ASTM A100-07(2018)

(Specification)Standard Specification for Ferrosilicon

Standard Specification for Ferrosilicon

ABSTRACT

This specification covers grades of ferrosilicon used for steel-making and foundry. The grades shall conform to the required chemical composition for silicon, carbon, sulfur, phosphorous, aluminum, manganese, calcium, and boron. Sizes available of ferrosilicon for various grades are specified. Ferroalloys exhibit varying degrees of friability; therefore, some attrition may be expected in transit, storage, and handling. Chemical analysis of the material shall be made.

SCOPE

1.1 This specification covers grades of ferrosilicon for steelmaking and foundry uses.

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units (SI units) given in parentheses may be approximate.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: A100 −07 (Reapproved 2018)

Standard Specification for

Ferrosilicon

This standard is issued under the fixed designation A100; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* ments of Specification A1025/A1025M constitutes nonconfor-

mance with this specification. In case of conflict between the

1.1 This specification covers grades of ferrosilicon for

requirements of this specification and Specification A1025/

steelmaking and foundry uses.

A1025M, this specification shall prevail.

1.2 The values stated in inch-pound units are to be regarded

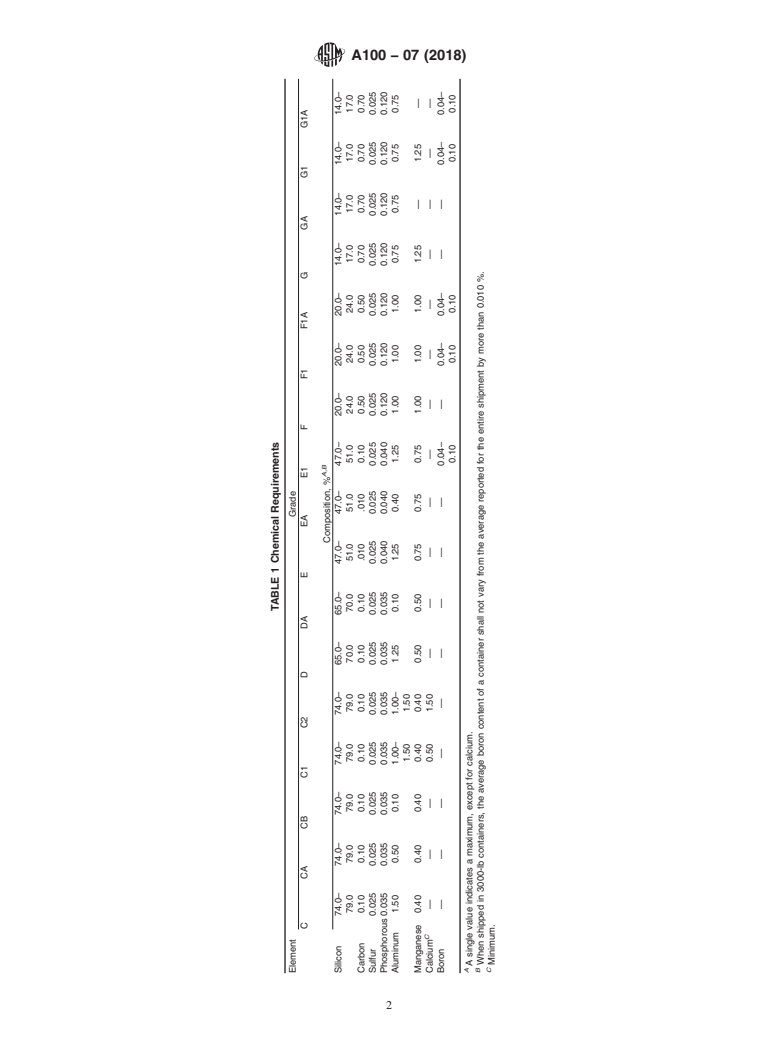

4. Chemical Composition

as the standard. The metric equivalents of inch-pound units (SI

units) given in parentheses may be approximate.

4.1 The various grades shall conform to the requirements as

to chemical composition prescribed in Table 1.

1.3 This international standard was developed in accor-

dance with internationally recognized principles on standard-

4.2 The manufacturer shall furnish an analysis of each

ization established in the Decision on Principles for the

shipment showing the silicon content and, when required, such

Development of International Standards, Guides and Recom-

of the other elements specified in Table 1.

mendations issued by the World Trade Organization Technical

5. Size

Barriers to Trade (TBT) Committee.

