ASTM E768-99(2010)

(Practice)Standard Guide for Preparing and Evaluating Specimens for Automatic Inclusion Assessment of Steel

Standard Guide for Preparing and Evaluating Specimens for Automatic Inclusion Assessment of Steel

SIGNIFICANCE AND USE

Inclusion ratings done either manually using Test Methods E45 or automatically using Practice E1122 or E1245 are influenced by the quality of specimen preparation. This guide provides examples of proven specimen preparation methods that retain inclusions in polished steel specimens.

This guide provides a procedure to determine if the prepared specimens are of suitable quality for subsequent rating of inclusions. None of these methods should be construed as defining or establishing specific procedures or limits of acceptability for any steel grade.

SCOPE

1.1 This guide covers two preparation methods for steel metallographic specimens that will be analyzed for nonmetallic inclusions with automatic image analysis (AIA) equipment. The two methods of preparation are offered as accepted methods used to retain nonmetallic inclusions in steel. This guide does not limit the user to these methods.

1.2 A procedure to test the suitability of the prepared specimen for AIA inclusion work, using differential interference contrast (DIC), is presented.

1.3 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E768 − 99(Reapproved 2010)

Standard Guide for

Preparing and Evaluating Specimens for Automatic

1

Inclusion Assessment of Steel

This standard is issued under the fixed designation E768; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

5

1. Scope 2.2 ASTM Adjuncts:

2 ADJE0768 Differential Interference Contrast Magnification

1.1 This guide covers two preparation methods for steel

100X and 500X (6 micrographs)

metallographicspecimensthatwillbeanalyzedfornonmetallic

inclusions with automatic image analysis (AIA) equipment.

3. Terminology

The two methods of preparation are offered as accepted

3.1 Definitions:

methods used to retain nonmetallic inclusions in steel. This

3.1.1 For definitions used in this practice, refer to Termi-

guide does not limit the user to these methods.

nology E7.

1.2 A procedure to test the suitability of the prepared

3.1.2 differential interference contrast microscopy—a com-

specimen for AIA inclusion work, using differential interfer-

prehensive definition appears in Guide E883, paragraph 11.8.

ence contrast (DIC), is presented.

3.2 Definitions of Terms Specific to This Standard:

1.3 The values stated in SI units are to be regarded as

3.2.1 rigid grinding disk—a non-fabric support surface,

standard. No other units of measurement are included in this

such as a composite of metal/ceramic or metal/polymer,

standard.

charged with an abrasive (usually 6 to 15-µm diamond

particles), and used as the fine grinding operation in a metal-

2. Referenced Documents

lographic preparation procedure.

3

2.1 ASTM Standards:

4. Significance and Use

E3Guide for Preparation of Metallographic Specimens

E7Terminology Relating to Metallography 4.1 Inclusion ratings done either manually usingTest Meth-

E45Test Methods for Determining the Inclusion Content of

ods E45 or automatically using Practice E1122 or E1245 are

Steel influenced by the quality of specimen preparation. This guide

E883Guide for Reflected–Light Photomicrography

provides examples of proven specimen preparation methods

E1122Practice for Obtaining JK Inclusion Ratings Using that retain inclusions in polished steel specimens.

4

Automatic Image Analysis (Withdrawn 2006)

4.2 This guide provides a procedure to determine if the

E1245Practice for Determining the Inclusion or Second-

prepared specimens are of suitable quality for subsequent

Phase Constituent Content of Metals byAutomatic Image

rating of inclusions. None of these methods should be con-

Analysis

strued as defining or establishing specific procedures or limits

of acceptability for any steel grade.

1

ThisguideisunderthejurisdictionofASTMCommitteeE04onMetallography

5. Preparation Methods

and is the direct responsibility of Subcommittee E04.01 on Specimen Preparation.

Current edition approved Nov. 1, 2010. Published January 2011. Originally

5.1 Background:

approved in 1999. Last previous edition approved in 2005 as E768–99(2005). DOI:

5.1.1 The inclusions in the plane of polish must be fully

10.1520/E0768-99R10.

