ASTM A743/A743M-98ae1

(Specification)Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, for General Application

Standard Specification for Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion Resistant, for General Application

SCOPE

1.1 This specification covers iron-chromium and iron-chromium-nickel alloy castings for general corrosion-resistant application. The grades covered by this specification represent types of alloy castings suitable for broad ranges of application which are intended for a wide variety of corrosion environments. Note 1-For alloy castings for severe corrosion-resistant service, reference should be made to Specification A744/A744M. For general heat-resistant alloy castings, reference should be made to Specification A297/A297M. For nickel alloy castings for corrosion-resistant service, reference should be made to Specification A494/A494M.

1.2 The values stated in either inch-pound units or SI units are to be regarded separately as standard. Within the text, the SI units are shown in brackets. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. Combining values from the two systems may result in nonconformance with the specification. Inch-pound units are applicable for material ordered to Specification A743 and SI units for material ordered to Specification A743M.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

e1

Designation: A 743/A 743M – 98a

Standard Specification for

Castings, Iron-Chromium, Iron-Chromium-Nickel, Corrosion

Resistant, for General Application

This standard is issued under the fixed designation A 743/A 743M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Section S12 was corrected editorially in May 1999.

1. Scope A 447/A447M Specification for Steel Castings, Chromium-

Nickel-Iron Alloy (25-12 Class), for High-Temperature

1.1 This specification covers iron-chromium and iron-

Service

chromium-nickel alloy castings for general corrosion-resistant

A 494/A494M Specification for Castings, Nickel and

application. The grades covered by this specification represent

Nickel Alloy

types of alloy castings suitable for broad ranges of application

A 744/A744M Specification for Castings, Iron-Chromium-

which are intended for a wide variety of corrosion environ-

Nickel, Corrosion Resistant, for Severe Service

ments.

A 781/A781M Specification for Castings, Steel and Alloy,

NOTE 1—For alloy castings for severe corrosion-resistant service, 3

Common Requirements, for General Industrial Use

reference should be made to Specification A 744/A 744M. For general

heat-resistant alloy castings, reference should be made to Specification

3. General Conditions for Delivery

A 297/A 297M. For nickel alloy castings for corrosion-resistant service,

3.1 Material furnished to this specification shall conform to

reference should be made to Specification A 494/A 494M.

the requirements of Specification A 781/A 781M, including

1.2 The values stated in either inch-pound units or SI units

any supplementary requirements that are indicated on the

are to be regarded separately as standard. Within the text, the

purchase order. Failure to comply with the general require-

SI units are shown in brackets. The values stated in each

ments of Specification A 781/A 781M constitutes nonconfor-

system are not exact equivalents; therefore, each system must

mance with this specification. In case of conflict between the

be used independently of the other. Combining values from the

requirements of this specification and Specification A 781/

two systems may result in nonconformance with the specifi-

A 781M, this specification shall prevail.

cation. Inch-pound units are applicable for material ordered to

Specification A 743 and SI units for material ordered to

4. Ordering Information

Specification A 743M.

4.1 Orders for material to this specification should include

the following, as required, to describe the material adequately:

2. Referenced Documents

4.1.1 Description of the casting by pattern number or

2.1 ASTM Standards:

drawing,

A 262 Practices for Detecting Susceptibility to Intergranu-

4.1.2 Grade,

lar Attack in Austenitic Stainless Steels

4.1.3 Heat treatment,

A 297/A297M Specification for Steel Castings, Iron-

4.1.4 Options in the specification, and

Chromium and Iron-Chromium-Nickel, Heat-Resistant,

4.1.5 Supplementary requirements desired, including the

for General Application

standards of acceptance.

A 370 Test Methods and Definitions for Mechanical Testing

of Steel Products

5. Process

5.1 The steel shall be made by the electric furnace process

1 with or without separate refining such as argon-oxygen decar-

This specification is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee burization (AOD).

A01.18 on Castings.

Current edition approved Sept. 10, 1998. Published December 1998. Originally

6. Heat Treatment

published as A 743 – 77. Last previous edition A 743/A 743M – 98.

