ASTM F15-04(2009)

(Specification)Standard Specification for Iron-Nickel-Cobalt Sealing Alloy

Standard Specification for Iron-Nickel-Cobalt Sealing Alloy

ABSTRACT

This specification covers an iron-nickel-cobalt alloy for use in sealing to glass in electronic applications. The alloy shall conform to the chemical composition specified and shall be manufactured in the form of wire, rod, bar, strip, sheet, and tube, with each form available in the specified temper condition. For example, tubes shall be bright annealed and supplied in the annealed temper condition. Strip and sheet shall be of temper A, B, C, D, or E or in deep-drawing temper condition, while wire and rod shall be bright annealed and supplied in temper A condition unless specified otherwise. The material shall be smooth, uniform in cross section, composition, and temper, and free of scale, corrosion, cracks, seams, scratches, slivers, and other defects. Tests for hardness, tensile strength, thermal expansion, and transformation shall be performed and shall conform to the requirements specified.

SCOPE

1.1 This specification covers an iron-nickel-cobalt alloy, UNS K94610 containing nominally 29 % nickel, 17 % cobalt, and 53 % iron, in the forms of wire, rod, bar, strip, sheet, and tubing, intended primarily for sealing to glass in electronic applications.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 The following hazard caveat pertains only to the test method portion, Sections 13 and 14 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F15 −04(Reapproved 2009)

Standard Specification for

Iron-Nickel-Cobalt Sealing Alloy

ThisstandardisissuedunderthefixeddesignationF15;thenumberimmediatelyfollowingthedesignationindicatestheyearoforiginal

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F14Practice for Making andTesting Reference Glass-Metal

Bead-Seal

1.1 This specification covers an iron-nickel-cobalt alloy,

F140Practice for Making Reference Glass-Metal Butt Seals

UNS K94610 containing nominally 29% nickel, 17% cobalt,

and Testing for Expansion Characteristics by Polarimetric

and 53% iron, in the forms of wire, rod, bar, strip, sheet, and

Methods

tubing, intended primarily for sealing to glass in electronic

F144Practice for Making Reference Glass-Metal Sandwich

applications.

Seal and Testing for Expansion Characteristics by Polari-

1.2 Thevaluesstatedininch-poundunitsaretoberegarded

metric Methods

as the standard. The values given in parentheses are for

information only.

3. Ordering Information

1.3 The following hazard caveat pertains only to the test

3.1 Ordersformaterialunderthisspecificationshallinclude

method portion, Sections 13 and 14 of this specification. This

the following information:

standard does not purport to address all of the safety concerns,

3.1.1 Size,

if any, associated with its use. It is the responsibility of the user

3.1.2 Temper (Section 6),

of this standard to establish appropriate safety and health

3.1.3 Surface finish (Section 10),

practices and determine the applicability of regulatory limita-

3.1.4 Marking and packaging (Section 17), and

tions prior to use.