2

preserved and clearly visible. Preparation should not produce

Supporting data have been filed atASTM International Headquarters and may

be obtained by requesting Research Report RR:E04-1002.

excessive relief around the perimeter of the inclusions that

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

would exaggerate the size and number of inclusions on the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

5

the ASTM website. Acolored plate, consisting of six micrographs that illustrate the use of DIC in

4

The last approved version of this historical standard is referenced on determining a properly prepared sample (at 100x and 500x), is available from

www.astm.org. ASTM Headquarters. Order Adjuct: ADJE0768.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

E768 − 99 (2010)

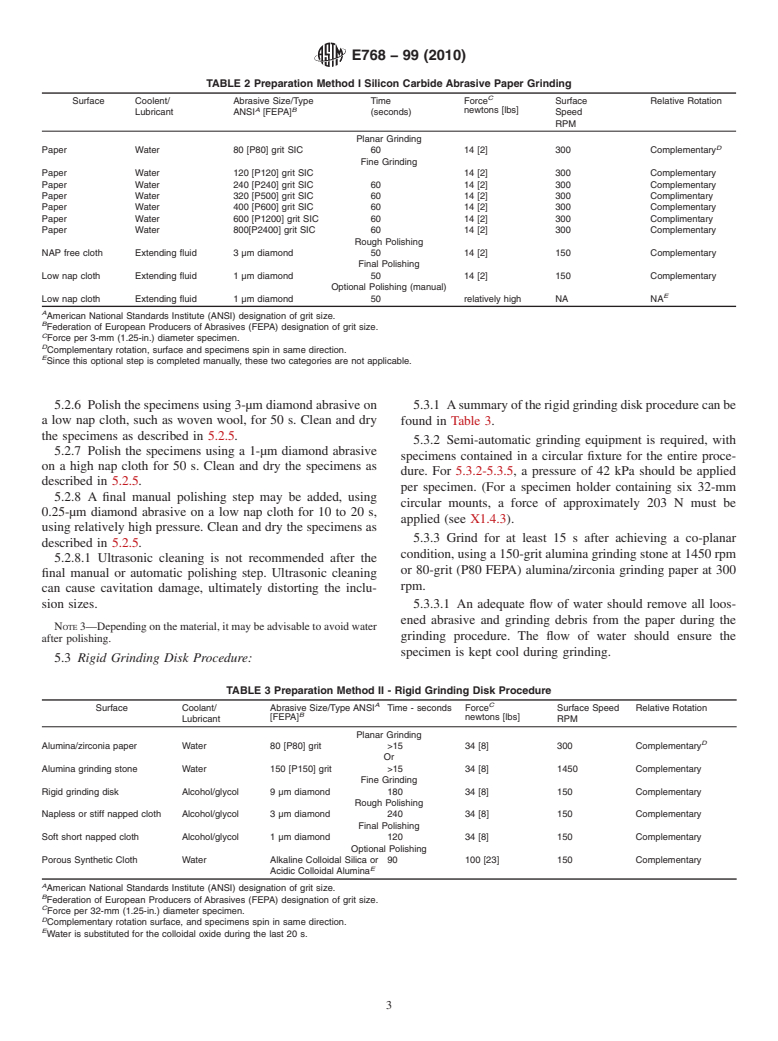

TABLE 1 Comparison of ANSI (CAMI) versus FEPA versus

plane of polish. In many cases, the preparation of specimens

Median Diameter of Grit Size in Micrometers

for inclusion rating is more readily performed after the

A B C

ANSI (CAMI) FEPA Approximate Median

specimens have been hardened by a suitable heat treatment

Diameter

procedure (austenize, quench to fully martensitic structure,

(µm)

temper at a relatively low temperature).

60 P60 250

80 P80 180

5.1.2 Cleanliness is an important consideration in all stages

100 P100 150

of specimen preparation.

120 P120 125

5.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.