ASTM C1503-08

(Specification)Standard Specification for Silvered Flat Glass Mirror

Standard Specification for Silvered Flat Glass Mirror

ABSTRACT

This specification covers the requirements for silvered flat glass mirrors of rectangular shape supplied as cut sizes, stock sheets or as lehr ends and to which no further processing (such as edgework or other fabrication) has been done. The quality requirements of silvered annealed monolithic clear and tinted flat glass mirrors up to a certain thickness are also discussed. The mirrors are intended to be used indoors for mirror glazing, for components of decorative accessories or for similar uses. The mirrors are not intended for use in environments where high humidity or airborne corrosion promoters, or both, are consistently present (such as swimming pool areas, ocean-going vessels, chemical laboratories and other corrosive environments). The classification of mirrors are according to the following properties: grades, cut size, stock sheet, lehr end, select quality, glazing quality, color (clear or tinted), and thickness. Different test methods shall be performed in order to determine or measure the following properties: reflectance, silver coating appearance, coating resistance, blemish (point and linear blemishes), dimension, and squareness.

SCOPE

1.1 This specification covers the requirements for silvered flat glass mirrors of rectangular shape supplied as cut sizes, stock sheets or as lehr ends and to which no further processing (such as edgework or other fabrication) has been done.

1.2 This specification covers the quality requirements of silvered annealed monolithic clear and tinted flat glass mirrors up to 6 mm (¼ in.) thick. The mirrors are intended to be used indoors for mirror glazing, for components of decorative accessories or for similar uses.

1.3 This specification does not address safety glazing materials nor requirements for mirror applications. Consult model building codes and other applicable standards for safety glazing applications.

1.4 Mirrors covered in this specification are not intended for use in environments where high humidity or airborne corrosion promoters, or both, are consistently present (such as swimming pool areas, ocean-going vessels, chemical laboratories and other corrosive environments).

1.5 The dimensional values stated in metric units are to be regarded as the standard. The inch-pound units given in parentheses are for information only.

1.6 The following safety hazards caveat pertains only to the test method portion Section 7 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1503 −08

StandardSpecification for

1

Silvered Flat Glass Mirror

This standard is issued under the fixed designation C1503; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

2

1. Scope 2.2 ASTM Standards:

B117Practice for Operating Salt Spray (Fog) Apparatus

1.1 This specification covers the requirements for silvered

C162Terminology of Glass and Glass Products

flat glass mirrors of rectangular shape supplied as cut sizes,

C1036Specification for Flat Glass

stock sheets or as lehr ends and to which no further processing

E903Test Method for Solar Absorptance, Reflectance, and

(such as edgework or other fabrication) has been done.

Transmittance of Materials Using Integrating Spheres

3

1.2 This specification covers the quality requirements of

(Withdrawn 2005)

silvered annealed monolithic clear and tinted flat glass mirrors

3. Terminology

1

up to 6 mm ( ⁄4 in.) thick. The mirrors are intended to be used

indoors for mirror glazing, for components of decorative

3.1 Definitions:

accessories or for similar uses.

3.1.1 Refer to Terminology C162 and the standards refer-

enced in 2.2 as appropriate.

1.3 This specification does not address safety glazing ma-

3.1.2 associated distortion, n—alteration of viewed images

terialsnorrequirementsformirrorapplications.Consultmodel

causebyvariationsinglassflatnessininhomogeneousportions

building codes and other applicable standards for safety

within the glass.

glazing applications.

3.1.3 blemishes—imperfections in the body, on the surface

1.4 Mirrorscoveredinthisspecificationarenotintendedfor

or in the silver coating of the mirror; for the purpose of this

useinenvironmentswherehighhumidityorairbornecorrosion

specification blemishes are divided into 3 categories:

promoters,orboth,areconsistentlypresent(suchasswimming

3.1.3.1 linear blemishes—scratches, rubs, digs, and other

pool areas, ocean-going vessels, chemical laboratories and

similar imperfections on either surface of the glass substrate.

other corrosive environments).

3.1.3.2 point blemishes—crush, knots, dirt, stones, gaseous

1.5 The dimensional values stated in metric units are to be

inclusions (seeds and bubbles), tin particles, and other similar

regarded as the standard. The inch-pound units given in

imperfections in the body of the glass substrate.

parentheses are for information only.

