ASTM D6117-97(2005)

(Test Method)Standard Test Methods for Mechanical Fasteners In Plastic Lumber and Shapes

Standard Test Methods for Mechanical Fasteners In Plastic Lumber and Shapes

SIGNIFICANCE AND USE

The resistance of plastic lumber and shapes to direct withdrawal of nails, staples, or screws is a measure of its ability to hold or be held to an adjoining object by means of such fasteners. Factors that affect this withdrawal resistance include the physical and mechanical properties of the plastic lumber and shapes; the size, shape, and surface condition of the fasteners; the speed of withdrawal; physical changes to plastic lumber and shapes or fasteners between time of driving and time of withdrawal; orientation of fiber axis; the occurrence and nature of prebored lead holes; and the temperatures during insertion and withdrawal. These factors will be as circumstances dictate, and representative of the normal manufacturing process.

By using a standard size and type of nail, staple, or screw, withdrawal resistance of plastic lumber and shapes can be determined. Throughout the method this is referred to as the basic withdrawal test. Similarly, comparative performances of different sizes or types of nail, staple, or screw can be determined by using a standard procedure with a particular plastic lumber and shape, which eliminates the plastic lumber and shapes product as a variable. Since differences in test methods can have considerable influence on results, it is important that a standard procedure be specified and adhered to, if test values are to be related to other test results.

SCOPE

1.1 These test methods cover the evaluation of fastener use with "as manufactured" plastic lumber and shapes through the use of two different testing procedures.

1.2 The test methods appear in the following order:SectionsTest Method A-Nail, Staple, or Screw Withdrawal Test4 to 13Test Method B-Lateral Nail, Staple, or Screw Resistance Test14 to 22

1.3 Plastic lumber and plastic shapes are currently made predominately from recycled plastics. However, these test methods would also be applicable to similar manufactured plastic products made from virgin resins where the product is non-homogeneous in the cross-section.

1.4 The values stated in inch-pound units are to be regarded as standard. The SI units given in brackets are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.Note 1

There is no similar or equivalent ISO standard.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6117–97 (Reapproved 2005)

Standard Test Methods for

Mechanical Fasteners in Plastic Lumber and Shapes

This standard is issued under the fixed designation D6117; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The use of plastic lumber and shapes often involves the use of mechanical fasteners, such as nails,

screws, bolts, lag screws, and connectors. Data on the strength and performance of such fasteners are

frequently needed for design and for comparative purposes. Presented herewith are methods of

conducting tests for nail, staple and screw withdrawal resistance and lateral load transmission by nail,

staple, screw, and bolt. The use of standard methods for these tests is recommended as a means of

obtaining comparable data and of eliminating variables in test results because of variation in testing

methods.

1. Scope 2. Referenced Documents

1.1 These test methods cover the evaluation of fastener use 2.1 ASTM Standards:

with “as manufactured” plastic lumber and shapes through the D883 Terminology Relating to Plastics

use of two different testing procedures. D1761 Test Methods for Mechanical Fasteners in Wood

1.2 The test methods appear in the following order: D5033 Guide for Development of ASTM Standards Relat-

ing to Recycling and Use of Recycled Plastics

Sections

Test MethodA—Nail, Staple, or Screw Withdrawal Test 4 to 13

D6111 Test Method for Bulk Density And Specific Gravity

Test Method B—Lateral Nail, Staple, or Screw Resistance Test 14 to 22

of Plastic Lumber and Shapes by Displacement

1.3 Plastic lumber and plastic shapes are currently made

E4 Practices for Force Verification of Testing Machines

predominately from recycled plastics. However, these test 2.2 ANSI Standards:

methods would also be applicable to similar manufactured

B18.61 American National Standard for Slotted and Head

plastic products made from virgin resins where the product is Wood Screws

non-homogeneous in the cross-section.

3. Terminology

1.4 The values stated in inch-pound units are to be regarded

as standard. The SI units given in brackets are for information 3.1 Definitions:

only. 3.1.1 plastic lumber, n—a manufactured product composed

1.5 This standard does not purport to address all of the of more than 50 weight percent resin, and in which the product

safety concerns, if any, associated with its use. It is the

generally is rectangular in cross-section and typically supplied

responsibility of the user of this standard to establish appro- in board and dimensional lumber sizes, may be filled or

priate safety and health practices and determine the applica-

unfilled, and may be composed of single or multiple resin

bility of regulatory limitations prior to use. blends.

