ASTM C1249-06a

(Guide)Standard Guide for Secondary Seal for Sealed Insulating Glass Units for Structural Sealant Glazing Applications

Standard Guide for Secondary Seal for Sealed Insulating Glass Units for Structural Sealant Glazing Applications

SIGNIFICANCE AND USE

It should be realized that the design of an IG unit edge seal for use in SSG systems is a collaborative effort of at least the IG unit fabricator, sealant manufacturer, and design professional, among others.

This guide provides information on silicone sealants that are used for the secondary seal of IG units that are glazed into SSG systems.

Information is also provided on the other major components of the IG unit edge seal, compatibility of components, durability, and quality assurance (QA).

SCOPE

1.1 This guide covers design and fabrication considerations for the edge seal of conventionally sealed insulating glass units, herein referred to as IG units. The IG units described are used in structural silicone sealant glazing systems, herein referred to as SSG systems. SSG systems typically are either two or four sided, glazed with a structural sealant. Other conditions such as one, three, five, six sided may be used.

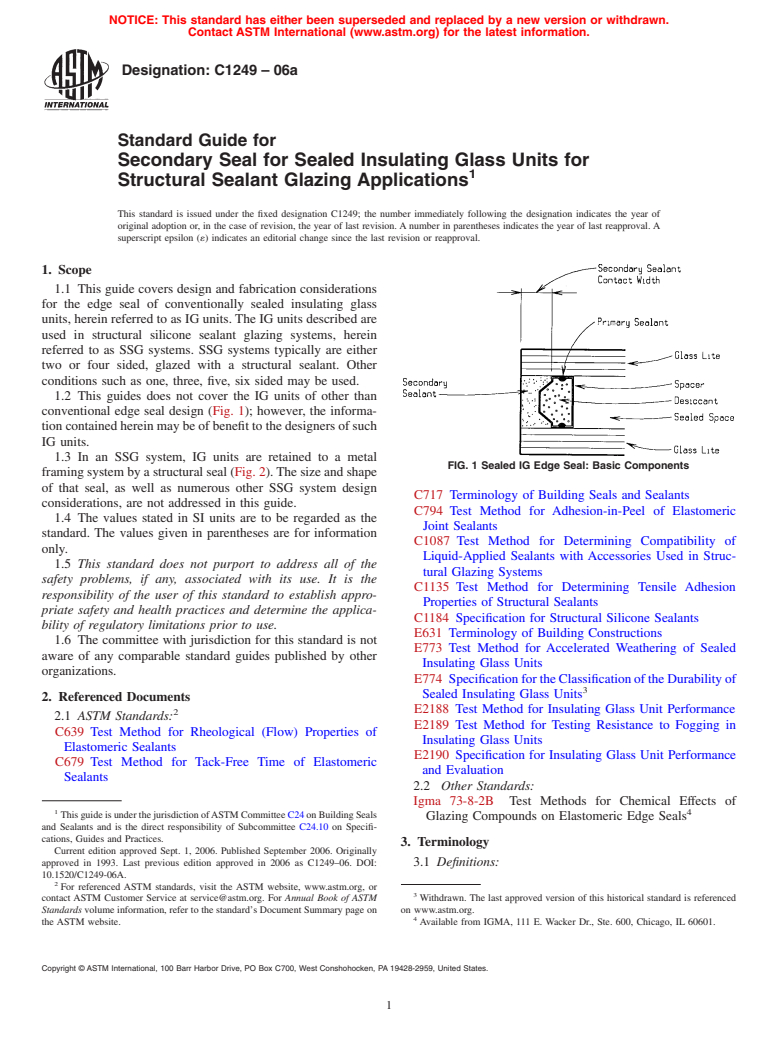

1.2 This guides does not cover the IG units of other than conventional edge seal design (Fig. 1); however, the information contained herein may be of benefit to the designers of such IG units.

1.3 In an SSG system, IG units are retained to a metal framing system by a structural seal (Fig. 2). The size and shape of that seal, as well as numerous other SSG system design considerations, are not addressed in this guide.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.5 The committee with jurisdiction for this standard is not aware of any comparable standard guides published by other organizations.

1.6 This test method determines the thoroughness of mixing of a multi-component sealant.

1.7 This test method determines whether the rate of cure of a mixed sealant sample is within the sealant manufacturer's written specifications.