3.1.5 Certification if required.

2. Referenced Documents

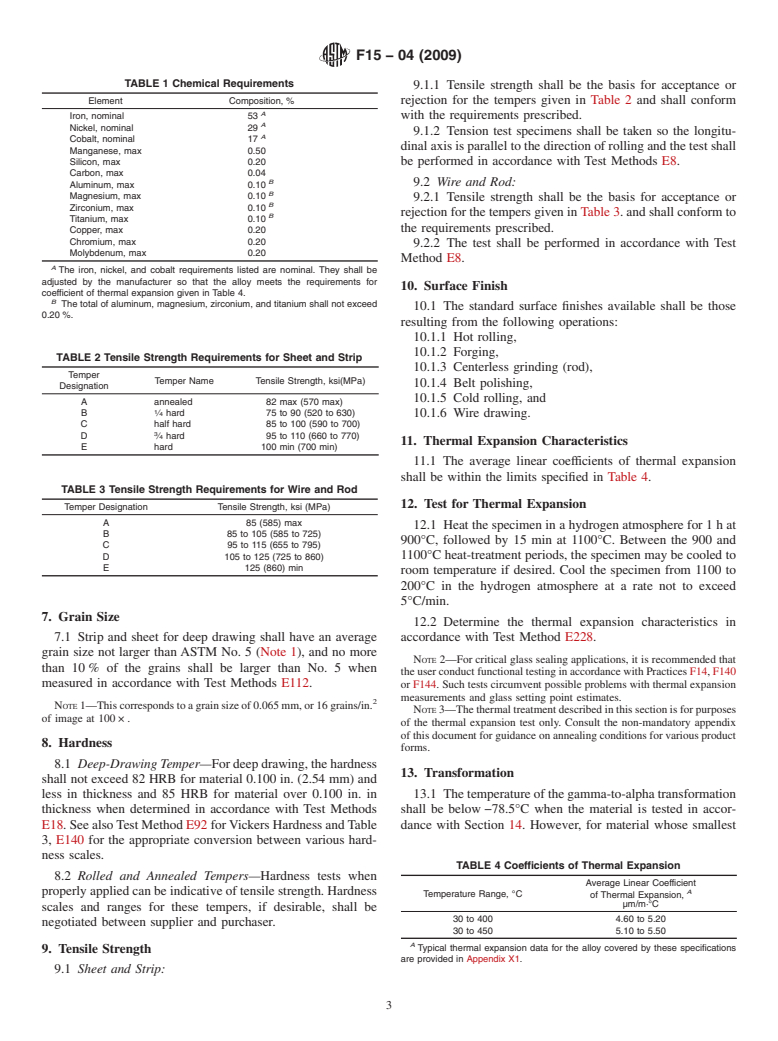

4. Chemical Requirements

2.1 ASTM Standards:

4.1 The material shall conform to the requirements as to

E3Guide for Preparation of Metallographic Specimens

chemical composition prescribed in Table 1.

E8Test Methods for Tension Testing of Metallic Materials

E18Test Methods for Rockwell Hardness of Metallic Ma-

5. Surface Lubricants

terials

5.1 All lubricants used during cold-working operations,

E92TestMethodforVickersHardnessofMetallicMaterials

such as drawing, rolling, or spinning, shall be capable of being

(Withdrawn 2010)

removed readily by any of the common organic degreasing

E112Test Methods for Determining Average Grain Size

solvents.

E140Hardness Conversion Tables for Metals Relationship

Among Brinell Hardness, Vickers Hardness, Rockwell

6. Temper

Hardness, Superficial Hardness, Knoop Hardness, and

Scleroscope Hardness

6.1 The desired temper of the material shall be specified in

E228Test Method for Linear Thermal Expansion of Solid

the purchase order.

Materials With a Push-Rod Dilatometer

6.2 Tube—Unless otherwise agreed upon by the supplier or

manufacturer and the purchaser, these forms shall be given a

final bright anneal by the manufacturer and supplied in the

This specification is under the jurisdiction of ASTM Committee F01 on

Electronics and is the direct responsibility of Subcommittee F01.03 on Metallic

annealed temper.

Materials.

6.3 Strip and Sheet— These forms shall be supplied in one

Current edition approved Dec. 1, 2009. Published December 2009. Originally

approved in 1961 as F15–61T. Last previous edition approved in 2004 as

of the tempers given in Table 2 or in deep-drawing temper, as

F15–04(2009). DOI: 10.1520/F0015-04R09.

specified.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.4 Wire and Rod—These forms shall be supplied in one of

Standards volume information, refer to the standard’s Document Summary page on

the tempers given in Table 3 as specified. Unless otherwise

the ASTM website.

specified, the material shall be bright annealed and supplied in

The last approved version of this historical standard is referenced on

www.astm.org. temper A (annealed).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F15−04 (2009)