3.1.3.3 silver film blemishes—visible clouding, spot silver

1.6 The following safety hazards caveat pertains only to the

faults and other similar imperfections of the silver coating.

test method portion Section 7 of this specification. This

3.1.4 chip—an imperfection on the edge of a mirror lite due

standard does not purport to address all of the safety concerns,

to breakage of a small fragment out of an otherwise regular

if any, associated with its use. It is the responsibility of the user

surface.

of this standard to establish appropriate safety and health

practices and determine the applicability of regulatory require- 3.1.4.1 shell chip—a circular indentation in the mirror edge

ments prior to use. due to breakage of a small fragment.

3.1.4.2 v-chip—a V-shaped chip indentation in the mirror

2. Referenced Documents

edge due to breakage of a small fragment.

2.1 Reference to these documents shall be the latest issue 3.1.4.3 chip width—the perpendicular distance from the

unless otherwise specified by the authority applying this edge of the mirror to the inner edge of the chip.

specification:

3.1.4.4 chip length—the distance, parallel to the edge of the

mirror, from one edge of a chip to the other.

1 2

This specification is under the jurisdiction ofASTM Committee C14 on Glass For referenced ASTM standards, visit the ASTM website, www.astm.org, or

and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Glass. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2008. Published January 2009. Originally the ASTM website.

3

approved in 2001. Last previous edition approved in 2001 as C1503–01. DOI: The last approved version of this historical standard is referenced on

