ASTM F1612-95(2000)

(Practice)Standard Practice for Cyclic Fatigue Testing of Metallic Stemmed Hip Arthroplasty Femoral Components with Torsion

Standard Practice for Cyclic Fatigue Testing of Metallic Stemmed Hip Arthroplasty Femoral Components with Torsion

SCOPE

1.1 This practice covers a method for the fatigue testing of metallic stemmed femoral components used in hip arthroplasty. The described method is intended to be used for evaluation in comparisons of various designs and materials used for stemmed femoral components used in the arthroplasty. This practice covers procedures for the performance of fatigue tests using (as a forcing function) a periodic constant amplitude force.

1.2 This practice applies primarily to one-piece prostheses and femoral stems with modular heads, with the head in place. Such prostheses should not have an anterior-posterior A-P bow or a medial-lateral M-L bow, and they should have a nearly straight section on the distal 50 mm of the stem. This practice may require modifications to accommodate other femoral stem designs.

1.3 The values stated in SI units are to be regarded as the standard.

1.4This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F1612–95 (Reapproved 2000)

Standard Practice for

Cyclic Fatigue Testing of Metallic Stemmed Hip Arthroplasty

Femoral Components with Torsion

This standard is issued under the fixed designation F1612; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope ISO 7206-3 (1988) Stem Test

1.1 This practice covers a method for the fatigue testing of

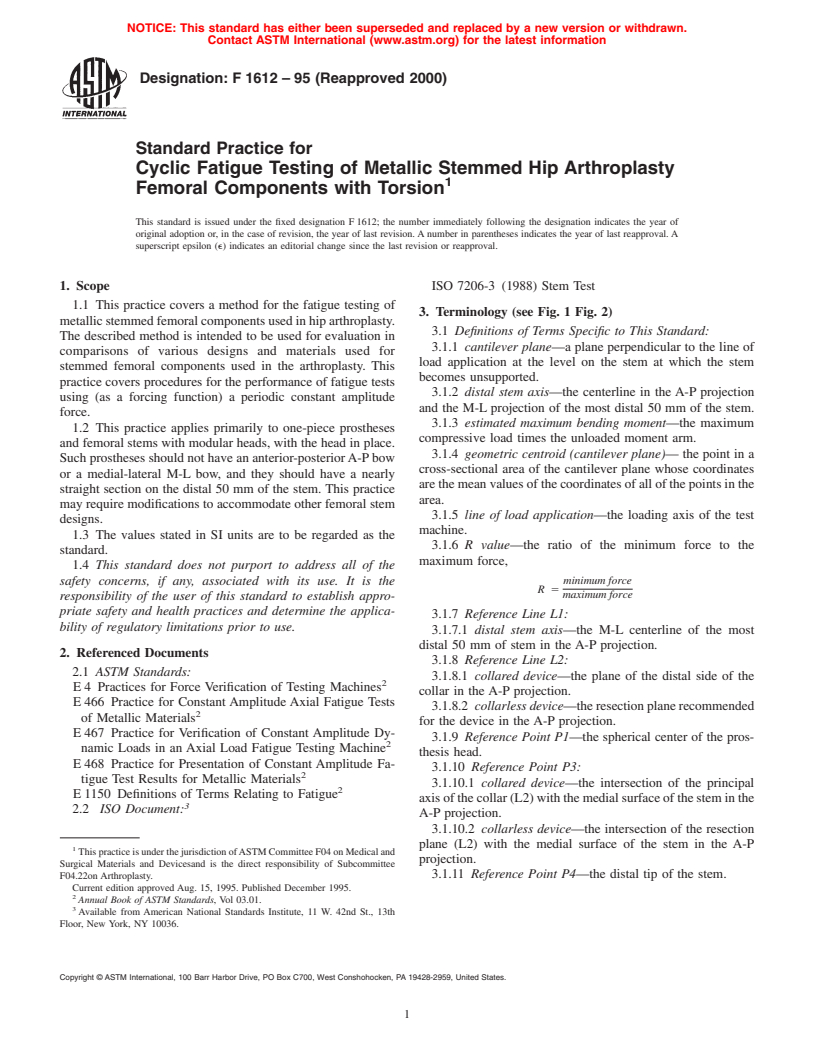

3. Terminology (see Fig. 1 Fig. 2)

metallicstemmedfemoralcomponentsusedinhiparthroplasty.