6.1 Castings shall be heat treated in accordance with the

Annual Book of ASTM Standards, Vol 01.03.

Annual Book of ASTM Standards, Vol 01.02. requirements in Table 1.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

A 743/A 743M – 98a

TABLE 1 Heat Treatment Requirements

Grade Heat Treatment

CF-8, CG-3M (J92999), CG-8M, CG-12, CF-20, Heat to 1900°F [1040°C] minimum, hold for sufficient time to heat casting to temperature, quench in water or rapid

CF-8M, CF-8C,CF-16F, CF-16Fa cool by other means.

CH-10, CH-20, CE-30, CK-20 Heat to 2000°F [1093°C] minimum, hold for sufficient time to heat casting to temperature, quench in water or rapid

cool by other means.

CA-15, CA-15M, CA-40, CA-40F (1) Heat to 1750°F [955°C] minimum, air cool and temper at 1100°F [595°C] minimum, or

(2) Anneal at 1450°F [790°C] minimum.

CB-30, CC-50 (1) Heat to 1450°F [790°C] minimum, and air cool, or

(2) Heat to 1450°F [790°C] minimum, and furnace cool.

CF-3, CF-3M, CF-3MN (1) Heat to 1900°F [1040°C] minimum, hold for sufficient time to heat casting to temperature, and cool rapidly. (2)

As cast if corrosion resistance is acceptable.

CN-3M (J94652) Heat to 2150°F [1175°C] minimum, hold for sufficient time to heat casting to temperature, quench in water or rapid

cool by other means.

CN-3MN Heat to 2100°F [1150°C] minimum, hold for sufficient time to heat casting to temperature, quench in water or rapid

cool by other means.

CN-7M, CG-6MMN Heat to 2050°F [1120°C] minimum, hold for sufficient time to heat casting to temperature, quench in water or rapid

cool by other means.

CN-7MS Heat to 2100°F [1150°C] minimum, 2150°F [1180°C] maximum, hold for sufficient time (2 h minimum) to heat

casting to temperature and quench in water.

CA-6NM Heat to 1850°F [1010°C] minimum, air cool to 200°F [95°C] or lower prior to any optional intermediate temper and

prior to the final temper. The final temper shall be between 1050°F [565°C] and 1150°F [620°C].

CA-6N (J91541) Heat to 1900°F [1040°C], air cool, reheat to 1500°F [815°C], air cool, and age at 800°F [425°C], holding at each

temperature sufficient time to heat casting uniformly to temperature.

CF10SMnN Heat to 1950°F [1065°C] minimum, hold for sufficient time to heat casting to temperature, quench in water or rapid

cool by other means.

CA-28MWV (1) Heat to 1875–1925°F [1025–1050°C], quench in air or oil, and temper at 1150°F [620°C] minimum, or

(2) Anneal at 1400°F [760°C] minimum.

CK-3MCuN Heat to 2100°F [1150°C] minimum, hold for sufficient time to heat casting to temperature, quench in water or rapid

cool by other means.

CK-35MN Heat to 2100-2190F [1150-1200C], hold for sufficient time to heat casting to temperature, quench in water or rapid

cool by other means.

CB-6 (J91804) Heat between 1800°F [980°C] and 1920°F [1050°C], forced air, cool to 120°F [50°C] maximum, and temper

between 1100°F and 1160°F [595°C and 625°C].

