ASTM C1129-89(1994)e1

(Practice)Standard Practice for Estimation of Heat Savings by Adding Thermal Insulation to Bare Valves and Flanges

Standard Practice for Estimation of Heat Savings by Adding Thermal Insulation to Bare Valves and Flanges

SCOPE

1.1 The mathematical methods included in this practice provide a calculational procedure for estimating heat loss or heat savings when thermal insulation is added to bare valves and flanges.

1.2 Questions of applicability to real systems should be resolved by qualified personnel familiar with insulation systems design and analysis.

1.3 Estimated accuracy is limited by the following:

1.3.1 The range and quality of the physical property data for the insulation materials and system,

1.3.2 The accuracy of the methodology used in calculation of the bare valve and insulation surface areas, and

1.3.3 The quality of workmanship, fabrication, and installation.

1.4 This procedure is considered applicable both for conventional-type insulation systems and for removable/reuseable covers. In both cases, for purposes of heat transfer calculations, the insulation system is assumed to be homogenous.

1.5 This practice does not intend to establish the criteria required in the design of the equipment over which thermal insulation is used, nor does this practice establish or recommend the applicability of thermal insulation over all surfaces.

1.6 The values stated in inch-pound units are to be regarded as the standard. The SI units in parentheses are provided for information only.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: C 1129 – 89 (Reapproved 1994)

Standard Practice for

Estimation of Heat Savings by Adding Thermal Insulation to

Bare Valves and Flanges

This standard is issued under the fixed designation C 1129; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords were added editorially in March 1994.

1. Scope 1.7 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 The mathematical methods included in this practice

responsibility of the user of this standard to establish appro-

provide a calculational procedure for estimating heat loss or

priate safety and health practices and determine the applica-

heat savings when thermal insulation is added to bare valves

bility of regulatory limitations prior to use.

and flanges.

1.2 Questions of applicability to real systems should be

2. Referenced Documents

resolved by qualified personnel familiar with insulation sys-

2.1 ASTM Standards:

tems design and analysis.

C 168 Terminology Relating to Thermal Insulating Materi-

1.3 Estimated accuracy is limited by the following:

als

1.3.1 The range and quality of the physical property data for

C 450 Practice for Prefabrication and Field Fabrication

the insulation materials and system,

Fitting Covers for NPS Piping, Vessel Lagging, and Dished

1.3.2 The accuracy of the methodology used in calculation

Head Segments

of the bare valve and insulation surface areas, and

C 680 Practice for Determination of Heat Gain or Loss and

1.3.3 The quality of workmanship, fabrication, and installa-

the Surface Temperatures of Insulated Pipe and Equipment

tion.

Systems by the Use of a Computer Program

1.4 This procedure is considered applicable both for

C 1094 Guide for Removable Insulation Covers

conventional-type insulation systems and for removable/

2.2 American National Standards Institute Standard:

reuseable covers. In both cases, for purposes of heat transfer

ANSI B16.5 Fittings, Flanges, and Valves

calculations, the insulation system is assumed to be homog-

enous.

3. Terminology

1.5 This practice does not intend to establish the criteria

3.1 Definitions—For definitions of terms used in this prac-

required in the design of the equipment over which thermal

tice, refer to Terminology C 168.

