ASTM D1048-12

(Specification)Standard Specification for Rubber Insulating Blankets

Standard Specification for Rubber Insulating Blankets

ABSTRACT

This specification covers the acceptance testing of insulating rubber blankets that are used for the personal protection of workers from accidental contact with live electrical conductors, apparatus, or circuits. Two types of blankets, differing in chemical and physical characteristics, are provided and are designated as: Type I, made from properly vulcanized high-grade cis-1,4-polyisoprene rubber compound of natural or synthetic origin that is non-resistant to ozone; and Type II, made of any elastomer or combination of elastomeric compounds that is resistant to ozone. Five classes of blankets, designated as Classes 0, 1, 2, 3, and 4, are assigned according to electrical protection characteristics. Styles of blankets are designated in accordance to construction characteristics, namely: Style A, blankets free of any reinforcements; and Style B, blankets incorporated with reinforcement(s). When evaluated in accordance with the test procedures detailed herein, the blankets shall adhere to the following property requirements: electrical properties such as phase-phase maximum use voltage, AC and DC proof-test voltages, AC and DC dielectric breakdown test voltages, and AC and DC clearances; and physical and chemical properties such as ozone resistance, moisture absorption, tensile strength, tension set, elongation, drape stiffness, flex stiffness, tear resistance, resistance to accelerated heat aging, and puncture resistance.

SCOPE

1.1 This specification covers acceptance testing of rubber insulating blankets for protection of workers from accidental contact with live electrical conductors, apparatus, or circuits.

1.2 Two types of blankets are provided and are designated as Type I, not resistant to ozone, and Type II, resistant to ozone.

