ASTM F3554-22

(Specification)Standard Specification for Additive Manufacturing – Finished Part Properties – Grade 4340 (UNS G43400) via Laser Beam Powder Bed Fusion for Transportation Applications

Standard Specification for Additive Manufacturing – Finished Part Properties – Grade 4340 (UNS G43400) via Laser Beam Powder Bed Fusion for Transportation Applications

SCOPE

1.1 This specification covers additive manufacturing of parts manufactured via laser beam powder bed fusion (PBF-LB) processing of Grade 4340 (UNS G43400) used in transportation applications, including automotive applications. Parts made using this processing method require heat treatment to achieve maximum strength and are typically used in applications that require mechanical properties similar to wrought Grade 4340 (UNS G43400) products. Products built to this specification may require additional post-processing in the form of machining, polishing etc. to meet necessary surface finish and dimensional tolerances.

1.2 This specification describes the required facility, training, equipment, and processing requirements necessary to support the production of parts with properties and associated quality metrics outlined in a part classification structure.

1.3 This specification is intended for the use of purchasers or producers, or both, of PBF-LB Grade 4340 (UNS G43400) parts for defining the requirements based on classification methodology. These requirements shall be agreed upon by the part supplier and purchaser.

1.4 Users are advised to use this specification as a basis for obtaining parts that will meet the minimum acceptance requirements established and revised by consensus of committee members.

1.5 User requirements considered more stringent may be met by additional requirements in the purchase order.

1.6 The values stated in SI units are to be regarded as standard. The values given in parentheses after SI units are provided for information only and are not considered standard.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F3554 −22

Standard Specification for

Additive Manufacturing – Finished Part Properties – Grade

4340 (UNS G43400) via Laser Beam Powder Bed Fusion for

1

Transportation Applications

This standard is issued under the fixed designation F3554; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.1 This specification covers additive manufacturing of

Barriers to Trade (TBT) Committee.

parts manufactured via laser beam powder bed fusion (PBF-

LB) processing of Grade 4340 (UNS G43400) used in trans-

2. Referenced Documents

portationapplications,includingautomotiveapplications.Parts

2

2.1 ASTM Standards:

made using this processing method require heat treatment to

B822 Test Method for Particle Size Distribution of Metal

achieve maximum strength and are typically used in applica-

Powders and Related Compounds by Light Scattering

tions that require mechanical properties similar to wrought

D3951 Practice for Commercial Packaging

Grade 4340 (UNS G43400) products. Products built to this

E3 Guide for Preparation of Metallographic Specimens

specification may require additional post-processing in the

E8/E8M Test Methods for Tension Testing of Metallic Ma-

form of machining, polishing etc. to meet necessary surface

terials

finish and dimensional tolerances.

E10 Test Method for Brinell Hardness of Metallic Materials

1.2 This specification describes the required facility,

E29 Practice for Using Significant Digits in Test Data to

training, equipment, and processing requirements necessary to

Determine Conformance with Specifications

support the production of parts with properties and associated

E407 Practice for Microetching Metals and Alloys

quality metrics outlined in a part classification structure.

E112 Test Methods for Determining Average Grain Size

E1019 Test Methods for Determination of Carbon, Sulfur,

1.3 This specification is intended for the use of purchasers

Nitrogen, and Oxygen in Steel, Iron, Nickel, and Cobalt

or producers, or both, of PBF-LB Grade 4340 (UNS G43400)

parts for defining the requirements based on classification Alloys by Various Combustion and Inert Gas Fusion

Techniques

methodology. These requirements shall be agreed upon by the

part supplier and purchaser. E1245 Practice for Determining the Inclusion or Second-

Phase Constituent Content of Metals byAutomatic Image

1.4 Users are advised to use this specification as a basis for

Analysis

obtainingpartsthatwillmeettheminimumacceptancerequire-

E1417 Practice for Liquid Penetrant Testing

ments established and revised by consensus of committee

E1479 Practice for Describing and Specifying Inductively

members.

