guide covers design and fabrication considerations

ants

for the edge seal of conventionally sealed insulating glass

C717Terminology of Building Seals and Sealants

units, herein referred to as IG units.The IG units described are

C794TestMethodforAdhesion-in-PeelofElastomericJoint

used in structural silicone sealant glazing systems, herein

Sealants

referred to as SSG systems. SSG systems typically are either

C1087 Test Method for Determining Compatibility of

two or four sided, glazed with a structural sealant. Other

Liquid-Applied Sealants with Accessories Used in Struc-

conditions such as one, three, five, six sided may be used.

tural Glazing Systems

1.2 This guides does not cover the IG units of other than

C1135TestMethodforDeterminingTensileAdhesionProp-

conventional edge seal design (Fig. 1); however, the informa-

erties of Structural Sealants

tioncontainedhereinmaybeofbenefittothedesignersofsuch

C1184Specification for Structural Silicone Sealants

IG units.

E631Terminology of Building Constructions

E773Test Method for Accelerated Weathering of Sealed

1.3 In an SSG system, IG units are retained to a metal

framingsystembyastructuralseal(Fig.2).Thesizeandshape Insulating Glass Units (Withdrawn 2010)

E774Specification for the Classification of the Durability of

of that seal, as well as numerous other SSG system design

considerations, are not addressed in this guide. Sealed Insulating Glass Units (Withdrawn 2006)

E2188Test Method for Insulating Glass Unit Performance

1.4 The values stated in SI units are to be regarded as the

E2189Test Method for Testing Resistance to Fogging in

standard. The values given in parentheses are for information

Insulating Glass Units

only.

E2190Specification for Insulating Glass Unit Performance

1.5 This standard does not purport to address all of the

and Evaluation

safety problems, if any, associated with its use. It is the

2.2 Other Standards:

responsibility of the user of this standard to establish appro-

Igma 73-8-2B Test Methods for Chemical Effects of Glaz-

priate safety and health practices and determine the applica- 4

ing Compounds on Elastomeric Edge Seals

bility of regulatory limitations prior to use.

1.6 The committee with jurisdiction for this standard is not

3. Terminology

aware of any comparable standard guides published by other

3.1 Definitions:

organizations.

3.1.1 Refer to Terminology C717 for definitions of the

following terms used in this guide: adhesive failure, bead,

2. Referenced Documents

cohesive failure, compatibility, cure, elongation, gasket,

2.1 ASTM Standards:

glazing, joint, lite, modulus, non-sag sealant, seal, sealant,

C639Test Method for Rheological (Flow) Properties of

sealant backing, setting block, shelf-life, silicone sealant,

spacer, structural sealant, substrate, tooling, and working life.

Refer to Terminology E631 for the definition of sealed insu-

ThisguideisunderthejurisdictionofASTMCommitteeC24onBuildingSeals

lating glass as used in this guide.

and Sealants and is the direct responsibility of Subcommittee C24.10 on

3.2 Definitions of Terms Specific to This Standard:

Specifications, Guides and Practices.

3.2.1 desiccant—a hygroscopic material that adsorbs water

CurrenteditionapprovedJune1,2010.PublishedJuly2010.Originallyapproved

in 1993. Last previous edition approved in 2006 as C1249–06a. DOI: 10.1520/

or may adsorb solvent vapors, or both (see Fig. 1).

C1249-06AR10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM The last approved version of this historical standard is referenced on

Standards volume information, refer to the standard’s Document Summary page on www.astm.org.

the ASTM website. Available from IGMA, 111 E. Wacker Dr., Ste. 600, Chicago, IL 60601.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C1249 − 06a (2010)

4.2 Thisguideprovidesinformationonsiliconesealantsthat

are used for the secondary seal of IG units that are glazed into

SSG systems.

4.3 Information is also provided on the other major compo-

nents of the IG unit edge seal, compatibility of components,

durability, and quality assurance (QA).

5. Insulating Glass Unit

5.1 Insulating Glass Unit Components—Theedgesealofan

SSG system IG unit consists of the two lites of glass, spacer,

desiccant, primary sealant, and secondary sealant (Fig. 1) (1).