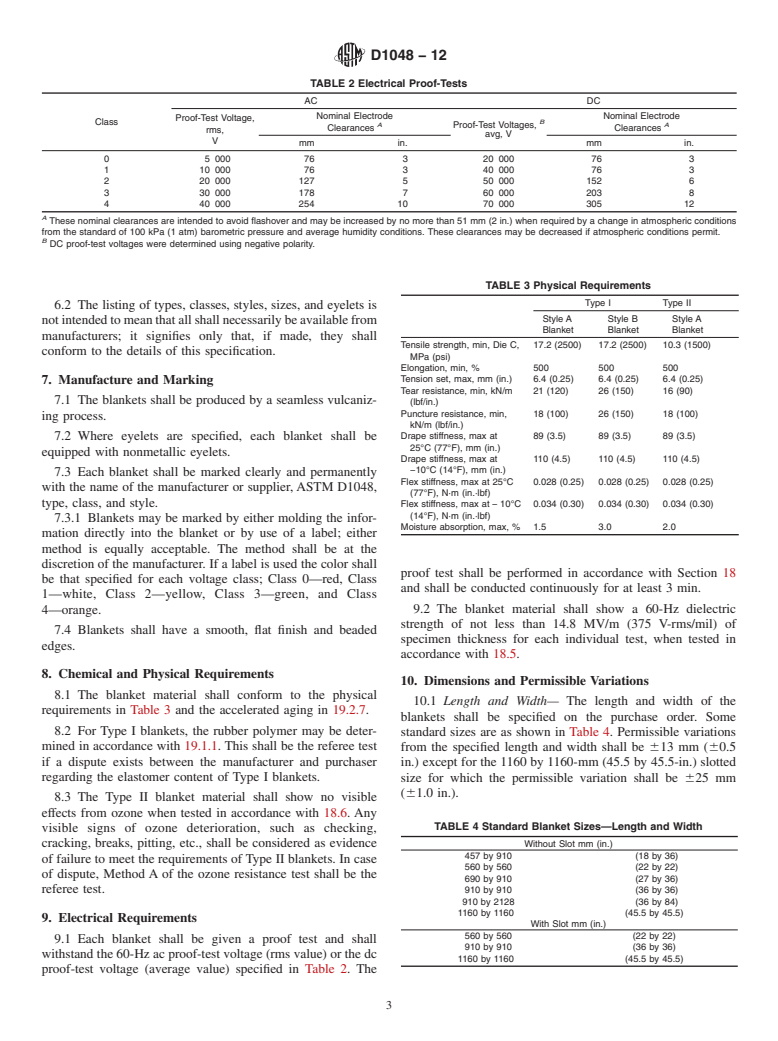

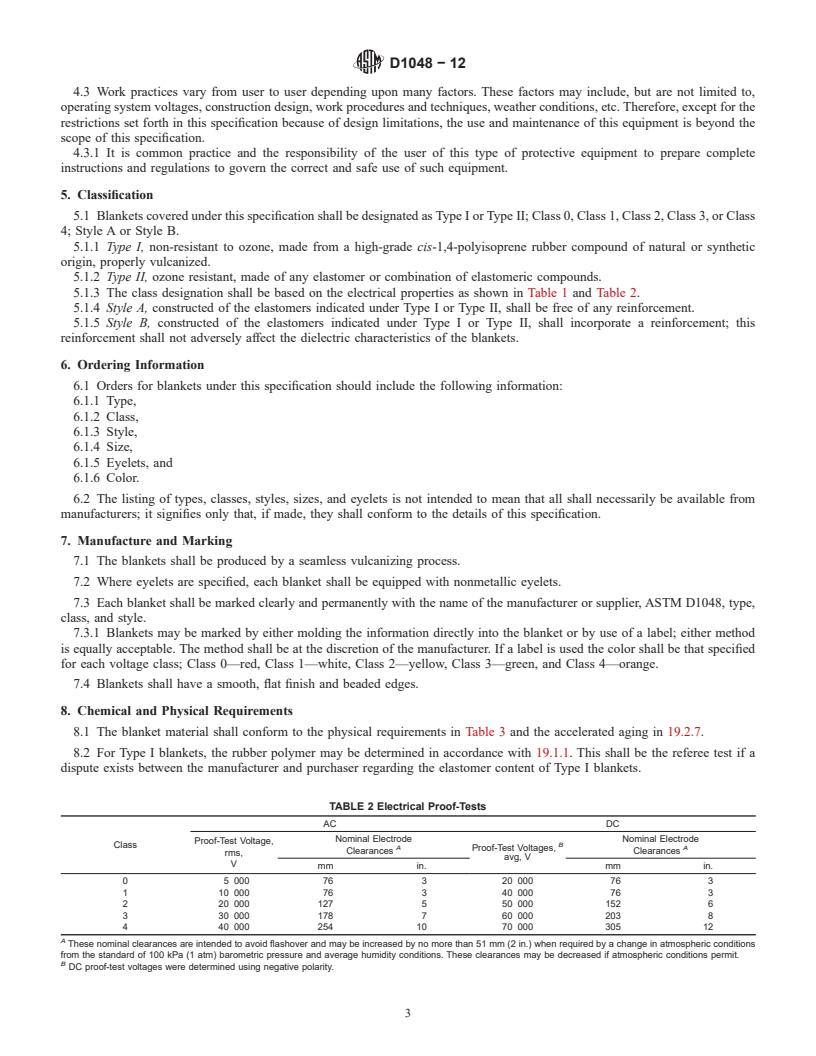

1.3 Five classes of blankets, differing in electrical characteristics, are provided and are designated as Class 0, Class 1, Class 2, Class 3, and Class 4.

1.4 Two styles of blankets, differing in construction characteristics, are provided and are designated as Style A and Style B.

1.5 The following safety hazards caveat pertains only to the test method portion, Sections 16-19, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D1048 −12

StandardSpecification for

1

Rubber Insulating Blankets

This standard is issued under the fixed designation D1048; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

3

1. Scope Cracking (Withdrawn 2007)

D570Test Method for Water Absorption of Plastics

1.1 This specification covers acceptance testing of rubber

D573Test Method for Rubber—Deterioration in an Air

insulating blankets for protection of workers from accidental

Oven

contact with live electrical conductors, apparatus, or circuits.

D624Test Method for Tear Strength of Conventional Vul-

1.2 Two types of blankets are provided and are designated

canized Rubber and Thermoplastic Elastomers

asTypeI,notresistanttoozone,andTypeII,resistanttoozone.

D1388Test Method for Stiffness of Fabrics

D2865Practice for Calibration of Standards and Equipment

1.3 Five classes of blankets, differing in electrical

characteristics, are provided and are designated as Class 0, for Electrical Insulating Materials Testing

F819Terminology Relating to Electrical Protective Equip-

Class 1, Class 2, Class 3, and Class 4.

ment for Workers

1.4 Two styles of blankets, differing in construction

2.2 American National Standards:

characteristics, are provided and are designated as StyleAand

4

ANSI/IEEE C 2National Electrical Safety Code

Style B.

C84.1Electric Power Systems and Equipment—Voltage

5

1.5 The following safety hazards caveat pertains only to the

Ratings (60 Hz)

test method portion, Sections 16-19, of this specification: This

3. Terminology

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

3.1 beaded edge— a narrow border of thicker rubber which

of this standard to establish appropriate safety and health

extends completely around the outer edges of the blanket.

practices and determine the applicability of regulatory limita-

3.2 breakdown—the electrical discharge or arc occurring

tions prior to use.

betweentheelectrodesandthroughtheequipmentbeingtested.

2. Referenced Documents 3.3 designated person—an individual who is qualified by

2

experience or training to perform an assigned task.

