ASTM F1742-03(2020)

(Specification)Standard Specification for PVC Insulating Sheeting

Standard Specification for PVC Insulating Sheeting

ABSTRACT

This guide provides a recommended list of selected ship structure details for use in ship construction. Structural details which have failed in service and are not recommended for use in ship construction are included as well. This guide is intended to convey the lessons learned on different configurations of ship structure details, not the dimensions, thickness, or construction methods which would result from structural calculations. Details are shown for the ten families of structural details, which are: beam brackets, clearance cut-outs, gunwale connections, miscellaneous cut-outs, non-tight collars, panel stiffeners, stanchion ends, stiffener ends, tight collars, and tripping brackets. Evaluation of details is based on in-service experience as described in "Design Guide for Structural Details". Data for over 400 details is summarized and rated by observed relative successful performance. Each of the ten families of details includes configurations with no signs of failures. The details without failures within each family group are shown in descending order of numbers observed. Those details with failures are shown in ascending order of failures (percentages are indicated for each). Thus the first detail shown in each family group has the best observed service performance and is most highly recommended while the last has the highest failure rate and therefore least desirable. The details provide guidance in the selection of structural detail configurations in future design and repair of such details.

SCOPE

1.1 This specification covers acceptance testing of Poly Vinyl Chloride insulating sheeting for use as a covering for protection of workers.

1.2 The following safety hazards caveat applies only to the test method portion, Sections 17 – 19, of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.3 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F1742 −03 (Reapproved 2020)

Standard Specification for

PVC Insulating Sheeting

This standard is issued under the fixed designation F1742; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D2240 Test Method for Rubber Property—Durometer Hard-

ness

1.1 This specification covers acceptance testing of Poly

2.2 American National Standard:

Vinyl Chloride insulating sheeting for use as a covering for

protection of workers. ANSI C84.1 Voltage Ratings for Electric Power Systems

and Equipment (60 Hz)

1.2 The following safety hazards caveat applies only to the

testmethodportion,Sections17–19,ofthisspecification:This

3. Terminology

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user 3.1 Definitions:

of this standard to establish appropriate safety, health, and 3.1.1 voltage, maximum use—the ac voltage (rms) classifi-

environmental practices and determine the applicability of cation of the protective equipment that designates the maxi-

regulatory limitations prior to use. mum nominal design voltage of the energized system that may

1.3 This international standard was developed in accor- be safely worked. The nominal design voltage is equal to

dance with internationally recognized principles on standard- phase-to-phase voltage on multiphase circuits.

ization established in the Decision on Principles for the 3.1.1.1 Discussion—If there is no multiphase exposure in a

Development of International Standards, Guides and Recom- system area, and the voltage exposure is limited to phase

mendations issued by the World Trade Organization Technical (polarityondcsystems)togroundpotential,thephase(polarity

ondcsystems)togroundpotentialshallbeconsideredtobethe

Barriers to Trade (TBT) Committee.

nominal design voltage.

2. Referenced Documents

3.1.1.2 Discussion—If electrical equipment and devices are

insulated, or isolated, or both, such that the multiphase expo-

2.1 ASTM Standards:

sure on a grounded wye circuit is removed, then the nominal

D149 Test Method for Dielectric Breakdown Voltage and

design voltage may be considered as the phase-to-ground

DielectricStrengthofSolidElectricalInsulatingMaterials

voltage on that circuit.

at Commercial Power Frequencies

D412 Test Methods forVulcanized Rubber andThermoplas-

3.1.2 voltage, nominal design—a nominal value consistent

tic Elastomers—Tension with the latest revision of ANSI C84.1, assigned to the circuit

D570 Test Method for Water Absorption of Plastics

or system for the purpose of conveniently designating its

D747 Test Method for Apparent Bending Modulus of Plas- voltage class.

tics by Means of a Cantilever Beam (Withdrawn 2019)

D1004 Test Method for Tear Resistance (Graves Tear) of 4. Significance and Use

Plastic Film and Sheeting

4.1 This specification covers the minimum electrical and

D1048 Specification for Rubber Insulating Blankets

physical properties guaranteed by the manufacturer and the

D1746 Test Method for Transparency of Plastic Sheeting

detailed procedures by which such properties are to be deter-

mined. The purchaser may at his option perform or have

performed any of these tests in order to verify the guarantee.