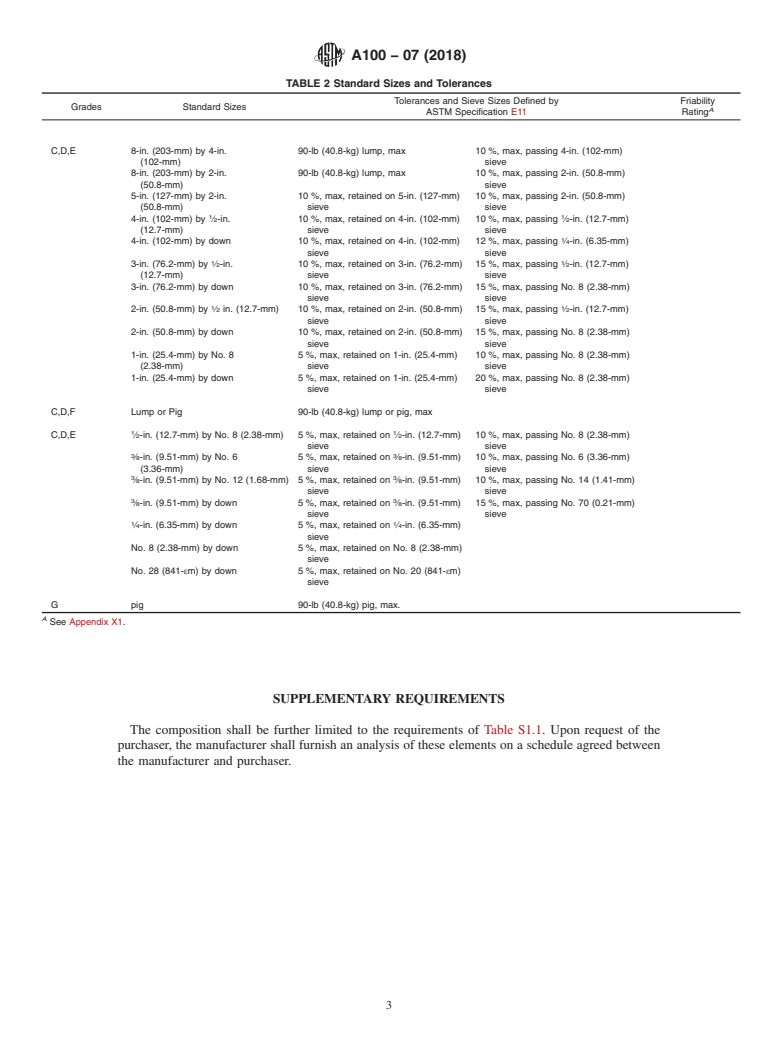

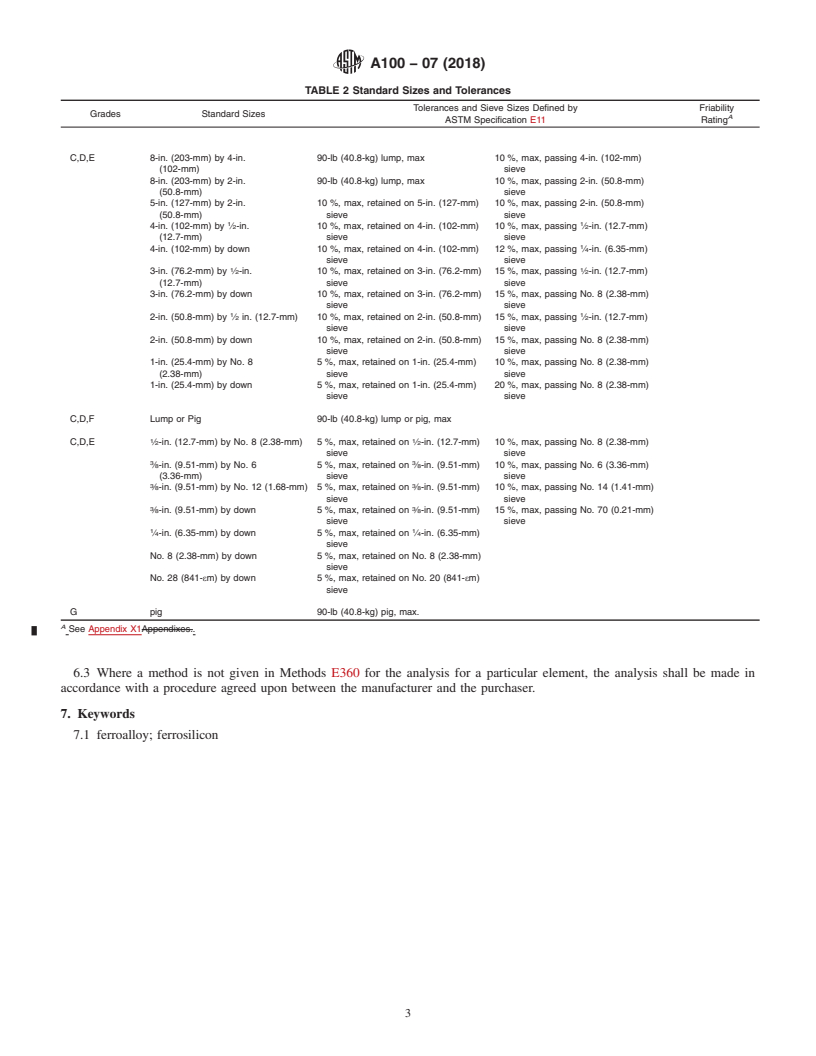

5.1 The various grades are available in sizes as listed in

2. Referenced Documents

Table 2.

2.1 ASTM Standards:

5.2 The sizes listed in Table 2 are typical as shipped from

A1025/A1025M Specification for Ferroalloys and Other Al-

the manufacturer’s plant. These alloys exhibit varying degrees

loying Materials, General Requirements

of friability; therefore, some attrition may be expected in

E11 Specification for Woven Wire Test Sieve Cloth and Test

transit, storage, and handling. A quantitative test is not avail-

Sieves

able for rating relative friability of ferroalloys. A code system

E360 Test Methods for Chemical Analysis of Silicon and

has been developed, therefore, for this purpose, and a number

Ferrosilicon (Withdrawn 2006)

rating for each product type is shown in the last column of

Table 2. Definitions applicable to these code numbers are given

3. General Conditions of Delivery

in Specification A1025/A1025M.

3.1 Materials furnished to this specification shall conform to

the requirements of Specification A1025/A1025M, including

6. Chemical Analysis

any supplementary requirements that are indicated in the

6.1 Unless otherwise agreed upon, the chemical analysis of

purchase order. Failure to comply with the general require-

the material shall be made in accordance with Test Methods

E360.

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

6.2 If alternative methods of analysis are used, Methods

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

E360 shall be used for referee.

A01.18 on Castings.

Current edition approved March 1, 2018. Published March 2018. Originally