ThistypeofIGunitisreferredtocommonlyasadual-sealunit

in that it has separate primary and secondary seals. A single-

FIG. 1 Sealed IG Edge Seal: Basic Components

seal IG unit is inappropriate at this time for SSG systems and

should not be used. The following sections describe the

3.2.1.1 Discussion—The desiccant maintains a low relative

components of a dual-seal IG unit briefly.

humidity in sealed insulating glass.

5.2 Glass and Architectural Coatings:

3.2.2 primary seal—Ajoint seal of which the sealant resists

5.2.1 Glass—All types of glass have been used in the

moisture vapor permeation into the desiccated space of sealed

fabrication of IG units, including monolithic, laminated,

insulating glass (see Fig. 1).

tempered, heat-strengthened, tinted, heat-absorbing, light

3.2.2.1 Discussion—It also resists inert gas permeation (for

reducing,patterned,andwired.Almostallglassisproducedby

example,argon)fromtheIGunitsealedspaceiftheintentisto

the float manufacturing process, in which the glass ribbon that

use an inert gas.

emerges from the furnace is floated on a bath of molten tin,

3.2.3 secondary seal—a joint seal of which the sealant

allowing gravity to produce essentially flat parallel surfaces.

structurally unites the two glass lites and spacer of sealed

5.2.2 Architectural Coatings—These coatings, which are

insulating glass (see Fig. 1).

applied to the surface of the glass prior to IG unit fabrication,

3.2.4 spacer—a fabricated shape that creates an appropriate

are generally grouped into one of two categories: low-

distance between two lites of glass in sealed insulating glass

emissivity or reflective. They are both metallic or metallic

(see Fig. 1).

oxide materials and in some cases are in multi-layers, depos-

3.2.4.1 Discussion—As a component of the edge seal

ited onto or into a glass surface. The coatings are deposited

system, the spacer also resists vapor migration into sealed

primarily by two methods: magnetic sputtering onto the glass

insulating glass and provides a container for a desiccant.

surface and pyrolitic deposition into the glass surface. Low-

emissivity coatings are visually transparent and reflect long-

3.2.5 structural seal—a joint seal of which the sealant

wave infrared radiation, thereby improving the thermal trans-

structurally adheres an IG unit to a metal framing system (see

mittance of the glass. In general, they also decrease but to a

Fig. 2).

lesserextentthanreflectivecoatings,visiblelighttransmission,

3.2.5.1 Discussion—The structural seal transfers applied

and transmitted solar radiant energy. Depending on lighting

loads to the framing system as well as accommodates differ-

conditions, reflective coatings are generally considerably less

ential movements between the IG unit and the framing system.

transparent than low-emissivity coatings. These coatings pro-

3.3 Symbols:

videareductionintransmittedsolarradiantenergy,conductive

2 2

3.3.1 A =area, m (in. ).

heatenergy,andvisiblelightintothebuildinginterior.Ceramic

3.3.2 C =sealant contact width, shear, mm (in.).

s

enamel, silicone, and pressure-sensitive vinyl and polyester

3.3.3 C =sealant contact width, tension, mm (in.).

t

film are applied to the surface of glass to make spandrel glass.

3.3.4 D =design factor, dimensionless.

5.3 Spacer—Spacers are fabricated primarily from roll-

3.3.5 F =allowable shear stress, Pa (psi).

s

formed hollow metal shapes and are available in numerous

3.3.6 F =allowable tensile stress, Pa (psi).

t

profiles, depending on the application. Metals typically used

3.3.7 F =yield stress, Pa (psi).

y

are aluminum, both mill finish and anodized, galvanized steel,

3.3.8 H =height, m (ft).

and stainless steel, with aluminum used predominately. The

3.3.9 L =perimeter length, m (ft).

2 2

spacer establishes the size of the sealed space, provides

3.3.10 M =mass per unit area, N/m (lb/ft ).

surfaces for installation of the primary sealant, is hollow for

3.3.11 P =applied load, Pa (lbf/ft ).

desiccant installation, and forms the third surface of the cavity

3.3.12 W =width, m (ft).

created at the edge of the glass lites for installation of the

4. Significance and Use

secondary sealant.

4.1 It should be realized that the design of an IG unit edge

seal for use in SSG systems is a collaborative effort of at least

the IG unit fabricator, sealant manufacturer, and design

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof

professional, among others. this guide.

