ASTM E360-96(2001)

(Test Method)Standard Test Methods for Chemical Analysis of Silicon and Ferrosilicon (Withdrawn 2006)

Standard Test Methods for Chemical Analysis of Silicon and Ferrosilicon (Withdrawn 2006)

SCOPE

DESIG: E360 96 (Reapproved 2001) ^TITLE: Standard Test Methods for Chemical Analysis of Silicon and Ferrosilicon ^SCOPE:

1.1 These test methods cover the chemical analysis of silicon and ferrosilicon having chemical compositions within the following limits:ElementConcentration, %Aluminum2.0 maxArsenic0.10 maxCalcium1.00 maxCarbon0.50 maxChromium0.50 maxCopper0.30 maxManganese1.00 maxNickel0.30 maxPhosphorus0.10 maxSilicon20.00 to 99.5Sulfur0.025 maxTitanium0.20 max

1.2 The test methods appear in the following order: SectionsArsenic by the Molybdenum Blue Photometric MethodAluminum by the Quinolinate Photometric and GravimetricMethodsSilicon by the Sodium Peroxide Fusion-Perchloric Acid Dehydration Method

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific precautionary statements are given in Section 5 and 26.8.1, 27.4.1.1, and 36.3.1.

WITHDRAWN RATIONALE

These test methods cover the chemical analysis of silicon and ferrosilicon having chemical compositions within established limits.

Formerly under the jurisdiction of Committee E01 on Analytical Chemistry for Metals, Ores, and Related Materials, these test methods were withdrawn in September 2006.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:E360–96(Reapproved2001)

Standard Test Methods for

Chemical Analysis of Silicon and Ferrosilicon

This standard is issued under the fixed designation E 360; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope Determine Conformance with Specifications

E32 Practices for Sampling Ferroalloys and SteelAdditives

1.1 These test methods cover the chemical analysis of

for Determination of Chemical Composition

silicon and ferrosilicon having chemical compositions within

E50 Practices forApparatus, Reagents, and Safety Consid-

the following limits:

erations for Chemical Analysis of Metals, Ores, and

Element Concentration, %

Related Materials

Aluminum 2.0 max

E60 Practice for Analysis of Metals, Ores, and Related

Arsenic 0.10 max

Materials by Molecular Absorption Spectrometry

Calcium 1.00 max

E 173 Practice for Conducting Interlaboratory Studies of

Carbon 0.50 max

Chromium 0.50 max

Methods for Chemical Analysis of Metals

Copper 0.30 max

E 362 Test Methods for ChemicalAnalysis of Silicomanga-

Manganese 1.00 max

nese and Ferrosilicon Manganese

Nickel 0.30 max

Phosphorus 0.10 max

E 363 Methods for Chemical Analysis of Chromium and

Silicon 20.00 to 99.5

Ferrochromium

Sulfur 0.025 max

Titanium 0.20 max E 364 Test Methods for ChemicalAnalysis of Ferrochrome-

Silicon

1.2 The test methods appear in the following order:

Sections

3. Significance and Use

3.1 These test methods for the chemical analysis of metals

Arsenic by the Molybdenum Blue Photometric Method 9-19

Aluminum by the Quinolinate Photometric and Gravimetric

and alloys are primarily intended to test such materials for

Methods 20-30

compliance with compositional specifications. It is assumed

Silicon by the Sodium Peroxide Fusion-Perchloric Acid

that all who use these test methods will be trained analysts

Dehydration Method 31-38

capable of performing common laboratory procedures skill-

1.3 This standard does not purport to address all of the

fully and safely. It is expected that work will be performed in

safety concerns, if any, associated with its use. It is the

a properly equipped laboratory.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Apparatus, Reagents, and Photometric Practice

bility of regulatory limitations prior to use. Specific precau-

4.1 Apparatus and reagents required for each determination

tionary statements are given in Section 5 and 26.8.1, 27.4.1.1,

are listed in separate sections preceding the procedure. The

and 36.3.1.

apparatus, standard solutions, and certain other reagents used

in more than one procedure are referred to by number and shall

2. Referenced Documents

conform to the requirements prescribed in Practices E50,

2.1 ASTM Standards:

except the photometers shall conform to the requirements

A 100 Specification for Ferrosilicon

prescribed in PracticeE60.