This specification is under the jurisdiction of ASTM Committee F18 on

Claims for failure to meet the specification are subject to

Electrical Protective Equipment for Workers and is the direct responsibility of

verification by the manufacturer.

Subcommittee F18.25 on Insulating Cover-Up Equipment.

Current edition approved Jan. 1, 2020. Published January 2020. Originally

NOTE 1—This material is intended for a single use application.

approved in 1996. Last previous edition approved in 2011 as F1742– 03(2011).

4.2 The safe and proper field use of PVC sheeting is beyond

DOI: 10.1520/F1742-03R20.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or the scope of this specification.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

The last approved version of this historical standard is referenced on Available from American National Standards Institute, 11 West 42nd St., 13th

www.astm.org. Floor, New York, NY 10036.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F1742−03 (2020)

TABLE 2 AC Voltage Requirements

4.2.1 When authorizing use of PVC sheeting for personal

protection, a margin of safety should be allowed between the Dielectric

Electrode Clearances

Proof Test

A Breakdown Test

Min

maximum voltage at which it is used and the proof-test voltage

Class Voltage

Voltage

rms V

at which it is tested. The relationship between proof-test and mm in.

rms V

the maximum voltage at which sheeting shall be used is shown 0 76 3 5000 10 000

1 76 3 10 000 20 000

in Table 1.

A

Thesenominalclearancesareintendedtoavoidflashoverandmaybeincreased

fromthestandardof100kPa(1atm)barometricpressureandaveragehumidityby

5. Classification

no more than 51 mm (2 in.) when required by change in atmospheric conditions.

5.1 PVCinsulatingsheetingcoveredunderthisspecification These clearances may be decreased if atmospheric conditions permit.

shall be designated as Class 0 or Class 1.

5.1.1 The class designation shall be based on the electrical

TABLE 3 DC Voltage Requirements

properties as shown in Table 2 or Table 3.

Dielectric

Electrode Clearances

Proof Test

A

Breakdown

6. Ordering Information Min

Class Voltage

Test Voltage

avg V

mm in.

6.1 Orders for PVC insulating sheeting under this specifi- avg V

0 76 3 8500 17 000

cation should include the following information:

1 76 3 17 000 44 000

6.1.1 Class,

A

Thesenominalclearancesareintendedtoavoidflashoverandmaybeincreased

6.1.2 Thickness,

fromthestandardof100kPa(1atm)barometricpressureandaveragehumidityby

6.1.3 Width, and no more than 51 mm (2 in.) when required by change in atmospheric conditions.

These clearances may be decreased if atmospheric conditions permit.

6.1.4 Length.

7. Manufacture and Marking

7.1 The insulating sheet shall consist of a clear PVC

9.2 The sheeting material when tested between 51-mm

compound with a smooth, polished finish on each surface (see

(2-in.) disk electrodes with edges rounded to a radius of 6 mm

Fig. 1).

(0.25 in.), shall show a 60-Hz dielectric strength of not less

7.2 Each piece of sheeting shall be marked clearly and than the requirements shown in Table 2 or Table 3 for the

permanently at a maximum interval of1m(3ft) with the name thickness of each individual specimen.

of the manufacture or supplier, ASTM D and class.

10. Dimensions and Permissible Variations

8. Physical Requirements

10.1 Width—Standard widths shall be 1220 6 25 mm (48 6

8.1 Insulating sheeting shall conform to the physical re-

1 in.). Other widths may be negotiated with the manufacturer.

quirements in Table 4.

10.2 Thickness—The thickness of the sheeting shall be as

8.2 PVC insulating sheeting should remain flexible for use

specified in Table 5.

through normal temperature ranges.

11. Workmanship and Finish

8.3 PVC insulating sheeting is clear but may be tinted to aid

11.1 The sheeting shall be smooth and uniform and free of

in visual identification.

harmful physical irregularities, which can be detected by a

9. Electrical Requirements

thorough test or inspection.

11.1.1 Nonharmful Irregularities—Flow marks may be

9.1 The entire length of each roll of sheeting when new

present on all PVC sheeting due to inherent difficulties in the

(unused) shall withstand the 60-Hz ac proof-test voltage (rms

manufacturing process. These irregularities may appear as

value) specified in Table 2 or the dc proof-test voltage (avg

waves in the sheeting which are acceptable provided that the

value) specified in Table 3. The test voltage shall be applied

sheeting thickness at any irregularity conforms to the thickness

continuously for 1 min.

requirements of Table 5.

