ASTM D3368-04

(Specification)Standard Specification for FEP-Fluorocarbon Resin Sheet and Film

Standard Specification for FEP-Fluorocarbon Resin Sheet and Film

ABSTRACT

This specification covers unfilled, unpigmented FEP-fluorocarbon resin sheet and film. The sheet and film shall be made from FEP-fluorocarbon resin without filler or plasticizer. This specification allows for the use of recycled, reprocessed, and reworked FEP materials provided that: the final physical, mechanical, and performance requirements are met; and the toxicological characteristics are essentially unaltered from that of virgin material. The tensile strength, elongation at break, dimensional change on heating, cementability, dielectric strength, and density of the sheet and film shall be tested.

SCOPE

1.1 This specification covers unfilled, unpigmented FEP-fluorocarbon resin sheet and film less than 3.175 mm [0.125 in.] thick. Recycled materials are allowed in accordance with .

1.2 The values stated in SI units as detailed in IEEE/ASTM SI 10 are to be regarded as standard and the practices of IEEE/ASTM SI 10 incorporated herein.

1.3 The following safety hazards caveat pertains only to the test methods portion, Section 14, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation: D3368 – 04

Standard Specification for

1

FEP-Fluorocarbon Sheet and Film

This standard is issued under the fixed designation D3368; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* D883 Terminology Relating to Plastics

D2116 Specification for FEP-Fluorocarbon Molding and

1.1 This specification covers unfilled, unpigmented FEP-

Extrusion Materials

fluorocarbon resin sheet and film less than 3.175 mm [0.125

D3892 Practice for Packaging/Packing of Plastics

in.] thick. Recycled materials are allowed in accordance with

D5740 Guide for Writing Material Standards in the Classi-

6.2.

fication D 4000 Format

1.2 The values stated in SI units as detailed in IEEE/ASTM

E691 Practice for Conducting an Interlaboratory Study to

SI 10IEEE/ASTM SI 10 are to be regarded as standard and the

Determine the Precision of a Test Method

practicesofIEEE/ASTMSI10IEEE/ASTMSI10incorporated

IEEE/ASTM SI 10 Standard for Use of the International

herein.

System of Units (SI)

1.3 The following safety hazards caveat pertains only to the

2.2 Other Standard:

test methods portion, Section 14, of this specification: This

TAPPI411 StandardThickness(Caliper)ofPaperandPaper

standard does not purport to address all of the safety concerns,

3

Products

if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health

3. Terminology

practices and determine the applicability of regulatory limita-

3.1 Definitions—For definitions of terms used in this speci-

tions prior to use.

fication, see Terminology D883.

NOTE 1—There is no similar or equivalent ISO standard.

3.1.1 lot, n—one production run or a uniform blend of two

or more production runs.

2. Referenced Documents

2

2.1 ASTM Standards: 4. Classification

D149 Test Method for Dielectric Breakdown Voltage and

4.1 This specification covers four types of FEP-

Dielectric Strength of Solid Electrical Insulating Materials

fluorocarbon sheet and film:

at Commercial Power Frequencies

4.1.1 Type I—General purpose.

D374 Test Methods for Thickness of Solid Electrical Insu-

4.1.2 Type II—Cementable film. Type II materials can be

lation

subdivided into two grades:

D618 Practice for Conditioning Plastics for Testing

4.1.2.1 Grade 1—One side cementable, and

D638 Test Method for Tensile Properties of Plastics

4.1.2.2 Grade 2—Two sides cementable.

D792 Test Methods for Density and Specific Gravity (Rela-

4.1.3 Type III—Special film for applications requiring un-

tive Density) of Plastics by Displacement

usual flexural endurance or extreme thermal and chemical

D882 Test Method for Tensile Properties of Thin Plastic

service.

Sheeting

4.1.4 Type IV—Film for mold release applications.

4.2 Aline callout system is used to specify materials in this

1

standard. The system uses predefined cells to refer to specific

This specification is under the jurisdiction of ASTM Committee D20 on

Plastics and is the direct responsibility of Subcommittee D20.15 on Thermoplastic aspects of this specification, which are illustrated as follows:

Materials, Section D20.15.12 on Fluoropolymers.

