ASTM D3379-75(1989)e1

(Test Method)Standard Test Method for Tensile Strength and Young's Modulus for High-Modulus Single-Filament Materials (Withdrawn 1998)

Standard Test Method for Tensile Strength and Young's Modulus for High-Modulus Single-Filament Materials (Withdrawn 1998)

SCOPE

1.1 This test method covers the preparation, mounting, and testing of high-modulus single-filament materials [over > 21 10 9 Pa (> 3 106 psi)] for the determination of tensile strength and Young's modulus, at room temperature.

1.2 This test method is limited to single filaments utilizing a fixed gage length at least 2000 times longer than the nominal filament diameter.

1.3 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

WITHDRAWN RATIONALE

This test method covers the preparation, mounting, and testing of high-modulus single-filament materials [over > 21 109 Pa (> 3 106 psi)] for the determination of tensile strength and Young's modulus, at room temperature.

Formerly under the jurisdiction of Committee C28 on Advanced Ceramics, this test method was withdrawn in July 1998 in accordance with section 10.5.3.1 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

Designation: D 3379 – 75 (Reapproved 1989)

Standard Test Method for

Tensile Strength and Young’s Modulus for High-Modulus

Single-Filament Materials

This standard is issued under the fixed designation D 3379; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Editorial changes were made throughout in May 1989.

1. Scope mined experimentally for a given combination of test machine

conditions, grip system and mounted specimen. It must be

1.1 This test method covers the preparation, mounting, and

subtracted from the indicated elongation to yield true specimen

testing of high-modulus single-filament materials [over >

elongation in the gage length (Note 1). System compliance

21 3 10 Pa (> 3 3 10 psi)] for the determination of tensile

correctionwillnotapplywhenelongationinthespecimengage

strength and Young’s modulus, at room temperature.

length is determined by direct measurement.

1.2 This test method is limited to single filaments utilizing a

fixed gage length at least 2000 times longer than the nominal

NOTE 1—The magnitude of the system compliance can be a significant

filament diameter.

portionoftheindicatedcompliance.Extremecaremustbeexercisedinthe

determination of this correction as outlined in 8.2.

1.3 This standard may involve hazardous materials, opera-

tions, and equipment. This standard does not purport to

3.2 Definitions of terms and symbols relating to this test

address all of the safety concerns associated with its use. It is

method appear in TerminologyE6, and the Appendix to Test

the responsibility of the user of this standard to establish

Method D 638.

appropriate safety and health practices and determine the

4. Summary of Test Method

applicability of regulatory limitations prior to use.

4.1 Arandom selection of single filaments is made from the

2. Referenced Documents

material to be tested. The filaments are center-line mounted on

2.1 ASTM Standards:

special slotted tabs. The tabs are gripped so that the test

D 638 Test Method for Tensile Properties of Plastics

specimen is aligned axially in the jaws of a constant-speed

E4 Practices for Force Verification of Testing Machines

movable-crosshead test machine. The filaments are then

E6 Terminology Relating to Methods of Mechanical Test-

stressed to failure at a constant strain rate.

ing

4.2 For this test method, filament cross-sectional areas are

determined by planimeter measurements of a representative

3. Terminology

number of filament cross sections as displayed on highly

3.1 Definitions:

magnified photomicrographs. Alternative methods of area de-

3.1.1 mounting tab—a thin paper, compliant metal, or

termination such as optical gages, image-splitting microscope,

plastic strip with a longitudinal slot of fixed gage length. The

linear weight-density method, etc, may also be used.

mounting tab should be as thin as practicable to minimize

4.3 Tensile strength and Young’s modulus are calculated

filament misalignment.

from the load-elongation records and the cross-sectional area

3.1.2 system compliance—that portion of the indicated

measurements.

elongation contributed by the load train system and the

specimen gripping system. This compliance must be deter- 5. Significance and Use

5.1 Properties determined by this test method are very

useful in the evaluation of new materials at the research and

This test method is under the jurisdiction of ASTM Committee C-28 on

development levels. Very short filaments, such as whiskers of

Advanced Ceramics and is the direct responsibility of Subcommittee C28.07 on

Ceramic Matrix Composites. nonuniform cross section, call for highly specialized test

Current edition approved Feb. 28, 1975. Published April 1975.

techniques not covered by this test method.

Annual Book of ASTM Standards, Vol 08.01.

