ASTM D4486-91(2010)

(Test Method)Standard Test Method for Kinematic Viscosity of Volatile and Reactive Liquids

Standard Test Method for Kinematic Viscosity of Volatile and Reactive Liquids

SIGNIFICANCE AND USE

Kinematic viscosity is a physical property which is of importance in the design of systems in which flowing liquids are used or handled.

SCOPE

1.1 This test method covers the measurement of kinematic viscosity of transparent, Newtonian liquids which because of their reactivity, instability, or volatility cannot be used in conventional capillary kinematic viscometers. This test method is applicable up to 2 × 10−5 N/m2 (2 atm) pressure and temperature range from −53 to +135 °C (−65 to +275 °F).

1.1.1 For the measurement of the kinematic viscosity of other liquids, see Test Method D445.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific warning statements, see 7.2, 7.3, 7.4, and Annex A1.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D4486–91 (Reapproved 2010)

Standard Test Method for

1

Kinematic Viscosity of Volatile and Reactive Liquids

This standard is issued under the fixed designation D4486; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.2.1 Discussion—For gravity flow under a given hydro-

static head, the pressure head of a liquid is proportional to its

1.1 This test method covers the measurement of kinematic

density r. For any particular viscometer, the time of flow of a

viscosity of transparent, Newtonian liquids which because of

fixedvolumeofliquidisdirectlyproportionalto h/r.Thisratio

their reactivity, instability, or volatility cannot be used in

is the kinematic viscosity coefficient (n). The cgs unit of

conventionalcapillarykinematicviscometers.Thistestmethod

−5 2

kinematic viscosity is the stoke and has the dimensions of

is applicable up to 2 310 N/m (2 atm) pressure and

centimetre squared per second: the centistoke (0.01 St) is

temperature range from −53 to +135 °C (−65 to +275 °F).

frequently used. The SI unit of kinematic viscosity has the

1.1.1 For the measurement of the kinematic viscosity of

2 4

dimensions of metre /second, and is equivalent to 10 St.

other liquids, see Test Method D445.

3.1.3 viscosity—the ratio between the applied shear stress

1.2 This standard does not purport to address all of the

and rate of shear.

safety concerns, if any, associated with its use. It is the

3.1.3.1 Discussion—This ratio is called the coefficient of

responsibility of the user of this standard to establish appro-

viscosity. The coefficient of viscosity (h) is thus a measure of

priate safety and health practices and determine the applica-

theresistancetoflowoftheliquid.Thisiscommonlycalledthe

bility of regulatory limitations prior to use. For specific

viscosity of the liquid.The cgs unit of viscosity is the poise. P,

warning statements, see 7.2, 7.3, 7.4, and Annex A1.

which has the dimensions of dyne-seconds per square centi-

2. Referenced Documents

metre: the centipoise (0.01 poise) is frequently used. The SI

2

2

unit of viscosity has the dimensions of newton second/metre ,

2.1 ASTM Standards:

and is equivalent to 10 P.

D445 Test Method for Kinematic Viscosity of Transparent

3.1.4 vulnerable liquid—a liquid which by reason of its

and Opaque Liquids (and Calculation of Dynamic Viscos-

volatility, instability or reactivity in the presence of air or any

ity)

other specific gaseous medium may undergo physical or

D2162 PracticeforBasicCalibrationofMasterViscometers

chemical changes that may affect its viscosity.

and Viscosity Oil Standards

E1 Specification for ASTM Liquid-in-Glass Thermometers

4. Summary of Test Method

3. Terminology 4.1 The time is measured, in seconds, for a fixed volume of

liquid to flow under gravity through the capillary of the

3.1 Definitions of Terms Specific to This Standard:

viscometer under a reproducible driving head and at a closely

3.1.1 density—the mass per unit volume of the liquid.

controlled temperature. The kinematic viscosity is calculated

3.1.1.1 Discussion—The cgs unit of density (r) has the

fromthemeasuredflowtimeandthecalibrationconstantofthe

dimensions of grams per cubic centimetre. The SI unit of

viscometer.

density has the dimensions of kilograms per cubic metre.

