ASTM D5526-94(2011)e1

(Test Method)Standard Test Method for Determining Anaerobic Biodegradation of Plastic Materials Under Accelerated Landfill Conditions

Standard Test Method for Determining Anaerobic Biodegradation of Plastic Materials Under Accelerated Landfill Conditions

SIGNIFICANCE AND USE

Decomposition of a plastic within a landfill involves biological processes that will affect the decomposition of other materials enclosed by, or in close proximity to, the plastic. Rapid degradation of the plastic has the ability to increase the economic feasibility of landfill-gas recovery, minimize the duration of after-care of the landfill, and make possible the recovery of the volume reduction of the waste due to biodegradation during the active life of the landfill. This procedure has been developed to permit determination of the anaerobic biodegradability of plastic products when placed in biologically active environments simulating landfill conditions.

As degradation occurs inevitably in a landfill, it is of immediate concern that the plastic materials do not produce toxic metabolites or end products under the various conditions that have the potential to occur in a landfill. The mixtures remaining after completion of the test method, containing fully or partially degraded plastic materials or extracts, can be submitted subsequently to ecotoxicity testing in order to assess the environmental hazards posed by the breakdown of plastics to varying degrees in landfills. This test method has been designed to assess biodegradation under optimum and less-than-optimum conditions.

Limitations—Because a wide variation exists in the construction and operation of landfills, and because regulatory requirements for landfills vary greatly, this procedure is not intended to simulate the environment of all landfills. However, it is expected to closely resemble the environment of a biologically active landfill. More specifically, the procedure is intended to create a standard laboratory environment that permits rapid and reproducible determination of the anaerobic biodegradability under accelerated landfill conditions, while at the same time producing reproducible mixtures of fully and partially decomposed household waste with plastic materials for ecotoxicological assessm...

SCOPE

1.1 This test method covers determination of the degree and rate of anaerobic biodegradation of plastic materials in an accelerated-landfill test environment. This test method is also designed to produce mixtures of household waste and plastic materials after different degrees of decomposition under conditions that resemble landfill conditions. The test materials are mixed with pretreated household waste and exposed to a methanogenic inoculum derived from anaerobic digesters operating only on pretreated household waste. The anaerobic decomposition occurs under dry (more than 30 % total solids) and static nonmixed conditions. The mixtures obtained after this test method can be used to assess the environmental and health risks of plastic materials that are degraded in a landfill.

1.2 This test method is designed to yield a percentage of conversion of carbon in the sample to carbon in the gaseous form under conditions that resemble landfill conditions. It is possible that this test method will not simulate all conditions found in landfills, especially biologically inactive landfills. This test method more closely resembles those types of landfills in which the gas generated is recovered or even actively promoted, or both, for example, by inoculation (codeposition of anaerobic sewage sludge and anaerobic leachate recirculation), moisture control in the landfill (leachate recirculation), and temperature control (short-term injection of oxygen and heating of recirculated leachate) (1-7).

1.3 This test method is designed to produce partially degraded mixtures of municipal solid waste and plastics that can be used to assess the ecotoxicological risks associated with the anaerobic degradation of plastics after various stages of anaerobic biodegradation in a landfill.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, asso...

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D5526 – 94 (Reapproved 2011)

Standard Test Method for

Determining Anaerobic Biodegradation of Plastic Materials

Under Accelerated Landfill Conditions

This standard is issued under the fixed designation D5526; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Reapproved with editorial changes throughout in February 2011.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 Thistestmethodcoversdeterminationofthedegreeand

responsibility of the user of this standard to establish appro-

rate of anaerobic biodegradation of plastic materials in an

priate safety and health practices and determine the applica-

accelerated-landfill test environment. This test method is also

bility of regulatory limitations prior to use. Specific hazards

designed to produce mixtures of household waste and plastic

statements are given in Section 8.

materials after different degrees of decomposition under con-

ditions that resemble landfill conditions. The test materials are

NOTE 1—There is no known ISO equivalent to this standard.

mixed with pretreated household waste and exposed to a

2. Referenced Documents

methanogenic inoculum derived from anaerobic digesters op-

erating only on pretreated household waste. The anaerobic

2.1 ASTM Standards:

decomposition occurs under dry (more than 30% total solids)

D618 Practice for Conditioning Plastics for Testing

and static nonmixed conditions. The mixtures obtained after

D883 Terminology Relating to Plastics

this test method can be used to assess the environmental and

D1293 Test Methods for pH of Water

health risks of plastic materials that are degraded in a landfill.

D1888 Methods Of Test for Particulate and Dissolved

1.2 This test method is designed to yield a percentage of

Matter in Water

conversion of carbon in the sample to carbon in the gaseous

D2908 Practice for Measuring Volatile Organic Matter in

form under conditions that resemble landfill conditions. It is

Water by Aqueous-Injection Gas Chromatography

possible that this test method will not simulate all conditions

D3590 Test Methods for Total Kjeldahl Nitrogen in Water

found in landfills, especially biologically inactive landfills.