Annual Book of ASTM Standards, Vol 03.01.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

e1

D 3379 – 75 (1989)

6. Apparatus test specimens are gently separated from the strand bundle.

Selection should be random. The critical considerations are

6.1 Tensile strength and Young’s modulus properties of

that the filament be not visibly damaged or attached to another

single-filament specimens may be determined by several es-

filament, and have sufficient length.

tablished testing procedures. The apparatus described herein

7.2 Segments used for area determinations shall represent

shall use a constant-strain-rate tensile testing machine with a

the same population as those used for tensile testing.

test specimen bonded to a suitable tab.

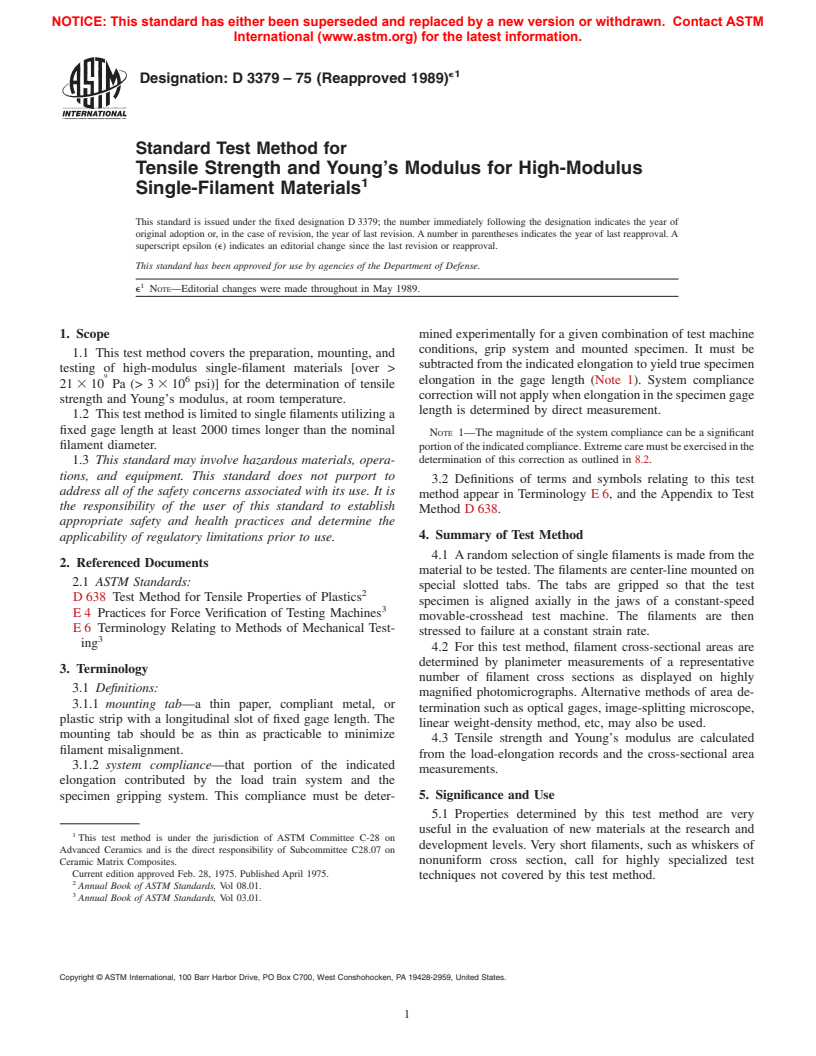

FIG. 1 Tab Showing Typical Specimen Mounting Method

6.2 Stationary Member—This member shall be rigidly fixed 8. Procedure

to the test machine frame and shall contain a housing, located

8.1 Test Specimen Mounting:

on the machine centerline, for a load cell and part of the

8.1.1 Loosely place a strand bundle from the material to be

specimen grip assembly.

tested on a suitable work surface.

6.3 Movable Member—This member, also called the cross-

8.1.2 Randomly choose and carefully separate a suitable

head, shall be driven at a constant preset strain rate. It shall

single-filament specimen from the strand bundle.

containanadaptor,onthemachinecenterline,fortheotherpart

8.1.3 The specimen gage length shall be the same for a

of the specimen grip assembly.

giventestgroup.Determinethelengthtothenearest 60.1mm.

6.4 Load Cell—The load-sensing device shall have suffi-

NOTE 2—For this test method, the specimen gage length shall be

cient capacity to accept and transmit load signals above the

between 20 and 30 mm. The tab shape should be proportioned as shown

highest anticipated loads. Its accuracy shall be verified in

in Fig. 1, with an overall length about three times the specimen gage

accordance with PracticesE4.

length and a width of about one half the gage length.

