ASTM F3626-23

(Guide)Standard Guide for Additive Manufacturing — Test Artifacts — Accelerated Build Quality Assurance for Laser Beam Powder Bed Fusion (PBF-LB)

Standard Guide for Additive Manufacturing — Test Artifacts — Accelerated Build Quality Assurance for Laser Beam Powder Bed Fusion (PBF-LB)

SIGNIFICANCE AND USE

5.1 This guide describes the use of torque and angle-of-twist data as a preliminary acceptance criteria for a production run utilizing a previously qualified AM process through periodical or continuous evaluation. A torsion device (for example, torque wrench, instrumented lathe with torque readout) is used to break strategically placed torque specimens within the build volume in the as-built state to provide evidence of build health. If a round of tests from a production run is determined to fall outside of some criteria (for example: 3 standard deviations from the mean or other user defined criteria), additional qualification procedures should be performed to ensure the AM machine or process health are acceptable.

Note 1: It is advantageous to locate the specimen at the same build height and near-critical locations of the part or component being fabricated for the evaluation to be representative of the specific region.

5.2 This guide is not intended to replace rigorous qualification procedures and should only be considered as a preliminary acceptance criterion to increase confidence that an AM machine or process has not been significantly compromised.

SCOPE

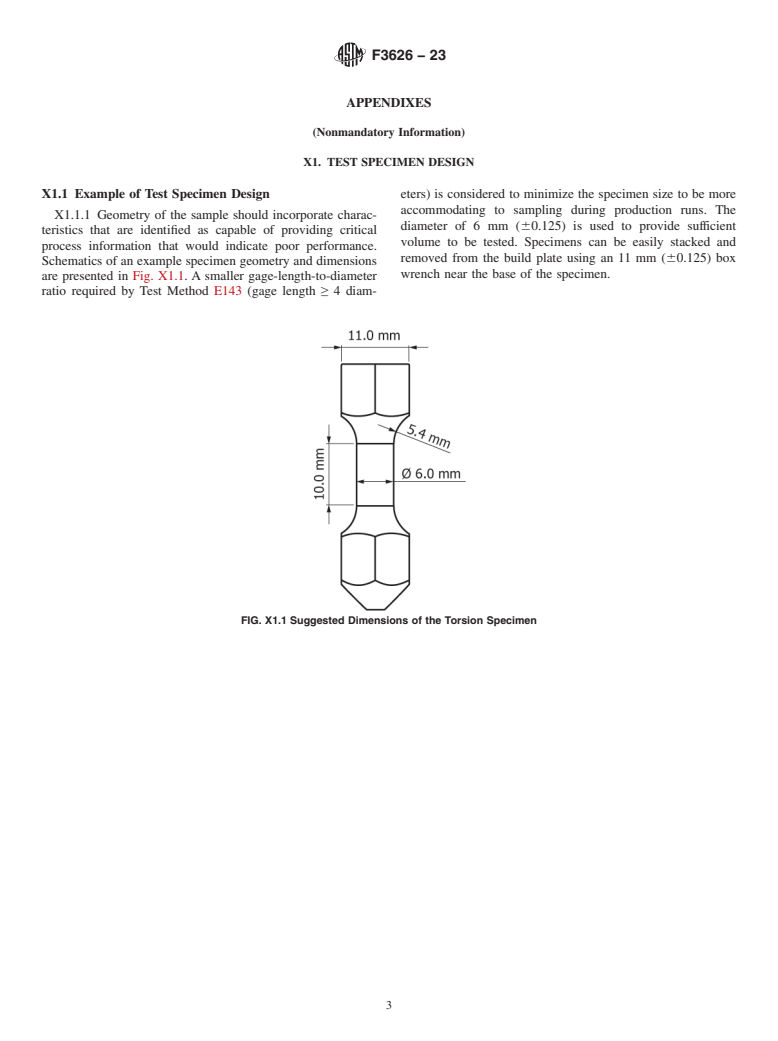

1.1 This guide illustrates a test specimen geometry and testing protocol that can be used to assess the quality of a metal powder bed fusion build cycle as it could be affected by major system errors (for example, corrupted calibration, disrupted inert gas flow, laser wear) severely affecting the quality of materials fabricated by laser beam powder bed fusion (PBF-LB).