C1249 − 06a (2010)

FIG. 2 Typical A-Side SSG System Mullion: Horizontal Section (Vertical Joint)

5.4 Desiccant—Thesesubstancesarehydrophiliccrystalline ant). These sealants are polysulfides, polyurethanes, hot-melt

materials that are installed into the hollow of the spacer, butyls, and silicones. For SSG systems, only IG units with a

usually on at least two sides of the IG unit. Commonly used dual-seal (polyisobutylene primary seal and silicone secondary

desiccants are molecular sieves or a blend of silica gel with seal)havetherequireddurabilityfortheapplicationandarethe

molecularsieves.Theirpurposeistoadsorbresidualwaterand only sealants permitted for SSG systems.

solvent vapor in the sealed space immediately after fabrication

5.7 Enclosed Gas—The IG unit sealed space encloses a gas

of the IG units. They also maintain a low relative humidity in

such as air, argon, krypton, or sulfur hexafloride. Air is

the sealed space for the life of the IG unit by absorbing

normallyusedifconventionalthermalresistancepropertiesare

infiltrating moisture vapor.

required. Argon and krypton are used to increase the IG unit

5.5 Primary Sealant—This sealant provides a high level of

thermal resistance. Sulfur hexafloride is used in applications in

moisture vapor migration resistance and controls and mini-

which increased resistance to sound transmission is necessary.

mizes gas and solvent migration into the IG unit sealed space.

When using gases other than air, the IG unit edge seal system

The sealant also acts as a barrier to the permeation of inert

mustbecapableofretainingasubstantialpercentofthegasfor

gases (for example, argon) when these gases are used in the

thelifeoftheIGunit;otherwise,thermalorsoundtransmission

sealed space of the IG unit. The sealant is designed to fill the

performance will decrease to an unacceptable level.

space between the sides of the spacer and the faces of the two

5.8 Breather and Capillary Tubes:

glass lites and to develop adequate adhesion to the surfaces of

5.8.1 Breather Tube—Abreathertubeisasmalltubeorhole

both materials. The primary sealant must also have sufficient

that is factory-placed through the spacer of the IG unit to

movement capability to not fail due to limited differential

accommodate an increase in sealed air space pressure when an

movement that may occur between the spacer and the glass

IG unit is shipped to a higher elevation than where fabricated.

lites. Polyisobutylene-based materials have been found to be

The breather tube allows the sealed air space pressure to

very suitable for this purpose. The primary sealant contributes

equalizetotheatmosphericpressureattheinstallationsite.The

little to the structural function of transferring lateral loads and

breather tube is sealed prior to the IG unit installation. Special

holding the IG unit edge assembly together. These functions

sealed space gases (see 5.7) cannot be used in IG units that

are fulfilled by the secondary sealant.

have breather tubes.

5.6 Secondary Sealant:

5.8.2 Capillary Tube—A capillary tube is a very thin bore

5.6.1 This sealant transfers negative lateral loads, occurring

tube of specific length and inside diameter that is factory-

on the exterior lite of glass, to the interior lite of glass, which

placed through the spacer of the IG unit. A capillary tube

then transfers the load to the structural sealant that adheres the

fulfills the same function as a breather tube and, in addition, is

IG unit to the metal framing system. It also functions as the

leftopenduringtransportationtopermitthesealedspaceofthe

adhesive that unites the two glass lites and spacer together as

IG unit to continue to pressure equalize with fluctuating

a unit and prevents excessive movement from occurring in the

ambient air pressure. Capillary tubes should be sealed with a

primary seal (2). The secondary sealant must maintain ad-

high performance sealant specified by the IG fabricator at the

equate adhesion to the glass lites and spacer and also maintain

finaldestinationimmediatelybeforeinstallation.Specialsealed

other performance properties, such as strength and flexibility

space gases (see 5.7) cannot be used in IG units that have

afterprolongedenvironmentalexposure.Failureofthesecond-

capillary tubes.

ary seal to do so could result in excessive movement in the

primarysealandfoggingoftheIGunitoradhesiveorcohesive

SECONDARY SEALANT DESIGN CONSIDERATIONS

failure of the secondary seal and catastrophic failure of the IG

unit.