10.1520/C1503-08. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

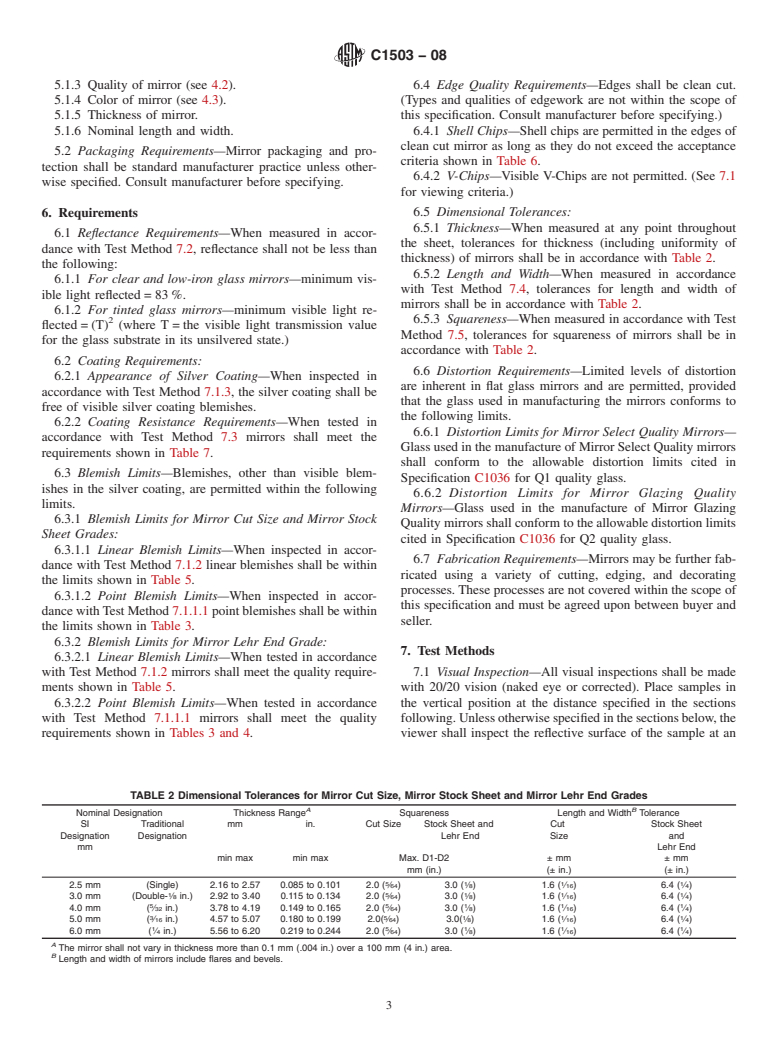

C1503−08

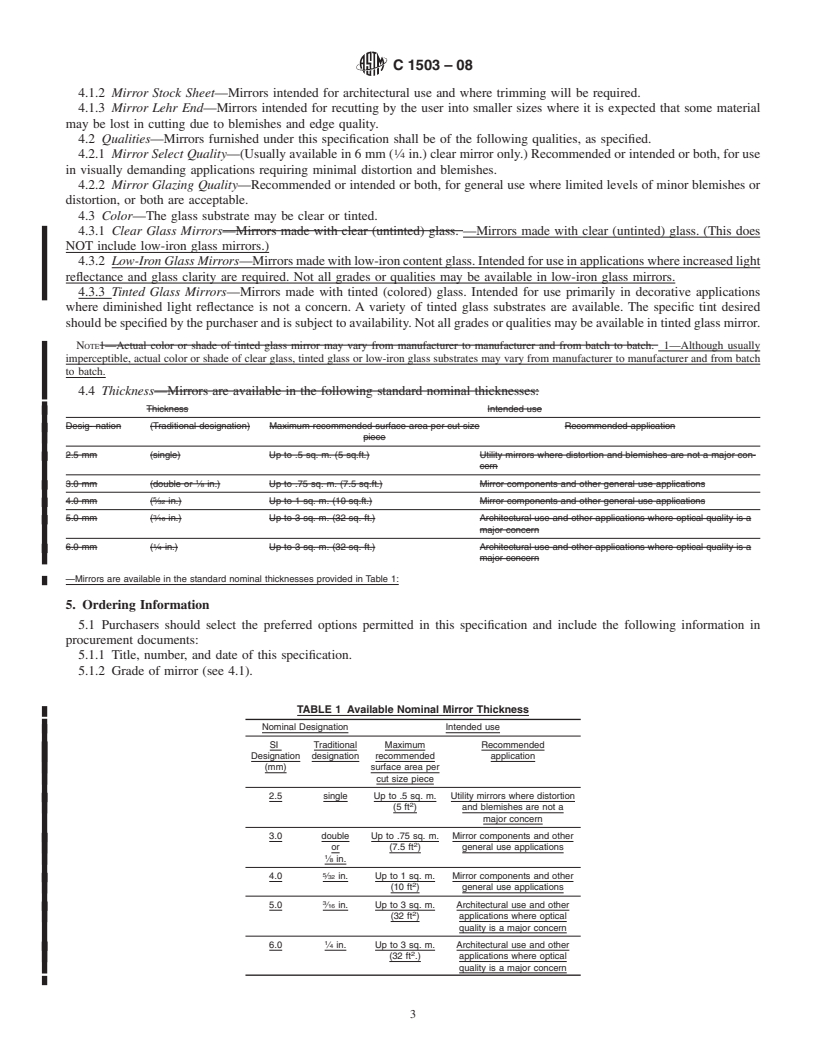

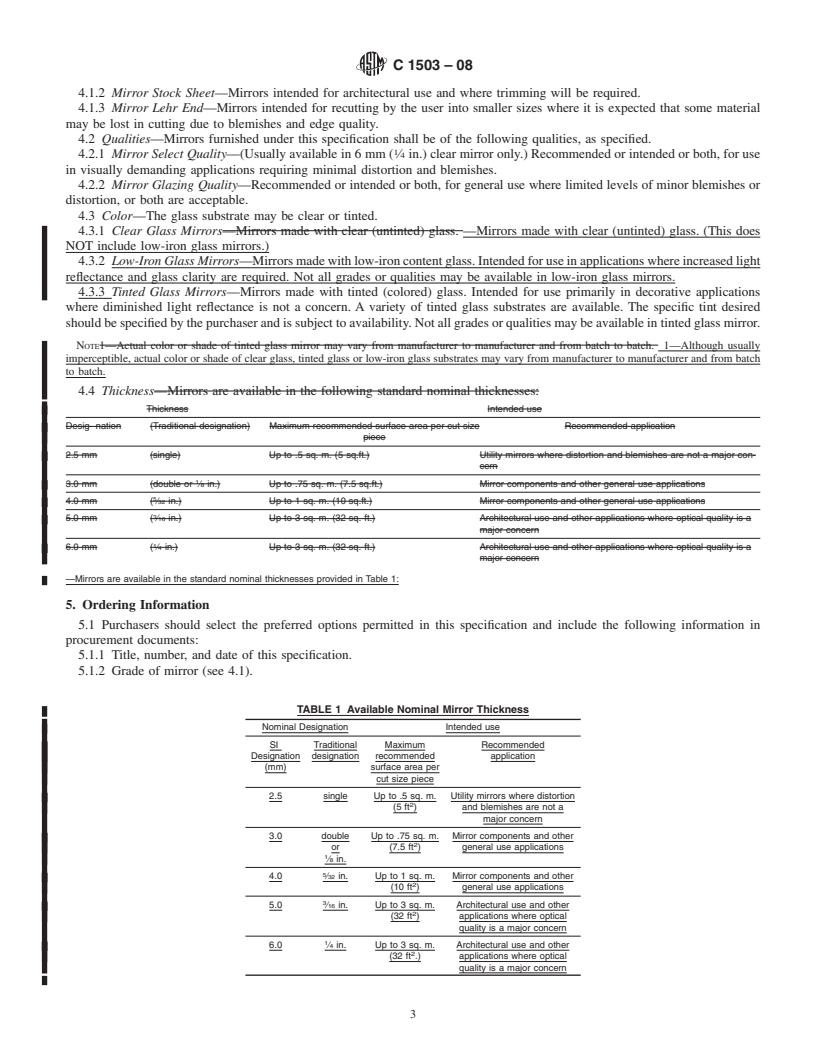

3.1.4.5 chip depth—the measured distance of a chip from 4.1.3 Mirror Lehr End—Mirrors intended for recutting by

the face of the mirror into the thickness. the user into smaller sizes where it is expected that so

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1503–01 Designation: C 1503 – 08

Standard Specification for

1

Silvered Flat Glass Mirror

This standard is issued under the fixed designation C 1503; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the requirements for silvered flat glass mirrors of rectangular shape supplied as cut sizes, stock

sheets or as lehr ends and to which no further processing (such as edgework or other fabrication) has been done.

1.2 This specification covers the quality requirements of silvered annealed monolithic clear and tinted flat glass mirrors up to

1

6mm( ⁄4 in.) thick. The mirrors are intended to be used indoors for mirror glazing, for components of decorative accessories or

for similar uses.

1.3 This specification does not address safety glazing materials nor requirements for mirror applications. Consult model

building codes and other applicable standards for safety glazing applications.

1.4 Mirrors covered in this specification are not intended for use in environments where high humidity or airborne corrosion

promoters, or both, are consistently present (such as swimming pool areas, ocean-going vessels, chemical laboratories and other

corrosive environments).

1.5 The dimensional values stated in metric units are to be regarded as the standard. The inch-pound units given in parentheses

are for information only.

