ASTM F771-99e1

(Specification)Standard Specification for Polyethylene (PE) Thermoplastic High-Pressure Irrigation Pipeline Systems

Standard Specification for Polyethylene (PE) Thermoplastic High-Pressure Irrigation Pipeline Systems

SCOPE

1.1 This specification covers polyethylene (PE) thermoplastic pipelines used to convey, at rated pressures of 80 to 200 psi, water that is to be used for irrigation purposes. This specification includes criteria for classifying the pipe materials, a system of nomenclature for plastic pipe, requirements for pipe, test methods, joints, fittings, certification, and marking.

1.2 The values stated in inch-pound units are to be regarded as the standard.

1.3 The following safety hazards caveat pertains only to the test method portion, Section 7, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation: F 771 – 99

Standard Specification for

Polyethylene (PE) Thermoplastic High-Pressure Irrigation

1

Pipeline Systems

This standard is issued under the fixed designation F 771; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Keywords added editorially in November 2003.

1. Scope D 2239 Specification for Polyethylene (PE) Plastic Pipe

4

(SIDR-PR) Based on Control Inside Diameter

1.1 This specification covers polyethylene (PE) thermoplas-

D 2609 Specification for Plastic Insert Fittings for Polyeth-

tic pipelines used to convey, at rated pressures of 80 to 200 psi,

4

ylene (PE) Plastic Pipe

water that is to be used for irrigation purposes. This specifica-

D 2683 Specification for Socket-Type Polyethylene Fittings

tion includes criteria for classifying the pipe materials, a

for Outside Diameter-Controlled Polyethylene Pipe and

system of nomenclature for plastic pipe, requirements for pipe,

4

Tubing

test methods, joints, fittings, certification, and marking.

D 2837 Test Method for Obtaining Hydrostatic Design

1.2 The values stated in inch-pound units are to be regarded

4

Basis for Thermoplastic Pipe Materials

as the standard.

D 3035 Specification for Polyethylene (PE) Plastic Pipe

1.3 The following safety hazards caveat pertains only to the

4

(DR-PR) Based on Controlled Outside Diameter

test method portion, Section 7, of this specification: This

D 3261 Specification for Butt Heat Fusion Polyethylene

standard does not purport to address all of the safety concerns,

(PE)PlasticFittingsforPolyethylene(PE)PlasticPipeand

if any, associated with its use. It is the responsibility of the user

4

Tubing

of this standard to establish appropriate safety and health

D 3350 Specification for Polyethylene Plastics Pipe and

practices and determine the applicability of regulatory limita-

5

Fittings Materials

tions prior to use.

4

F 412 Terminology Relating to Plastic Piping Systems

2. Referenced Documents 2.2 Federal Standard:

6

Fed. Std. No. 123 Marking for Shipment (Civil Agencies)

2.1 ASTM Standards:

2.3 Military Standard:

D 1238 Test Method for Flow Rates of Thermoplastics by

6

2

MIL-STD-129 Marking for Shipment and Storage

Extrusion Plastomer

D 1248 Specification for Polyethylene Plastics Extrusion

3. Terminology

3

Materials for Wire and Cable

3.1 Definitions:

D 1505 Test Method for Density of Plastics by the Density-

2

3.1.1 General—Nomenclature is in accordance with Termi-

Gradient Technique

nology F 412 and abbreviations are in accordance with Termi-

D 1598 Test Method for Time-to-Failure of Plastic Pipe

4

nology D 1600, unless otherwise indicated.

Under Constant Internal Pressure

3.1.2 high-pressure irrigation pipeline—this term applies to

D 1599 TestMethodforShort-TimeHydraulicFailurePres-

4

underground pipelines constructed of PE pipe from 0.5 to 6 in.

sure of Plastic Pipe, Tubing, and Fittings

nominal diameter and subject to pressures, including surge

D 1600 Terminology for Abbreviated Terms Relating to

2

pressures, from 80 to 200 psi (550 to 1380 kPa).