150×

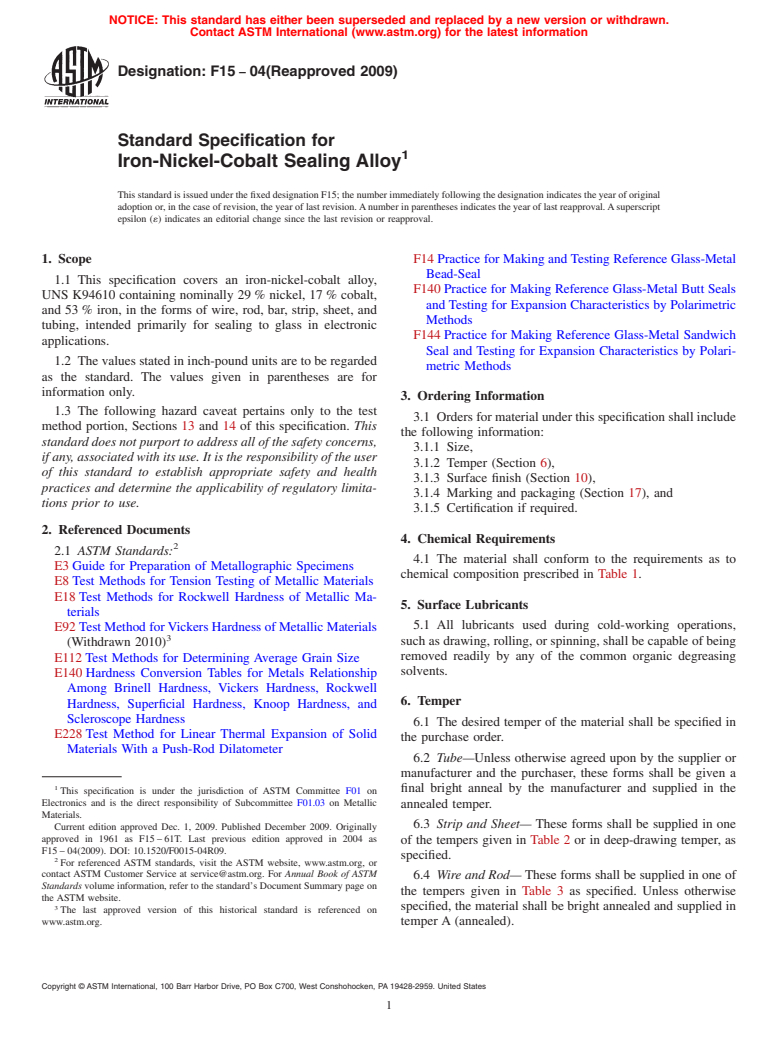

FIG. 1 Normal Annealed Specimen Showing No Transformation

150×

FIG. 2 Partially Transformed Specimen

F15−04 (2009)

TABLE 1 Chemical Requirements

9.1.1 Tensile strength shall be the basis for acceptance or

Element Composition, % rejection for the tempers given in Table 2 and shall conform

A

Iron, nominal 53 with the requirements prescribed.

A

Nickel, nominal 29

9.1.2 Tension test specimens shall be taken so the longitu-

A

Cobalt, nominal 17

dinalaxisisparalleltothedirectionofrollingandthetestshall

Manganese, max 0.50

Silicon, max 0.20 be performed in accordance with Test Methods E8.

Carbon, max 0.04

B

9.2 Wire and Rod:

Aluminum, max 0.10

B

Magnesium, max 0.10

9.2.1 Tensile strength shall be the basis for acceptance or

B

Zirconium, max 0.10

rejectionforthetempersgiveninTable3.andshallconformto

B

Titanium, max 0.10

the requirements prescribed.

Copper, max 0.20

Chromium, max 0.20

9.2.2 The test shall be performed in accordance with Test

Molybdenum, max 0.20

Method E8.

A

The iron, nickel, and cobalt requirements listed are nominal. They shall be

adjusted by the manufacturer so that the alloy meets the requirements for

10. Surface Finish

coefficient of thermal expansion given in Table 4.

B

The total of aluminum, magnesium, zirconium, and titanium shall not exceed

10.1 The standard surface finishes available shall be those

0.20 %.

resulting from the following operations:

10.1.1 Hot rolling,

10.1.2 Forging,

TABLE 2 Tensile Strength Requirements for Sheet and Strip

10.1.3 Centerless grinding (rod),

Temper

Temper Name Tensile Strength, ksi(MPa)

10.1.4 Belt polishing,

Designation

10.1.5 Cold rolling, and

A annealed 82 max (570 max)

B ⁄4 hard 75 to 90 (520 to 630)

10.1.6 Wire drawing.

C half hard 85 to 100 (590 to 700)

D ⁄4 hard 95 to 110 (660 to 770)

11. Thermal Expansion Characteristics

E hard 100 min (700 min)

11.1 The average linear coefficients of thermal expansion

shall be within the limits specified in Table 4.

TABLE 3 Tensile Strength Requirements for Wire and Rod

12. Test for Thermal Expansion

Temper Designation Tensile Strength, ksi (MPa)

A 85 (585) max

12.1 Heat the specimen in a hydrogen atmosphere for1hat

B 85 to 105 (585 to 725)

900°C, followed by 15 min at 1100°C. Between the 900 and

C 95 to 115 (655 to 795)

1100°C heat-treatment periods, the specimen may be cooled to

D 105 to 125 (725 to 860)

E 125 (860) min

room temperature if desired. Cool the specimen from 1100 to

200°C in the hydrogen atmosphere at a rate not to exceed

5°C/min.

7. Grain Size

12.2 Determine the thermal expansion characteristics in

7.1 Strip and sheet for deep drawing shall have an average accordance with Test Method E228.

grain size not larger thanASTM No. 5 (Note 1), and no more

NOTE 2—For critical glass sealing applications, it is recommended that

than 10% of the grains shall be larger than No. 5 when

theuserconductfunctionaltestinginaccordancewithPracticesF14,F140

measured in accordance with Test Methods E112.

or F144. Such tests circumvent possible problems with thermal expansion

measurements and glass setting point estimates.