E29 Practice for Using Significant Digits in Test Data to

4.2 Photometric practice prescribed in these test methods

shall conform to PracticeE60.

These methods are under the jurisdiction of ASTM Committee E01 on

Analytical Chemistry for Metals, Ores, and Related Materials and are the direct

responsibility of Subcommittee E01.01 on Iron, Steel, and Ferroalloys.

Current edition approved April 10, 1996. Published June 1996. Originally

Annual Book of ASTM Standards, Vol 14.02.

e1

published as E 360 – 70 T. Last previous edition E 360 – 85 (1991) .

Annual Book of ASTM Standards, Vol 03.05.

Annual Book of ASTM Standards, Vol 01.02.

Discontinued; see 1997 Annual Book of ASTM Standards, Vol 03.06.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E360–96 (2001)

5. Safety Hazards 11. Concentration Range

5.1 For precautions to be observed in the use of certain 11.1 The recommended concentration range is 0.01 to 0.15

reagents in these test methods, refer to PracticesE50. mg of arsenic per 50 mL of solution using a 1-cm cell.

NOTE 1—This method has been written for cells having a 1-cm light

6. Sampling

path. Cells having other dimensions may be used, provided suitable

adjustments can be made in the amount of sample and reagents used.

6.1 For procedures for sampling the material, and for

particle size of the sample for chemical analysis, refer to

12. Stability of Color

PracticesE32.

12.1 The color is stable for at least 2 h.

7. Rounding Off Calculated Values

13. Interferences

7.1 Calculated values shall be rounded off to the desired

13.1 The elements ordinarily present do not interfere if their

number of places as directed in 3.4 to 3.6 of PracticeE29.

concentrations are under the maximum limits shown in 1.1.