Plastic

3.1.3 hydrostatic design stress—the recommended maxi-

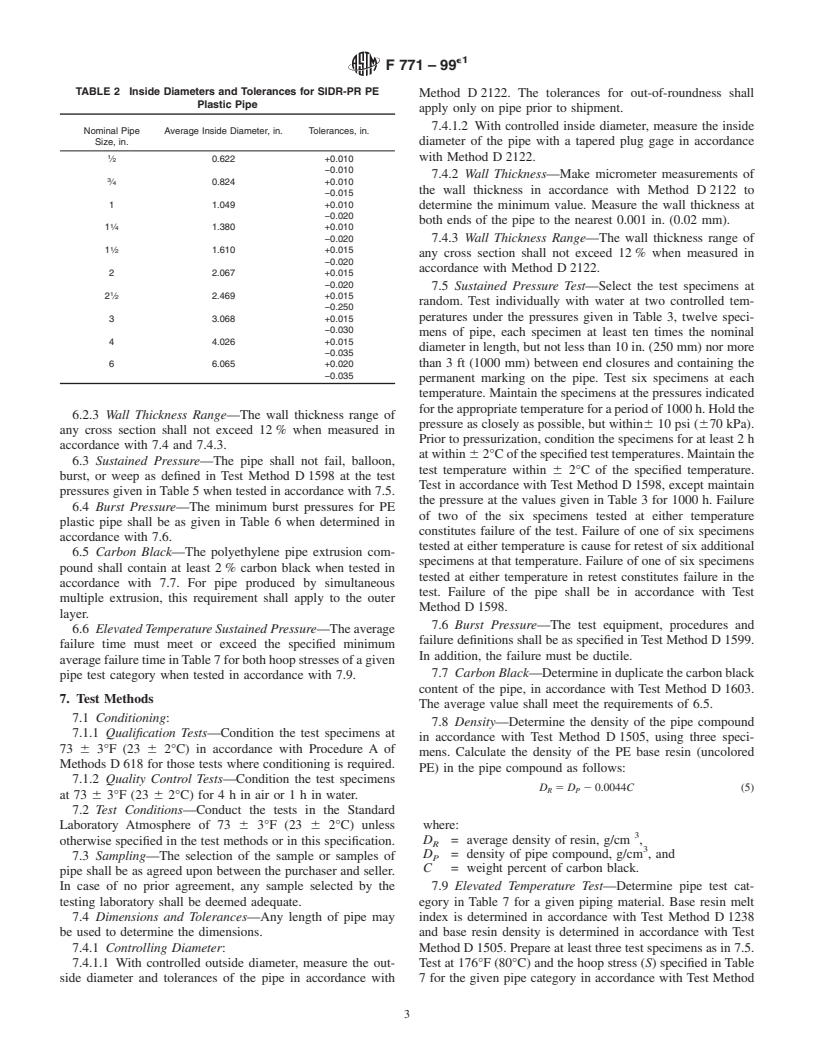

D 2122 Test Method for Determining Dimensions of Ther-

4

mum hoop stress that can be applied continuously with a high

moplastic Pipe and Fittings

degree of certainty that failure of the pipe will not occur.

3.1.4 pressure rating (PR)—the estimated maximum pres-

1 sure that the medium in the pipe can exert continuously with a

ThisspecificationisunderthejurisdictionofASTMCommitteeF-17onPlastic

Piping Systems and is the direct responsibility of Subcommittee F 17.61 on Water. high degree of certainty that failure of the pipe will not occur.

Current edition approved April 10, 1999. Published July 1999. Originally

published as F 771 – 82. Last previous edition F 771 – 95.

2 5

Annual Book of ASTM Standards, Vol 08.01. Annual Book of ASTM Standards, Vol 08.03.

3 6

Annual Book of ASTM Standards, Vol 08.03. AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

4

Annual Book of ASTM Standards, Vol 08.04. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

F 771–99

3.1.5 relation between standard dimension ratio, hydro- 5. Materials

static design stress and pressure rating—the following expres-

5.1 General—Thepolyethylenesusedtomakepipemeeting

sion, commonly known as the ISO equation, is used to relate

the requirements of this specification are categorized by means

standard dimension r

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.