1.6 The following safety hazards caveat pertains only to the test method portion Section 7 of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to

use.

2. Referenced Documents

2.1 Reference to these documents shall be the latest issue unless otherwise specified by the authority applying this specification:

2.2 ASTM Standards:

B117 Practice for Operating Salt Spray (Fog) Apparatus

C 162 Terminology of Glass &and Glass Products

C 1036 Specification for Flat Glass

E 903 Test Method for Solar Absorptance, Reflectance, and Transmittance of Materials Using Integrating Spheres

3. Terminology

3.1 Definitions—Refer to Terminology C 162 and the standards referenced in 2.2 as appropriate.

3.1.1 associated distortion, n—alteration of viewed images cause by variations in glass flatness in inhomogeneous portions

within the glass.

3.1.2 blemishes—an imperfections in the body or on the surface of the mirror. For the purpose of this specification blemishes

are divided into 2 categories:

3.1.1.1point blemishes—knots, dirt, stones, gaseous inclusions (seeds and bubbles), tin particles, crush and other similar

imperfections.

3.1.1.2—imperfections in the body, on the surface or in the silver coating of the mirror; for the purpose of this specification

blemishes are divided into 3 categories:

3.1.2.1 linear blemishes—scratches, rubs, digs and other similar imperfections.

3.1.2—scratches, rubs, digs, and other similar imperfections on either surface of the glass substrate.

3.1.2.2 point blemishes—crush, knots, dirt, stones, gaseous inclusions (seeds and bubbles), tin particles, and other similar

imperfections in the body of the glass substrate.

3.1.2.3 silver film blemishes—visible clouding, spot silver faults and other similar imperfections of the silver coating.