NOTE1—Thiscorrespondstoagrainsizeof0.065mm,or16grains/in.

NOTE3—Thethermaltreatmentdescribedinthissectionisforpurposes

of image at 100×.

of the thermal expansion test only. Consult the non-mandatory appendix

ofthisdocumentforguidanceonannealingconditionsforvariousproduct

8. Hardness

forms.

8.1 Deep-Drawing Temper—Fordeepdrawing,thehardness

13. Transformation

shall not exceed 82 HRB for material 0.100 in. (2.54 mm) and

less in thickness and 85 HRB for material over 0.100 in. in 13.1 Thetemperatureofthegamma-to-alphatransformation

thickness when determined in accordance with Test Methods shall be below−78.5°C when the material is tested in accor-

E18.SeealsoTestMethodE92forVickersHardnessandTable dance with Section 14. However, for material whose smallest

3, E140 for the appropriate conversion between various hard-

ness scales.

TABLE 4 Coefficients of Thermal Expansion

8.2 Rolled and Annealed Tempers—Hardness tests when

Average Linear Coefficient

A

properlyappliedcanbeindicativeoftensilestrength.Hardness

Temperature Range, °C of Thermal Expansion,

µm/m·°C

scales and ranges for these tempers, if desirable, shall be

30 to 400 4.60 to 5.20

negotiated between supplier and purchaser.

30 to 450 5.10 to 5.50

A

Typical thermal expansion data for the alloy covered by these specifications

9. Tensile Strength

are provided in Appendix X1.

9.1 Sheet and Strip:

F15−04 (2009)

dimension is over ⁄8 in. (22.2 mm), some localized transfor- Table 6, and Table 7.

mation, acceptable to the purchaser, may be tolerated.

15.2 Round Wire and Rod—Wire and rod shall conform to

NOTE 4—Lower transformation temperatures, ranging to as low as

the permissible variations in dimensions prescribed in Table 8.

−196°C, may be negotiated between supplier and purchaser. The −196°C

transformation temperature corresponds to immersing a sample (prepared

15.3 Cold-Drawn Tubing—Cold-drawntubing,availableei-

according to 14.1) in liquid nitrogen for a minimum of 1 h.

ther as seamless or welded, shall conform to the permissible

variations prescribed in Table 9.

14. Test for Transformation

14.1 Cut the specimen from any part of the material, but

16. General Requirements

preferably including the entire cross section, degrease it, then

16.1 Thematerialshallbecommerciallysmooth,uniformin

heat treat it as described in 12.1. When cool, polish the cross

cross section, in composition, and in temper; it shall be free of

sectionofthespecimenandetch(Note5)itinaccordancewith

scale, corrosion, cracks, seams, scratches, slivers, and other

Method E3. Then subject the specimen to the temperature

defects as best commercial practice will permit.

produced by an excess of dry ice in acetone (−78.5°C) for at

least 4 h. After the low-temperature treatment, examine the

17. Packaging and Marking

specimen at a mangification of 150× for the presence of the

17.1 Packaging shall be subject to agreement between the

acicular crystals characteristic of the alpha phase. Because

purchaser and the seller.

thesecrystalsmayoccuronlyinsmalllocalizedareas,examine

carefully the entire polished cross section.

17.2 The material as furnished under this specification shall

beidentifiedbythenameorsymbolofthemanufacturerandby

14.2 Specimens that show no transformation and that show

melt number.The lot size for determining compliance with the

partial transformation are illustrated in Fig. 1 and Fig. 2,

requirements of this specification shall be one heat.

respectively.

NOTE 5—Asuggested etchant is a solution of three parts by volume of

18. Investigation of Claims

concentrated hydrochloric acid and one part of concentrated nitric acid

18.1 Where any material fails to meet the requirements of

saturated with cupric chloride (CuCl ·2H O). This etchant is more

2 2

effective when allowed to stand for 20 min after mixing. After several

thisspecification,thematerialsodesignatedshallbehandledin

hours it loses its strength and should be discarded at the end of the day.

accordance with a mutual agreement between the purchaser

Etching is best accomplished by swabbing the specimen with cotton

and the seller.

soaked with the etchant. Etching is usually complete when the surface of

the metal appears to have turned dull.

19. Keywords

15. Dimensions and Permissible Variations

19.1 controlled expansion alloy; glass to metal sealing;

15.1 Cold-Rolled Strip—Cold-rolled strip shall conform to iron-nickel-cobalt alloy; UNS #K94610; vacuum electronic

the permissible variations in dimensions prescribed in Table 5, applications

TABLE 5 Permissible Variations in Thickness of Cold-Rolled Strip

NOTE 1— Measurement shall be made at least ⁄8 in. (9.5 mm) from the edge of strip over 1 in. (25.4 mm) wide.