insulation is used, nor does this practice establish or recom-

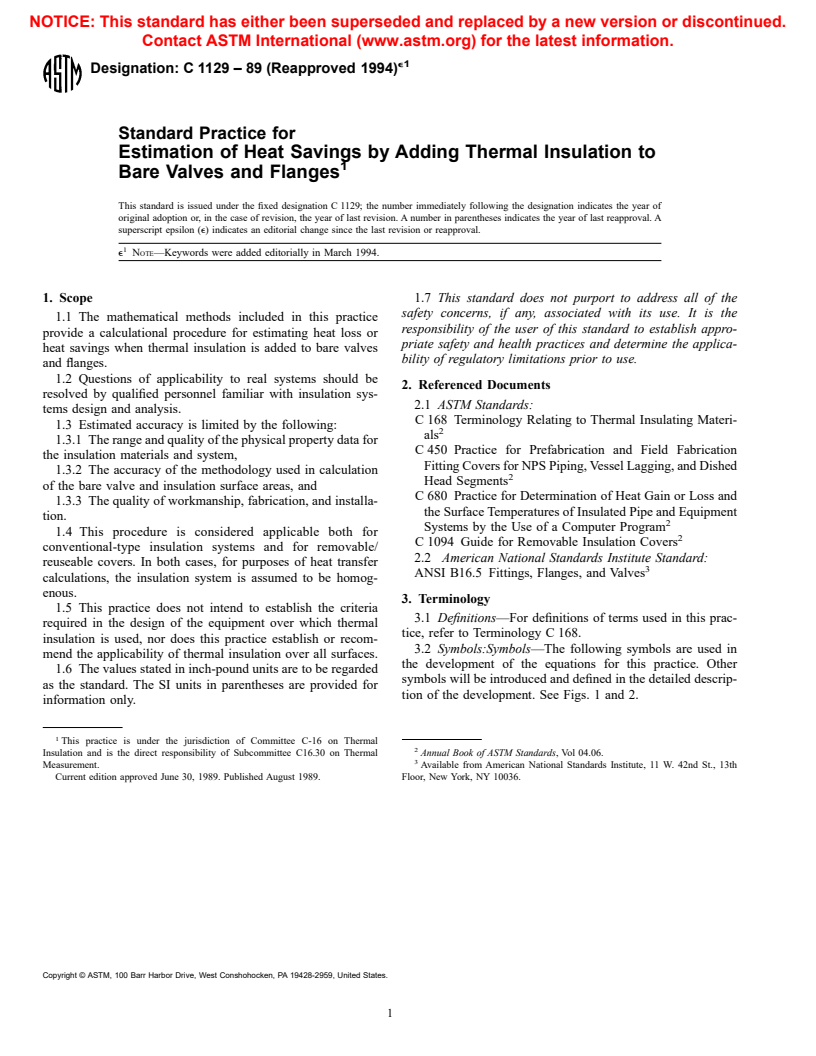

3.2 Symbols:Symbols—The following symbols are used in

mend the applicability of thermal insulation over all surfaces.

the development of the equations for this practice. Other

1.6 The values stated in inch-pound units are to be regarded

symbols will be introduced and defined in the detailed descrip-

as the standard. The SI units in parentheses are provided for

tion of the development. See Figs. 1 and 2.

information only.

This practice is under the jurisdiction of Committee C-16 on Thermal

Insulation and is the direct responsibility of Subcommittee C16.30 on Thermal Annual Book of ASTM Standards, Vol 04.06.

Measurement. Available from American National Standards Institute, 11 W. 42nd St., 13th

Current edition approved June 30, 1989. Published August 1989. Floor, New York, NY 10036.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

C 1129

to it). This practice is used to estimate the heat loss per unit

surface area for the particular conditions and for all configu-

rations.

4.2 The procedures for estimating surface areas used in this

practice are based on standard geometric logic: for a bare valve

or flange, the contours of the metal surface are considered. For

an insulated valve or flange, the fabricated shape of the finished

insulation system is considered.

4.3 Data Input:

4.3.1 Total bare surface area and total insulation surface

area of the bare valve or flange,

4.3.2 Service and ambient temperatures,

4.3.3 Wind speed,

4.3.4 Surface emittances,

4.3.5 Insulation thickness and type, and

4.3.6 Number of service hours per year.

4.4 System Description—Insulation thickness, insulation

FIG. 1 Equation 1 for a Bare Valve, A 5 [D (L +2L +(C − D /

B P V F P

V

2 2 type, bare valve or flange surface emittance, insulation surface

2)−6T) + 1.5(D − D )+6 D T] p

F P F

emittance.