3.1.2 kinematic viscosity—The ratio of the viscosity to the

5. Significance and Use

density of the liquid.

5.1 Kinematic viscosity is a physical property which is of

importance in the design of systems in which flowing liquids

1

This test method is under the jurisdiction of Committee D02 on Petroleum

are used or handled.

ProductsandLubricantsandisthedirectresponsibilityofSubcommitteeD02.11on

Engineering Sciences of High Performance Fluids and Solids.

6. Apparatus

Current edition approved Aug. 1, 2010. Published October 2010. Originally

6.1 Viscometer Thermostat—Any transparent liquid or va-

approved in 1991. Last previous edition approved in 2006 as D4486–91(2006).

DOI: 10.1520/D4486-91R10.

por bath of sufficient depth such that at no time during the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

measurement will any portion of the sample in the viscometer

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

be less than 20 mm below the surface of the bath liquid or less

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. than 20 mm above the bottom of the bath may be used. The

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page

...

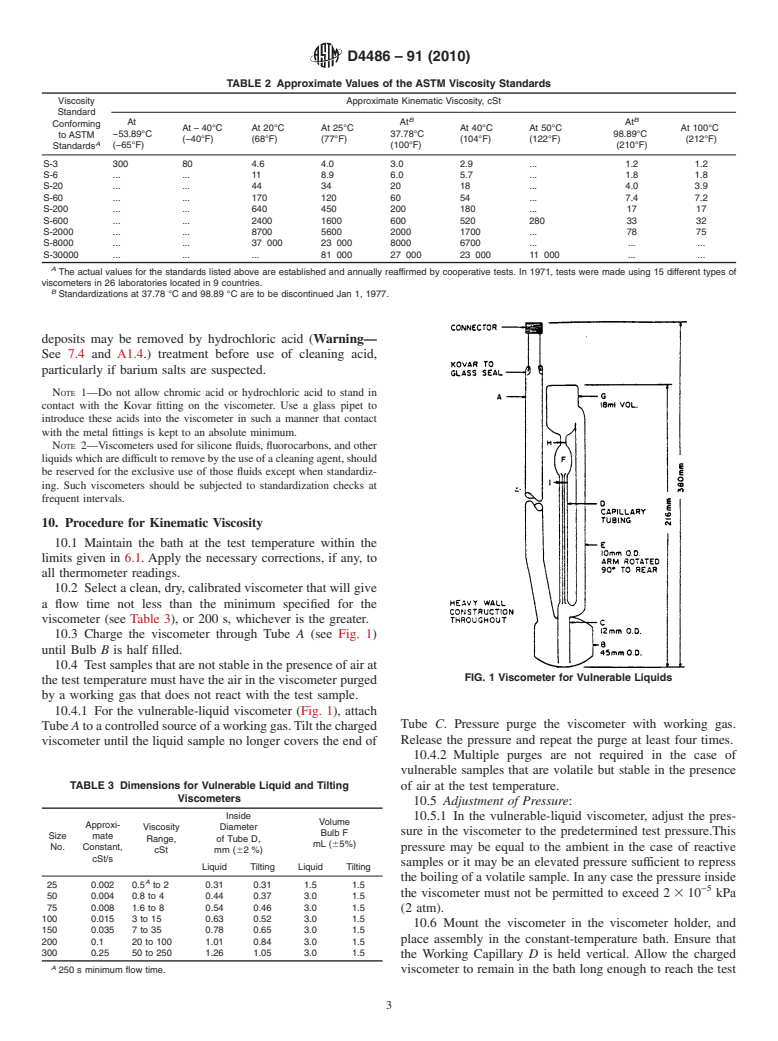

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.