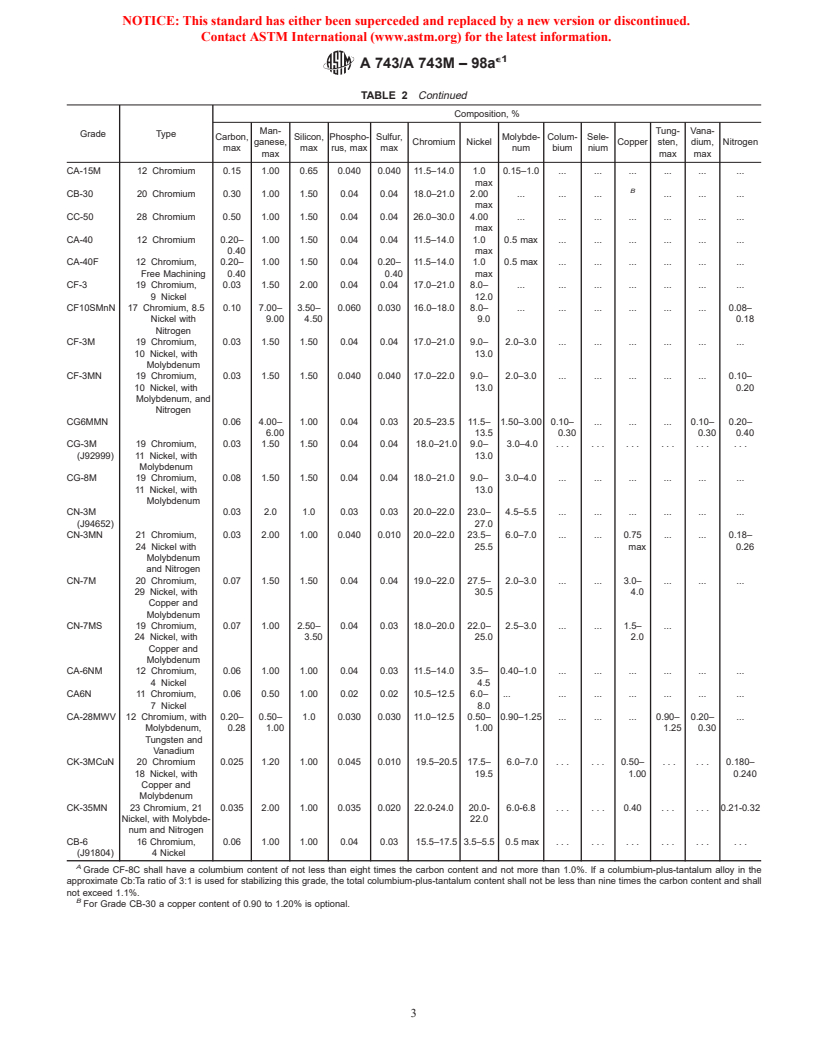

TABLE 2 Chemical Requirements

NOTE 1—CD-4MCu has been deleted from A 743/A 743M and added to A 890/A 890M. CD-4MCu may now be supplied and purchased in compliance

with A 890/A 890M. The chemical and mechanical property requirements of CD-4MCu were identical in A 743/A 743M and A 890/A 890M at the time

of removal from A 743/A 743M.

Composition, %

Man- Tung- Vana-

Grade Type

Carbon, Silicon, Phospho- Sulfur, Molybde- Colum- Sele-

ganese, Chromium Nickel Copper sten, dium, Nitrogen

max max rus, max max num bium nium

max max max

CF-8 19 Chromium, 0.08 1.50 2.00 0.04 0.04 18.0–21.0 8.0– . . . . . . .

9 Nickel 11.0

CG-12 22 Chromium, 0.12 1.50 2.00 0.04 0.04 20.0–23.0 10.0– . . . . . . .

12 Nickel 13.0

CF-20 19 Chromium, 0.20 1.50 2.00 0.04 0.04 18.0–21.0 8.0– . . . . . . .

9 Nickel 11.0

CF-8M 19 Chromium, 0.08 1.50 2.00 0.04 0.04 18.0–21.0 9.0– 2.0–3.0 . . . . . .

10 Nickel, with 12.0

Molybdenum

A

CF-8C 19 Chromium, 0.08 1.50 2.00 0.04 0.04 18.0–21.0 9.0– . . . . . .

10 Nickel, with 12.0

Columbium

CF-16F 19 Chromium, 0.16 1.50 2.00 0.17 0.04 18.0–21.0 9.0– 1.50 max . 0.20– . . . .

9 Nickel, Free 12.0 0.35

Machining

CF-16Fa 19 Chromium, 0.16 1.50 2.00 0.04 0.20– 18.0–21.0 9.0– 0.40–0.80 . . . . . .