Coupled Plasma Atomic Emission Spectrometers

1.5 User requirements considered more stringent may be

E1742 Practice for Radiographic Examination

met by additional requirements in the purchase order.

E2234 Practice for Sampling a Stream of Product by Attri-

butes Indexed by AQL

1.6 The values stated in SI units are to be regarded as

E2594 Test Method forAnalysis of NickelAlloys by Induc-

standard. The values given in parentheses after SI units are

tively Coupled Plasma Atomic Emission Spectrometry

provided for information only and are not considered standard.

(Performance-Based)

1.7 This international standard was developed in accor-

E2762 Practice for Sampling a Stream of Product by Vari-

dance with internationally recognized principles on standard-

ables Indexed by AQL

ization established in the Decision on Principles for the

F2971 Practice for Reporting Data for Test Specimens Pre-

pared by Additive Manufacturing

1

This specification is under the jurisdiction of ASTM Committee F42 on

2

Additive Manufacturing Technologies and is the direct responsibility of Subcom- For referenced ASTM standards, visit the ASTM website, www.astm.org, or

mittee F42.07 on Applications. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved Oct. 1, 2022. Published November 2022. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/F3554-22. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

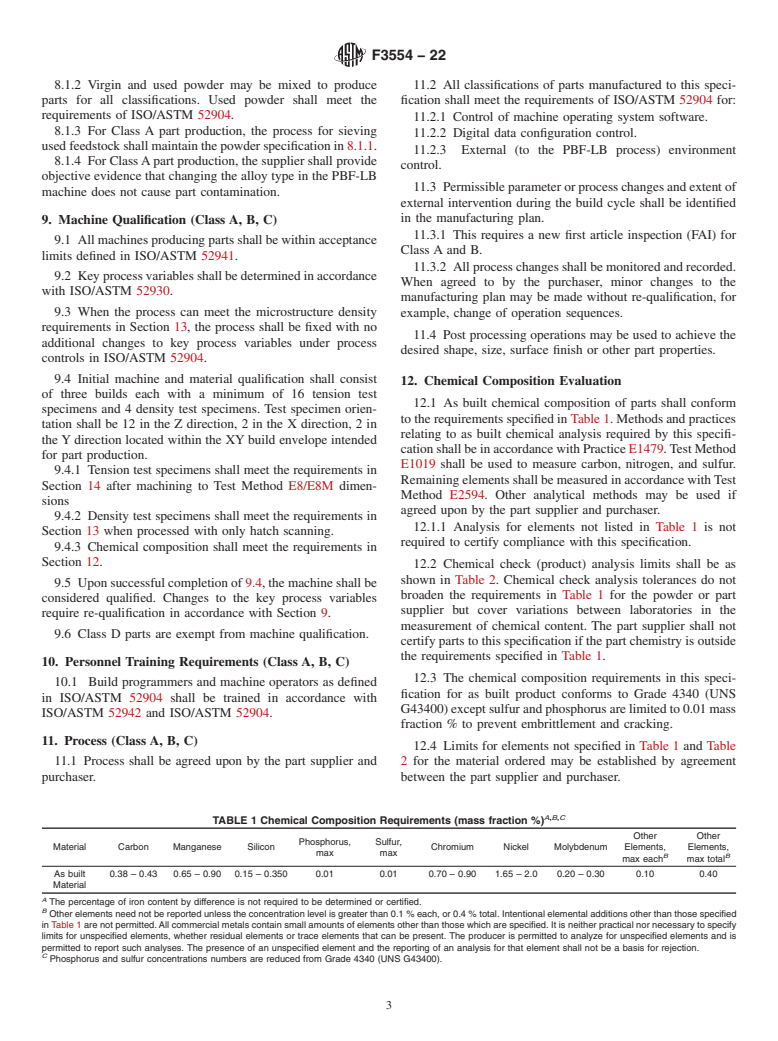

F3554−22

7

F3122 Guide for Evaluating Mechanical Properties of Metal 2.7 ANSI/A

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.