3.1 Definitions of Terms Specific to This Standard:

The described method is intended to be used for evaluation in

3.1.1 cantilever plane—a plane perpendicular to the line of

comparisons of various designs and materials used for

load application at the level on the stem at which the stem

stemmed femoral components used in the arthroplasty. This

becomes unsupported.

practice covers procedures for the performance of fatigue tests

3.1.2 distal stem axis—the centerline in the A-P projection

using (as a forcing function) a periodic constant amplitude

and the M-L projection of the most distal 50 mm of the stem.

force.

3.1.3 estimated maximum bending moment—the maximum

1.2 This practice applies primarily to one-piece prostheses

compressive load times the unloaded moment arm.

and femoral stems with modular heads, with the head in place.

3.1.4 geometric centroid (cantilever plane)— the point in a

Suchprosthesesshouldnothaveananterior-posteriorA-Pbow

cross-sectional area of the cantilever plane whose coordinates

or a medial-lateral M-L bow, and they should have a nearly

arethemeanvaluesofthecoordinatesofallofthepointsinthe

straight section on the distal 50 mm of the stem. This practice

area.

mayrequiremodificationstoaccommodateotherfemoralstem

3.1.5 line of load application—the loading axis of the test

designs.

machine.

1.3 The values stated in SI units are to be regarded as the

3.1.6 R value—the ratio of the minimum force to the

standard.

maximum force,

1.4 This standard does not purport to address all of the

minimum force

safety concerns, if any, associated with its use. It is the

R 5

maximum force

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

3.1.7 Reference Line L1:

bility of regulatory limitations prior to use.

3.1.7.1 distal stem axis—the M-L centerline of the most

distal 50 mm of stem in the A-P projection.

2. Referenced Documents

3.1.8 Reference Line L2:

2.1 ASTM Standards:

3.1.8.1 collared device—the plane of the distal side of the

E4 Practices for Force Verification of Testing Machines

collar in the A-P projection.

E466 Practice for Constant Amplitude Axial Fatigue Tests

3.1.8.2 collarless device—theresectionplanerecommended

of Metallic Materials

for the device in the A-P projection.

E467 Practice for Verification of Constant Amplitude Dy-

3.1.9 Reference Point P1—the spherical center of the pros-

namic Loads in an Axial Load Fatigue Testing Machine

thesis head.

E468 Practice for Presentation of Constant Amplitude Fa-

3.1.10 Reference Point P3:

tigue Test Results for Metallic Materials

3.1.10.1 collared device—the intersection of the principal

E1150 Definitions of Terms Relating to Fatigue

axisofthecollar(L2)withthemedialsurfaceofthesteminthe

2.2 ISO Document:

A-P projection.

3.1.10.2 collarless device—the intersection of the resection

plane (L2) with the medial surface of the stem in the A-P

ThispracticeisunderthejurisdictionofASTMCommitteeF04onMedicaland

projection.

Surgical Materials and Devicesand is the direct responsibility of Subcommittee

3.1.11 Reference Point P4—the distal tip of the stem.

F04.22on Arthroplasty.

Current edition approved Aug. 15, 1995. Published December 1995.

Annual Book of ASTM Standards, Vol 03.01.