9 Nickel, Free 0.40 12.0

Machining

CH-10 25 Chromium, 0.10 1.50 2.00 0.04 0.04 22.0–26.0 12.0– . . . . . . . . .

12 Nickel 15.0

CH-20 25 Chromium, 0.20 1.50 2.00 0.04 0.04 22.0–26.0 12.0– . . . . . . .

12 Nickel 15.0

CK-20 25 Chromium, 0.20 2.00 2.00 0.04 0.04 23.0–27.0 19.0– . . . . . . .

20 Nickel 22.0

CE-30 29 Chromium, 0.30 1.50 2.00 0.04 0.04 26.0–30.0 8.0– . . . . . . .

9 Nickel 11.0

CA-15 12 Chromium 0.15 1.00 1.50 0.04 0.04 11.5–14.0 1.00 0.50 max . . . . . .

max

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

A 743/A 743M – 98a

TABLE 2 Continued

Composition, %

Man- Tung- Vana-

Grade Type

Carbon, Silicon, Phospho- Sulfur, Molybde- Colum- Sele-

ganese, Chromium Nickel Copper sten, dium, Nitrogen

max max rus, max max num bium nium

max max max

CA-15M 12 Chromium 0.15 1.00 0.65 0.040 0.040 11.5–14.0 1.0 0.15–1.0 . . . . . .

max

B

CB-30 20 Chromium 0.30 1.00 1.50 0.04 0.04 18.0–21.0 2.00 . . . . . .

max

CC-50 28 Chromium 0.50 1.00 1.50 0.04 0.04 26.0–30.0 4.00 . . . . . . .

max

CA-40 12 Chromium 0.20– 1.00 1.50 0.04 0.04 11.5–14.0 1.0 0.5 max . . . . . .

0.40 max

CA-40F 12 Chromium, 0.20– 1.00 1.50 0.04 0.20– 11.5–14.0 1.0 0.5 max . . . . . .

Free Machining 0.40 0.40 max

CF-3 19 Chromium, 0.03 1.50 2.00 0.04 0.04 17.0–21.0 8.0– . . . . . . .

9 Nickel 12.0

CF10SMnN 17 Chromium, 8.5 0.10 7.00– 3.50– 0.060 0.030 16.0–18.0 8.0– . . . . . . 0.08–

Nickel with 9.00 4.50 9.0 0.18

Nitrogen

CF-3M 19 Chromium, 0.03 1.50 1.50 0.04 0.04 17.0–21.0 9.0– 2.0–3.0 . . . . . .

10 Nickel, with 13.0

Molybdenum

CF-3MN 19 Chromium, 0.03 1.50 1.50 0.040 0.040 17.0–22.0 9.0– 2.0–3.0 . . . . . 0.10–

10 Nickel, with 13.0 0.20

Molybdenum, and

Nitrogen

CG6MMN 0.06 4.00– 1.00 0.04 0.03 20.5–23.5 11.5– 1.50–3.00 0.10– . . . 0.10– 0.20–

6.00 13.5 0.30 0.30 0.40

CG-3M 19 Chromium, 0.03 1.50 1.50 0.04 0.04 18.0–21.0 9.0– 3.0–4.0 . . . . . . . . . . . . . . . . . .

(J92999) 11 Nickel, with 13.0

Molybdenum

CG-8M 19 Chromium, 0.08 1.50 1.50 0.04 0.04 18.0–21.0 9.0– 3.0–4.0 . . . . . .

11 Nickel, with 13.0

Molybdenum

CN-3M 0.03 2.0 1.0 0.03 0.03 20.0–22.0 23.0– 4.5–5.5 . . . . . .

(J94652) 27.0

CN-3MN 21 Chromium, 0.03 2.00 1.00 0.040 0.010 20.0–22.0 23.5– 6.0–7.0 . . 0.75 . . 0.18–

24 Nickel with 25.5 max 0.26

Molybdenum

and Nitrogen

CN-7M 20 Chromium, 0.07 1.50 1.50 0.04 0.04 19.0–22.0 27.5– 2.0–3.0 . . 3.0– . . .