2.1 ASTM Standards:

D149Test Method for Dielectric Breakdown Voltage and 3.4 electrical testing facility—a location with qualified

personnel,testingequipment,andproceduresfortheinspection

DielectricStrengthofSolidElectricalInsulatingMaterials

at Commercial Power Frequencies and electrical testing of electrical insulating protective equip-

ment.

D297Test Methods for Rubber Products—ChemicalAnaly-

sis

3.5 electrode clearance—the shortest path from the ener-

D412TestMethodsforVulcanizedRubberandThermoplas-

gized electrode to the ground electrode.

tic Elastomers—Tension

3.6 flashover—the electrical discharge or arc occurring be-

D518 Test Method for Rubber Deterioration—Surface

tween electrodes and over or around, but not through, the

equipment being tested.

1 3.7 insulated—separated from other conducting surfaces by

This specification is under the jurisdiction of ASTM Committee F18 on

Electrical Protective Equipment for Workers and is the direct responsibility of

a dielectric substance (including air space) offering a high

Subcommittee F18.25 on Insulating Cover-Up Equipment. This standard replaces

resistance to the passage of current.

ANSI Standard J6.4, which is no longer available.

Current edition approved Oct. 1, 2012. Published October 2012. Originally

3

approved in 1949 as D1048–49 T. Last previous edition approved in 2011 as The last approved version of this historical standard is referenced on

D1048-11. DOI: 10.1520/D1048-12. www.astm.org.

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

5

Standards volume information, refer to the standard’s Document Summary page on AvailablefromNationalElectricalManufacturersAssociation,1300North17th

the ASTM website. Street, Rosslyn, VA 22209.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1048−12

3.7.1 Discussion—Whenanyobjectissaidtobeinsulated,it 4.2 Blankets are used for personal protection; therefore,

is understood to be insulated in a suitable manner for the whenauthorizingtheiruse,amarginofs

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D1048 − 11 D1048 − 12

Standard Specification for

1

Rubber Insulating Blankets

This standard is issued under the fixed designation D1048; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope

1.1 This specification covers acceptance testing of rubber insulating blankets for protection of workers from accidental contact

with live electrical conductors, apparatus, or circuits.

1.2 Two types of blankets are provided and are designated as Type I, not resistant to ozone, and Type II, resistant to ozone.

1.3 Five classes of blankets, differing in electrical characteristics, are provided and are designated as Class 0, Class 1, Class 2,

Class 3, and Class 4.

1.4 Two styles of blankets, differing in construction characteristics, are provided and are designated as Style A and Style B.

1.5 The following safety hazards caveat pertains only to the test method portion, Sections 16-19, of this specification:This

standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user

of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior

to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D297 Test Methods for Rubber Products—Chemical Analysis

D412 Test Methods for Vulcanized Rubber and Thermoplastic Elastomers—Tension

3

D518 Test Method for Rubber Deterioration—Surface Cracking (Withdrawn 2007)

D570 Test Method for Water Absorption of Plastics

D573 Test Method for Rubber—Deterioration in an Air Oven

D624 Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers

D1388 Test Method for Stiffness of Fabrics

D2865 Practice for Calibration of Standards and Equipment for Electrical Insulating Materials Testing

F819 Terminology Relating to Electrical Protective Equipment for Workers

2.2 American National Standards:

4

ANSI/IEEE C 2 National Electrical Safety Code

5

C84.1 Electric Power Systems and Equipment—Voltage Ratings (60 Hz)

3. Terminology

3.1 beaded edge— a narrow border of thicker rubber which extends completely around the outer edges of the blanket.

3.2 breakdown—the electrical discharge or arc occurring between the electrodes and through the equipment being tested.

3.3 designated person—an individual who is qualified by experience or training to perform an assigned task.

1

This specification is under the jurisdiction of ASTM Committee F18 on Electrical Protective Equipment for Workers and is the direct responsibility of Subcommittee

F18.25 on Insulating Cover-Up Equipment. This standard replaces ANSI Standard J 6.4, which is no longer available.

Current edition approved June 1, 2011Oct. 1, 2012. Published July 2011 October 2012. Originally approved in 1949 as D1048 – 49 T. Last previous edition approved in

20052011 as D1048 – 05.D1048-11. DOI: 10.1520/D1048-11.10.1520/D1048-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The last approved version of this historical standard is referenced on www.astm.org.

4

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE), 445 Hoes Ln., P.O. Box 1331, Piscataway, NJ 08854-1331, http://www.ieee.org.

5

Available from National Electrical Manufacturers Association, 1300 North 17th Street, Rosslyn, VA 22209.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D1048 − 12

3.4 electrical testing facility—a location with qualified personnel, testing equipment, and procedures for the inspection and

electrical testing of electrical insulating protective equipment.

3.5 electrode clearance—the shortest path from the energized electrode to the ground electrode.

3.6 flashover—the electrical discharge or arc occurring between electrodes and over or around, but not

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.