ASTM E2142-08(2015)

(Test Method)Standard Test Methods for Rating and Classifying Inclusions in Steel Using the Scanning Electron Microscope

Standard Test Methods for Rating and Classifying Inclusions in Steel Using the Scanning Electron Microscope

SIGNIFICANCE AND USE

5.1 This test method is established to cover automated SEM/EDX-based procedures for:

5.1.1 Rating the inclusion content of steels based on procedures listed in Standards E45 and E1245, with the significant difference that the composition of the individual inclusions, as determined by X-ray analysis, is utilized to sort them into chemical classes.

5.1.2 Determining the number, size and morphological distribution of inclusions in steels sorted by chemical class.

5.2 Methods 1 and 2 of this test method are primarily intended for rating the inclusion content of steels deoxidized with silicon or aluminum, both silicon and aluminum, or vacuum-treated steels without either silicon or aluminum additions. Guidelines are provided to rate inclusions in steel treated with rare earth additions or calcium-bearing compounds (13.4). When such steels are evaluated, the test report should describe the nature of the inclusions rated according to each inclusion category (A, B, C, D).

5.3 Methods 1 and 2 will provide a quantitative rating of the inclusion content in half-severity number increments from 0 to 5 for each inclusion type and thickness (Method D of Test Method E45), and in tabulated in Table 2. Test Method E45 ratings by SEM may differ from those determined following E45 because of the use of chemistry in the classifications. In order to differentiate E45 ratings obtained using the SEM from traditional ratings using light microscopy, the ratings obtained using Method 1 or 2 of this Test Method shall be identified as E45-SEM1 and E45-SEM2, respectively.

5.4 Method 3 defines procedures to analyze and report inclusions by arbitrary size distribution and chemical classifications. It may be made applicable to any material by appropriate choice of these classifications.

5.4.1 Method 3 determines and reports basic (as used in Test Method E1245) stereological measurements (for example, volume fraction of sulfides and oxides, the number of sulfides or oxides per sq...

SCOPE

1.1 This test method covers procedures to obtain particle size distribution, chemical classification, and Test Methods E45 ratings of inclusions in steels using an automated scanning electron microscope (SEM) with X-ray analysis and automatic image analysis capabilities.