D4129 Test Method for Total and Organic Carbon in Water

This test method more closely resembles those types of

by High Temperature Oxidation and by Coulometric De-

landfills in which the gas generated is recovered or even

tection

actively promoted, or both, for example, by inoculation (code-

E260 Practice for Packed Column Gas Chromatography

position of anaerobic sewage sludge and anaerobic leachate

E355 Practice for Gas Chromatography Terms and Rela-

recirculation), moisture control in the landfill (leachate recir-

tionships

culation), and temperature control (short-term injection of

2.2 APHA-AWWA-WPCF Standards:

oxygen and heating of recirculated leachate) (1-7).

2540D Total Suspended Solids Dried at 103°–105°C

1.3 This test method is designed to produce partially de-

2540E Fixed and Volatile Solids Ignited at 550°C

graded mixtures of municipal solid waste and plastics that can

212 Nitrogen Ammonia

be used to assess the ecotoxicological risks associated with the

3. Terminology

anaerobic degradation of plastics after various stages of an-

aerobic biodegradation in a landfill.

3.1 Definitions—For definitions of terms used in this test

1.4 The values stated in SI units are to be regarded as the method see Terminology D883.

standard.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

ThistestmethodisunderthejurisdictionofASTMCommitteeD20onPlastics contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

and is the direct responsibility of Subcommittee D20.96 on Environmentally Standards volume information, refer to the standard’s Document Summary page on

Degradable Plastics and Biobased Products. the ASTM website.

Current edition approved Feb. 1, 2011. Published February 2011. Originally Withdrawn. The last approved version of this historical standard is referenced

´1

approved in 1994. Last previous edition approved in 2002 as D5526–94(2002) on www.astm.org.

5 th

. DOI: 10.1520/D5526-94R11E01. Standard Methods for the Examination of Water and Wastewater,20 ed.,

Theboldfacenumbersinparenthesesrefertothelistofreferencesattheendof 1999, available from American Public Health Association, 800 I Street, NW,

this standard. Washington, D.C. 20001-3710, or http://www.standardmethods.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

D5526 – 94 (2011)

3.2 Definitions of Terms Specific to This Standard: 6. Apparatus

3.2.1 methanogenic inoculum—anaerobically digested or-

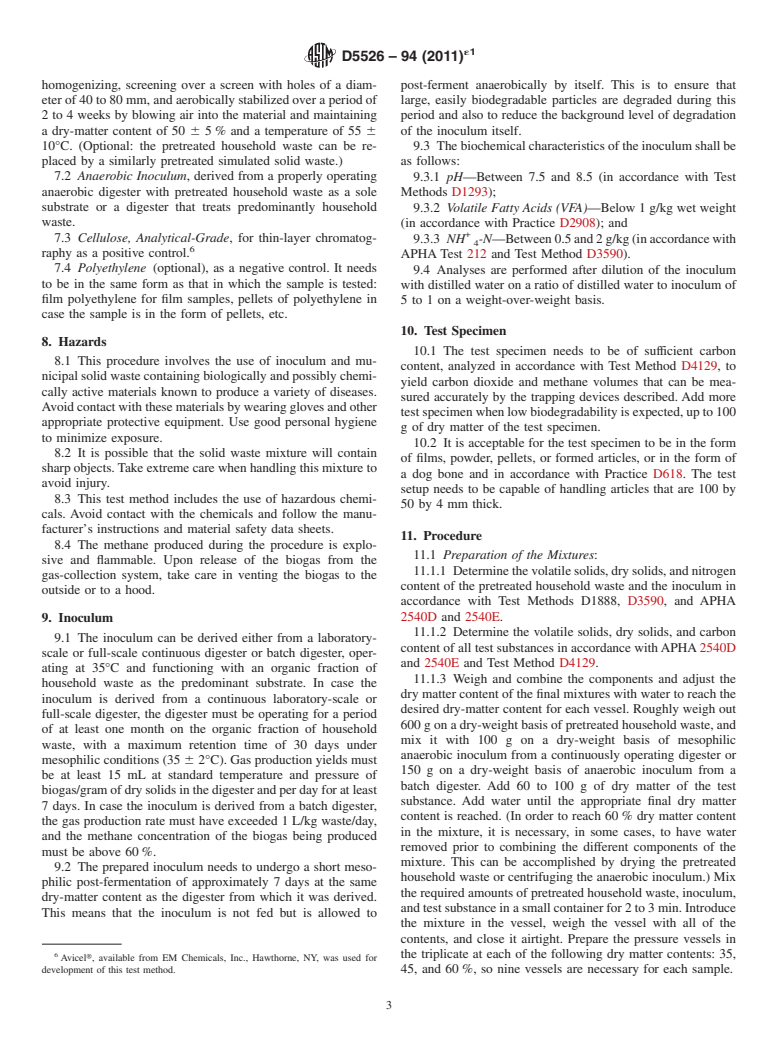

6.1 Pressure-Resistant Glass Vessels—Twenty-seven, each

ganic waste containing a high concentration of anaerobic

with a volume of 4 to 6 L, which can be closed airtight and

methane-producing microorganisms.

capable of withstanding an overpressure of two atmospheres.