6. Structural Properties

5.6.2 Four generic classes of sealants are used presently for

a conventional IG unit edge seal system (non-structural seal- 6.1 General:

C1249 − 06a (2010)

6.1.1 The design of an IG unit edge seal parallels the tor’s QA program for fabricating the IG unit edge seal. Better

methodology used for the design of the SSG system structural QA results in more consistent adhesion of the secondary

joint that adheres an IG unit to a framing system. SSG system

sealant, and higher values for F can therefore be maintained

t

structural sealants must meet the requirements of Specification reliably.Inaddition,thecladdingdesignloadisusuallychosen

C1184. Presently, there is no comparable specification for

ast

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1249–06a Designation:C1249–06a (Reapproved 2010)

Standard Guide for

Secondary Seal for Sealed Insulating Glass Units for

Structural Sealant Glazing Applications

This standard is issued under the fixed designation C1249; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers design and fabrication considerations for the edge seal of conventionally sealed insulating glass units,

herein referred to as IG units. The IG units described are used in structural silicone sealant glazing systems, herein referred to as

SSG systems. SSG systems typically are either two or four sided, glazed with a structural sealant. Other conditions such as one,

three, five, six sided may be used.

1.2 This guides does not cover the IG units of other than conventional edge seal design (Fig. 1); however, the information

contained herein may be of benefit to the designers of such IG units.

1.3 In an SSG system, IG units are retained to a metal framing system by a structural seal (Fig. 2). The size and shape of that

seal, as well as numerous other SSG system design considerations, are not addressed in this guide.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

1.6 The committee with jurisdiction for this standard is not aware of any comparable standard guides published by other

organizations.

2. Referenced Documents

2.1 ASTM Standards:

C639 Test Method for Rheological (Flow) Properties of Elastomeric Sealants

C679 Test Method for Tack-Free Time of Elastomeric Sealants

C717 Terminology of Building Seals and Sealants

C794 Test Method for Adhesion-in-Peel of Elastomeric Joint Sealants

C1087 Test Method for Determining Compatibility of Liquid-Applied Sealants with Accessories Used in Structural Glazing

Systems

C1135 Test Method for Determining Tensile Adhesion Properties of Structural Sealants

C1184 Specification for Structural Silicone Sealants

E631 Terminology of Building Constructions

E773 Test Method for Accelerated Weathering of Sealed Insulating Glass Units

E774 Specification for the Classification of the Durability of Sealed Insulating Glass Units

E2188 Test Method for Insulating Glass Unit Performance

E2189 Test Method for Testing Resistance to Fogging in Insulating Glass Units

E2190 Specification for Insulating Glass Unit Performance and Evaluation

2.2 Other Standards:

Igma 73-8-2B Test Methods for Chemical Effects of Glazing Compounds on Elastomeric Edge Seals

3. Terminology

3.1 Definitions:

3.1.1 Refer to Terminology C717 for definitions of the following terms used in this guide: adhesive failure, bead, cohesive

This guide is under the jurisdiction ofASTM Committee C24 on Building Seals and Sealants and is the direct responsibility of Subcommittee C24.10 on Specifications,

Guides and Practices.

Current edition approved Sept.June 1, 2006.2010. Published September 2006.July 2010. Originally approved in 1993. Last previous edition approved in 2006 as

C1249–06a. DOI: 10.1520/C1249-06AR10.

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from IGMA, 111 E. Wacker Dr., Ste. 600, Chicago, IL 60601.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1249–06a (2010)

FIG. 1 Sealed IG Edge Seal: Basic Components

FIG. 2 Typical A-Side SSG System Mullion: Horizontal Section (Vertical Joint)

failure, compatibility, cure, elongation, gasket, glazing, joint, lite, modulus, non-sag sealant, seal, sealant, sealant backing, setting

block,shelf-life,siliconesealant,spacer,structuralsealant,substrate,tooling,andworkinglife.RefertoTerminologyE631forthe

definition of sealed insulating glass as used in this guide.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 desiccant—a hygroscopic material that adsorbs water or may adsorb solvent vapors, or both (see Fig. 1).

3.2.1.1 Discussion—The desiccant maintains a low relative humidity in sealed insulating glass.

3.2.2 primary seal—A joint seal of which the sealant resists moisture vapor permeation into the desiccated space of sealed

insulating glass (see Fig. 1).

3.2.2.1 Discussion—Italsoresistsinertgaspermeation(forexample,argon)fromtheIGunitsealedspaceiftheintentistouse

an inert gas.

3.2.3 secondary seal—ajointsealofwhichthesealantstructurallyunitesthetwoglasslitesandspacerofsealedinsulatingglass

(see Fig. 1).