6.5 Grips—The gripping system shall be of a design such

8.1.4 Use a tab (Fig. 1) for specimen mounting. Center the

that axial alignment may be easily accomplished without

specimen over the tab slot with one end taped to the tab.

damaging the specimens.

8.1.5 Lightlystretchthefilamentandtapeitsoppositeendto

6.6 Load- and Elongation-Measuring System—A record of

the tab.

test load to failure, with corresponding indicated elongation,

8.1.6 Carefully place a small amount of suitable adhesive

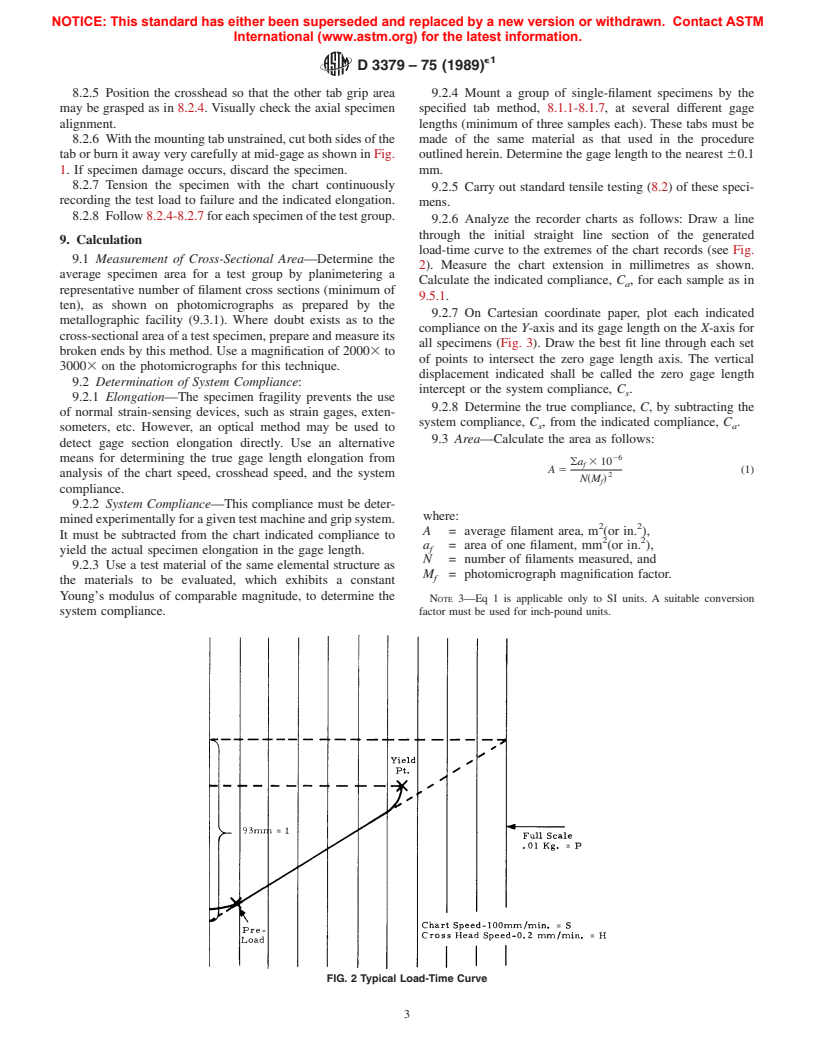

shall be provided. For this test method, chart and crosshead

on the filament at each edge of the slot and bond the filament

speeds shall be provided to produce acceptable data.

to the mounting tab.

6.7 Mounting Tabs—A typical test specimen mounting tab

8.1.7 Repeat 8.1.2-8.1.6 to complete the test group.

is shown in Fig. 1.Alternative methods of specimen mounting

8.2 Filament Specimen Testing:

may be used.

8.2.1 Stabilize the tensile test machine in accordance with

6.8 Metallographic Capability—This test area should have

the manufacturer’s instructions.

the following capabilities:

8.2.2 Calibrate the test machine before testing begins and at

6.8.1 Sample Preparation and Encapsulation in Potting

4-h intervals throughout the work period.

Compound.

8.2.3 Set the crosshead and chart recorder speeds to provide

6.8.2 Metallographic Polishing Units.

a test time to specimen fracture of about 1 min. Make load

6.8.3 Metallograph Unit, with high magnification capabili-

scale range selection such that specimen fracture occu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.