ASTM C621-09

(Test Method)Standard Test Method for Isothermal Corrosion Resistance of Refractories to Molten Glass

Standard Test Method for Isothermal Corrosion Resistance of Refractories to Molten Glass

SIGNIFICANCE AND USE

This test method provides a rapid, inexpensive method for comparing the corrosion resistance of refractories. The isothermal conditions of this test method represent the most severe static corrosion environment possible at the specified test temperature. This test method is suitable for quality control, research and development applications, and for product value studies on similar materials. Tests run at a series of temperatures are often helpful in determining the use temperature limitations of a particular material. Melt-line corrosion results are also a useful indication of relative resistance to both upward and downward drilling corrosion mechanisms. Examination of test specimens also provides information about the tendency for a particular refractory to form stones or other glass defects.

Because this test method is both isothermal and static and since most glass-contact refractories operate in a dynamic system with a thermal gradient, test results do not directly predict service in a furnace. The effects of differing thermal conductivities, refractory thickness, artificial cooling or insulation upon the refractory thermal gradient, and the erosive action of moving molten glass currents are not evaluated with this test.

SCOPE

1.1 This test method covers the determination of the corrosion resistance of refractories in contact with molten glass under static, isothermal conditions.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C621 − 09

StandardTest Method for

Isothermal Corrosion Resistance of Refractories to Molten

1

Glass

This standard is issued under the fixed designation C621; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope nation of test specimens also provides information about the

tendency for a particular refractory to form stones or other

1.1 This test method covers the determination of the corro-

glass defects.

sion resistance of refractories in contact with molten glass

under static, isothermal conditions.

3.2 Because this test method is both isothermal and static

and since most glass-contact refractories operate in a dynamic

1.2 The values stated in inch-pound units are to be regarded

system with a thermal gradient, test results do not directly

as standard. The values given in parentheses are mathematical

predict service in a furnace. The effects of differing thermal

conversions to SI units that are provided for information only

conductivities, refractory thickness, artificial cooling or insu-

and are not considered standard.

lation upon the refractory thermal gradient, and the erosive

1.3 This standard does not purport to address all of the

action of moving molten glass currents are not evaluated with

safety concerns, if any, associated with its use. It is the

this test.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Apparatus

bility of regulatory limitations prior to use.

4.1 Glass-Melting Test Furnace, heated with some type of

2. Referenced Documents electrical resistor (Note 1) and having a chamber large enough

2 to receive four crucible assemblies of the type used in the test

2.1 ASTM Standards:

(Fig. 1) is required. The zone of the furnace in which the

E220 Test Method for Calibration of Thermocouples By

crucibles will rest should possess a maximum transverse

Comparison Techniques

thermal gradient of 61.8°F (61°C). Fig. A1.1 shows a

schematic drawing of a furnace that is satisfactory for this test.

3. Significance and Use

NOTE 1—It has been demonstrated that gas-fired furnaces show greater

3.1 This test method provides a rapid, inexpensive method

variability and higher average corrosion with this test method and are

for comparing the corrosion resistance of refractories. The

therefore generally unsuitable.

isothermal conditions of this test method represent the most

4.2 Temperature-Control Instrumentation, capable of main-

severe static corrosion environment possible at the specified

taining the desired temperature to 61.8°F (61°C).

test temperature. This test method is suitable for quality

control, research and development applications, and for prod-

4.3 Thermocouple, for use as the temperature-measuring

uct value studies on similar materials. Tests run at a series of

device. The type of thermocouple chosen will depend on the

temperatures are often helpful in determining the use tempera-

normal use temperature of the furnace. Since thermocouples

ture limitations of a particular material. Melt-line corrosion

age with a consequent drift in the signal fed to the control

results are also a useful indication of relative resistance to both

instrument, check the couple before each test run with a

upward and downward drilling corrosion mechanisms. Exami-

calibrated thermocouple. Method E220 specifies calibration

procedures for thermocouples. If drift becomes severe, replace

the thermocouple. Position the thermocouple hot junction in

1

This test method is under the jurisdiction of ASTM Committee C08 on

thefurnacetocoincidewiththeleveloftheglasslineofthetest

RefractoriesandisthedirectresponsibilityofSubcommitteeC08.10onRefractories

samples.

for Glass.