3.1.3 chip—an imperfection on the edge of a mirror lite due to breakage of a small fragment out of an otherwise regular surface.

1

This specification is under the jurisdiction ofASTM Committee C14 on Glass and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat Glass.

Current edition approved June 10, 2001. Published August 2001.

Current edition approved Oct. 1, 2008. Published January 2009. Originally approved in 2001. Last previous edition approved in 2001 as C 1503–01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1503–08

3.1.2.1

3.1.3.1 shell chip—a circular indentation in the mirror edge due to breakage of a small fragment.

3.1.2.2

3.1.3.2 v-chip—a V-shaped chip indentation in the mirror edge due to breakage of a small fragment.

3.1.2.3

3.1.3.3 chip width—the p

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C1503–01 Designation: C 1503 – 08

Standard Specification for

1

Silvered Flat Glass Mirror

This standard is issued under the fixed designation C 1503; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers the requirements for silvered flat glass mirrors of rectangular shape supplied as cut sizes, stock

sheets or as lehr ends and to which no further processing (such as edgework or other fabrication) has been done.

1.2 This specification covers the quality requirements of silvered annealed monolithic clear and tinted flat glass mirrors up to

1

6mm( ⁄4 in.) thick. The mirrors are intended to be used indoors for mirror glazing, for components of decorative accessories or

for similar uses.

1.3 This specification does not address safety glazing materials nor requirements for mirror applications. Consult model

building codes and other applicable standards for safety glazing applications.

1.4 Mirrors covered in this specification are not intended for use in environments where high humidity or airborne corrosion

promoters, or both, are consistently present (such as swimming pool areas, ocean-going vessels, chemical laboratories and other

corrosive environments).

1.5 The dimensional values stated in metric units are to be regarded as the standard. The inch-pound units given in parentheses

are for information only.

1.6 The following safety hazards caveat pertains only to the test method portion Section 7 of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety and health practices and determine the applicability of regulatory requirements prior to

use.

2. Referenced Documents

2.1 Reference to these documents shall be the latest issue unless otherwise specified by the authority applying this specification:

2.2 ASTM Standards:

B117 Practice for Operating Salt Spray (Fog) Apparatus

C 162 Terminology of Glass &and Glass Products

C 1036 Specification for Flat Glass

E 903 Test Method for Solar Absorptance, Reflectance, and Transmittance of Materials Using Integrating Spheres

3. Terminology

3.1 Definitions—Refer to Terminology C 162 and the standards referenced in 2.2 as appropriate.

3.1.1 associated distortion, n—alteration of viewed images cause by variations in glass flatness in inhomogeneous portions

within the glass.

3.1.2 blemishes—an imperfections in the body or on the surface of the mirror. For the purpose of this specification blemishes

are divided into 2 categories:

3.1.1.1point blemishes—knots, dirt, stones, gaseous inclusions (seeds and bubbles), tin particles, crush and other similar

imperfections.

3.1.1.2—imperfections in the body, on the surface or in the silver coating of the mirror; for the purpose of this specification

blemishes are divided into 3 categories:

3.1.2.1 linear blemishes—scratches, rubs, digs and other similar imperfections.

3.1.2—scratches, rubs, digs, and other similar imperfections on either surface of the glass substrate.

3.1.2.2 point blemishes—crush, knots, dirt, stones, gaseous inclusions (seeds and bubbles), tin particles, and other similar

imperfections in the body of the glass substrate.

3.1.2.3 silver film blemishes—visible clouding, spot silver faults and other similar imperfections of the silver coating.

3.1.3 chip—an imperfection on the edge of a mirror lite due to breakage of a small fragment out of an otherwise regular surface.

1

This specification is under the jurisdiction ofASTM Committee C14 on Glass and Glass Products and is the direct responsibility of Subcommittee C14.08 on Flat Glass.

Current edition approved June 10, 2001. Published August 2001.

Current edition approved Oct. 1, 2008. Published January 2009. Originally approved in 2001. Last previous edition approved in 2001 as C 1503–01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C1503–08

3.1.2.1

3.1.3.1 shell chip—a circular indentation in the mirror edge due to breakage of a small fragment.

3.1.2.2

3.1.3.2 v-chip—a V-shaped chip indentation in the mirror edge due to breakage of a small fragment.

3.1.2.3

3.1.3.3 chip width—the p

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.