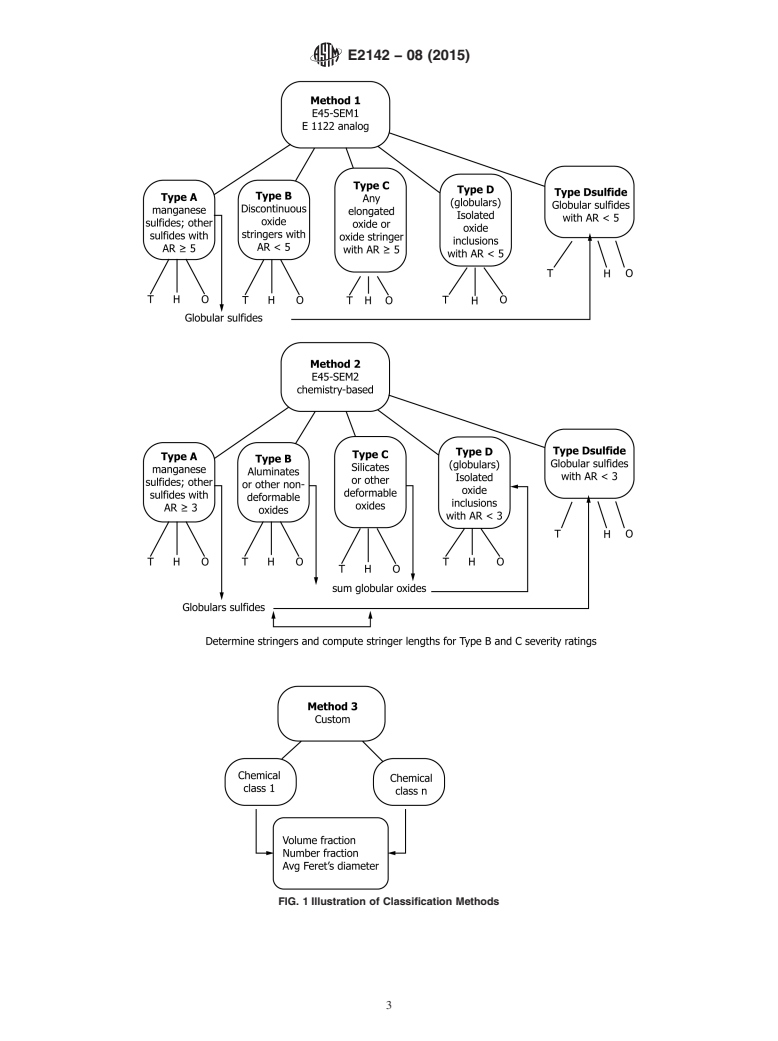

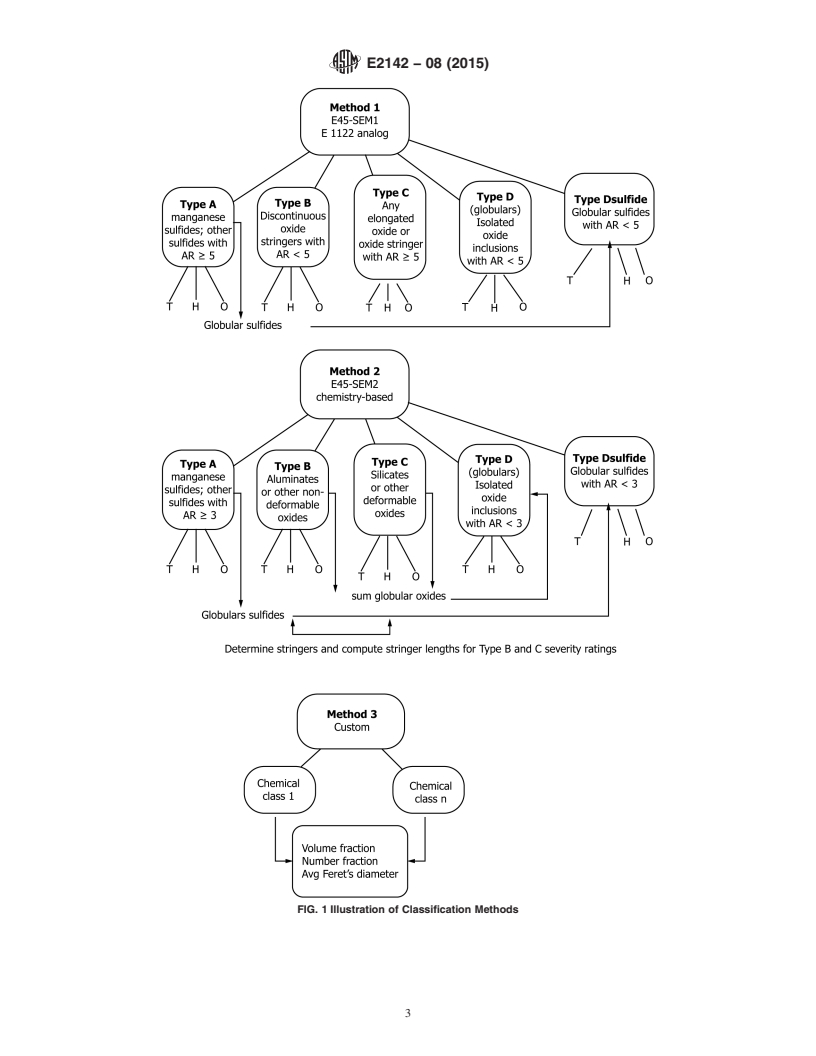

1.2 There are three discrete methods described. Method 1 is the SEM analog of Test Method E45, which uses image analysis and light microscopy to produce automated Test Methods E45 ratings. Method 2 produces similar ratings based predominantly on sorting inclusions by chemistry into the traditional classes defined in Test Methods E45. Method 3 is recommended when explicit detail is needed on particular inclusion types, not necessarily defined in Test Methods E45, such as to verify the composition of inclusions in inclusion-engineered steel. Method 3 reports stereological parameters such as volume or number fraction, rather than Test Methods E45 type ratings.

1.3 This test method deals only with the recommended test methods and nothing in it should be construed as defining or establishing limits of acceptability for any grade of steel or other alloy where the method is appropriate.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: E2142 − 08 (Reapproved 2015)

Standard Test Methods for

Rating and Classifying Inclusions in Steel Using the

Scanning Electron Microscope

This standard is issued under the fixed designation E2142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 This test method covers procedures to obtain particle

E3 Guide for Preparation of Metallographic Specimens

size distribution, chemical classification, and Test Methods

E7 Terminology Relating to Metallography

E45 ratings of inclusions in steels using an automated scanning

electron microscope (SEM) with X-ray analysis and automatic E45 Test Methods for Determining the Inclusion Content of

Steel

image analysis capabilities.

E766 Practice for Calibrating the Magnification of a Scan-

1.2 There are three discrete methods described. Method 1 is

ning Electron Microscope

the SEM analog of Test Method E45, which uses image

E768 Guide for Preparing and Evaluating Specimens for

analysis and light microscopy to produce automated Test

Automatic Inclusion Assessment of Steel

Methods E45 ratings. Method 2 produces similar ratings based

E1245 Practice for Determining the Inclusion or Second-

predominantly on sorting inclusions by chemistry into the

Phase Constituent Content of Metals by Automatic Image

traditional classes defined in Test Methods E45. Method 3 is

Analysis

recommended when explicit detail is needed on particular

E1508 Guide for Quantitative Analysis by Energy-

inclusion types, not necessarily defined in Test Methods E45,

Dispersive Spectroscopy

such as to verify the composition of inclusions in inclusion-

2.2 Adjuncts:

engineered steel. Method 3 reports stereological parameters

ANSI/IEEE STD 759 IEEE Standard Test Procedure for

such as volume or number fraction, rather than Test Methods

Semiconductor X-Ray Energy Spectrometers

E45 type ratings.

3. Terminology

1.3 This test method deals only with the recommended test

methods and nothing in it should be construed as defining or

3.1 Definitions—For definitions of terms used in this test

establishing limits of acceptability for any grade of steel or

method, see Terminology E7.

other alloy where the method is appropriate.

3.2 Definitions of Terms Specific to This Standard:

1.4 The values stated in SI units are to be regarded as 3.2.1 Analysis Rules—

standard. No other units of measurement are included in this

3.2.1.1 acquisition analysis rules—include the criteria to

standard.

terminate X-ray collection (counts or time, or both), the list of

1.5 This standard does not purport to address all of the elements to be analyzed, the number of fields or particles to be

safety concerns, if any, associated with its use. It is the analyzed, morphologies of particles from which spectra will be

responsibility of the user of this standard to establish appro- collected, etc. (see Appendix X1 for a more complete listing of

priate safety and health practices and determine the applica- typical Acquisition Rules).

bility of regulatory limitations prior to use.

3.2.1.2 post-acquisition analysis rules—define ratios of

X-ray intensities or elemental compositions required to identify

1 2

These test methods are under the jurisdiction of ASTM Committee E04 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Metallography and are the direct responsibility of Subcommittee E04.11 on X-Ray contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and Electron Metallography. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2015. Published November 2015. Originally the ASTM website.

approved in 2001. Last previous edition approved in 2008 as E2142–08. DOI: Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

10.1520/E2142-08R15.

445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2142 − 08 (2015)

an inclusion as belonging to a particular chemical classification vided as thin, heavy and oversized, according to their width

and, for Methods 1 and 2 herein, define the main inclusion (tabulated in Table 1). E45-equivalent ratings are determined

class (A, B, or C) to which each chemical classification and recorded, and reported particles are usually limited to those

belongs. ≥ 2 μm in size.