Available from American National Standards Institute, 11 W. 42nd St., 13th

Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F1612

FIG. 2 1(b) Collarless Device, M-L Projection

FIG. 1 1(a) Collared Device, M-L Projection

4. Significance and Use

4.1 This practice can be used to describe the effects of

3.1.12 Reference Point P6 — the intersection of the canti-

materials, manufacturing, and design variables on the fatigue

lever plane with the medial surface of the stem in the A-P

resistance of metallic stemmed femoral components subjected

projection.

to cyclic loading for relatively large numbers of cycles. The

3.1.13 stem reference angles—Since the distal stem axis is

recommended test assumes a worst case situation in which

obscurred by the grouting agent after preparation of the test

proximal support for the stem has been lost. It is also

sample,thestemreferenceanglesaretobeusedtomeasurethe

recognized that, for some materials, the environment has an

repeatability of the stem orientation.They may also be used to

effect on the response to cyclic loading (see section 12.7). The

estimate the actual orientation of the distal stem to the line of

test environment used and rationale for the choice of that

load application if the stem geometry is well known.

environment should be described in the test report.

3.1.13.1 X (M-L)—the angle between the stem reference

4.2 Itisrecognizedthatactualinvivoloadingconditionsare

line and line of load application in the M-L projection.

not constant amplitude. However, sufficient information is not

3.1.13.2 X (A-P)—theanglebetweenthestemreferenceline

available to create standard load spectrums for metallic

and line of load application in the M-L and A-P projections.

stemmed femoral components. A simple periodic constant

3.1.14 stem reference line—a line passing through Refer-

amplitude force is accordingly recommended.

ence Point P6 and the center of the prosthesis head (P1).

5. Purpose

3.1.15 supported stem length—the vertical distance be-

tween the distal tip of the stem (P4) and cantilever plane. 5.1 In order for fatigue data on femoral stems to be useful

for comparison, it must be reproducible among different

3.1.16 unloaded moment arm—the vector sum of the per-

pendicular distance between the line of load application and laboratories. It is consequently essential that uniform proce-

dures for testing and reporting test data be established.

geometric centroid of the stem cross section at the cantilever

plane in the A-P and M-L projections.

6. Apparatus

3.1.17 unsupported stem length—the vertical distance be-

6.1 Thespecimenshallbeconstrainedbyasuitablegrouting

tween Point P3 and the cantilever plane.

agent within a rigid cavity. A common grouting agent used is

polymethyl methacrylate (PMMA, bone cement). The mini-

mumthicknessofthegroutingagentshouldbe1cm.Although

The reference points and lines are consistent with the proposed Specification

bone cement is the recommended grouting agent, other mate-

for CementableTotal Hip Prostheses with Femoral Stems.The Reference Points P2

rial may be used, provided that it does not alter the test

and P5 in that specification are not relevant to this practice. Consequently, they are

not used in this practice. specimen chemically or mechanically.