29 Nickel, with 30.5 4.0

Copper and

Molybdenum

CN-7MS 19 Chromium, 0.07 1.00 2.50– 0.04 0.03 18.0–20.0 22.0– 2.5–3.0 . . 1.5– .

24 Nickel, with 3.50 25.0 2.0

Copper and

Molybdenum

CA-6NM 12 Chromium, 0.06 1.00 1.00 0.04 0.03 11.5–14.0 3.5– 0.40–1.0 . . . . . .

4 Nickel 4.5

CA6N 11 Chromium, 0.06 0.50 1.00 0.02 0.02 10.5–12.5 6.0– . . . . . . .

7 Nickel 8.0

CA-28MWV 12 Chromium, with 0.20– 0.50– 1.0 0.030 0.030 11.0–12.5 0.50– 0.90–1.25 . . . 0.90– 0.20– .

Molybdenum, 0.28 1.00 1.00 1.25 0.30

Tungsten and

Vanadium

CK-3MCuN 20 Chromium 0.025 1.20 1.00 0.045 0.010 19.5–20.5 17.5– 6.0–7.0 . . . . . . 0.50– . . . . . . 0.180–

18 Nickel, with 19.5 1.00 0.240

Copper and

Molybdenum

CK-35MN 23 Chromium, 21 0.035 2.00 1.00 0.035 0.020 22.0-24.0 20.0- 6.0-6.8 . . . . . . 0.40 . . . . . . 0.21-0.32

Nickel, with Molybde- 22.0

num and Nitrogen

CB-6 16 Chromium, 0.06 1.00 1.00 0.04 0.03 15.5–17.5 3.5–5.5 0.5 max . . . . . . . . . . . . . . . . . .

(J91804) 4 Nickel

A

Grade CF-8C shall have a columbium content of not less than eight times the carbon content and not more than 1.0%. If a columbium-plus-tantalum alloy in the

approximate Cb:Ta ratio of 3:1 is used for stabilizing this grade, the total columbium-plus-tantalum content shall not be less than nine times the carbon content and shall

not exceed 1.1%.

B

For Grade CB-30 a copper content of 0.90 to 1.20% is optional.

NOTICE: This standard has either been superceded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

A 743/A 743M – 98a

NOTE 2—Proper heat treatment of these alloys is usually necessary to

of the manufacturer, furnace heat treating will be damaging to

enhance corrosion resistance and in some cases to meet mechanical

the finished surface of a machined casting. Heat treatment,

properties. Minimum heat treat temperatures are specified; however, it is

other than tempering, of grades CA-6NM, CA-15, CA-15M,

sometimes necessary to heat treat at higher temperatures, hold for some

CB–6, and CA-40 after weld repairing shall be performed only

minimum time at temperature and then rapidly cool the castings in order

when agreed upon between the manufacturer and the pur-

to enhance the corrosion resistance and meet mechanical properties.

chaser. Weld repair on Grade CA-40F is not recommended

7. Chemical Requirements

because of the risk of local hardening and possible cracking in

the heat affected zone.

7.1 The chemical requirements are shown in Table 2.

8.3.2 Post weld heat treatment is not required on the other

8. Repair by Welding

grades of this specification. When post weld heat treatment is

believed necessary for adequate corrosion resistance in the

8.1 Repair welding of Grade CA-28MWV is not permitted

service environment, castings should be ordered in accordance

unless by agreement between the manufacturer and the pur-

with Specification A 744/A 744M.

chaser.

8.2 When methods involving high temperature are used in

9. Product Marking

the removal of discontinuities, castings shall be preheated in

accordance with Table 3. Weld repairs shall be subject to the

9.1 Castings shall be marked for material identification with

same quality standards as are used to inspect the castings.

the ASTM specification number (A 743/A 743M) and grade

8.3 Post weld heat treatment, if required, shall be in accor-

symbol, that is, CF-8, CA-15, CB-30, etc. In addition, the

dance with Table 1.

manufacturer’s name or identification mark and the pattern

8.3.1 The martensitic grades CA-6NM, CA-15, CA-15M,

number shall be cast or stam

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.