1.2 This method is designed to interrupt the manufacturing process if poor material quality is identified through go/no-go torque/angle of twist measurements of witness coupons after each fabrication.

1.3 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this guide.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.5 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3626 − 23

Standard Guide for

Additive Manufacturing — Test Artifacts — Accelerated

Build Quality Assurance for Laser Beam Powder Bed Fusion

1

(PBF-LB)

This standard is issued under the fixed designation F3626; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope men Alignment Under Tensile and Compressive Axial

Force Application

1.1 This guide illustrates a test specimen geometry and

2

2.2 ISO/ASTM Standard:

testing protocol that can be used to assess the quality of a metal

ISO/ASTM 52900 Additive manufacturing — General prin-

powder bed fusion build cycle as it could be affected by major

ciples — Fundamentals and vocabulary

system errors (for example, corrupted calibration, disrupted

inert gas flow, laser wear) severely affecting the quality of

3. Terminology

materials fabricated by laser beam powder bed fusion (PBF-

LB).

3.1 Definitions—Terminology relating to additive manufac-

turing in ISO/ASTM 52900 should apply.

1.2 This method is designed to interrupt the manufacturing

process if poor material quality is identified through go/no-go

4. Summary

torque/angle of twist measurements of witness coupons after

each fabrication.

4.1 Directly after a build cycle is completed, witness speci-

mens in their as-built state (prior to any post-processing) are

1.3 Units—The values stated in SI units are to be regarded

torqued to fracture. The maximum value of torque and (if

as the standard. No other units of measurement are included in

necessary) angle-of-twist are recorded. Identifying measure-

this guide.

ments of torque or angle-of-twist or both outside of a specified

1.4 This standard does not purport to address all of the

range of variation are cause to interrupt the production cycle

safety concerns, if any, associated with its use. It is the

until the additive manufacturing (AM) machine performance

responsibility of the user of this standard to establish appro-

and resulting material quality is further evaluated.

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

5. Significance and Use

1.5 This international standard was developed in accor-

5.1 This guide describes the use of torque and angle-of-twist

dance with internationally recognized principles on standard-

data as a preliminary acceptance criteria for a production run

ization established in the Decision on Principles for the

utilizing a previously qualified AM process through periodical

Development of International Standards, Guides and Recom-

or continuous evaluation. A torsion device (for example, torque

mendations issued by the World Trade Organization Technical

wrench, instrumented lathe with torque readout) is used to

Barriers to Trade (TBT) Committee.

break strategically placed torque specimens within the build

2. Referenced Documents volume in the as-built state to provide evidence of build health.

2

If a round of tests from a production run is determined to fall

2.1 ASTM Standards:

outside of some criteria (for example: 3 standard deviations

E143 Test Method for Shear Modulus at Room Temperature

from the mean or other user defined criteria), additional

E1012 Practice for Verification of Testing Frame and Speci-

qualification procedures should be performed to ensure the AM

machine or process health are acceptable.

1

This guide is under the jurisdiction of ASTM Committee F42 on Additive

NOTE 1—It is advantageous to locate the specimen at the same build

Manufacturing Technologies and is the direct responsibility of Subcommittee

height and near-critical locations of the part or component being fabri-

F42.01 on Test Methods.

cated for the evaluation to be representative of the specific region.

Current edition approved Feb. 15, 2023. Published April 2023. DOI: 10.1520/

F3626-23.

5.2 This guide is not intended to replace rigorous qualifica-

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

tion procedures and should only be considered as a preliminary

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

acceptance criterion to increase confidence that an AM ma-

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. chine or process has not been significantly compromised.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 -------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.