3.2.4 spacer—a fabricated shape that creates an appropriate distance between two lites of glass in sealed insulating glass (see

Fig. 1).

3.2.4.1 Discussion—Asacomponentoftheedgesealsystem,thespaceralsoresistsvapormigrationintosealedinsulatingglass

and provides a container for a desiccant.

3.2.5 structural seal—a joint seal of which the sealant structurally adheres an IG unit to a metal framing system (see Fig. 2).

3.2.5.1 Discussion—The structural seal transfers applied loads to the framing system as well as accommodates differential

movements between the IG unit and the framing system.

3.3 Symbols:Symbols:

2 2

3.3.1 A =area, m (in. ).

3.3.2 C =sealant contact width, shear, mm (in.).

s

3.3.3 C =sealant contact width, tension, mm (in.).

t

3.3.4 D =design factor, dimensionless.

3.3.5 F =allowable shear stress, Pa (psi).

s

3.3.6 F =allowable tensile stress, Pa (psi).

t

3.3.7 F =yield stress, Pa (psi).

y

3.3.8 H =height, m (ft).

C1249–06a (2010)

3.3.9 L =perimeter length, m (ft).

2 2

3.3.10 M =mass per unit area, N/m (lb/ft ).

3.3.11 P =applied load, Pa (lbf/ft ).

3.3.12 W =width, m (ft).

4. Significance and Use

4.1 It should be realized that the design of an IG unit edge seal for use in SSG systems is a collaborative effort of at least the

IG unit fabricator, sealant manufacturer, and design professional, among others.

4.2 ThisguideprovidesinformationonsiliconesealantsthatareusedforthesecondarysealofIGunitsthatareglazedintoSSG

systems.

4.3 Information is also provided on the other major components of the IG unit edge seal, compatibility of components,

durability, and quality assurance (QA).

5. Insulating Glass Unit

5.1 Insulating Glass Unit Components—The edge seal of an SSG system IG unit consists of the two lites of glass, spacer,

desiccant, primary sealant, and secondary sealant (Fig. 1) (1). This type of IG unit is referred to commonly as a dual-seal unit

in that it has separate primary and secondary seals.Asingle-seal IG unit is inappropriate at this time for SSG systems and should

not be used. The following sections describe the components of a dual-seal IG unit briefly.

5.2 Glass and Architectural Coatings:

5.2.1 Glass—All types of glass have been used in the fabrication of IG units, including monolithic, laminated, tempered,

heat-strengthened, tinted, heat-absorbing, light reducing, patterned, and wired. Almost all glass is produced by the float

manufacturingprocess,inwhichtheglassribbonthatemergesfromthefurnaceisfloatedonabathofmoltentin,allowinggravity

to produce essentially flat parallel surfaces.

5.2.2 Architectural Coatings—These coatings, which are applied to the surface of the glass prior to IG unit fabrication, are

generally grouped into one of two categories: low-emissivity or reflective. They are both metallic or metallic oxide materials and

in some cases are in multi-layers, deposited onto or into a glass surface. The coatings are deposited primarily by two methods:

magnetic sputtering onto the glass surface and pyrolitic deposition into the glass surface. Low-emissivity coatings are visually

transparentandreflectlong-waveinfraredradiation,therebyimprovingthethermaltransmittanceoftheglass.Ingeneral,theyalso

decrease but to a lesser extent than reflective coatings, visible light transmission, and transmitted solar radiant energy. Depending

on lighting conditions, reflective coatings are generally considerably less transparent than low-emissivity coatings.These coatings

provideareductionintransmittedsolarradiantenergy,conductiveheatenergy,andvisiblelightintothebuildinginterior.Ceramic

enamel, silicone, and pressure-sensitive vinyl and polyester film are applied to the surface of glass to make spandrel glass.

5.3 Spacer—Spacers are fabricated primarily from roll-formed hollow metal shapes and are available in numerous profiles,

depending on the application. Metals typically used are aluminum, both mill finish and anodized, galvanized steel, and stainless

steel, with aluminum used predominately. The spacer establishes the size of the sealed space, provides surfaces for installation of

the primary sealant, is hollow for desiccant installation, and forms the third surface of the cavity created at the edge of the glass

lites for installation of the secondary sealant.