NOTE 1—There is no similar or equivalent ISO standard.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

These test methods are under the jurisdiction of ASTM Committee D20 on Standards volume information, refer to the standard’s Document Summary page on

Plastics and are the direct responsibility of Subcommittee D20.20 on Plastic the ASTM website.

Products (Section D20.20.01). Withdrawn. The last approved version of this historical standard is referenced

Current edition approved Nov. 1, 2005. Published January 2006. Originally on www.astm.org.

approved in 1997. Last previous edition approved in 1997 as D6117 - 97. DOI: Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

10.1520/D6117-97R05. 4th Floor, New York, NY 10036.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

D6117–97 (2005)

3.1.2 plastic shape, n—manufactured product composed of important that a standard procedure be specified and adhered

more than 50 weight percent resin, and in which the product to, if test values are to be related to other test results.

generally is not rectangular in cross-section, may be filled or

unfilled, and may be composed of single or multiple resin 7. Apparatus

blends.

7.1 Testing Machine—Any suitable testing machine that is

3.1.3 resin, n—a solid or pseudosolid organic material often

capable of operation at a constant rate of motion of the

of high molecular weight, which exhibits a tendency to flow

movable head and has an accuracy of 61 % when calibrated in

when subjected to stress, usually has a softening or melting

accordance with Test Methods E4.

range, and usually fractures conchoidally. (See Terminology

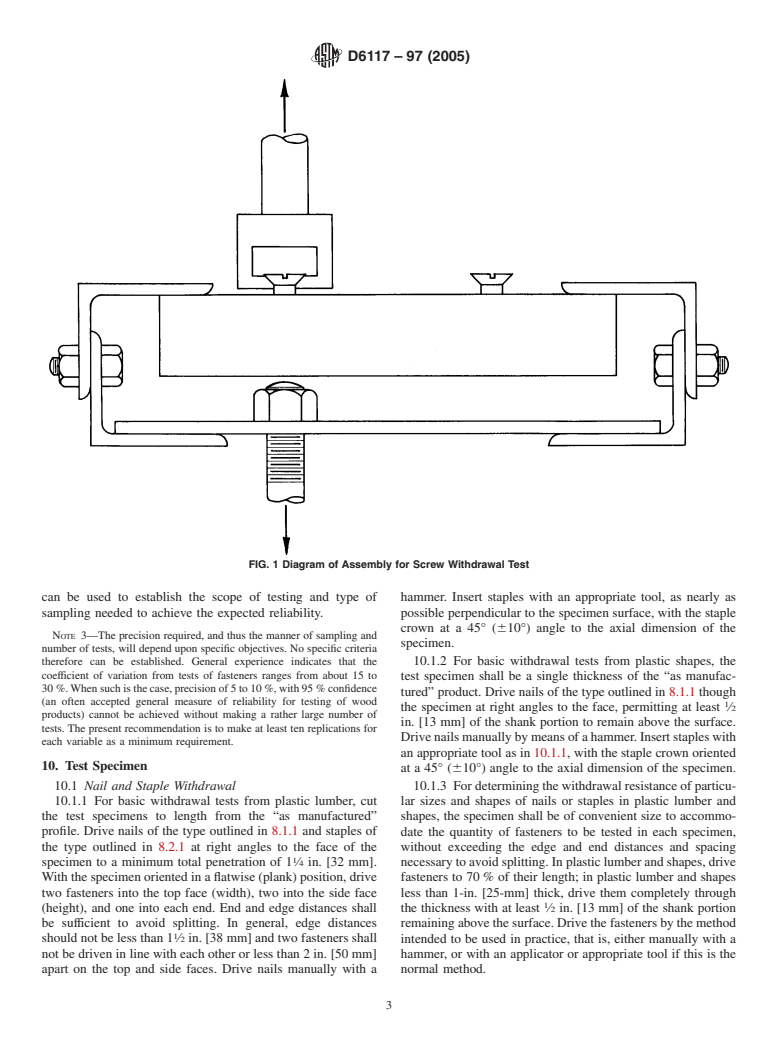

7.2 Grips—A gripping device shaped to fit the base of the

D883.)

fastener head and of such a design as to allow accurate

3.1.3.1 Discussion—In a broad sense, the term is used to

clamping assembly that will hold the specimen to one platen of

designate any polymer that is basic material for plastics.

the machine is also required. A suitable test mechanism for

3.2 Additional definition of terms applying to these test

screw withdrawal is illustrated in Fig. 1.

methods appear in Terminology D883 and Guide D5033.