Current edition approved March 1, 2009. Published March 2009. Originally

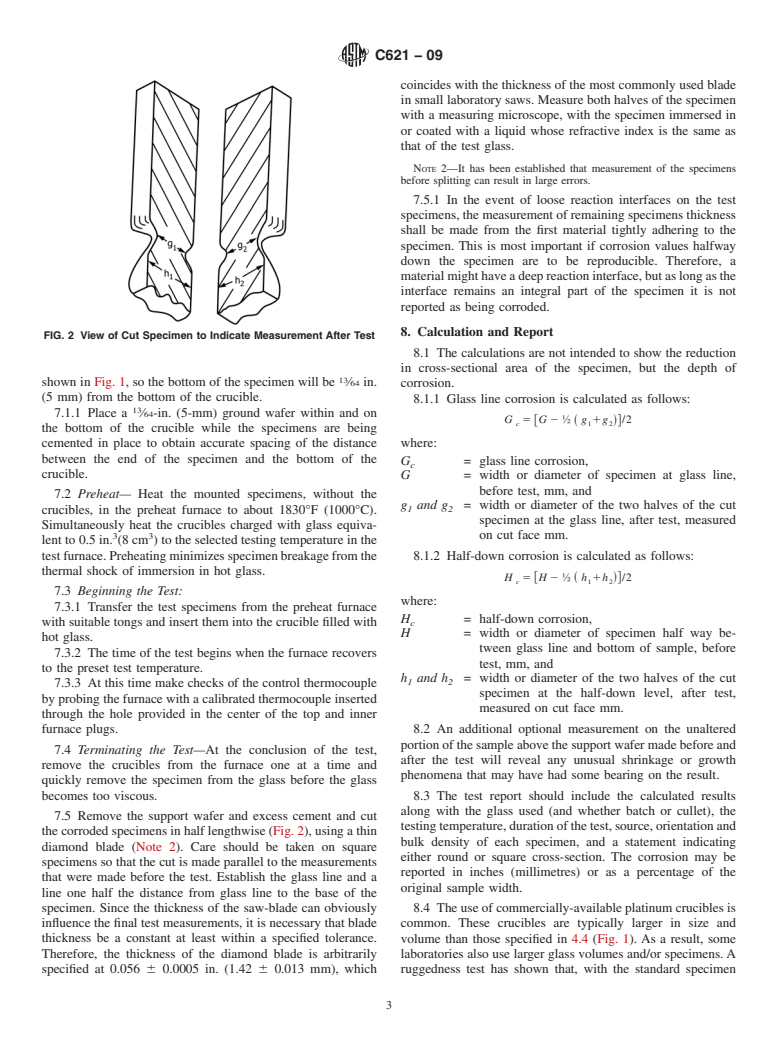

4.4 Platinum Crucibles (Fig. 1).

approved in 1968. Last previous edition approved in 2001 as C621 – 84 (2001).

DOI: 10.1520/C0621-09.

4.5 Sintered Zircon, or other refractory wafers (Annex A2).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.6 Zircon Cement (Annex A3).

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 4.7 Measuring Microscope.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

C621 − 09

the casting. Such specimens avoid edge and corner crystalli-

zation effects and have chemistries similar to those represent-

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C 621–84 (Reapproved 2001) Designation:C 621–09

Standard Test Method for

Isothermal Corrosion Resistance of Refractories to Molten

1

Glass

This standard is issued under the fixed designation C 621; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the corrosion resistance of refractories in contact with molten glass under

static, isothermal conditions.

1.2The values stated in inch-pound units are to be regarded as the standard. The values in parentheses are provided for

information only.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E220 Test Method for Calibration of Thermocouples byBy Comparison Techniques

3. Significance and Use

3.1 Thistestmethodprovidesarapid,inexpensivemethodforcomparingthecorrosionresistanceofrefractories.Theisothermal

conditionsofthistestmethodrepresentthemostseverestaticcorrosionenvironmentpossibleatthespecifiedtesttemperature.This

test method is suitable for quality control, research and development applications, and for product value studies on similar

materials. Tests run at a series of temperatures are often helpful in determining the use temperature limitations of a particular

material. Melt-line corrosion results are also a useful indication of relative resistance to both upward and downward drilling

corrosion mechanisms. Examination of test specimens also provides information about the tendency for a particular refractory to

form stones or other glass defects.

3.2 Becausethistestmethodisbothisothermalandstaticandsincemostglass-contactrefractoriesoperateinadynamicsystem

with a thermal gradient, test results do not directly predict service in a furnace. The effects of differing thermal conductivities,

refractory thickness, artificial cooling or insulation upon the refractory thermal gradient, and the erosive action of moving molten

glass currents are not evaluated with this test.