Permissible Variations in Thickness for Width Given, ± in. (mm)

Specified Thickness, in. (mm)

Under 3 (76) Over 3 to 6 (76 to 152) Over 6 to 12 (152 to 305) Over 12 to 16 (305 to 406)

0.160 to 0.100 (4.06 to 2.54), incl 0.002 (0.051) 0.003 (0.076) 0.004 (0.102) 0.004 (0.102)

0.099 to 0.069 (2.51 to 1.75), incl 0.002 (0.051) 0.003 (0.076) 0.003 (0.076) 0.004 (0.102)

0.068 to 0.050 (1.73 to 1.27), incl 0.002 (0.051) 0.003 (0.076) 0.003 (0.076) 0.003 (0.076)

0.049 to 0.035 (1.24 to 0.89), incl 0.002 (0.051) 0.0025 (0.064) 0.003 (0.076) 0.003 (0.076)

0.034 to 0.029 (0.86 to 0.74), incl 0.0015 (0.038) 0.002 (0.051) 0.0025 (0.064) 0.0025 (0.064)

0.028 to 0.026 (0.71 to 0.66), incl 0.0015 (0.038) 0.0015 (0.038) 0.002 (0.051) 0.002 (0.051)

0.025 to 0.020 (0.64 to 0.51), incl 0.001 (0.025) 0.0015 (0.038) 0.002 (0.051) 0.002 (0.051)

0.019 to 0.017 (0.48 to 0.43), incl 0.001 (0.025) 0.001 (0.025) 0.0015 (0.038) 0.002 (0.051)

0.016 to 0.012 (0.41 to 0.31), incl 0.001 (0.025) 0.001 (0.025) 0.0015 (0.038) 0.0015 (0.038)

0.011 to 0.0101 (0.28 to 0.26), incl 0.001 (0.025) 0.001 (0.025) 0.001 (0.025) 0.0015 (0.038)

0.010 to 0.0091 (0.25 to 0.23), incl 0.001 (0.025) 0.001 (0.025) 0.001 (0.025) 0.001 (0.025)

0.009 to 0.006 (0.23 to 0.15), incl 0.00075 (0.019) 0.00075 (0.019) . .

Under 0.006 (0.15) 0.0005 (0.013) 0.0005 (0.013) . .

F15−04 (2009)

TABLE 6 Permissible Variations in Thickness Across Width of Strip

Maximum Variation in Thickness Across Width of Strip, Within Those Provided for in

Specified Thickness

Table 4 for Edge Measurements for Widths and Thicknesses Given, in. (mm)

Over 12 to 24 (300 to

5 (127) and Under Over 5 to 12 (127 to 300)

in. mm 600), incl

in. mm in. mm in. mm

0.005 to 0.010, incl 0.17 to 0.03, incl 0.00075 0.0191 0.001 0.025 0.0015 0.038

Over 0.010 to 0.025, incl 0.03 to 0.06, incl 0.001 0.025 0.0015 0.038 0.002 0.051

Over 0.025 to 0.065, incl 0.06 to 0.16, incl 0.0015 0.038 0.002 0.051 0.0025 0.064

Over 0.065 to ⁄16 , excl 0.16 to 0.48, excl 0.002 0.051 0.0025 0.064 0.003 0.076

TABLE 7 Permissible Variations in Width of Cold-Rolled Strip Supplied in Coils

Permissible Variations in Width for Widths Given, ± in. (mm)

Specified Thickness, in. (mm) 1 3 1 15

Under ⁄2 to ⁄16 ⁄2to6(12.7to Over 6 to 9 (152 Over 9 to 12 (229 Over 12 to 20 Over 20 to 23 ⁄16

(12.7to4.8) 152) to 229) to 305) (305 to 508) (508 to 608)

0.187 to 0.161 (4.75 to 4.09) . 0.016 (0.41) 0.020 (0.51) 0.020 (0.51) 0.031 (0.79) 0.031 (0.79)

0.160 to 0.100 (4.06 to 2.54) 0.010 (0.25) 0.010 (0.25) 0.016 (0.41) 0.016 (0.41) 0.020 (0.51) 0.020 (0.51)

0.099 to 0.069 (2.51 to 1.75) 0.008 (0.20) 0.008 (0.20) 0.010 (0.25) 0.010 (0.25) 0.016 (0.41) 0.020 (0.51)

0.068 (1.73) and under 0.005 (0.13) 0.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.