4.3.2 The inclusion classification strategy in Method 2 is

3.2.2 chemical classification—defined compositional cat-

based predominantly on chemistry, but uses morphology when

egories in which inclusions are placed according to the analysis

necessary, such as to classify Type D (globular) inclusions and

rules. Categories may be broad (for example, sulfide,

to compute severity ratings for Type B and C inclusions (which

aluminate, silicate) or more precise (for example, calcium

require determination of stringer lengths). Method 2 is based

sulfide, calcium silicate, anorthite, etc.).

on the underlying intention of Test Method E45, namely, that

3.2.3 critical aspect ratio—the aspect ratio of a single

Type A inclusions are deformable sulfides, Type B inclusions

inclusion that defines the boundary between “globular” and

are non-deformable oxides (typically alumina), and Type C

“elongated”.

inclusions are deformable oxides (typically silicates). Each

3.2.4 discontinuous stringer—two or more Type C or three

defined chemical class is assigned to one of these categories.

or more Type B inclusions aligned in a plane parallel to the hot

Once classifications are made based on chemistry, the globular

working axis and offset from the stringer centerline by no more

particles from each classification, or from designated

than 15 μm, with a separation of < 40 μm between any two

classifications, can be re-classified as Type D inclusions.

nearest neighbor inclusions.

E45-equivalent ratings are determined and recorded, and re-

3.2.5 stringer—an individual oxide inclusion that is highly ported particles are usually limited to those ≥ 2 μm in size.

4.3.3 Method 3 allows inclusions to be analyzed and re-

elongated in the deformation direction; or two or more Type C,

or three or more Type B, inclusions aligned in a plane parallel ported in a manner individualized to the material and applica-

tion of interest. It allows complete freedom in formulating

to the hot working axis and offset (from the stringer centerline)

by no more than 15 μm, with a separation of < 40 μm between chemical classes. Aspect ratio definitions can be chosen appro-

priately for the application. Termination of the analysis can be

any two nearest neighbor inclusions.

based on detecting a certain number of inclusions rather than

4. Summary of Test Method

sample area. Size and morphology distributions of all inclu-

sions by chemical class are determined. Indirect terminology

4.1 A properly prepared as-polished metallographic speci-

such as “Type A, B, C and D” and “thin” and “heavy” is not

men is mounted in a computer-controlled SEM equipped with

used; rather, inclusions are classified directly by chemical class

image analysis and X-ray analysis subsystems such that

and size range of interest. Particles may be further subdivided

inclusions intersecting the plane of polish can be imaged and

by morphology. Method 3, as in Practice E1245, reports basic

analyzed.

stereological parameters, such as volume and number fractions

4.2 During analysis, an inclusion is detected by its gray

of inclusions within each field, as well the maximum Feret’s

level in the back-scattered electron signal. Once detected, size

diameter for each inclusion. This method would be used for

parameters of the inclusion are automatically determined and

custom analyses, such to report all non-sulfide particles by

its X-ray spectrum collected. Particle morphology, chemistry,

thickness, as may be useful in tire cord applications.

and location are stored in the computer, allowing re-

examination of the data or the particle itself. In this manner, a

5. Significance and Use

complete or partial size distribution of inclusions by chemical

5.1 This test method is established to cover automated

class can be determined.

SEM/EDX-based procedures for:

4.3 There are three methods described (see Fig. 1):

5.1.1 Rating the inclusion content of steels based on proce-

4.3.1 Method 1 is most similar to Test Methods E45 which

dures listed in Standards E45 and E1245, with the significant

uses light microscopy, and is intended to be its SEM analog. As

difference that the composition of the individual inclusions, as

such, it uses morphology as the primary basis for sorting

determined by X-ray analysis, is utilized to sort them into

particles into classes. As in Test Methods E45, a critical aspect

chemical classes.

ratio of 2 is defined. Chemistry is used to identify sulfide

5.1.2 Determining the number, size and morphological dis-

inclusions and to discriminate among sulfides when more than

tribution of inclusions in steels sorted by chemical class.

one type is present, as well as to ensure that exogenous

5.2 Methods 1 and 2 of this test method are primarily

inclusions and surface scratches and debris are not included in

intended for rating the inclusion content of steels deoxidized

the ratings. Inclusions will be classified into four categories,

with silicon or aluminum, both silicon and aluminum, or

Types A, B, C and D as described in Test Methods E45.

vacuum-treated steels without either silicon or aluminum

Elongated sulfides are Type A. Other inclusions are oxides and

additions. Guidelines are provided to rate inclusions in steel

are classified as Types B, C or D, depending on their

treated with rare earth additions or calcium-bearing compounds

morphology, as follows: discontinuous stringers of three or

(13.4). When such steels are evaluated, the test report should

more inclusions with member particles having low aspect ratio

describe the nature of the inclusions rated according to each

are Type B; discontinuous stringers of two or more inclusions

inclusion category (A, B, C, D).

with member particles having high aspect ratio and single

elongated oxide inclusions are Type C; remaining isolated 5.3 Methods 1 and 2 will provide a quantitative rating of the

inclusions are Type D. The categories will be further subdi- inclusion content in half-severity number increments from 0 to

E2142 − 08 (2015)

FIG. 1 Illustration of Classification Methods

E2142 − 08 (2015)

TABLE 1 Inclusion Width Parameters

Thin Heavy Oversize

Inclusion Minimum Maximum Minimum Maximum Minimum

Type Width (μm) Width (μm) Width (μm) Width (μm) Width (μm)

A $2 4 >4 12 >12

B $2 9 >9 15 >15

C $2 5 >5 12 >12

D $2 8 >8 13 >13

5 for each inclusion type and thickness (Method D of Test Therefore, an automated stage, although not essential, is highly

Method E45), and in tabulated in Table 2. Test Method E45 recommended and is assumed throughout this document.

ratings by SEM may differ from those determined following 6.1.3 Energy Dispersive X-Ray (EDX) Analyzer. A “light