8. Interlaboratory Studies

14. Apparatus

8.1 These test methods have been evaluated in accordance

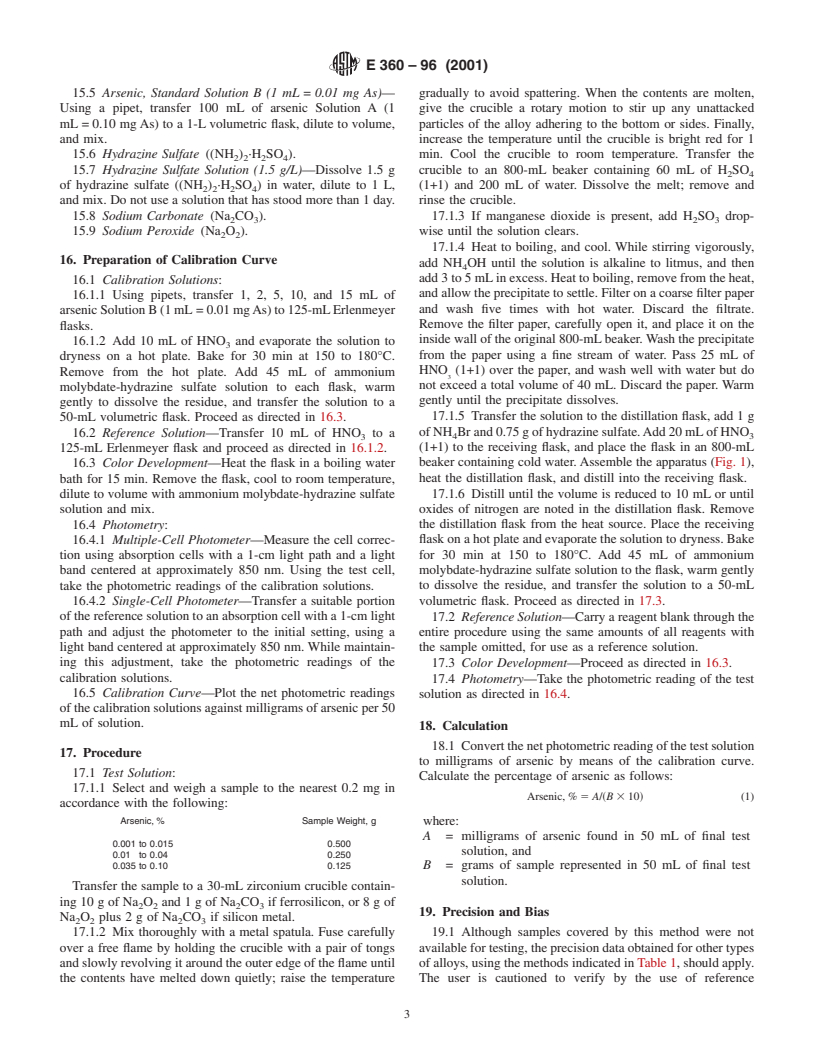

14.1 Distillation Apparatus, Fig. 1.

with Practice E 173, unless otherwise noted in the Precision

14.2 Zirconium Crucibles, 30-mL capacity.

and Bias section.

15. Reagents

ARSENIC BY THE MOLYBDENUM BLUE

15.1 Ammonium Bromide (NH Br).

PHOTOMETRIC METHOD

15.2 Ammonium Molybdate Solution (10 g/L)—Dissolve

2.5 g of ammonium heptamolybdate tetrahydrate ((NH )

4 6-

9. Scope

Mo O ·4H O) in 40 mL of warm water. Add 128 mL of

7 24 2

9.1 This method covers the determination of arsenic in

H SO (1+3), dilute to 250 mL, and mix.

siliconandferrosiliconinconcentrationsfrom0.001to0.10 %.

15.3 Ammonium Molybdate-Hydrazine Sulfate Solution—

Dilute 100 mL of ammonium molybdate solution to 900 mL,

10. Summary of Method

add 10 mLof hydrazine sulfate solution, dilute to 1 L, and mix.

10.1 Arsenic is first separated by distillation as the trivalent Do not use a solution that has stood more than 1 h.

chloride. Ammonium molybdate is added to form arsenomo- 15.4 Arsenic, Standard Solution A (1 mL=0.10 mg As)—

lybdate which is then reduced by hydrazine sulfate to form the Transfer 0.1320 g of arsenic trioxide (As O)toa1-L

2 3

molybdenum blue complex. Photometric measurement is made volumetric flask, dissolve in 100 mL of HCl, cool, dilute to

at approximately 850 nm. volume, and mix.

FIG. 1 Arsenic Distillation Apparatus

E360–96 (2001)

15.5 Arsenic, Standard Solution B (1 mL=0.01 mg As)— gradually to avoid spattering. When the contents are molten,

Using a pipet, transfer 100 mL of arsenic Solution A (1 give the crucible a rotary motion to stir up any unattacked

mL = 0.10 mg As) to a 1-L volumetric flask, dilute to volume, particles of the alloy adhering to the bottom or sides. Finally,

and mix. increase the temperature until the crucible is bright red for 1

15.6 Hydrazine Sulfate ((NH ) ·H SO ). min. Cool the crucible to room temperature. Transfer the

2 2 2 4

15.7 Hydrazine Sulfate Solution (1.5 g/L)—Dissolve 1.5 g crucible to an 800-mL beaker containing 60 mL of H SO

2 4

of hydrazine sulfate ((NH ) ·H SO ) in water, dilute to 1 L, (1+1) and 200 mL of water. Dissolve the melt; remove and

2 2 2 4

and mix. Do not use a solution that has stood more than 1 day. rinse the crucible.