1.8 This test method determines whether there is adequate adhesion of a sealant to the surface of a spacer.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:C1249–06a

Standard Guide for

Secondary Seal for Sealed Insulating Glass Units for

1

Structural Sealant Glazing Applications

This standard is issued under the fixed designation C1249; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide covers design and fabrication considerations

for the edge seal of conventionally sealed insulating glass

units, herein referred to as IG units.The IG units described are

used in structural silicone sealant glazing systems, herein

referred to as SSG systems. SSG systems typically are either

two or four sided, glazed with a structural sealant. Other

conditions such as one, three, five, six sided may be used.

1.2 This guides does not cover the IG units of other than

conventional edge seal design (Fig. 1); however, the informa-

tioncontainedhereinmaybeofbenefittothedesignersofsuch

IG units.

1.3 In an SSG system, IG units are retained to a metal

FIG. 1 Sealed IG Edge Seal: Basic Components

framingsystembyastructuralseal(Fig.2).Thesizeandshape

of that seal, as well as numerous other SSG system design

C717 Terminology of Building Seals and Sealants

considerations, are not addressed in this guide.

C794 Test Method for Adhesion-in-Peel of Elastomeric

1.4 The values stated in SI units are to be regarded as the

Joint Sealants

standard. The values given in parentheses are for information

C1087 Test Method for Determining Compatibility of

only.

Liquid-Applied Sealants with Accessories Used in Struc-

1.5 This standard does not purport to address all of the

tural Glazing Systems

safety problems, if any, associated with its use. It is the

C1135 Test Method for Determining Tensile Adhesion

responsibility of the user of this standard to establish appro-

Properties of Structural Sealants

priate safety and health practices and determine the applica-

C1184 Specification for Structural Silicone Sealants

bility of regulatory limitations prior to use.

E631 Terminology of Building Constructions

1.6 The committee with jurisdiction for this standard is not

E773 Test Method for Accelerated Weathering of Sealed

aware of any comparable standard guides published by other

Insulating Glass Units

organizations.

E774 SpecificationfortheClassificationoftheDurabilityof

3

Sealed Insulating Glass Units

2. Referenced Documents

E2188 Test Method for Insulating Glass Unit Performance

2

2.1 ASTM Standards:

E2189 Test Method for Testing Resistance to Fogging in

C639 Test Method for Rheological (Flow) Properties of

Insulating Glass Units

Elastomeric Sealants

E2190 Specification for Insulating Glass Unit Performance

C679 Test Method for Tack-Free Time of Elastomeric

and Evaluation

Sealants

2.2 Other Standards:

Igma 73-8-2B Test Methods for Chemical Effects of

1

4

ThisguideisunderthejurisdictionofASTMCommitteeC24onBuildingSeals

Glazing Compounds on Elastomeric Edge Seals

and Sealants and is the direct responsibility of Subcommittee C24.10 on Specifi-

cations, Guides and Practices.

3. Terminology

Current edition approved Sept. 1, 2006. Published September 2006. Originally

approved in 1993. Last previous edition approved in 2006 as C1249–06. DOI: 3.1 Definitions:

10.1520/C1249-06A.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Withdrawn. The last approved version of this historical standard is referenced

Standards volume information, refer to the standard’s Document Summary page on on www.astm.org.

4

the ASTM website. Available from IGMA, 111 E. Wacker Dr., Ste. 600, Chicago, IL 60601.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1249–06a

FIG. 2 Typical A-Side SSG System Mullion: Horizontal Section (Vertical Joint)

3.1.1 Refer to Terminology C717 for definitions of the 3.3.8 H =height, m (ft).

following terms used in this guide: adhesive failure, bead, 3.3.9 L =perimeter length, m (ft).

2 2

cohesive failure, compatibility, cure, elongation, gasket, glaz- 3.3.10 M =mass per unit area, N/m (lb/ft ).

2

ing, joint, lite, modulus, non-sag sealant, seal, sealant, sealant 3.3.11 P =applied load, Pa (lbf/ft ).

backing, setting block, shelf-life, silicone sealant, spacer, 3.3.12 W =width, m (ft).

structural sealant, substrate, tooling, and working life. Refer to

4. Significance and Use

Terminology E631 for the definition of sealed insulating glass

4.1 It should be realized that the design of an IG unit edge

as used in this guide.

seal for use in SSG systems is a collaborat

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.