E45 because of the use of chemistry in the classifications. In element detector” (one equipped with a sufficiently thin win-

order to differentiate E45 ratings obtained using the SEM from dow to effectively transmit the low energy X rays characteristic

traditional ratings using light microscopy, the ratings obtained of the elements below sodium) is required if oxygen is to be

using Method 1 or 2 of this Test Method shall be identified as

discretely measured, or if analysis of carbides, borides, or

E45-SEM1 and E45-SEM2, respectively. nitrides is to be included. The EDX detector must have

resolution better than 155 eV as measured in accordance with

5.4 Method 3 defines procedures to analyze and report

ANSI/IEEE STD 759.

inclusions by arbitrary size distribution and chemical classifi-

6.1.4 Backscattered Electron Detector and electronics with

cations. It may be made applicable to any material by appro-

ability to set one or more thresholds to enable discrimination

priate choice of these classifications.

between inclusions and matrix.

5.4.1 Method 3 determines and reports basic (as used in Test

6.1.5 Control and Image Collection Software to control the

Method E1245) stereological measurements (for example,

beam and stage and to collect images and spectra according to

volume fraction of sulfides and oxides, the number of sulfides

user-specified parameters.

or oxides per square millimeter, and so forth). This test method,

however, does not address the measurement of such param-

6.2 Automated Feature-Analysis Software, capable of:

eters. E45 ratings are not produced in Method 3 because the

6.2.1 Allowing analysis rules to be set such that chemical

inclusion classifications do not follow those defined in Test

classifications can be made and features sorted according to

Method E45.

chemistry as well as size and morphology.

6.2.2 Distinguishing between elongated and globular par-

5.5 The quantitative results are intended to provide a de-

ticles based on aspect ratio.

scription of the types and amounts of inclusions in a heat of

6.2.3 Separating the stringered oxides according to the

steel. This test method contains no guidelines for such use.

difference in morphology (Type B or C) and measuring the

stringer lengths per field of each type.

6. Apparatus

6.2.4 Connecting stringers which cross field boundaries.

6.1 An automated computer-controlled Scanning Electron

6.2.5 Generating standardized reports.

Microscope equipped with the following accessories:

6.3 Special Considerations—The environment housing the

6.1.1 Digital Imaging hardware and software.

6.1.2 Computer-Controlled Motorized X-Y Stage. It is con- equipment must be controlled. Computer equipment, SEMs

and EDX systems all require control of temperature and

ceivable that the method described in this standard may be

performed without an automated stage. Performing this method humidity and the air must be relatively dust free.

with a manual stage will be tedious, and accuracy will suffer

due to difficulty in tracking inclusions across field boundaries. 7. Sampling

7.1 Sampling is done in accordance with the guidelines

given in Test Method E45.

TABLE 2 Minimum Values for Inclusion Severity Rating

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E2142 − 08 (Reapproved 2015)

Standard Test Methods for

Rating and Classifying Inclusions in Steel Using the

Scanning Electron Microscope

This standard is issued under the fixed designation E2142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers procedures to obtain particle 2.1 ASTM Standards:

size distribution, chemical classification, and Test Methods E3 Guide for Preparation of Metallographic Specimens

E45 ratings of inclusions in steels using an automated scanning E7 Terminology Relating to Metallography

electron microscope (SEM) with X-ray analysis and automatic E45 Test Methods for Determining the Inclusion Content of

image analysis capabilities. Steel

E766 Practice for Calibrating the Magnification of a Scan-

1.2 There are three discrete methods described. Method 1 is

ning Electron Microscope

the SEM analog of Test Method E45, which uses image

E768 Guide for Preparing and Evaluating Specimens for

analysis and light microscopy to produce automated Test

Automatic Inclusion Assessment of Steel

Methods E45 ratings. Method 2 produces similar ratings based

E1245 Practice for Determining the Inclusion or Second-

predominantly on sorting inclusions by chemistry into the

Phase Constituent Content of Metals by Automatic Image

traditional classes defined in Test Methods E45. Method 3 is

Analysis

recommended when explicit detail is needed on particular

E1508 Guide for Quantitative Analysis by Energy-

inclusion types, not necessarily defined in Test Methods E45,

Dispersive Spectroscopy

such as to verify the composition of inclusions in inclusion-

2.2 Adjuncts:

engineered steel. Method 3 reports stereological parameters

ANSI/IEEE STD 759 IEEE Standard Test Procedure for

such as volume or number fraction, rather than Test Methods

Semiconductor X-Ray Energy Spectrometers

E45 type ratings.

3. Terminology

1.3 This test method deals only with the recommended test

methods and nothing in it should be construed as defining or

3.1 Definitions—For definitions of terms used in this test

establishing limits of acceptability for any grade of steel or

method, see Terminology E7.

other alloy where the method is appropriate.

3.2 Definitions of Terms Specific to This Standard:

1.4 The values stated in SI units are to be regarded as

3.2.1 Analysis Rules—

standard. No other units of measurement are included in this

3.2.1.1 acquisition analysis rules—include the criteria to

standard.

terminate X-ray collection (counts or time, or both), the list of

1.5 This standard does not purport to address all of the

elements to be analyzed, the number of fields or particles to be

safety concerns, if any, associated with its use. It is the

analyzed, morphologies of particles from which spectra will be

responsibility of the user of this standard to establish appro-

collected, etc. (see Appendix X1 for a more complete listing of

priate safety and health practices and determine the applica-

typical Acquisition Rules).

bility of regulatory limitations prior to use.

3.2.1.2 post-acquisition analysis rules—define ratios of

X-ray intensities or elemental compositions required to identify

1 2

These test methods are under the jurisdiction of ASTM Committee E04 on For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Metallography and are the direct responsibility of Subcommittee E04.11 on X-Ray contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and Electron Metallography. Standards volume information, refer to the standard’s Document Summary page on

Current edition approved Oct. 1, 2015. Published November 2015. Originally the ASTM website.

approved in 2001. Last previous edition approved in 2008 as E2142–08. DOI: Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

10.1520/E2142-08R15.