4. Apparatus

4.1 Glass-Melting Test Furnace , heated with some type of electrical resistor (Note 1) and having a chamber large enough to

receive four crucible assemblies of the type used in the test (Fig. 1) is required. The zone of the furnace in which the crucibles

will rest should possess a maximum transverse thermal gradient of 61.8°F (61°C). Fig. A1.1 shows a schematic drawing of a

furnace that is satisfactory for this test.

NOTE 1—Ithasbeendemonstratedthatgas-firedfurnacesshowgreatervariabilityandhigheraveragecorrosionwiththistestmethodandaretherefore

generally unsuitable.

4.2 Temperature-Control Instrumentation , capable of maintaining the desired temperature to 61.8°F (61°C).

4.3 Thermocouple, for use as the temperature-measuring device. The type of thermocouple chosen will depend on the normal

use temperature of the furnace. Since thermocouples age with a consequent drift in the signal fed to the control instrument, check

1

This test method is under the jurisdiction ofASTM Committee C08 on Refractories and is the direct responsibility of Subcommittee C08.10 on Refractories for Glass.

Current edition approved Jan. 27, 1984. Published December 1984. Originally published as C621–68. Last previous edition C621–84(1995).

Current edition approved March 1, 2009. Published March 2009. Originally approved in 1968. Last previous edition approved in 2001 as C621–84 (2001).

2

Discontinued. See 1994

2

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.ForAnnualBookofASTMStandards

, Vol 14.03.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C621–09

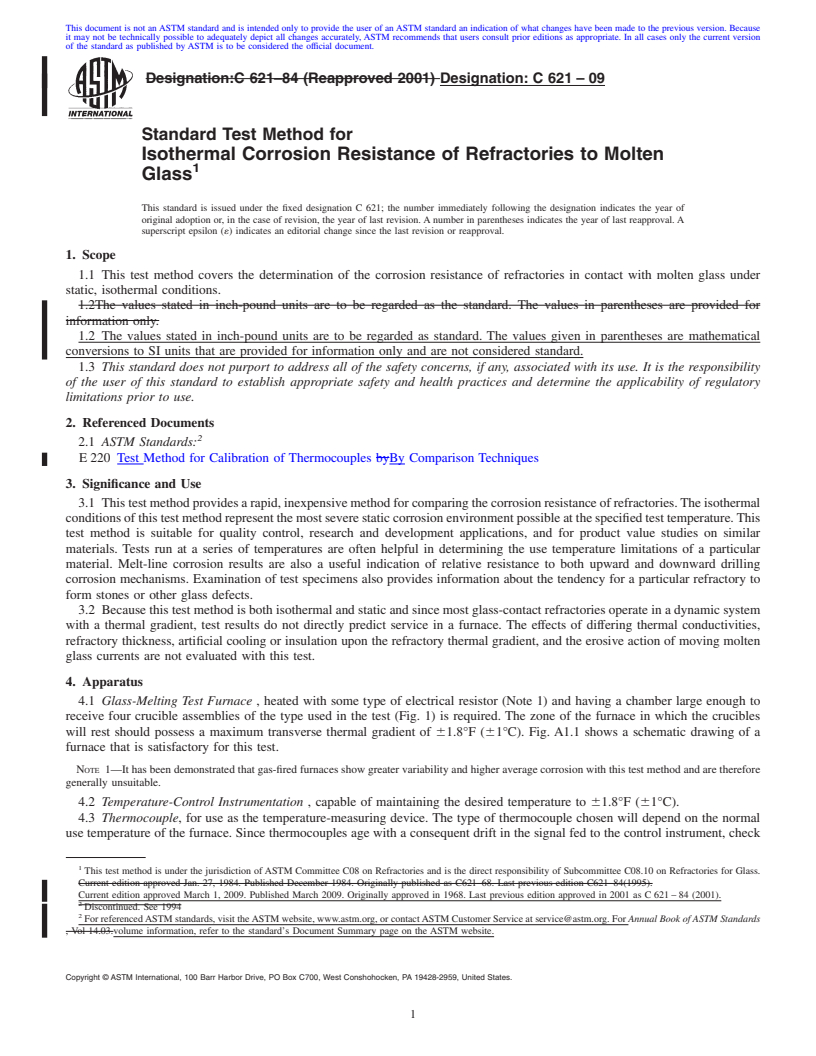

SI Equivalents

in. mm

0.030 0.76

13

⁄64 5

1

⁄2 13

33

⁄64

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.