6.3 Where a method is not given in Methods E360 for the

approved in 1925. Last previous edition approved in 2012 as A100 – 07 (2012).

analysis for a particular element, the analysis shall be made in

DOI: 10.1520/A0100-07R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or accordance with a procedure agreed upon between the manu-

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

facturer and the purchaser.

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

7. Keywords

The last approved version of this historical standard is referenced on

www.astm.org. 7.1 ferroalloy; ferrosilicon

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A100 − 07 (2018)

TABLE 1 Chemical Requirements

Element Grade

C CA CB C1 C2 D DA E EA E1 F F1 F1A G GA G1 G1A

A,B

Composition, %

Silicon 74.0– 74.0– 74.0– 74.0– 74.0– 65.0– 65.0– 47.0– 47.0– 47.0– 20.0– 20.0– 20.0– 14.0– 14.0– 14.0– 14.0–

79.0 79.0 79.0 79.0 79.0 70.0 70.0 51.0 51.0 51.0 24.0 24.0 24.0 17.0 17.0 17.0 17.0

Carbon 0.10 0.10 0.10 0.10 0.10 0.10 0.10 .010 .010 0.10 0.50 0.50 0.50 0.70 0.70 0.70 0.70

Sulfur 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025

Phosphorous 0.035 0.035 0.035 0.035 0.035 0.035 0.035 0.040 0.040 0.040 0.120 0.120 0.120 0.120 0.120 0.120 0.120

Aluminum 1.50 0.50 0.10 1.00– 1.00– 1.25 0.10 1.25 0.40 1.25 1.00 1.00 1.00 0.75 0.75 0.75 0.75

1.50 1.50

Manganese 0.40 0.40 0.40 0.40 0.40 0.50 0.50 0.75 0.75 0.75 1.00 1.00 1.00 1.25 — 1.25 —

C

Calcium —— — 0.50 1.50 — — — — — ——— —— — —

Boron — — — — — — — — — 0.04– — 0.04– 0.04– — — 0.04– 0.04–

0.10 0.10 0.10

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A100 − 07 (Reapproved 2018)