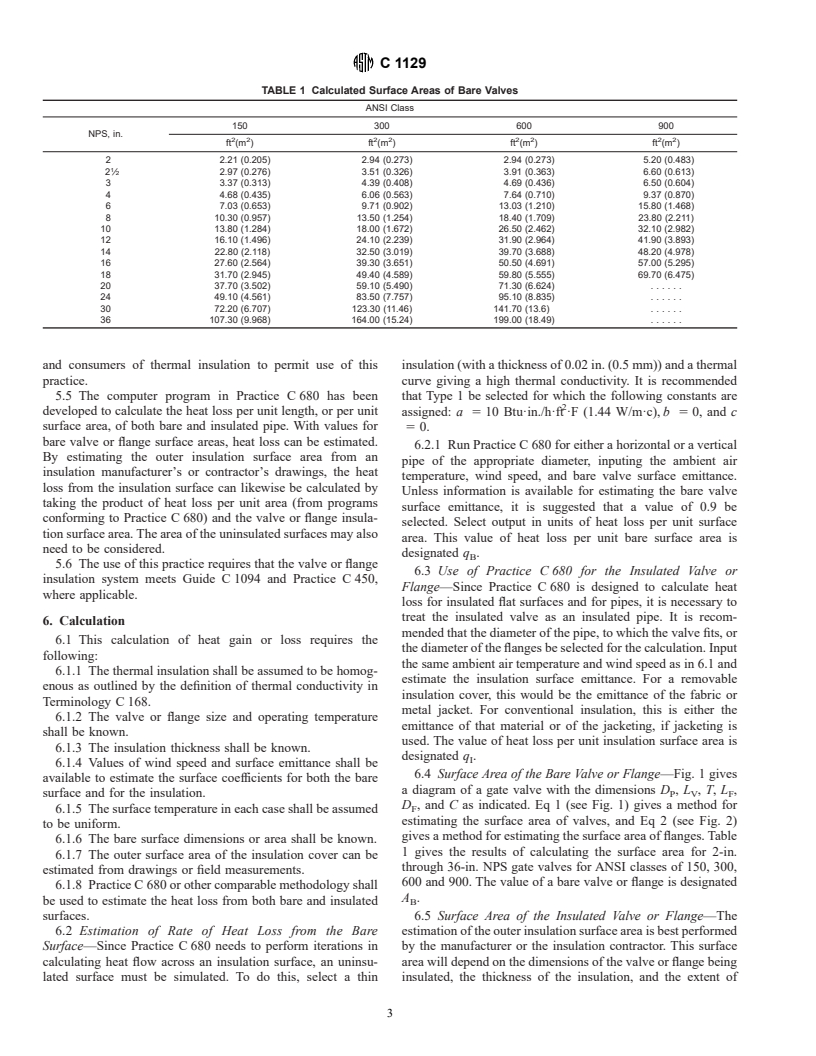

4.5 Analysis—Once input data is entered, the program

calculates the surface coefficients (if not entered directly), the

insulation resistance, the bare metal heat loss per unit area, and

the insulation surface heat loss per unit area. The rate of heat

loss per unit area is computed by Practice C 680 for the

appropriate diameter. For bare gate valves, the particular

surface area can be taken from a look-up table. Table 1 gives

these areas for typical (ANSI Class 150, 300, 600, and 900)

flanged gate valves and flanges. If these valves are not

considered sufficiently accurate, they can be calculated using

FIG. 2 Equation 2 for a Bare Flange, A 5 [D

B P

F Eq 1 (see Fig. 1) and Eq 2 (see Fig. 2). Similar equations can

2 2

(L +2L −4T)+(D − D )+4 D T] p

V F F P F

be developed for other types of valves and flanges. For the

insulation, the outer surface area may be obtained from the

insulation fabricator or contractor.

A 5 outer surface area of the bare valve or flange (does

B

2 2

not include the wheel and stem of the valve), ft (m ). 5. Significance and Use

A 5 surface area of the insulation cover over the valve or

I

5.1 Manufacturers of thermal insulation for valves typically

2 2

flange, ft (m ).

express the performance of their products in charts and tables

C 5 distance from the center-line axis of the pipe (to

showing heat loss per valve. These data are presented for both

which the valve is attached) to the uppermost posi-

bare and insulated valves of different pipe sizes, ANSI classes,

tion of the valve that is to be insulated (recommended

insulation types, insulation thicknesses, and service tempera-

to be below the gland seal), ft (m).

tures. Additional information on effects of wind velocity, jacket

D 5 the valve flange and the bonnet flange outer diameter

F

emittance, bare valve emittance, and ambient conditions may

(assumed equal), ft (m).

also be required to properly select an insulation system. Due to

D 5 the actual diameter of the pipe, ft (m).

