ASTM F3489-23

(Guide)Standard Guide for Additive Manufacturing of Polymers — Material Extrusion — Recommendation for Material Handling and Evaluation of Static Mechanical Properties

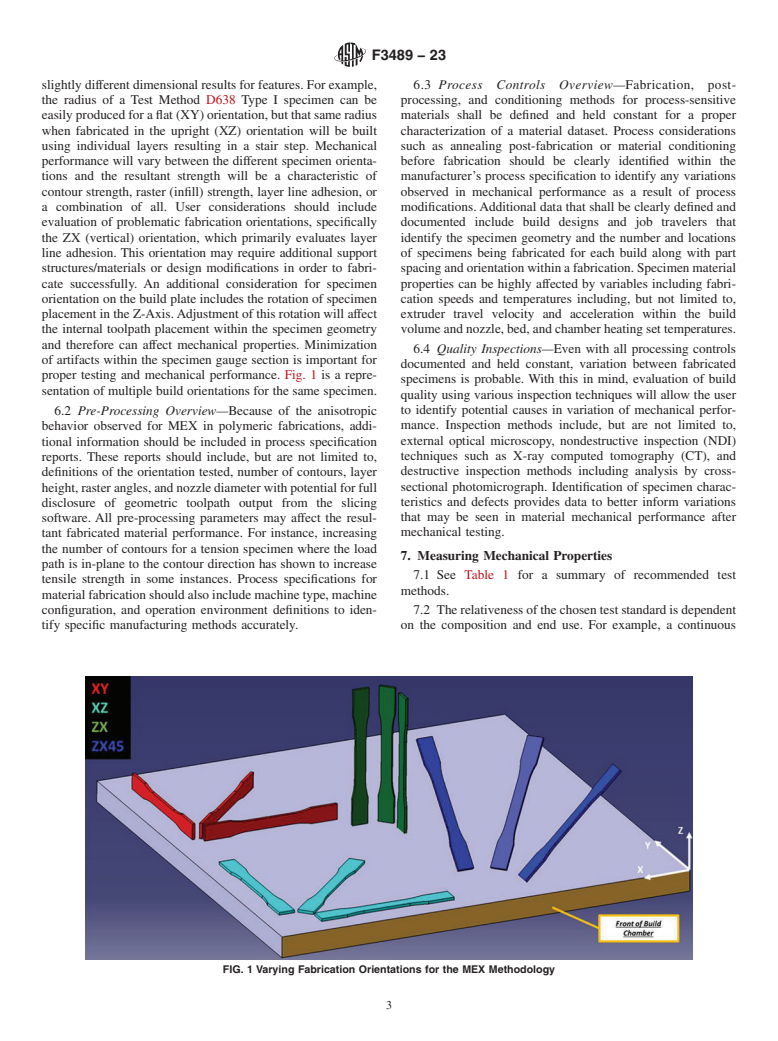

Standard Guide for Additive Manufacturing of Polymers — Material Extrusion — Recommendation for Material Handling and Evaluation of Static Mechanical Properties

SIGNIFICANCE AND USE

4.1 As noted in many of the standards in Section 2, there are multiple factors that may influence the reported properties, including material choice, material anisotropy, methods of material storage and preparation, porosity, methods of specimen storage and preparation, orientation and specimen build plate location during fabrication, testing environment, specimen alignment and gripping during testing, testing speed, and testing temperature. These factors should be recorded according to Practice F2971 and the guidelines of the referenced standards. This guide is intended to inform users of best practices for static mechanical testing of additive manufactured polymer specimens fabricated using material extrusion (MEX).

SCOPE

1.1 This guide covers existing standards or variations of existing standards that may be applicable to determine specific static mechanical properties of polymeric specimens fabricated with the material extrusion (MEX) additive manufacturing (AM) process. The test methods covered within this document are recommendations supplied coming from the experience previous material qualification programs have provided. Additional test methods may be considered as well depending when evaluating material performance for specific applications. Recommendations for material handling prior to testing and characterization are included as they can greatly affect material properties. It is for the end user to determine if the recommended tests adequately evaluate the material performance for the intended application.