8. Test Nails, Staples, or Screws

TEST METHOD A—NAIL, STAPLE, OR SCREW

8.1 Nails:

WITHDRAWAL TEST

8.1.1 Nails used for basic withdrawal tests shall be

4. Scope

diamond-point round-wire, low-carbon-steel nails nominally

0.148 in. [3.76 mm] in diameter and 3 in. [76 mm] in length

4.1 This test method provides a basic procedure for evalu-

(See Note 2). Use each nail only once.

ating the resistance or plastic lumber and shapes materials to

direct withdrawal of nails, staples, and screws. Spikes are

NOTE 2—A 10d galvanized common steel wire nail meets this require-

included as nails in this test method.

ment.

4.2 This test method also provides a basis for determining

8.1.2 For determining holding ability of different sizes or

comparable performance of different types and sizes of nails,

types of nails in plastic lumber and shapes, the respective sizes

staples, and screws in direct withdrawal from plastic lumber

and types of nail will be as circumstances dictate. These nails

and shapes.

shall be representative of the normal manufacturing process,

and special cleaning of the shank shall normally not be

5. Summary of Test Method

undertaken.

5.1 Specimens consist of “as manufactured” plastic lumber

8.2 Staples:

and shapes, with nails, staples, or screws driven at right angles

8.2.1 Staples used for basic leg withdrawal resistance shall

to one or more faces. The fasteners are withdrawn at a uniform

be nominally 2.0-in. [51-mm] long, ⁄16-in. [11-mm] crown, 15

rate of speed by means of a testing machine, and the maximum

gage (0.072-in. [1.83-mm]) galvanized steel staples. Use each

load is recorded. Supplementary physical properties of the

staple only once.

plastic lumber and shapes are also determined.

8.2.2 For determining holding ability of different types or

sizes of staples in plastic lumber and shapes, the respective

6. Significance and Use

staples shall be representative of the normal manufacturing

6.1 The resistance of plastic lumber and shapes to direct

process, and special cleaning of the legs shall not normally be

withdrawalofnails,staples,orscrewsisameasureofitsability

undertaken.

to hold or be held to an adjoining object by means of such

8.3 Screws:

fasteners. Factors that affect this withdrawal resistance include

8.3.1 Screws used for basic withdrawal tests shall be nomi-

the physical and mechanical properties of the plastic lumber

nally 1-in. [25-mm] No. 10–gage flathead low-carbon-steel

and shapes; the size, shape, and surface condition of the

wood screws as described in ANSI B18.61. Use each screw

fasteners; the speed of withdrawal; physical changes to plastic

only once.

lumber and shapes or fasteners between time of driving and

8.3.2 For determining holding ability of different sizes and

time of withdrawal; orientation of fiber axis; the occurrence

types of screws in plastic lumber and shapes, the respective

and nature of prebored lead holes; and the temperatures during

size and types of screw will be as circumstances dictate. These

insertion and withdrawal. These factors will be as circum-

screws shall be representative of the normal manufacturing

stancesdictate,andrepresentativeofthenormalmanufacturing

process.

process.

6.2 By using a standard size and type of nail, staple, or

9. Sampling

screw, withdrawal resistance of plastic lumber and shapes can

be determined.Throughout the method this is referred to as the 9.1 Sampling should provide for selection of representative

basic withdrawal test. Similarly, comparative performances of test materials on an objective and unbiased basis, covering an

different sizes or types of nail, staple, or screw can be appropriate range in density and properties as circumstances

suggest.

determined by using a standard procedure with a particular

plastic lumber and shape, which eliminates the plastic lumber 9.2 The tests should be sufficiently extensive to provide

and shapes product as a variable. Since differences in test reliable results. Where analysis by statistical procedures is

methods can have considerable influence on results, it is contemplated, experience and sometimes advance estimates

D6117–97 (2005)

FIG. 1 Diagram of Assembly for Screw Withdrawal Test

can be used to establish the scope of testing and type of hammer. Insert staples with an appropriate tool, as nearly as

sampling needed to achieve the expected reliability. possible perpendicular to the specimen surface, with the staple

crown at a 45° (610°) angle to the axial dimension of the

NOTE 3—The precision required, and thus the manner of sampling and

specimen.