5.4 Desiccant—These substances are hydrophilic crystalline materials that are installed into the hollow of the spacer, usually

on at least two sides of the IG unit. Commonly used desiccants are molecular sieves or a blend of silica gel with molecular sieves.

Their purpose is to adsorb residual water and solvent vapor in the sealed space immediately after fabrication of the IG units.They

also maintain a low relative humidity in the sealed space for the life of the IG unit by absorbing infiltrating moisture vapor.

5.5 Primary Sealant—Thissealantprovidesahighlevelofmoisturevapormigrationresistanceandcontrolsandminimizesgas

andsolventmigrationintotheIGunitsealedspace.Thesealantalsoactsasabarriertothepermeationofinertgases(forexample,

argon) when these gases are used in the sealed space of the IG unit. The sealant is designed to fill the space between the sides of

the spacer and the faces of the two glass lites and to develop adequate adhesion to the surfaces of both materials. The primary

sealant must also have sufficient movement capability to not fail due to limited differential movement that may occur between the

spacer and the glass lites. Polyisobutylene-based materials have been found to be very suitable for this purpose. The primary

sealant contributes little to the structural function of transferring lateral loads and holding the IG unit edge assembly together.

These functions are fulfilled by the secondary sealant.

5.6 Secondary Sealant:

5.6.1 This sealant transfers negative lateral loads, occurring on the exterior lite of glass, to the interior lite of glass, which then

transfers the load to the structural sealant that adheres the IG unit to the metal framing system. It also functions as the adhesive

that unites the two glass lites and spacer together as a unit and prevents excessive movement from occurring in the primary seal

(2). The secondary sealant must maintain adequate adhesion to the glass lites and spacer and also maintain other performance

properties, such as strength and flexibility after prolonged environmental exposure. Failure of the secondary seal to do so could

result in excessive movement in the primary seal and fogging of the IG unit or adhesive or cohesive failure of the secondary seal

and catastrophic failure of the IG unit.

The boldface numbers in parentheses refer to the list of references at the end of this guide.

C1249–06a (2010)

5.6.2 Four generic classes of sealants are used presently for a conventional IG unit edge seal system (non-structural sealant).

These sealants are polysulfides, polyurethanes, hot-melt butyls, and silicones. For SSG systems, only IG units with a dual-seal

(polyisobutyleneprimarysealandsiliconesecondaryseal)havetherequireddurabilityfortheapplicationandaretheonlysealants

permitted for SSG systems.

5.7 Enclosed Gas—The IG unit sealed space encloses a gas such as air, argon, krypton, or sulfur hexafloride.Air is normally

used if conventional thermal resistance properties are required. Argon and krypton are used to increase the IG unit thermal

resistance. Sulfur hexafloride is used in applications in which increased resistance to sound transmission is necessary.When using

gases other than air, the IG unit edge seal system must be capable of retaining a substantial percent of the gas for the life of the

IG unit; otherwise, thermal or sound transmission performance will decrease to an unacceptable level.

5.8 Breather and Capillary Tubes:

5.8.1 Breather Tube—A breather tube is a small tube or hole that is factory-placed through the spacer of the IG unit to

accommodate an increase in sealed air space pressure when an IG unit is shipped to a higher elevation than where fabricated.The

breather tube allows the sealed air space pressure to equalize to the atmospheric pressure at the installation site.The breather tube

is sealed prior to the IG unit installation. Special sealed space gases (see 5.7) cannot be used in IG units that have breather tubes.

5.8.2 Capillary Tube—A capillary tube is a very thin bore tube of specific length and inside diameter that is factory-placed

through the spacer of the IG unit.Acapillary tube fulfills the same function as a breather tube and, in addition, is left open during

transportation to permit the sealed space of the IG unit to continue to pressure equalize with fluctuating ambient air pressure.

CapillarytubesshouldbesealedwithahighperformancesealantspecifiedbytheIGfabricatoratthefinaldestinationimmediately

before installation. Special sealed space gases (see 5.7) cannot be used in IG units that have capillary tubes.

SECONDARY SEALANT DESIGN CONSIDERATIONS

6. Structural Properties

6.1 General:

6.1.1 The design of an IG unit edge seal parallels the methodology used for the design of the SSG system structural joint that

adheres an IG unit to a framing system. SSG system structural sealants must meet the requirements of Specification C1184.

Presently, there is no comparable specification for sealants used for the secondary sealant of IG units; however, sealants should

mee

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.