P

the infinite combination of pipe sizes, ANSI classes, insulation

L 5 overall length of the valve, flange to flange, ft (m).

V

types and thicknesses, service temperatures, insulation cover

T 5 thickness of the valve flange and of the bonnet flange,

geometries, surface emittances, and ambient conditions, it is

ft (m).

not possible to publish data for each possible case.

q 5 time rate of heat loss per unit area from the bare valve

B

2 2

5.2 Users of thermal insulation for piping systems faced

or flange surface, Btu/h·ft (W/m ).

with the problem of designing large systems of insulated

q 5 time rate of heat loss per unit area from the insulation

I

2 2

piping, encounter substantial engineering costs to obtain the

surface, Btu/h·ft ) (W/m ).

required thermal information. This cost can be substantially

Q 5 time rate of heat loss from the bare valve or flange

B

reduced by both the use of accurate engineering data tables, or

surface, Btu/h (W).

by the use of available computer analysis tools, or both.

Q 5 time rate of heat loss from the insulated surface,

I

5.3 The use of this practice by the manufacturer, contractor,

Btu/h (W).

and users of thermal insulation for valves and flanges will

4. Summary of Practice

provide standardized engineering data of sufficient accuracy

4.1 The procedures for estimating heat loss used in this and consistency for predicting the savings in heating energy

practice are based upon standard steady-state heat transfer use by insulating bare valves and flanges.

theory as outlined in Practice C 680 (or programs conforming 5.4 Computers are now readily available to most producers

C 1129

TABLE 1 Calculated Surface Areas of Bare Valves

ANSI Class

150 300 600 900

NPS, in.

2 2 2 2 2 2 2 2

ft (m)ft (m)ft (m)ft (m )

2 2.21 (0.205) 2.94 (0.273) 2.94 (0.273) 5.20 (0.483)

2 ⁄2 2.97 (0.276) 3.51 (0.326) 3.91 (0.363) 6.60 (0.613)

3 3.37 (0.313) 4.39 (0.408) 4.69 (0.436) 6.50 (0.604)

4 4.68 (0.435) 6.06 (0.563) 7.64 (0.710) 9.37 (0.870)

6 7.03 (0.653) 9.71 (0.902) 13.03 (1.210) 15.80 (1.468)

8 10.30 (0.957) 13.50 (1.254) 18.40 (1.709) 23.80 (2.211)

10 13.80 (1.284) 18.00 (1.672) 26.50 (2.462) 32.10 (2.982)

12 16.10 (1.496) 24.10 (2.239) 31.90 (2.964) 41.90 (3.893)

14 22.80 (2.118) 32.50 (3.019) 39.70 (3.688) 48.20 (4.978)

16 27.60 (2.564) 39.30 (3.651) 50.50 (4.691) 57.00 (5.295)

18 31.70 (2.945) 49.40 (4.589) 59.80 (5.555) 69.70 (6.475)

20 37.70 (3.502) 59.10 (5.490) 71.30 (6.624) .

24 49.10 (4.561) 83.50 (7.757) 95.10 (8.835) .

30 72.20 (6.707) 123.30 (11.46) 141.70 (13.6) .

36 107.30 (9.968) 164.00 (15.24) 199.00 (18.49) .

and consumers of thermal insulation to permit use of this insulation (with a thickness of 0.02 in. (0.5 mm)) and a thermal

practice. curve giving a high thermal conductivity. It is recommended

5.5 The computer program in Practice C 680 has been

that Type 1 be selected for which the following constants are

developed to calculate the heat loss per unit length, or per unit assigned: a 5 10 Btu·in./h·ft ·F (1.44 W/m·c), b 5 0, and c

surface area, of both bare and insulated pipe. With values for

5 0.

bare valve or flange surface areas, heat loss can be estimated.

6.2.1 Run Practice C 680 for either a horizontal or a vertical

By estimating the outer insulation surface area from an

pipe of the appropriate diameter, inputing the ambient air

insulation manufacturer’s or contractor’s drawings, the heat

temperature, wind speed, and bare valve surface emittance.

loss from the insulation surface can likewise be calculated by

Unless information is available for estimating the bare valve

taking the product of heat loss per unit area (from programs

surface emittance, it is suggested that a value of 0.9 be

conforming to Practice C 680) and the valve or flange insula-

selected. Select output in units of heat loss per unit surface

tion surface area. The area of the uninsulated surfaces may also

area. This value of heat loss per unit bare surface area is

need to be considered.

designated q .