1.2 Units—The values stated in SI units are to be regarded as the standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F3489 − 23

Standard Guide for

Additive Manufacturing of Polymers — Material Extrusion —

Recommendation for Material Handling and Evaluation of

1

Static Mechanical Properties

This standard is issued under the fixed designation F3489; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

2.1 ASTM Standards:

1.1 This guide covers existing standards or variations of

D638 Test Method for Tensile Properties of Plastics

existing standards that may be applicable to determine specific

D695 Test Method for Compressive Properties of Rigid

static mechanical properties of polymeric specimens fabricated

Plastics

with the material extrusion (MEX) additive manufacturing

D790 Test Methods for Flexural Properties of Unreinforced

(AM) process. The test methods covered within this document

and Reinforced Plastics and Electrical Insulating Materi-

are recommendations supplied coming from the experience

als

previous material qualification programs have provided. Addi-

D3039 Test Method for Tensile Properties of Polymer Ma-

tional test methods may be considered as well depending when

trix Composite Materials

evaluating material performance for specific applications. Rec-

D5229/D5229M Test Method for Moisture Absorption Prop-

ommendations for material handling prior to testing and

erties and Equilibrium Conditioning of Polymer Matrix

characterization are included as they can greatly affect material

Composite Materials

properties. It is for the end user to determine if the recom-

D5379 Test Method for Shear Properties of Composite

mended tests adequately evaluate the material performance for

Materials by the V-Notched Beam Method

the intended application.

D5766 Test Method for Open-Hole Tensile Strength of

Polymer Matrix Composite Laminates

1.2 Units—The values stated in SI units are to be regarded

D5961 Test Method for Bearing Response of Polymer Ma-

as the standard. No other units of measurement are included in

trix Composite Laminates

this standard.

D6484 Test Method for Open-Hole Compressive Strength of

1.3 This standard does not purport to address all of the

Polymer Matrix Composite Laminates

safety concerns, if any, associated with its use. It is the

D6641 Test Method for Compressive Properties of Polymer

responsibility of the user of this standard to establish appro-

Matrix Composite Materials Using a Combined Loading

priate safety, health, and environmental practices and deter- Compression (CLC) Test Fixture

mine the applicability of regulatory limitations prior to use. D6742 Practice for Filled-Hole Tension and Compression

Testing of Polymer Matrix Composite Laminates

1.4 This international standard was developed in accor-

D7191 Test Method for Determination of Moisture in Plas-

dance with internationally recognized principles on standard-

tics by Relative Humidity Sensor

ization established in the Decision on Principles for the

F2971 Practice for Reporting Data for Test Specimens Pre-

Development of International Standards, Guides and Recom-

pared by Additive Manufacturing

mendations issued by the World Trade Organization Technical

2

2.2 ISO/ASTM Standards:

Barriers to Trade (TBT) Committee.

ISO/ASTM 52900 Additive manufacturing — General prin-

ciples — Terminology

ISO/ASTM 52921 Standard terminology for additive manu-

facturing — Coordinate systems and test methodologies

1

This guide is under the jurisdiction of ASTM Committee F42 on Additive

2

Manufacturing Technologies and is the direct responsibility of Subcommittee For referenced ASTM standards, visit the ASTM website, www.astm.org, or

F42.01 on Test Methods. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Current edition approved May 1, 2023. Published June 2023. DOI: 10.1520/ Standards volume information, refer to the standard’s Document Summary page on

F3489-23. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F3489 − 23

3. Terminology 5.4 Filament Material Conditioning—Environment control

should be in place for both pre- and post-fabrication states

3.1 Definitions—Terminology relating to additive manufac-

(filament and fabricated specimens), as material performance

turing (AM) in Terminologies ISO/ASTM 52900 and ISO/

for both fabrication and testing mechanical performance can be

ASTM 52921 shall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.