The lids of the reactors are equipped with an overpressure

4. Summary of Test Method

valve (to prevent the overpressure from becoming higher than

4.1 Thistestmethoddescribedconsistsofthefollowing:(1)

2 bars), a manometer that provides a rough indication of the

selecting and analyzing material for testing; (2) obtaining a

overpressure,aseptumthatallowsonetotakegassamplesand

pretreated municipal-solid-waste fraction and a concentrated

measure the exact overpressure, and, finally, a valve to release

anaerobic inoculum from an anaerobic digester; (3) exposing

the overpressure (Fig. 1).

the material to an anaerobic static batch fermentation at more

6.2 Incubators, sufficient to store the vessels in the dark at

than 30% solids; (4) measuring total carbon in the gas (CO

35 6 2°C for the duration of the test.

and CH ) evolved as a function of time; (5) removing the

6.3 Pressure Transducer, connected to a syringe needle to

specimens for cleaning (optional), conditioning, testing, and

measure the headspace pressure in the test vessel.

reporting; (6) assessing the degree of biodegradability; and (7)

6.4 Gas Chromatograph, or other apparatus, equipped with

assessing the degree of biodegradability under less than opti-

a suitable detector and column(s) for measuring methane and

mum conditions.

carbon dioxide concentrations in the evolved gases.

4.2 The percentage of biodegradability is obtained by de-

6.5 pH Meter, precision balance (60.1 g), analytical bal-

termining the percent of conversion of carbon from the test

ance (60.1 mg), thermometer, and barometer.

material to carbon in the gaseous phase (CH and CO ). This

4 2

6.6 Suitable Devices, for determining volatile fatty acids by

percentage of biodegradability will not include the amount of

aqueous-injection chromatography, total Kjeldahl nitrogen,

carbonfromthetestsubstancethatisconvertedtocellbiomass

ammonia nitrogen, dry solids (105°C), and volatile solids

and that is not, in turn, metabolized to CO and CH .

2 4

(550°C) concentrations.

5. Significance and Use

7. Reagents and Materials

5.1 Decomposition of a plastic within a landfill involves

7.1 Pretreated-Household Waste, derived from mixed mu-

biologicalprocessesthatwillaffectthedecompositionofother

nicipal solid waste or the organic fraction thereof, after

materials enclosed by, or in close proximity to, the plastic.

Rapid degradation of the plastic has the ability to increase the

economic feasibility of landfill-gas recovery, minimize the

duration of after-care of the landfill, and make possible the

recovery of the volume reduction of the waste due to biodeg-

radation during the active life of the landfill. This procedure

has been developed to permit determination of the anaerobic

biodegradability of plastic products when placed in biologi-

cally active environments simulating landfill conditions.

5.2 As degradation occurs inevitably in a landfill, it is of

immediate concern that the plastic materials do not produce

toxic metabolites or end products under the various conditions

that have the potential to occur in a landfill. The mixtures

remainingaftercompletionofthetestmethod,containingfully

or partially degraded plastic materials or extracts, can be

submittedsubsequentlytoecotoxicitytestinginordertoassess

the environmental hazards posed by the breakdown of plastics

to varying degrees in landfills. This test method has been

designed to assess biodegradation under optimum and less-

than-optimum conditions.

5.3 Limitations—Because a wide variation exists in the

construction and operation of landfills, and because regulatory

requirements for landfills vary greatly, this procedure is not

intended to simulate the environment of all landfills. However,

it is expected to closely resemble the environment of a

biologically active landfill. More specifically, the procedure is

intended to create a standard laboratory environment that

1 = Digester.

permits rapid and reproducible determination of the anaerobic

2 = Incubation chamber.

3 = Overpressure valve.

biodegradability under accelerated landfill conditions, while at

4 = Manometer.

the same time producing reproducible mixtures of fully and

5 = Septum.

partially decomposed household waste with plastic materials

6 = Valve.

for ecotoxicological assessment. FIG. 1 Setup of Accelerated Landfill

´1

D5526 – 94 (2011)

homogenizing, screening over a screen with holes of a diam- post-ferment anaerobically by itself. This is to ensure that

eterof40to80mm,andaerobicallystabilizedoveraperiodof large, easily biodegradable particles are degraded during this

2 to 4 weeks by blowing air into the material and maintaining period and also to reduce the background level of degradation

a dry-matter content of 50 6 5% and a temperature of 55 6 of the inoculum itself.