B

5.6 The use of this practice requires that the valve or flange

6.3 Use of Practice C 680 for the Insulated Valve or

insulation system meets Guide C 1094 and Practice C 450,

Flange—Since Practice C 680 is designed to calculate heat

where applicable.

loss for insulated flat surfaces and for pipes, it is necessary to

treat the insulated valve as an insulated pipe. It is recom-

6. Calculation

mended that the diameter of the pipe, to which the valve fits, or

6.1 This calculation of heat gain or loss requires the

the diameter of the flanges be selected for the calculation. Input

following:

the same ambient air temperature and wind speed as in 6.1 and

6.1.1 The thermal insulation shall be assumed to be homog-

estimate the insulation surface emittance. For a removable

enous as outlined by the definition of thermal conductivity in

insulation cover, this would be the emittance of the fabric or

Terminology C 168.

metal jacket. For conventional insulation, this is either the

6.1.2 The valve or flange size and operating temperature

emittance of that material or of the jacketing, if jacketing is

shall be known.

used. The value of heat loss per unit insulation surface area is

6.1.3 The insulation thickness shall be known.

designated q .

I

6.1.4 Values of wind speed and surface emittance shall be

6.4 Surface Area of the Bare Valve or Flange—Fig. 1 gives

available to estimate the surface coefficients for both the bare

a diagram of a gate valve with the dimensions D , L , T, L ,

P V F

surface and for the insulation.

D , and C as indicated. Eq 1 (see Fig. 1) gives a method for

6.1.5 The surface temperature in each case shall be assumed F

estimating the surface area of valves, and Eq 2 (see Fig. 2)

to be uniform.

gives a method for estimating the surface area of flanges. Table

6.1.6 The bare surface dimensions or area shall be known.

1 gives the results of calculating the surface area for 2-in.

6.1.7 The outer surface area of the insulation cover can be

through 36-in. NPS gate valves for ANSI classes of 150, 300,

estimated from drawings or field measurements.

600 and 900. The value of a bare valve or flange is designated

6.1.8 Practice C 680 or other comparable methodology shall

A .

be used to estimate the heat loss from both bare and insulated B

surfaces. 6.5 Surface Area of the Insulated Valve or Flange—The

6.2 Estimation of Rate of Heat Loss from the Bare estimation of the outer insulation surface area is best performed

Surface—Since Practice C 680 needs to perform iterations in by the manufacturer or the insulation contractor. This surface

calculating heat flow across an insulation surface, an uninsu- area will depend on the dimensions of the valve or flange being

lated surface must be simulated. To do this, select a thin insulated, the thickness of the insulation, and the extent of

C 1129

coverage to either side of the valve or flange. This practice does 8.2 There are a number of factors which influence the

not recommend a specific method for arriving at this area, estimation of heat loss savings, however. The result of a

which would be designated as A . savings estimate is far more dependent upon the calculated heat

I

6.6 Calculation of Bare Valve or Flange Heat Loss—This loss from the bare surface than from the insulated surface. The

value is determined by taking the product of the bare valve or calculated heat loss from the bare surface, in turn, is highly

flange heat loss per unit surface area and of the bare surface dependent on the values of valve or flange service temperature,

area. It will be designated as Q : ambient temperature, wind speed, and surface area, with a

B

lesser dependence on surface emissivity.

Q 5 q A (1)

B B B

8.3 Since the service temperature should be reasonably well

6.7 Calculation of Insulated Valve or Flange Heat Loss—

known, the person performing this estimation is advised to

This value is determined by taking the product of the insulated

perform Practice C 680 calculations on the bare surface under

valve or flange heat loss per unit surface area and of the

extreme environmental conditions. This may not be necessary

insulation outer surface area. It would be designated as Q :

I

if the piping system is located indoors in a controlled environ-

Q 5 q A (2)

I I I ment, but it is strongl

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.