445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2142 − 08 (2015)

an inclusion as belonging to a particular chemical classification vided as thin, heavy and oversized, according to their width

and, for Methods 1 and 2 herein, define the main inclusion (tabulated in Table 1). E45-equivalent ratings are determined

class (A, B, or C) to which each chemical classification and recorded, and reported particles are usually limited to those

belongs. ≥ 2 µm in size.

4.3.2 The inclusion classification strategy in Method 2 is

3.2.2 chemical classification—defined compositional cat-

based predominantly on chemistry, but uses morphology when

egories in which inclusions are placed according to the analysis

necessary, such as to classify Type D (globular) inclusions and

rules. Categories may be broad (for example, sulfide,

to compute severity ratings for Type B and C inclusions (which

aluminate, silicate) or more precise (for example, calcium

require determination of stringer lengths). Method 2 is based

sulfide, calcium silicate, anorthite, etc.).

on the underlying intention of Test Method E45, namely, that

3.2.3 critical aspect ratio—the aspect ratio of a single

Type A inclusions are deformable sulfides, Type B inclusions

inclusion that defines the boundary between “globular” and

are non-deformable oxides (typically alumina), and Type C

“elongated”.

inclusions are deformable oxides (typically silicates). Each

3.2.4 discontinuous stringer—two or more Type C or three

defined chemical class is assigned to one of these categories.

or more Type B inclusions aligned in a plane parallel to the hot

Once classifications are made based on chemistry, the globular

working axis and offset from the stringer centerline by no more

particles from each classification, or from designated

than 15 µm, with a separation of < 40 µm between any two

classifications, can be re-classified as Type D inclusions.

nearest neighbor inclusions.

E45-equivalent ratings are determined and recorded, and re-

ported particles are usually limited to those ≥ 2 µm in size.

3.2.5 stringer—an individual oxide inclusion that is highly

elongated in the deformation direction; or two or more Type C, 4.3.3 Method 3 allows inclusions to be analyzed and re-

ported in a manner individualized to the material and applica-

or three or more Type B, inclusions aligned in a plane parallel

to the hot working axis and offset (from the stringer centerline) tion of interest. It allows complete freedom in formulating

chemical classes. Aspect ratio definitions can be chosen appro-

by no more than 15 µm, with a separation of < 40 µm between

any two nearest neighbor inclusions. priately for the application. Termination of the analysis can be

based on detecting a certain number of inclusions rather than

4. Summary of Test Method

sample area. Size and morphology distributions of all inclu-

sions by chemical class are determined. Indirect terminology

4.1 A properly prepared as-polished metallographic speci-

such as “Type A, B, C and D” and “thin” and “heavy” is not

men is mounted in a computer-controlled SEM equipped with

used; rather, inclusions are classified directly by chemical class

image analysis and X-ray analysis subsystems such that

and size range of interest. Particles may be further subdivided

inclusions intersecting the plane of polish can be imaged and

by morphology. Method 3, as in Practice E1245, reports basic

analyzed.

stereological parameters, such as volume and number fractions

4.2 During analysis, an inclusion is detected by its gray

of inclusions within each field, as well the maximum Feret’s

level in the back-scattered electron signal. Once detected, size

diameter for each inclusion. This method would be used for

parameters of the inclusion are automatically determined and

custom analyses, such to report all non-sulfide particles by

its X-ray spectrum collected. Particle morphology, chemistry,

thickness, as may be useful in tire cord applications.

and location are stored in the computer, allowing re-

examination of the data or the particle itself. In this manner, a

5. Significance and Use

complete or partial size distribution of inclusions by chemical

5.1 This test method is established to cover automated

class can be determined.

SEM/EDX-based procedures for:

4.3 There are three methods described (see Fig. 1):

5.1.1 Rating the inclusion content of steels based on proce-

4.3.1 Method 1 is most similar to Test Methods E45 which

dures listed in Standards E45 and E1245, with the significant

uses light microscopy, and is intended to be its SEM analog. As

difference that the composition of the individual inclusions, as

such, it uses morphology as the primary basis for sorting

determined by X-ray analysis, is utilized to sort them into

particles into classes. As in Test Methods E45, a critical aspect

chemical classes.

ratio of 2 is defined. Chemistry is used to identify sulfide

5.1.2 Determining the number, size and morphological dis-

inclusions and to discriminate among sulfides when more than

tribution of inclusions in steels sorted by chemical class.

one type is present, as well as to ensure that exogenous

5.2 Methods 1 and 2 of this test method are primarily

inclusions and surface scratches and debris are not included in

intended for rating the inclusion content of steels deoxidized

the ratings. Inclusions will be classified into four categories,

with silicon or aluminum, both silicon and aluminum, or

Types A, B, C and D as described in Test Methods E45.

vacuum-treated steels without either silicon or aluminum

Elongated sulfides are Type A. Other inclusions are oxides and

additions. Guidelines are provided to rate inclusions in steel

are classified as Types B, C or D, depending on their

treated with rare earth additions or calcium-bearing compounds

morphology, as follows: discontinuous stringers of three or

(13.4). When such steels are evaluated, the test report should

more inclusions with member particles having low aspect ratio

describe the nature of the inclusions rated according to each

are Type B; discontinuous stringers of two or more inclusions

inclusion category (A, B, C, D).

with member particles having high aspect ratio and single

elongated oxide inclusions are Type C; remaining isolated 5.3 Methods 1 and 2 will provide a quantitative rating of the

inclusions are Type D. The categories will be further subdi- inclusion content in half-severity number increments from 0 to

E2142 − 08 (2015)

FIG. 1 Illustration of Classification Methods

E2142 − 08 (2015)

TABLE 1 Inclusion Width Parameters

Thin Heavy Oversize

Inclusion Minimum Maximum Minimum Maximum Minimum

Type Width (µm) Width (µm) Width (µm) Width (µm) Width (µm)

