ASTM D4466-02(2018)

(Terminology)Standard Terminology Related to Multicomponent Textile Fibers

Standard Terminology Related to Multicomponent Textile Fibers

SCOPE

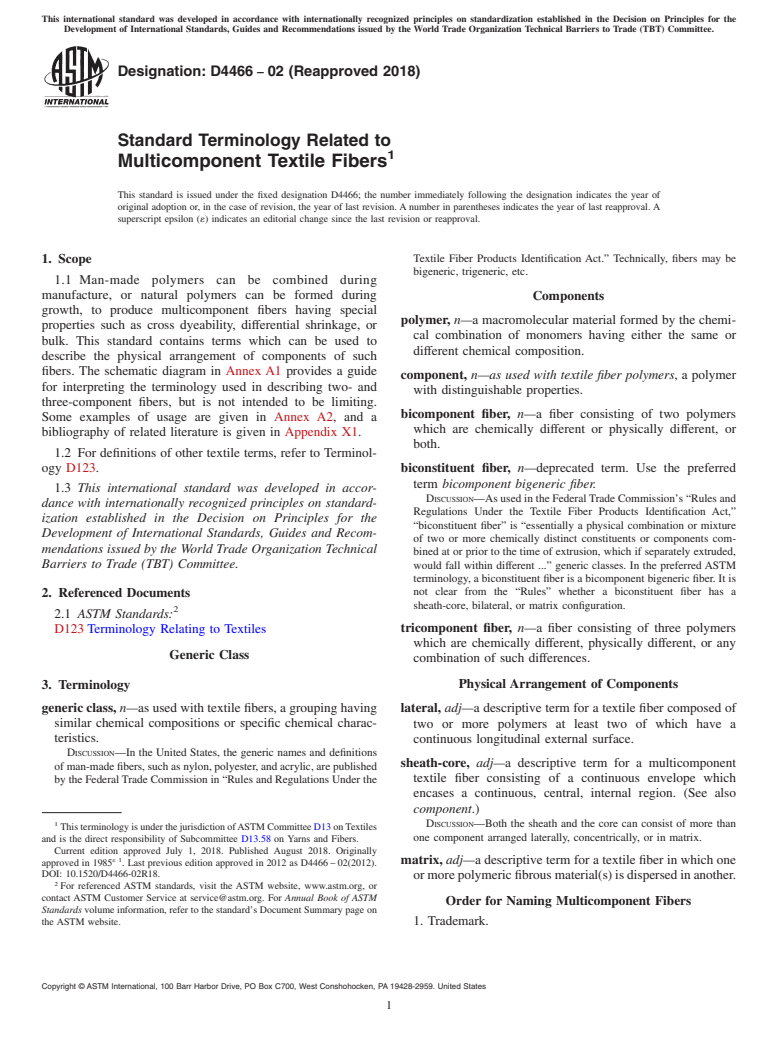

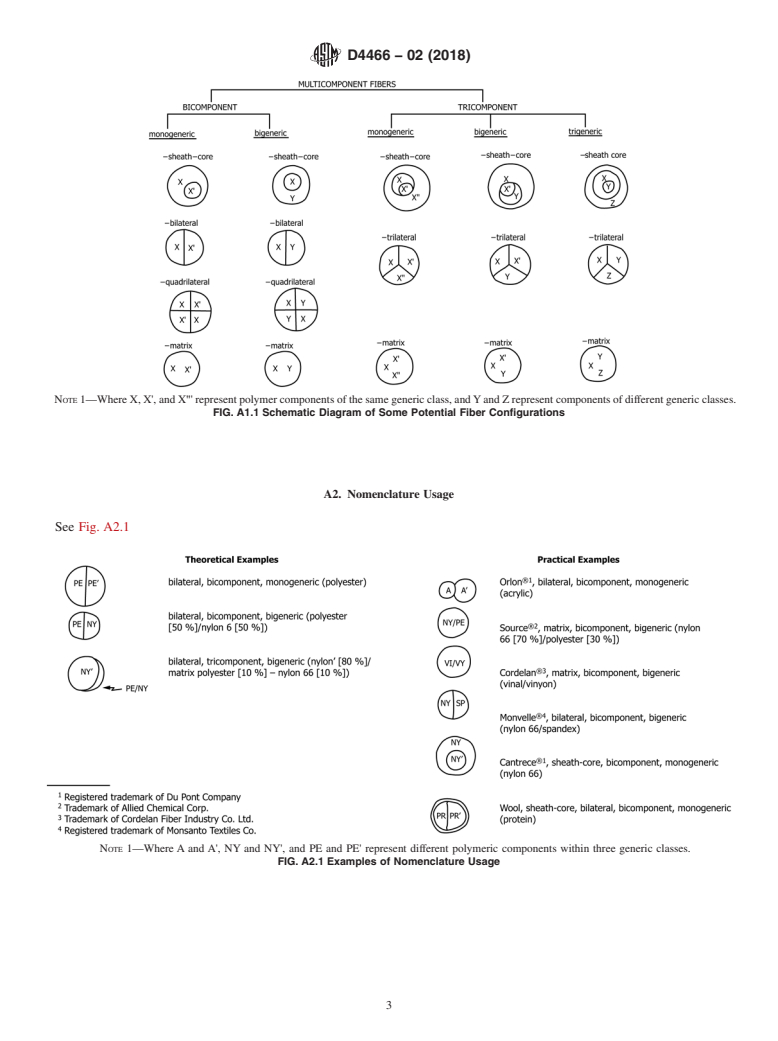

1.1 Man-made polymers can be combined during manufacture, or natural polymers can be formed during growth, to produce multicomponent fibers having special properties such as cross dyeability, differential shrinkage, or bulk. This standard contains terms which can be used to describe the physical arrangement of components of such fibers. The schematic diagram in Annex A1 provides a guide for interpreting the terminology used in describing two- and three-component fibers, but is not intended to be limiting. Some examples of usage are given in Annex A2, and a bibliography of related literature is given in Appendix X1.

1.2 For definitions of other textile terms, refer to Terminology D123.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4466 − 02 (Reapproved 2018)

Standard Terminology Related to

Multicomponent Textile Fibers

This standard is issued under the fixed designation D4466; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

Textile Fiber Products Identification Act.” Technically, fibers may be

1. Scope

bigeneric, trigeneric, etc.

1.1 Man-made polymers can be combined during

manufacture, or natural polymers can be formed during

Components

growth, to produce multicomponent fibers having special

polymer, n—a macromolecular material formed by the chemi-

properties such as cross dyeability, differential shrinkage, or

cal combination of monomers having either the same or

bulk. This standard contains terms which can be used to

different chemical composition.

describe the physical arrangement of components of such

fibers. The schematic diagram in Annex A1 provides a guide

component, n—as used with textile fiber polymers, a polymer

for interpreting the terminology used in describing two- and

with distinguishable properties.

three-component fibers, but is not intended to be limiting.

bicomponent fiber, n—a fiber consisting of two polymers

Some examples of usage are given in Annex A2, and a

which are chemically different or physically different, or

bibliography of related literature is given in Appendix X1.

both.

1.2 For definitions of other textile terms, refer to Terminol-

ogy D123. biconstituent fiber, n—deprecated term. Use the preferred

term bicomponent bigeneric fiber.

1.3 This international standard was developed in accor-