15.8 Sodium Carbonate (Na CO ).

17.1.3 If manganese dioxide is present, add H SO drop-

2 3

2 3

15.9 Sodium Peroxide (Na O ). wise until the solution clears.

2 2

17.1.4 Heat to boiling, and cool. While stirring vigorously,

16. Preparation of Calibration Curve

add NH OH until the solution is alkaline to litmus, and then

add 3 to 5 mLin excess. Heat to boiling, remove from the heat,

16.1 Calibration Solutions:

and allow the precipitate to settle. Filter on a coarse filter paper

16.1.1 Using pipets, transfer 1, 2, 5, 10, and 15 mL of

and wash five times with hot water. Discard the filtrate.

arsenicSolutionB(1mL = 0.01mgAs)to125-mLErlenmeyer

Remove the filter paper, carefully open it, and place it on the

flasks.

inside wall of the original 800-mLbeaker.Wash the precipitate

16.1.2 Add 10 mL of HNO and evaporate the solution to

from the paper using a fine stream of water. Pass 25 mL of

dryness on a hot plate. Bake for 30 min at 150 to 180°C.

HNO (1+1) over the paper, and wash well with water but do

Remove from the hot plate. Add 45 mL of ammonium

not exceed a total volume of 40 mL. Discard the paper. Warm

molybdate-hydrazine sulfate solution to each flask, warm

gently until the precipitate dissolves.

gently to dissolve the residue, and transfer the solution to a

17.1.5 Transfer the solution to the distillation flask, add 1 g

50-mL volumetric flask. Proceed as directed in 16.3.

ofNH Brand0.75gofhydrazinesulfate.Add20mLofHNO

16.2 Reference Solution—Transfer 10 mL of HNO to a

3 4 3

(1+1) to the receiving flask, and place the flask in an 800-mL

125-mL Erlenmeyer flask and proceed as directed in 16.1.2.

beaker containing cold water.Assemble the apparatus (Fig. 1),

16.3 Color Development—Heat the flask in a boiling water

bath for 15 min. Remove the flask, cool to room temperature, heat the distillation flask, and distill into the receiving flask.

dilute to volume with ammonium molybdate-hydrazine sulfate 17.1.6 Distill until the volume is reduced to 10 mL or until

solution and mix. oxides of nitrogen are noted in the distillation flask. Remove

16.4 Photometry: the distillation flask from the heat source. Place the receiving

16.4.1 Multiple-Cell Photometer—Measure the cell correc- flask on a hot plate and evaporate the solution to dryness. Bake

tion using absorption cells with a 1-cm light path and a light for 30 min at 150 to 180°C. Add 45 mL of ammonium

band centered at approximately 850 nm. Using the test cell, molybdate-hydrazine sulfate solution to the flask, warm gently

take the photometric readings of the calibration solutions. to dissolve the residue, and transfer the solution to a 50-mL

16.4.2 Single-Cell Photometer—Transfer a suitable portion volumetric flask. Proceed as directed in 17.3.

of the reference solution to an absorption cell with a 1-cm light 17.2 ReferenceSolution—Carry a reagent blank through the

path and adjust the photometer to the initial setting, using a entire procedure using the same amounts of all reagents with

light band centered at approximately 850 nm. While maintain- the sample omitted, for use as a reference solution.

ing this adjustment, take the photometric readings of the

17.3 Color Development—Proceed as directed in 16.3.

calibration solutions.

17.4 Photometry—Take the photometric reading of the test

16.5 Calibration Curve—Plot the net photometric readings

solution as directed in 16.4.

of the calibration solutions against milligrams of arsenic per 50

mL of solution.

18. Calculation

18.1 Convertthenetphotometricreadingofthetestsolution

17. Procedure

to milligrams of arsenic by means of the calibration curve.

17.1 Test Solution:

Calculate the percentage of arsenic as follows:

17.1.1 Select and weigh a sample to the nearest 0.2 mg in

Arsenic, % 5A/~B 3 10! (1)

accordance with the following:

Arsenic, % Sample Weight, g

where:

A = milligrams of arsenic found in 50 mL of final test

0.001 to 0.015 0.500

solution, and

0.01 to 0.04 0.250

B = grams of sample represented in 50 mL of final test

0.035 to 0.10 0.125

solution.