TABLE 1 Proof Test/Use Voltage Relationship

12. Guarantee

NOTE 1—The ac voltage (rms) classification of the protective equip-

12.1 The manufacturer or supplier shall replace, without

ment designates the maximum nominal design voltage of the energized

charge to the purchaser, unused sheeting which at any time

systemthatmaybesafelyworked.Thenominaldesignvoltageisequalto:

within a period of nine months from date of initial delivery of

(a) The phase to phase on multiphase circuits, or

shipment to the purchaser or his designee, fail to pass the tests

(b) The phase to ground voltage on single phase grounded circuits.

in this specification. This guarantee will be binding on the

Maximum Use

Class of Insulating AC Proof-Test DC Proof-Test

A

Voltage Phase-

manufacturer or supplier only if the sheeting has been properly

Sheeting Voltage, rms V Voltage, avg V

Phase ac rms, max

stored and has not been subjected to more than an original

0 1000 5000 8500

1 7500 10 000 17 000 acceptance test and one retest.

A

Except for class 0 equipment, the maximum AC use voltage is based on the

12.2 Any acceptance test made by the purchaser or the

following formula: Maximum use voltage (maximum nominal design voltage) =

purchaser’s designee, shall be performed within the first two

0.95 ac proof-test voltage-2000.

months of the guarantee period unless otherwise specified.

F1742−03 (2020)

FIG. 1 PVC Insulating Sheeting

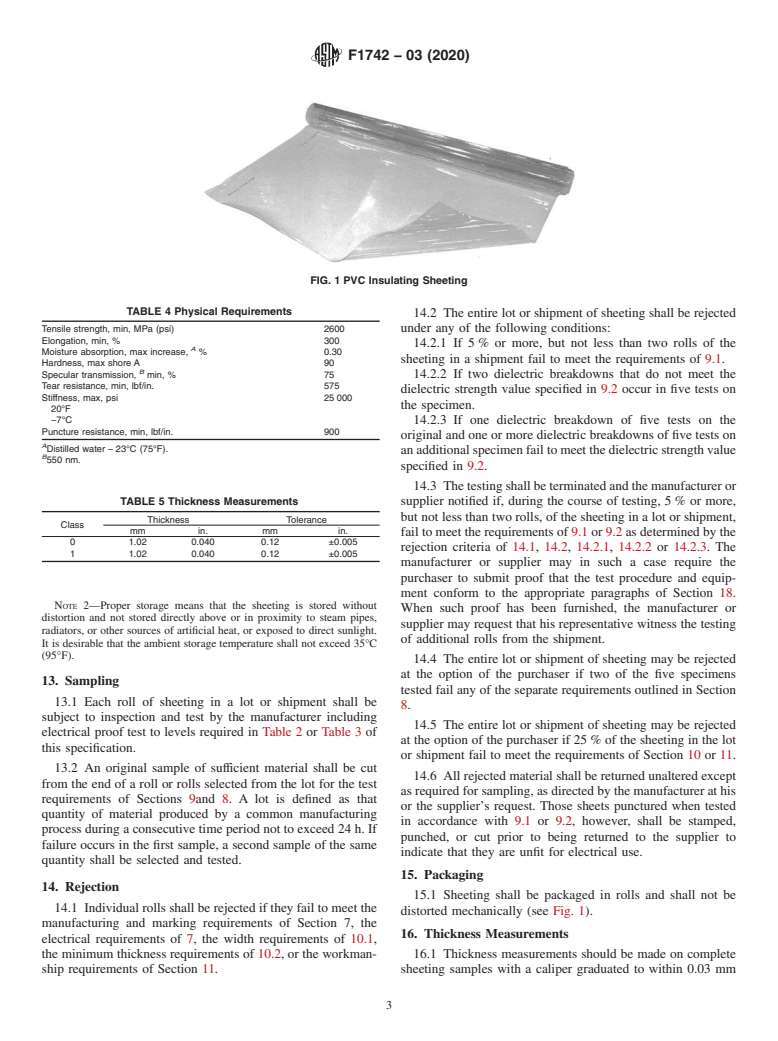

TABLE 4 Physical Requirements

14.2 The entire lot or shipment of sheeting shall be rejected

Tensile strength, min, MPa (psi) 2600 under any of the following conditions:

Elongation, min, % 300

14.2.1 If 5 % or more, but not less than two rolls of the

A

Moisture absorption, max increase, % 0.30

sheeting in a shipment fail to meet the requirements of 9.1.