A $2 4 >4 12 >12

B $2 9 >9 15 >15

C $2 5 >5 12 >12

D $2 8 >8 13 >13

5 for each inclusion type and thickness (Method D of Test Therefore, an automated stage, although not essential, is highly

Method E45), and in tabulated in Table 2. Test Method E45 recommended and is assumed throughout this document.

ratings by SEM may differ from those determined following 6.1.3 Energy Dispersive X-Ray (EDX) Analyzer. A “light

E45 because of the use of chemistry in the classifications. In element detector” (one equipped with a sufficiently thin win-

order to differentiate E45 ratings obtained using the SEM from dow to effectively transmit the low energy X rays characteristic

traditional ratings using light microscopy, the ratings obtained

of the elements below sodium) is required if oxygen is to be

using Method 1 or 2 of this Test Method shall be identified as discretely measured, or if analysis of carbides, borides, or

E45-SEM1 and E45-SEM2, respectively.

nitrides is to be included. The EDX detector must have

resolution better than 155 eV as measured in accordance with

5.4 Method 3 defines procedures to analyze and report

ANSI/IEEE STD 759.

inclusions by arbitrary size distribution and chemical classifi-

6.1.4 Backscattered Electron Detector and electronics with

cations. It may be made applicable to any material by appro-

ability to set one or more thresholds to enable discrimination

priate choice of these classifications.

between inclusions and matrix.

5.4.1 Method 3 determines and reports basic (as used in Test

6.1.5 Control and Image Collection Software to control the

Method E1245) stereological measurements (for example,

beam and stage and to collect images and spectra according to

volume fraction of sulfides and oxides, the number of sulfides

user-specified parameters.

or oxides per square millimeter, and so forth). This test method,

however, does not address the measurement of such param- 6.2 Automated Feature-Analysis Software, capable of:

eters. E45 ratings are not produced in Method 3 because the

6.2.1 Allowing analysis rules to be set such that chemical

inclusion classifications do not follow those defined in Test

classifications can be made and features sorted according to

Method E45.

chemistry as well as size and morphology.

6.2.2 Distinguishing between elongated and globular par-

5.5 The quantitative results are intended to provide a de-

ticles based on aspect ratio.

scription of the types and amounts of inclusions in a heat of

6.2.3 Separating the stringered oxides according to the

steel. This test method contains no guidelines for such use.

difference in morphology (Type B or C) and measuring the

stringer lengths per field of each type.

6. Apparatus

6.2.4 Connecting stringers which cross field boundaries.

6.1 An automated computer-controlled Scanning Electron

6.2.5 Generating standardized reports.

Microscope equipped with the following accessories:

6.1.1 Digital Imaging hardware and software. 6.3 Special Considerations—The environment housing the

equipment must be controlled. Computer equipment, SEMs

6.1.2 Computer-Controlled Motorized X-Y Stage. It is con-

ceivable that the method described in this standard may be and EDX systems all require control of temperature and

humidity and the air must be relatively dust free.

performed without an automated stage. Performing this method

with a manual stage will be tedious, and accuracy will suffer

due to difficulty in tracking inclusions across field boundaries.

7. Sampling

7.1 Sampling is done in accordance with the guidelines

given in Test Method E45.

TABLE 2 Minimum Values for Inclusion Severity Rating Levels

for Measurements in Micrometers (For expression in other units,

8. Test Specimens

see Test Meth

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: E2142 − 08 E2142 − 08 (Reapproved 2015)

Standard Test Methods for

Rating and Classifying Inclusions in Steel Using the

Scanning Electron Microscope

This standard is issued under the fixed designation E2142; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers procedures to obtain particle size distribution, chemical classification, and Test Methods E45 ratings

of inclusions in steels using an automated scanning electron microscope (SEM) with X-ray analysis and automatic image analysis

capabilities.

1.2 There are three discrete methods described. Method 1 is the SEM analog of Test Method E45, which uses image analysis

and light microscopy to produce automated Test Methods E45 ratings. Method 2 produces similar ratings based predominantly on

sorting inclusions by chemistry into the traditional classes defined in Test Methods E45. Method 3 is recommended when explicit

detail is needed on particular inclusion types, not necessarily defined in Test Methods E45, such as to verify the composition of

inclusions in inclusion-engineered steel. Method 3 reports stereological parameters such as volume or number fraction, rather than

Test Methods E45 type ratings.

1.3 This test method deals only with the recommended test methods and nothing in it should be construed as defining or

establishing limits of acceptability for any grade of steel or other alloy where the method is appropriate.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

E3 Guide for Preparation of Metallographic Specimens

E7 Terminology Relating to Metallography

E45 Test Methods for Determining the Inclusion Content of Steel

E766 Practice for Calibrating the Magnification of a Scanning Electron Microscope

E768 Guide for Preparing and Evaluating Specimens for Automatic Inclusion Assessment of Steel

E1245 Practice for Determining the Inclusion or Second-Phase Constituent Content of Metals by Automatic Image Analysis

E1508 Guide for Quantitative Analysis by Energy-Dispersive Spectroscopy

2.2 Adjuncts:

ANSI/IEEE STD 759 IEEE Standard Test Procedure for Semiconductor X-Ray Energy Spectrometers

3. Terminology

3.1 Definitions—For definitions of terms used in this test method, see Terminology E7.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 Analysis Rules—

These test methods are under the jurisdiction of ASTM Committee E04 on Metallography and are the direct responsibility of Subcommittee E04.11 on X-Ray and

Electron Metallography.

Current edition approved Oct. 1, 2008Oct. 1, 2015. Published October 2008.November 2015. Originally approved in 2001. Last previous edition approved in 20012008

as E2142–01.E2142–08. DOI: 10.1520/E2142-08.10.1520/E2142-08R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE), 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E2142 − 08 (2015)

3.2.1.1 acquisition analysis rules—include the criteria to terminate X-ray collection (counts or time, or both), the list of elements

to be analyzed, the number of fields or particles to be analyzed, morphologies of particles from which spectra will be collected,

etc. (see Appendix X1 for a more complete listing of typical Acquisition Rules).