Transfer the sample to a 30-mL zirconium crucible contain-

ing10gofNa O and1gofNa CO if ferrosilicon, or8gof

2 2 2 3

19. Precision and Bias

Na O plus2gofNa CO if silicon metal.

2 2 2 3

17.1.2 Mix thoroughly with a metal spatula. Fuse carefully 19.1 Although samples covered by this method were not

over a free flame by holding the crucible with a pair of tongs available for testing, the precision data obtained for other types

and slowly revolving it around the outer edge of the flame until of alloys, using the methods indicated inTable 1, should apply.

the contents have melted down quietly; raise the temperature The user is cautioned to verify by the use of reference

E360–96 (2001)

TABLE 1 Statistical Information—Arsenic

in water, add 15 mL of HCL (1+1), dilute to volume, and mix.

Repeatability Reproducibility Using a pipet, transfer 50 mL to a 1-L volumetric flask, dilute

Ferroalloy Type Arsenic Found, %

(R , E 173) (R , E 173)

1 2

to volume, and mix. Store the solution in a polyethylene bottle.

1. No. 1, E 363 0.0015 0.0001 0.0005

26.2 Ammonium Acetate Buffer Solution (180 g/L)—

2. No. 1, E 364 0.0018 0.0003 0.0003

Dissolve 90 g of ammonium acetate in water and dilute to 500

3. No. 1, E 362 0.025 0.001 0.002

mL.

4. No. 2, E 362 0.039 0.001 0.002

26.3 BromineWater(Saturated)—Add 20 mLof bromine to

400 mL of water, and shake. Store in a glass stoppered bottle.

26.4 Bromocresol Purple Indicator Solution (0.4 g/L)—

materials, if available, that the precision and bias of this

method is adequate for the contemplated use. Reagent No. 120.

26.5 Chloroform (CHCl ).

ALUMINUM BY THE QUINOLINATE

26.6 Cupferron Solution (60 g/L)—Reagent No. 115.

PHOTOMETRIC AND GRAVIMETRIC

26.7 8-Quinolinol Solution (50 g/L)—Dissolve 25 g of

METHODS

8-quinolinol in 60 mL of acetic acid, dilute to 300 mL with

warm water, mix, filter through a medium filter paper, and

20. Scope

dilute to 500 mL. Store in an amber bottle away from direct

20.1 This method covers the determination of aluminum in

sunlight. Do not use a solution that has stood for more than one

concentrations from 0.01 to 2.0 %.

month.

26.8 Sodium Cyanide Solution (100 g/L)—Dissolve 100 g

21. Summary of Method

of sodium cyanide (NaCN) in 800 mL of water and dilute to 1

21.1 Thesampleisdissolvedinnitricandhydrofluoricacids

L. Store in a polyethylene bottle.

and fumed with perchloric acid. After the removal of interfer-

26.8.1 Warning: The preparation, storage, and use of

ing elements, aluminum is separated as the quinolinate. The

NaCN solution require care and attention. Avoid inhalation of

determination is completed gravimetrically when aluminum is

fumes and exposure of the skin to the chemical and its

present in concentrations greater than 0.2 % or photometrically

solutions.Work in a well-ventilated hood. Refer to Section 6 of

when aluminum is present in concentrations less than 0.2 %.

PracticesE50. Because of the strongly alkaline properties of

Photometric measurement is made at approximately 395 nm.

NaCN solution, contact with glass may result in appreciable

contamination of the reagent with aluminum.

22. Concentration Range (Photometric Method)

26.9 Sodium Hydroxide Solution (200 g/L)—Dissolve 40 g

22.1 The recommended concentration range is 0.005 to 0.10

of sodium hydroxide (NaOH) in 150 mL of water in a plastic

mg of aluminum per 25 mL of solution, using a 1-cm cell.

beaker and dilute to 200 mL.

26.10 Tartaric Acid Solution (100 g/L)—Dissol

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.