Standard Specification for

Ferrosilicon

This standard is issued under the fixed designation A100; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* purchase order. Failure to comply with the general require-

ments of Specification A1025/A1025M constitutes nonconfor-

1.1 This specification covers grades of ferrosilicon for

mance with this specification. In case of conflict between the

steelmaking and foundry uses.

requirements of this specification and Specification A1025/

1.2 The values stated in inch-pound units are to be regarded

A1025M, this specification shall prevail.

as the standard. The metric equivalents of inch-pound units (SI

units) given in parentheses may be approximate.

4. Chemical Composition

1.3 This international standard was developed in accor-

4.1 The various grades shall conform to the requirements as

dance with internationally recognized principles on standard-

to chemical composition prescribed in Table 1.

ization established in the Decision on Principles for the

4.2 The manufacturer shall furnish an analysis of each

Development of International Standards, Guides and Recom-

shipment showing the silicon content and, when required, such

mendations issued by the World Trade Organization Technical

of the other elements specified in Table 1.

Barriers to Trade (TBT) Committee.

2. Referenced Documents

5. Size

2.1 ASTM Standards:

5.1 The various grades are available in sizes as listed in

A1025/A1025M Specification for Ferroalloys and Other Al-

Table 2.

loying Materials, General Requirements

5.2 The sizes listed in Table 2 are typical as shipped from

E11 Specification for Woven Wire Test Sieve Cloth and Test

the manufacturer’s plant. These alloys exhibit varying degrees

Sieves

of friability; therefore, some attrition may be expected in

E360 Test Methods for Chemical Analysis of Silicon and

transit, storage, and handling. A quantitative test is not avail-

Ferrosilicon (Withdrawn 2006)

able for rating relative friability of ferroalloys. A code system

has been developed, therefore, for this purpose, and a number

3. General Conditions of Delivery

rating for each product type is shown in the last column of

3.1 Materials furnished to this specification shall conform to

Table 2. Definitions applicable to these code numbers are given

the requirements of Specification A1025/A1025M, including

in Specification A1025/A1025M.

any supplementary requirements that are indicated in the

6. Chemical Analysis

6.1 Unless otherwise agreed upon, the chemical analysis of

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee the material shall be made in accordance with Test Methods

A01.18 on Castings.

E360.

Current edition approved March 1, 2018. Published March 2018. Originally

approved in 1925. Last previous edition approved in 2012 as A100 – 07 (2012).

6.2 If alternative methods of analysis are used, Methods

DOI: 10.1520/A0100-07R18.

E360 shall be used for referee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

6.3 Where a method is not given in Methods E360 for the

Standards volume information, refer to the standard’s Document Summary page on

analysis for a particular element, the analysis shall be made in

the ASTM website.

3 accordance with a procedure agreed upon between the manu-

The last approved version of this historical standard is referenced on

www.astm.org. facturer and the purchaser.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A100 − 07 (Reapproved 2018)

7. Keywords

7.1 ferroalloy; ferrosilicon

A100 − 07 (2018)

TABLE 1 Chemical Requirements

Element Grade

C CA CB C1 C2 D DA E EA E1 F F1 F1A G GA G1 G1A

A,B

Composition, %

Silicon 74.0– 74.0– 74.0– 74.0– 74.0– 65.0– 65.0– 47.0– 47.0– 47.0– 20.0– 20.0– 20.0– 14.0– 14.0– 14.0– 14.0–

79.0 79.0 79.0 79.0 79.0 70.0 70.0 51.0 51.0 51.0 24.0 24.0 24.0 17.0 17.0 17.0 17.0

Carbon 0.10 0.10 0.10 0.10 0.10 0.10 0.10 .010 .010 0.10 0.50 0.50 0.50 0.70 0.70 0.70 0.70

Sulfur 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025

Phosphorous 0.035 0.035 0.035 0.035 0.035 0.035 0.035 0.040 0.040 0.040 0.120 0.120 0.120 0.120 0.120 0.120 0.120

Aluminum 1.50 0.50 0.10 1.00– 1.00– 1.25 0.10 1.25 0.40 1.25 1.00 1.00 1.00 0.75 0.75 0.75 0.75

1.50 1.50

Manganese 0.40 0.40 0.40 0.40 0.40 0.50 0.50 0.75 0.75 0.75 1.00 1.00 1.00 1.25 — 1.25 —