10°C. (Optional: the pretreated household waste can be re- 9.3 Thebiochemicalcharacteristicsoftheinoculumshallbe

placed by a similarly pretreated simulated solid waste.) as follows:

7.2 Anaerobic Inoculum, derived from a properly operating

9.3.1 pH—Between 7.5 and 8.5 (in accordance with Test

anaerobic digester with pretreated household waste as a sole Methods D1293);

substrate or a digester that treats predominantly household

9.3.2 Volatile Fatty Acids (VFA)—Below 1 g/kg wet weight

waste. (in accordance with Practice D2908); and

+

7.3 Cellulose, Analytical-Grade, for thin-layer chromatog-

9.3.3 NH -N—Between0.5and2g/kg(inaccordancewith

raphy as a positive control. APHATest 212 and Test Method D3590).

7.4 Polyethylene (optional), as a negative control. It needs

9.4 Analyses are performed after dilution of the inoculum

to be in the same form as that in which the sample is tested:

with distilled water on a ratio of distilled water to inoculum of

film polyethylene for film samples, pellets of polyethylene in

5 to 1 on a weight-over-weight basis.

case the sample is in the form of pellets, etc.

10. Test Specimen

8. Hazards

10.1 The test specimen needs to be of sufficient carbon

8.1 This procedure involves the use of inoculum and mu-

content, analyzed in accordance with Test Method D4129,to

nicipalsolidwastecontainingbiologicallyandpossiblychemi-

yield carbon dioxide and methane volumes that can be mea-

cally active materials known to produce a variety of diseases.

sured accurately by the trapping devices described. Add more

Avoidcontactwiththesematerialsbywearingglovesandother

testspecimenwhenlowbiodegradabilityisexpected,upto100

appropriate protective equipment. Use good personal hygiene

g of dry matter of the test specimen.

to minimize exposure.

10.2 It is acceptable for the test specimen to be in the form

8.2 It is possible that the solid waste mixture will contain

of films, powder, pellets, or formed articles, or in the form of

sharpobjects.Takeextremecarewhenhandlingthismixtureto

a dog bone and in accordance with Practice D618. The test

avoid injury.

setup needs to be capable of handling articles that are 100 by

8.3 This test method includes the use of hazardous chemi-

50 by 4 mm thick.

cals. Avoid contact with the chemicals and follow the manu-

facturer’s instructions and material safety data sheets.

11. Procedure

8.4 The methane produced during the procedure is explo-

11.1 Preparation of the Mixtures:

sive and flammable. Upon release of the biogas from the

11.1.1 Determinethevolatilesolids,drysolids,andnitrogen

gas-collection system, take care in venting the biogas to the

content of the pretreated household waste and the inoculum in

outside or to a hood.

accordance with Test Methods D1888, D3590, and APHA

2540D and 2540E.

9. Inoculum

11.1.2 Determine the volatile solids, dry solids, and carbon

9.1 The inoculum can be derived either from a laboratory-

content of all test substances in accordance withAPHA2540D

scale or full-scale continuous digester or batch digester, oper-

and 2540E and Test Method D4129.

ating at 35°C and functioning with an organic fraction of

11.1.3 Weigh and combine the components and adjust the

household waste as the predominant substrate. In case the

drymattercontentofthefinalmixtureswithwatertoreachthe

inoculum is derived from a continuous laboratory-scale or

desired dry-matter content for each vessel. Roughly weigh out

full-scale digester, the digester must be operating for a period

600gonadry-weightbasisofpretreatedhouseholdwaste,and

of at least one month on the organic fraction of household

mix it with 100 g on a dry-weight basis of mesophilic

waste, with a maximum retention time of 30 days under

anaerobic inoculum from a continuously operating digester or

mesophilic conditions (35 6 2°C). Gas production yields must

150 g on a dry-weight basis of anaerobic inoculum from a

be at least 15 mL at standard temperature and pressure of

batch digester. Add 60 to 100 g of dry matter of the test

biogas/gramofdrysolidsinthedigesterandperdayforatleast

substance. Add water until the appropriate final dry matter

7 days. In case the inoculum is derived from a batch digester,

content is reached. (In order to reach 60% dry matter content

the gas production rate must have exceeded 1 L/kg waste/day,

in the mixture, it is necessary, in some cases, to have water

and the methane concentration of the biogas being produced

removed prior to combining the different components of the

must be above 60%.

mixture. This can be accomplished by drying the pretreated

9.2 The prepared inoculum needs to undergo a short meso-

household waste or centrifuging the anaerobic inoculum.) Mix

philic post-ferment

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.