number of tests, will depend upon specific objectives. No specific criteria

therefore can be established. General experience indicates that the 10.1.2 For basic withdrawal tests from plastic shapes, the

coefficient of variation from tests of fasteners ranges from about 15 to

test specimen shall be a single thickness of the “as manufac-

30 %.Whensuchisthecase,precisionof5to10 %,with95 %confidence

tured” product. Drive nails of the type outlined in 8.1.1 though

(an often accepted general measure of reliability for testing of wood

the specimen at right angles to the face, permitting at least ⁄2

products) cannot be achieved without making a rather large number of

in. [13 mm] of the shank portion to remain above the surface.

tests. The present recommendation is to make at least ten replications for

Drivenailsmanuallybymeansofahammer.Insertstapleswith

each variable as a minimum requirement.

an appropriate tool as in 10.1.1, with the staple crown oriented

10. Test Specimen

at a 45° (610°) angle to the axial dimension of the specimen.

10.1 Nail and Staple Withdrawal 10.1.3 For determining the withdrawal resistance of particu-

10.1.1 For basic withdrawal tests from plastic lumber, cut lar sizes and shapes of nails or staples in plastic lumber and

the test specimens to length from the “as manufactured” shapes, the specimen shall be of convenient size to accommo-

profile. Drive nails of the type outlined in 8.1.1 and staples of date the quantity of fasteners to be tested in each specimen,

the type outlined in 8.2.1 at right angles to the face of the without exceeding the edge and end distances and spacing

specimen to a minimum total penetration of 1 ⁄4 in. [32 mm]. necessarytoavoidsplitting.Inplasticlumberandshapes,drive

With the specimen oriented in a flatwise (plank) position, drive fasteners to 70 % of their length; in plastic lumber and shapes

two fasteners into the top face (width), two into the side face less than 1-in. [25-mm] thick, drive them completely through

(height), and one into each end. End and edge distances shall the thickness with at least ⁄2 in. [13 mm] of the shank portion

be sufficient to avoid splitting. In general, edge distances remaining above the surface. Drive the fasteners by the method

should not be less than 1 ⁄2 in. [38 mm] and two fasteners shall intended to be used in practice, that is, either manually with a

not be driven in line with each other or less than 2 in. [50 mm] hammer, or with an applicator or appropriate tool if this is the

apart on the top and side faces. Drive nails manually with a normal method.

D6117–97 (2005)

10.1.3.1 If the withdrawal resistance may be influenced by means of a tensile force applied at a uniform rate of with-

the material in which the fastener is to be driven, drive the drawal. Attach the specimen to one platen of the testing

fastener through the fastened member (cleat) into the base machine. Attach the fastener head to a suitably designed grip

fastening member. that is fastened to the other platen through a universal joint.

10.2 Screw Withdrawal: Apply the load by separation of the platens of the testing

10.2.1 For basic withdrawal tests from plastic lumber, cut machine at a uniform rate of withdrawal. Read the maximum

the test specimens to length from the “as manufactured” load required to withdraw the fastener from the plastic lumber

profile. With the specimen oriented in a flatwise (plank) and shape to three significant figures. Disregard test values

position, thread two screws of the type outlined in 8.3.1 into resulting from any failure of the fastener in the evaluation of

lead holes at right angles to the top face (width), two into the the performance of the plastic lumber and shapes materials but

side face (height), and one into each end, each to a total report them; consider such failures in the evaluation of the

penetrationequaltothelengthofthethreadedportion.Endand performance of different types and sizes of fasteners. In such

edge distance shall be sufficient to avoid splitting. that in cases, an additional replication is desirable.

3 1

general will be at least ⁄4 in. [19 mm] from the edge and 1 ⁄2 12.2.2 Wherethespecimenconsistsofabasepiecetowhich

in. [38 mm] from the end, and spacing will be at least 2 ⁄2 in.

one or more cleats have been fastened thereto with a fastener,

[63 mm] apart on the top and side faces.

two test procedures are possible. The fastened member (cleat)

10.2.2 For basic withdrawal tests from plastic shapes, the

can be grasped and pushed or pulled away for the base

test specimen shall be a single thickness of the “as manufac-

fastening member in the axial direction of the fastener,

tured” product. The depth of the specimen shall be at least whereby the fastener head exerts a force on the fastened

equal to the length of the screw. T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.