Hardness, max shore A 90

B

Specular transmission, min, % 75 14.2.2 If two dielectric breakdowns that do not meet the

Tear resistance, min, lbf/in. 575

dielectric strength value specified in 9.2 occur in five tests on

Stiffness, max, psi 25 000

the specimen.

20°F

−7°C 14.2.3 If one dielectric breakdown of five tests on the

Puncture resistance, min, lbf/in. 900

original and one or more dielectric breakdowns of five tests on

A

Distilled water − 23°C (75°F).

anadditionalspecimenfailtomeetthedielectricstrengthvalue

B

550 nm.

specified in 9.2.

14.3 Thetestingshallbeterminatedandthemanufactureror

TABLE 5 Thickness Measurements supplier notified if, during the course of testing, 5 % or more,

but not less than two rolls, of the sheeting in a lot or shipment,

Thickness Tolerance

Class

mm in. mm in.

fail to meet the requirements of 9.1 or 9.2 as determined by the

0 1.02 0.040 0.12 ±0.005

rejection criteria of 14.1, 14.2, 14.2.1, 14.2.2 or 14.2.3. The

1 1.02 0.040 0.12 ±0.005

manufacturer or supplier may in such a case require the

purchaser to submit proof that the test procedure and equip-

ment conform to the appropriate paragraphs of Section 18.

NOTE 2—Proper storage means that the sheeting is stored without

When such proof has been furnished, the manufacturer or

distortion and not stored directly above or in proximity to steam pipes,

supplier may request that his representative witness the testing

radiators, or other sources of artificial heat, or exposed to direct sunlight.

of additional rolls from the shipment.

It is desirable that the ambient storage temperature shall not exceed 35°C

(95°F).

14.4 The entire lot or shipment of sheeting may be rejected

at the option of the purchaser if two of the five specimens

13. Sampling

tested fail any of the separate requirements outlined in Section

13.1 Each roll of sheeting in a lot or shipment shall be

8.

subject to inspection and test by the manufacturer including

14.5 The entire lot or shipment of sheeting may be rejected

electrical proof test to levels required in Table 2 or Table 3 of

at the option of the purchaser if 25 % of the sheeting in the lot

this specification.

or shipment fail to meet the requirements of Section 10 or 11.

13.2 An original sample of sufficient material shall be cut

14.6 All rejected material shall be returned unaltered except

from the end of a roll or rolls selected from the lot for the test

as required for sampling, as directed by the manufacturer at his

requirements of Sections 9and 8. A lot is defined as that

or the supplier’s request. Those sheets punctured when tested

quantity of material produced by a common manufacturing

in accordance with 9.1 or 9.2, however, shall be stamped,

process during a consecutive time period not to exceed 24 h. If

punched, or cut prior to being returned to the supplier to

failure occurs in the first sample, a second sample of the same

indicate that they are unfit for electrical use.

quantity shall be selected and tested.

15. Packaging

14. Rejection

15.1 Sheeting shall be packaged in rolls and shall not be

14.1 Individual rolls shall be rejected if they fail to meet the

distorted mechanically (see Fig. 1).

manufacturing and marking requirements of Section 7, the

16. Thickness Measurements

electrical requirements of 7, the width requirements of 10.1,

the minimum thickness requirements of 10.2, or the workman- 16.1 Thickness measurements should be made on complete

ship requirements of Section 11. sheeting samples with a caliper graduated to within 0.03 mm

F1742−03 (2020)

(0.001 in.).At least five thickness measurements shall be made 18.2.2.3 The accuracy of the voltage-measuring circuit shall

at selected points uniformly distributed over the test area of the be within 62 % of full scale. The correct rms value of the

sheeting. actual sinusoidal voltage wave-form applied to the sheeting

may be measured by one of the following methods: (1)a

TEST METHODS

voltmeter used in conjunction with a calibrated instrument

transformer connected directly across the high-voltage circuit,

17. Sequence of Testing

(2 ) a calibrated electrostatic voltmeter connected directly

17.1 The following order of procedure is suggested for

across the high-voltage circuit, or (3) an ac meter connected in

testing PVC insulating sheeting.

series with appropriate high-voltage type resistors directly

17.1.1 Inspection of the surfaces in accordance with Section

across the high-voltage circuit.

11.

18.2.2.4 The crest factor may be checked by the use of a

17.1.2 The dimensions in accordance with Sections 10 and

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.