F1612

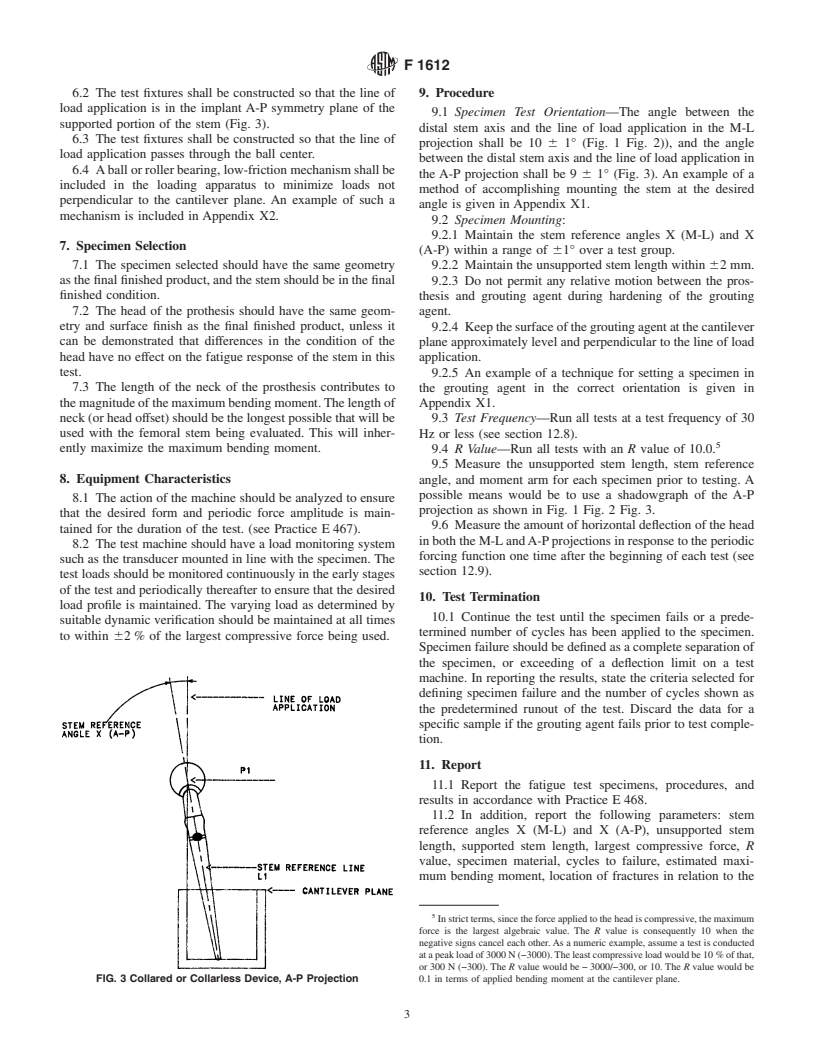

6.2 The test fixtures shall be constructed so that the line of 9. Procedure

load application is in the implant A-P symmetry plane of the

9.1 Specimen Test Orientation—The angle between the

supported portion of the stem (Fig. 3).

distal stem axis and the line of load application in the M-L

6.3 The test fixtures shall be constructed so that the line of

projection shall be 10 6 1° (Fig. 1 Fig. 2)), and the angle

load application passes through the ball center.

between the distal stem axis and the line of load application in

6.4 Aballorrollerbearing,low-frictionmechanismshallbe

the A-P projection shall be 9 6 1° (Fig. 3). An example of a

included in the loading apparatus to minimize loads not

method of accomplishing mounting the stem at the desired

perpendicular to the cantilever plane. An example of such a

angle is given in Appendix X1.

mechanism is included in Appendix X2.

9.2 Specimen Mounting:

9.2.1 Maintain the stem reference angles X (M-L) and X

7. Specimen Selection

(A-P) within a range of 61° over a test group.

7.1 The specimen selected should have the same geometry

9.2.2 Maintain the unsupported stem length within 62 mm.

asthefinalfinishedproduct,andthestemshouldbeinthefinal 9.2.3 Do not permit any relative motion between the pros-

finished condition.

thesis and grouting agent during hardening of the grouting

7.2 The head of the prothesis should have the same geom- agent.

etry and surface finish as the final finished product, unless it 9.2.4 Keepthesurfaceofthegroutingagentatthecantilever

can be demonstrated that differences in the condition of the planeapproximatelylevelandperpendiculartothelineofload

head have no effect on the fatigue response of the stem in this application.

test.

9.2.5 An example of a technique for setting a specimen in

7.3 The length of the neck of the prosthesis contributes to the grouting agent in the correct orientation is given in

themagnitudeofthemaximumbendingmoment.Thelengthof

Appendix X1.

neck(orheadoffset)shouldbethelongestpossiblethatwillbe 9.3 Test Frequency—Run all tests at a test frequency of 30

used with the femoral stem being evaluated. This will inher-

Hz or less (see section 12.8).

ently maximize the maximum bending moment. 9.4 R Value—Run all tests with an R value of 10.0.

9.5 Measure the unsupported stem length, stem reference

8. Equipment Characteristics

angle, and moment arm for each specimen prior to testing. A

possible means would be to use a shadowgraph of the A-P

8.1 The action of the machine should be analyzed to ensure

projection as shown in Fig. 1 Fig. 2 Fig. 3.

that the desired form and periodic force amplitude is main-

9.6 Measuretheamountofhorizontaldeflectionofthehead

tained for the duration of the test. (see Practice E467).

inboththeM-LandA-Pprojectionsinresponsetotheperiodic

8.2 The test machine should have a load monitoring system

forcing function one time after the beginning of each test (see

such as the transducer mounted in line with the specimen. The

section 12.9).

test loads should be monitored continuously in the early stages

of the test and periodically thereafter to ensure that the desired

10. Test Termination

load profile is maintained. The varying load as determined by

10.1 Continue the test until the specimen fails or a prede-

suitable dynamic verification should be maintained at all times

termined number of cycles has been applied to the specimen.

to within 62% of the largest compressive force being used.