DISCUSSION—As used in the Federal Trade Commission’s “Rules and

dance with internationally recognized principles on standard-

Regulations Under the Textile Fiber Products Identification Act,”

ization established in the Decision on Principles for the

“biconstituent fiber” is “essentially a physical combination or mixture

Development of International Standards, Guides and Recom-

of two or more chemically distinct constituents or components com-

mendations issued by the World Trade Organization Technical

bined at or prior to the time of extrusion, which if separately extruded,

Barriers to Trade (TBT) Committee.

would fall within different .” generic classes. In the preferred ASTM

terminology, a biconstituent fiber is a bicomponent bigeneric fiber. It is

not clear from the “Rules” whether a biconstituent fiber has a

2. Referenced Documents

sheath-core, bilateral, or matrix configuration.

2.1 ASTM Standards:

tricomponent fiber, n—a fiber consisting of three polymers

D123 Terminology Relating to Textiles

which are chemically different, physically different, or any

Generic Class

combination of such differences.

Physical Arrangement of Components

3. Terminology

generic class, n—as used with textile fibers, a grouping having lateral, adj—a descriptive term for a textile fiber composed of

similar chemical compositions or specific chemical charac-

two or more polymers at least two of which have a

teristics. continuous longitudinal external surface.

DISCUSSION—In the United States, the generic names and definitions

sheath-core, adj—a descriptive term for a multicomponent

of man-made fibers, such as nylon, polyester, and acrylic, are published

by the FederalTrade Commission in “Rules and Regulations Under the textile fiber consisting of a continuous envelope which

encases a continuous, central, internal region. (See also

component.)

DISCUSSION—Both the sheath and the core can consist of more than

ThisterminologyisunderthejurisdictionofASTMCommitteeD13onTextiles

and is the direct responsibility of Subcommittee D13.58 on Yarns and Fibers. one component arranged laterally, concentrically, or in matrix.

Current edition approved July 1, 2018. Published August 2018. Originally

ε 1

matrix, adj—a descriptive term for a textile fiber in which one

approved in 1985 . Last previous edition approved in 2012 as D4466 – 02(2012).

DOI: 10.1520/D4466-02R18.

ormorepolymericfibrousmaterial(s)isdispersedinanother.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.