Current edition approved February 1, 2004. Published March 2004. Originally

approved in 1975. Last previous edition approved in 1999 as D3368 - 99. DOI:

10.1520/D3368-04.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from TechnicalAssociation of the Pulp and Paper Industry (TAPPI),

Standards volume information, refer to the standard’s Document Summary page on P.O. Box 105113,Atlanta, GA30348; 15Technology Parkway South, Norcross, GA

the ASTM website. 30092. Phone: 1-800-332-8686.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

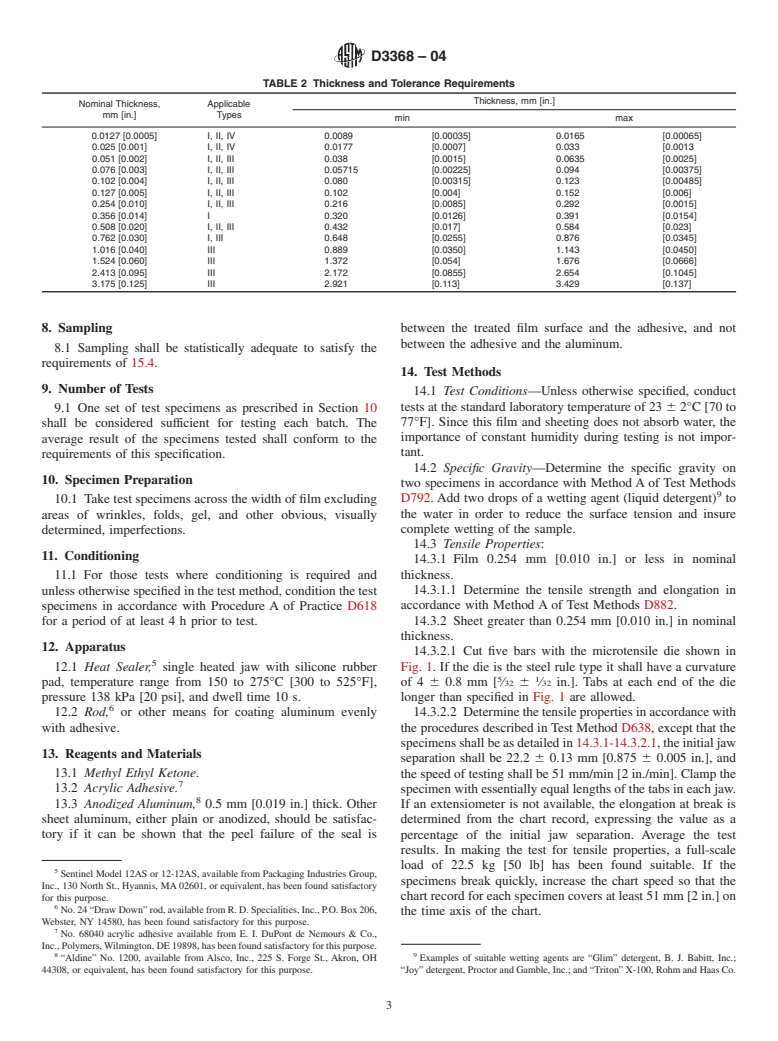

D3368 – 04

TABLE 1 Detail Requirements for Property Values

Type I Type II Type III Type IV

Tensile Strength, min, MPa [psi], at nominal thickness, mm [in.]:

0.0127 [0.0005] 13.8 [2000] 13.8 [2000] . 11.0 [1600]

0.025 to 3.175 [0.001 to 0.125] 17.25 [2500] 17.25 [2500] 17.25 [2500] 14.5 [2100]

Elongation at Break, min, %, at nominal thickness, mm [in.]:

0.0127 to 0.025 [0.0005 to 0.001] 175 175 . 150

0.051 to 3.175 [0.002 to 0.125] 250 250 250 250

Dimensional Change on Heating, max, %, at nominal thickness, mm [in.]:

0.0127 to 0.025 [0.0005 to 0.001] 65 65 . 65

0.051 [0.002] 6

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.