Specimenfailureshouldbedefinedasacompleteseparationof

the specimen, or exceeding of a deflection limit on a test

machine. In reporting the results, state the criteria selected for

defining specimen failure and the number of cycles shown as

the predetermined runout of the test. Discard the data for a

specific sample if the grouting agent fails prior to test comple-

tion.

11. Report

11.1 Report the fatigue test specimens, procedures, and

results in accordance with Practice E468.

11.2 In addition, report the following parameters: stem

reference angles X (M-L) and X (A-P), unsupported stem

length, supported stem length, largest compressive force, R

value, specimen material, cycles to failure, estimated maxi-

mum bending moment, location of fractures in relation to the

Instrictterms,sincetheforceappliedtotheheadiscompressive,themaximum

force is the largest algebraic value. The R value is consequently 10 when the

negative signs cancel each other.As a numeric example, assume a test is conducted

atapeakloadof3000N(−3000).Theleastcompressiveloadwouldbe10%ofthat,

or 300 N (−300). The R value would be−3000/−300, or 10. The R value would be

FIG. 3 Collared or Collarless Device, A-P Projection 0.1 in terms of applied bending moment at the cantilever plane.

F1612

cantilever plane, average dimensions of the stem cross section

in the cantilever plane, grouting agent, test environment, test

frequency, head/neck offset of the stem (neck length), and

deflection limit used to cut off testing (see 10.1).

12. Precision and Bias

12.1 The precision and bias of this practice is being

established.

APPENDIXES

(Nonmandatory Information)

X1. EXAMPLE PROSTHESIS MOUNTING PROCEDURE

X1.1 Adrawingorshadowgraphoftheprosthesisshouldbe ringstand and test tube holder can be used to grip the head of

available before mounting to establish the angular relationship the subject prosthesis.

between the distal stem axis and stem reference angle.

X1.3 The prosthesis is held by the head permitting the

X1.2 A gripping device, as illustrated in Fig. X1.1, or a

distal tip to rest on a flat surface. The angle jig illustrated in

Fig. X1.2 is positioned with the distal stem in the notch. The

stem is adjusted so that it is centered in the notch of the angle

jig. This will orient the distal stem at approximately 10° to the

line of load application. The head is now gripped firmly to

maintain the angular orientation of the stem.

X1.4 The angle jig can be removed and the prosthesis

mounted at the appropriate depth in an appropriate specimen

holder.

X1.5 Grouting material can be placed around the test

prosthesis into the specimen holder and permitted to harden.

X1.6 Thegripontheheadoftheprosthesisisreleasedafter

hardening of the grouting agent, and a shadowgraph may be

prepared of the profile of the test specimen and specimen

holder assembly.

X1.7 Asecondadjustablestopmaybeaddedbelowthegrip

and adjusted to rest against the medial surface of an appropri-

ately oriented prosthesis to facilitate repeatable mounting of

FIG. X1.1 Example of a Low-Friction Mechanism the test group.

F1612

FIG. X1.2 Apparatus for Gripping the Test Specimen While

Embedding it in the Correct Orientation

X2. RATIONALE

X2.1 Thebreakageoffemoralstemsinhiparthroplastyhas X2.3 Thispracticeattemptstomodelsimplytheorientation

occurred in clinical application. The stem design, PMMA of the stemmed femoral component in relation to the peak

support, quality of bone, and other features contribute to stem loads that are applied in the human body. To accomplish this,

fracture. One recognizable mode of breakage is with the distal thedistalstemwillhaveananatomicorientationtotheapplied

portion of the stem anchored firmly, while medial proximal load in both the M-LandA-Pplane of the prosthesis. Because

support is lost.As the body loads are applied through

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.