3.2.1.2 post-acquisition analysis rules—define ratios of X-ray intensities or elemental compositions required to identify an

inclusion as belonging to a particular chemical classification and, for Methods 1 and 2 herein, define the main inclusion class (A,

B, or C) to which each chemical classification belongs.

3.2.2 chemical classification—defined compositional categories in which inclusions are placed according to the analysis rules.

Categories may be broad (for example, sulfide, aluminate, silicate) or more precise (for example, calcium sulfide, calcium silicate,

anorthite, etc.).

3.2.3 critical aspect ratio—the aspect ratio of a single inclusion that defines the boundary between “globular” and “elongated”.

3.2.4 discontinuous stringer—two or more Type C or three or more Type B inclusions aligned in a plane parallel to the hot

working axis and offset from the stringer centerline by no more than 15 μm, with a separation of < 40 μm between any two nearest

neighbor inclusions.

3.2.5 stringer—an individual oxide inclusion that is highly elongated in the deformation direction; or two or more Type C, or

three or more Type B, inclusions aligned in a plane parallel to the hot working axis and offset (from the stringer centerline) by no

more than 15 μm, with a separation of < 40 μm between any two nearest neighbor inclusions.

4. Summary of Test Method

4.1 A properly prepared as-polished metallographic specimen is mounted in a computer-controlled SEM equipped with image

analysis and X-ray analysis subsystems such that inclusions intersecting the plane of polish can be imaged and analyzed.

4.2 During analysis, an inclusion is detected by its gray level in the back-scattered electron signal. Once detected, size

parameters of the inclusion are automatically determined and its X-ray spectrum collected. Particle morphology, chemistry, and

location are stored in the computer, allowing re-examination of the data or the particle itself. In this manner, a complete or partial

size distribution of inclusions by chemical class can be determined.

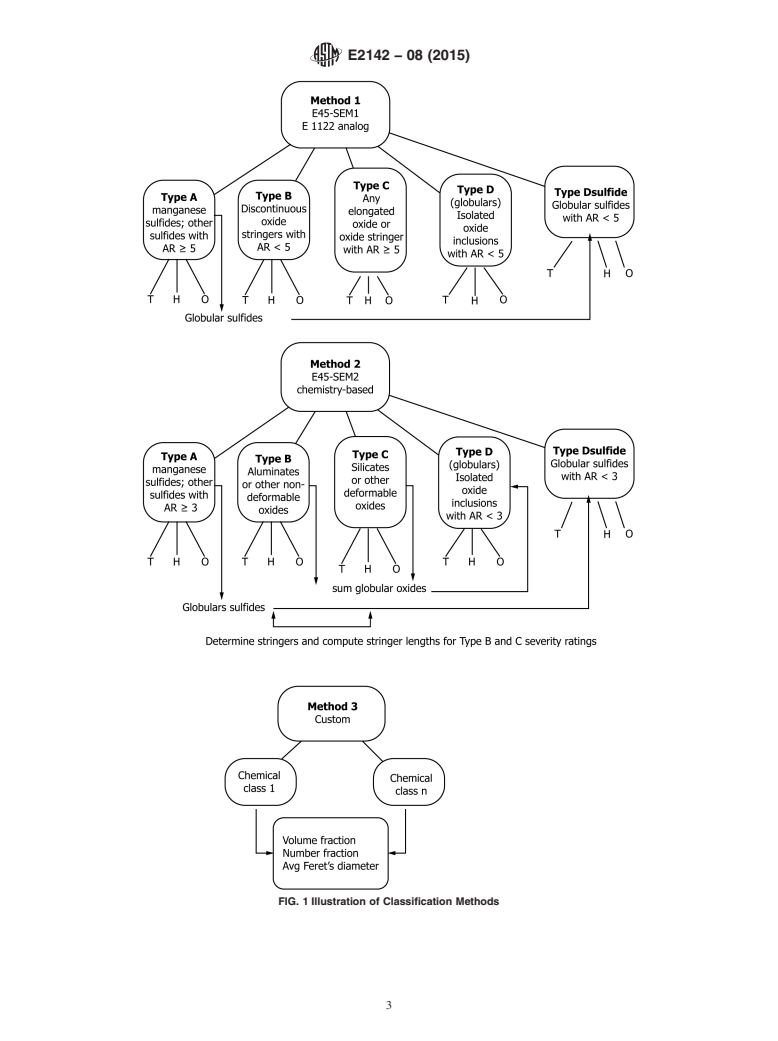

4.3 There are three methods described (see Fig. 1):

4.3.1 Method 1 is most similar to Test Methods E45 which uses light microscopy, and is intended to be its SEM analog. As such,

it uses morphology as the primary basis for sorting particles into classes. As in Test Methods E45, a critical aspect ratio of 2 is

defined. Chemistry is used to identify sulfide inclusions and to discriminate among sulfides when more than one type is present,

as well as to ensure that exogenous inclusions and surface scratches and debris are not included in the ratings. Inclusions will be

classified into four categories, Types A, B, C and D as described in Test Methods E45. Elongated sulfides are Type A. Other

inclusions are oxides and are classified as Types B, C or D, depending on their morphology, as follows: discontinuous stringers

of three or more inclusions with member particles having low aspect ratio are Type B; discontinuous stringers of two or more

inclusions with member particles having high aspect ratio and single elongated oxide inclusions are Type C; remaining isolated

inclusions are Type D. The categories will be further subdivided as thin, heavy and oversized, according to their width (tabulated

in Table 1). E45-equivalent ratings are determined and recorded, and reported particles are usually limited to those ≥ 2 μm in size.