C

Calcium — — — 0.50 1.50 — — — — — — — — — — — —

Boron — — — — — — — — — 0.04– — 0.04– 0.04– — — 0.04– 0.04–

0.10 0.10 0.10 0.10 0.10

A

A single value indicates a maximum,

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A100 − 07 (Reapproved 2012) A100 − 07 (Reapproved 2018)

Standard Specification for

Ferrosilicon

This standard is issued under the fixed designation A100; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope*

1.1 This specification covers grades of ferrosilicon for steelmaking and foundry uses.

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents of inch-pound units (SI

units) given in parentheses may be approximate.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

A1025A1025/A1025M Specification for Ferroalloys and Other Alloying Materials, General Requirements

E11 Specification for Woven Wire Test Sieve Cloth and Test Sieves

E360 Test Methods for Chemical Analysis of Silicon and Ferrosilicon (Withdrawn 2006)

3. General Conditions of Delivery

3.1 Materials furnished to this specification shall conform to the requirements of Specification A1025A1025/A1025M,

including any supplementary requirements that are indicated in the purchase order. Failure to comply with the general requirements

of Specification A1025A1025/A1025M constitutes nonconformance with this specification. In case of conflict between the

requirements of this specification and Specification A1025A1025/A1025M, this specification shall prevail.

4. Chemical Composition

4.1 The various grades shall conform to the requirements as to chemical composition prescribed in Table 1.

4.2 The manufacturer shall furnish an analysis of each shipment showing the silicon content and, when required, such of the

other elements specified in Table 1.

5. Size

5.1 The various grades are available in sizes as listed in Table 2.

5.2 The sizes listed in Table 2 are typical as shipped from the manufacturer’s plant. These alloys exhibit varying degrees of

friability; therefore, some attrition may be expected in transit, storage, and handling. A quantitative test is not available for rating

relative friability of ferroalloys. A code system has been developed, therefore, for this purpose, and a number rating for each

product type is shown in the last column of Table 2. Definitions applicable to these code numbers are given in Specification

A1025A1025/A1025M.

6. Chemical Analysis

6.1 Unless otherwise agreed upon, the chemical analysis of the material shall be made in accordance with Test Methods E360.

6.2 If alternative methods of analysis are used, Methods E360 shall be used for referee.

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.18

on Castings.

Current edition approved March 1, 2012March 1, 2018. Published April 2012March 2018. Originally approved in 1925. Last previous edition approved in 20072012 as

A100 – 07.A100 – 07 (2012). DOI: 10.1520/A0100-12.10.1520/A0100-07R18.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

The last approved version of this historical standard is referenced on www.astm.org.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A100 − 07 (2018)

TABLE 1 Chemical Requirements

Element Grade

C CA CB C1 C2 D DA E EA E1 F F1 F1A G GA G1 G1A

A,B

Composition, %

Silicon 74.0– 74.0– 74.0– 74.0– 74.0– 65.0– 65.0– 47.0– 47.0– 47.0– 20.0– 20.0– 20.0– 14.0– 14.0– 14.0– 14.0–

79.0 79.0 79.0 79.0 79.0 70.0 70.0 51.0 51.0 51.0 24.0 24.0 24.0 17.0 17.0 17.0 17.0

Carbon 0.10 0.10 0.10 0.10 0.10 0.10 0.10 .010 .010 0.10 0.50 0.50 0.50 0.70 0.70 0.70 0.70

Sulfur 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025 0.025

Phosphorous 0.035 0.035 0.035 0.035 0.035 0.035 0.035 0.040 0.040 0.040 0.120 0.120 0.120 0.120 0.120 0.120 0.120

Aluminum 1.50 0.50 0.10 1.00– 1.00– 1.25 0.10 1.25 0.40 1.25 1.00 1.00 1.00 0.75 0.75 0.75 0.75

1.50 1.50

Manganese 0.40 0.40 0.40 0.40 0.40 0.50 0.50 0.75 0.75 0.75 1.00 1.00 1.00 1.25 — 1.25 —

C

Calcium — — — 0.50 1.50 — — — — — — — — — — — —

Boron — — — — — — — — — 0.04– — 0.04– 0.04– — — 0.04– 0.04–

0.10 0.10 0.10 0.10 0.10

A

A single value indicates a maximum, except for calcium.

B

When shipped in 3000 lb 3000-lb containers, the average boron content of a container shall not vary from the average reported for the entire shi

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.