4.3.2 The inclusion classification strategy in Method 2 is based predominantly on chemistry, but uses morphology when

necessary, such as to classify Type D (globular) inclusions and to compute severity ratings for Type B and C inclusions (which

require determination of stringer lengths). Method 2 is based on the underlying intention of Test Method E45, namely, that Type

A inclusions are deformable sulfides, Type B inclusions are non-deformable oxides (typically alumina), and Type C inclusions are

deformable oxides (typically silicates). Each defined chemical class is assigned to one of these categories. Once classifications are

made based on chemistry, the globular particles from each classification, or from designated classifications, can be re-classified as

Type D inclusions. E45-equivalent ratings are determined and recorded, and reported particles are usually limited to those ≥ 2 μm

in size.

4.3.3 Method 3 allows inclusions to be analyzed and reported in a manner individualized to the material and application of

interest. It allows complete freedom in formulating chemical classes. Aspect ratio definitions can be chosen appropriately for the

application. Termination of the analysis can be based on detecting a certain number of inclusions rather than sample area. Size and

morphology distributions of all inclusions by chemical class are determined. Indirect terminology such as “Type A, B, C and D”

and “thin” and “heavy” is not used; rather, inclusions are classified directly by chemical class and size range of interest. Particles

may be further subdivided by morphology. Method 3, as in Practice E1245, reports basic stereological parameters, such as volume

and number fractions of inclusions within each field, as well the maximum Feret’s diameter for each inclusion. This method would

be used for custom analyses, such to report all non-sulfide particles by thickness, as may be useful in tire cord applications.

5. Significance and Use

5.1 This test method is established to cover automated SEM/EDX-based procedures for:

5.1.1 Rating the inclusion content of steels based on procedures listed in Standards E45 and E1245, with the significant

difference that the composition of the individual inclusions, as determined by X-ray analysis, is utilized to sort them into chemical

classes.

E2142 − 08 (2015)

FIG. 1 Illustration of Classification Methods

E2142 − 08 (2015)

TABLE 1 Inclusion Width Parameters

Thin Heavy Oversize

Inclusion Minimum Maximum Minimum Maximum Minimum

Type Width (μm) Width (μm) Width (μm) Width (μm) Width (μm)

A $2 4 >4 12 >12

B $2 9 >9 15 >15

C $2 5 >5 12 >12

D $2 8 >8 13 >13

5.1.2 Determining the number, size and morphological distribution of inclusions in steels sorted by chemical class.

5.2 Methods 1 and 2 of this test method are primarily intended for rating the inclusion content of steels deoxidized with silicon

or aluminum, both silicon and aluminum, or vacuum-treated steels without either silicon or aluminum additions. Guidelines are

provided to rate inclusions in steel treated with rare earth additions or calcium-bearing compounds (13.4). When such steels are

evaluated, the test report should describe the nature of the inclusions rated according to each inclusion category (A, B, C, D).

5.3 Methods 1 and 2 will provide a quantitative rating of the inclusion content in half-severity number increments from 0 to

5 for each inclusion type and thickness (Method D of Test Method E45), and in tabulated in Table 2. Test Method E45 ratings by

SEM may differ from those determined following E45 because of the use of chemistry in the classifications. In order to differentiate

E45 ratings obtained using the SEM from traditional ratings using light microscopy, the ratings obtained using Method 1 or 2 of

this Test Method shall be identified as E45-SEM1 and E45-SEM2, respectively.

5.4 Method 3 defines procedures to analyze and report inclusions by arbitrary size distribution and chemical classifications. It

may be made applicable to any material by appropriate choice of these classifications.

5.4.1 Method 3 determines and reports basic (as used in Test Method E1245) stereological measurements (for example, volume

fraction of sulfides and oxides, the number of sulfides or oxides per square millimeter, and so forth). This test method, however,

does not address the measurement of such parameters. E45 ratings are not produced in Method 3 because the inclusion

classifications do not follow those defined in Test Method E45.

5.5 The quantitative results are intended to provide a description of the types and amounts of inclusions in a heat of steel. This

test method contains no guidelines for such use.

6. Apparatus

6.1 An automated computer-controlled Scanning Electron Microscope equipped with the following accessories:

6.1.1 Digital Imaging hardware and software.

6.1.2 Computer-Controlled Motorized X-Y Stage. It is conceivable that the method described in this standard may be performed

without an automated stage. Performing this method with a manual stage will be tedious, and accuracy will suffer due to difficulty

in tracking inclusions across field boundaries. Therefore, an automated stage, although not essential, is highly recommended and

is assumed throughout this document.

6.1.3 Energy Dispersive X-Ray (EDX) Analyzer. A “light element detector” (one equipped with a sufficiently thin window to

effectively transmit the low energy X rays characteristic of the elements below sodium) is required if oxygen is to be discretely

measured, or if analysis of carbides, borides, or nitrides is to be included. The EDX detector must have resolution better than 155

eV as measured in accordance with ANSI/IEEE STD 759.

6.1.4 Backscattered Electron Detector and electronics with ability to set one or more thresholds to enable discrimination

between inclusions and matrix.

6.1.5 Control and Image Collection Software to control the beam and stage and to collect images and spectra according to

user-specified parameters.

TABLE 2 Minimum Values for Inclusion Severity Rating Levels

for Measurements in Micrometers (For expression in other units,

see Test Methods E45, Table 2)

Test Method E45 Rating Limits (μm at 1× or count)

Severity A B C D

0.5 37.0 17.2 17.8 1

1.0 127.0 76.8 75.6 2

1.5 261.0 184.2 176.0 4

2.0 436.1 342.7 320.5 9

2.5 649.0 554.7 510.3 16

3.0 898.0 822.2 746.1 25

3.5 1181.0 1147.0 1029.0 36

4.0 1498.0 1530.0 1359.0 49

4.5 1898.0 1973.0 1737.0 81

5.0 2230.0 2476.0 2163.0 100

E2142 − 08 (2015)

6.2 Automated Feature-Analysis Software, capable of:

6.2.1 Allowing analysis rules to be set such that chemical classifications can be made and features sorted according to chemistry

as well as size and morpholo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.