ASTM D6332-99(2005)

(Guide)Standard Guide for Testing Systems for Measuring Dynamic Responses of Carbon Monoxide Detectors to Gases and Vapors

Standard Guide for Testing Systems for Measuring Dynamic Responses of Carbon Monoxide Detectors to Gases and Vapors

SIGNIFICANCE AND USE

This guide provides information on testing systems and their components used for measuring responses of CO alarms or detectors subjected to gases, vapors, and their mixtures. Components of a testing system include a chamber, clean air supply module, humidification module, gas and vapor delivery module, and verification and control instrumentation.

The CO detector is tested by sequential exposure to CO and interference gases at the specified challenge concentrations. A properly functioning alarm/detector will sound upon sufficient exposure to CO but will not sound upon any exposure to interference gases consistent with applicable standards (for example, IAS 6-96 (1)6 , BS 7860, UL 2034).

SCOPE

1.1 This guide describes testing systems used for measuring responses of carbon monoxide (CO) alarms or detectors subjected to gases, vapors, and their mixtures.

1.2 The systems are used to evaluate responses of CO detectors to various CO concentrations, to verify that the detectors alarm at certain specified CO concentrations, and to verify that CO detectors do not alarm at certain other specified CO concentrations.

1.3 The systems are used for evaluating CO detector responses to gases and vapors that may interfere with the ability of detectors to respond to CO.

1.4 Major components of such a testing system include a chamber, clean air supply module, humidification module, gas and vapor delivery module, and verification and control instrumentation.

1.5 For each component, this guide provides a comparison of different approaches and discusses their advantages and disadvantages.

1.6 This guide also presents recommendations for a minimum configuration of a testing system.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For more specific safety precautionary information, see 6.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6332 – 99 (Reapproved 2005)

Standard Guide for

Testing Systems for Measuring Dynamic Responses of

Carbon Monoxide Detectors to Gases and Vapors

This standard is issued under the fixed designation D6332; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D1945 Test Method for Analysis of Natural Gas by Gas

Chromatography

1.1 This guide describes testing systems used for measuring

D3162 Test Method for Carbon Monoxide in the Atmo-

responses of carbon monoxide (CO) alarms or detectors

sphere (Continuous Measurement by Nondispersive Infra-

subjected to gases, vapors, and their mixtures.

red Spectrometry)

1.2 The systems are used to evaluate responses of CO

D3195 Practice for Rotameter Calibration

detectors to various CO concentrations, to verify that the

D3249 Practice for General Ambient Air Analyzer Proce-

detectors alarm at certain specified CO concentrations, and to

dures

verify that CO detectors do not alarm at certain other specified

D3687 Practice for Analysis of Organic Compound Vapors

CO concentrations.

Collected by the Activated Charcoal Tube Adsorption

1.3 The systems are used for evaluating CO detector re-

Method

sponses to gases and vapors that may interfere with the ability

2.2 Other Standards:

of detectors to respond to CO.

BS 7860 Specification for Carbon Monoxide Detectors

1.4 Major components of such a testing system include a

(Electrical) For Domestic Use

chamber, clean air supply module, humidification module, gas

UL 2034 Single and Multiple Station Carbon Monoxide

and vapor delivery module, and verification and control instru-

Detectors

mentation.

CFR 1910.1450 Occupational Exposure to Hazardous

1.5 For each component, this guide provides a comparison

Chemicals in Laboratories

of different approaches and discusses their advantages and

disadvantages.

3. Terminology

1.6 The guide also presents recommendations for a mini-

3.1 Definitions:

mum configuration of a testing system.

For definitions of terms used in this guide, refer to Termi-

1.7 This guide does not purport to address all of the safety

nology D1356.

concerns, if any, associated with its use. It is the responsibility

3.2 Definitions of Terms Specific to This Standard:

of the user of this standard to establish appropriate safety and

3.2.1 air change rate—the volume of clean, humidified air

health practices and determine the applicability of regulatory

plus contaminants that enters the chamber in 1 h, divided by

limitations prior to use. For more specific safety precautionary

the internal volume of the chamber, expressed as air changes

information, see 6.2.

–1

per hour (h ).

2. Referenced Documents 3.2.2 chamber—an enclosed test volume composed of

2 chemicallyinertmaterialssuppliedwithamixtureofair,gases,

2.1 ASTM Standards:

or vapors, or combination thereof, having known composi-

D1193 Specification for Reagent Water

tions.

D1356 Terminology Relating to Sampling and Analysis of

3.2.3 CO alarm/detector—an alarm device consisting of an

Atmospheres

assemblyofelectricalandmechanicalcomponentswithchemi-

cal, electrochemical, solid-state electronic, or other types of

sensors to detect the presence of CO gas in specified ranges of

This guide is under the jurisdiction ofASTM Committee D22 on Sampling and

concentrations.

Analysis of Atmospheres and is the direct responsibility of Subcommittee D22.05

on Indoor Air.

Current edition approved January 1, 2005. Published January 2005. Originally

approved in 1998. Last previous edition approved in 1999 as D6332 - 99. DOI: Available from British Standards Institute (BSI), 389 Chiswick High Rd.,

10.1520/D6332-99R05. London W4 4AL, UK

2 4

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Underwriters Laboratories (UL), Corporate Progress, 333

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Pfingsten Rd., Northbrook, IL 60062.

Standards volume information, refer to the standard’s Document Summary page on AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

the ASTM website. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6332 – 99 (2005)

3.2.4 sensor—the component included in the CO alarm/ 6.3 Size of the Chamber—The chamber size can be large

detector that senses CO gas. (that is, room-size) or small and depends on the number of

detectors to be tested. Detectors should be placed on a wire

4. Summary of Guide

rackorsimilarsupportingstructure.Detectorsshouldbeplaced

at least 0.1-m [4-in.] away from the chamber walls. If multiple

4.1 This guide describes components of systems for testing

detectors are undergoing simultaneous testing, they should be

CO detectors with mixtures of air and CO at different concen-

spacedatleast0.05m[2in.]fromeachother.Thechambersize

trations of CO. The systems are also used for evaluating the

required by UL 2034 is a 0.9 by 0.9 by 0.9-m [3 by 3 by 3-ft]

responses of CO detectors to mixtures of air and various gases

box, which has been found to be practical for testing several

or vapors, or both. Such systems require clean air with a

detectors at a time.

preselected level of relative humidity supplied to an environ-

6.4 Material of Construction—The chamber should be

mental chamber. Gases and vapors are introduced in the clean

made of relatively inert materials, such as glass, stainless steel,

air supply or placed directly in the chamber to achieve desired

or certain types of polymers/plastics. Materials, such as wood

chamber concentration. The components of such systems

or gypsum board, may not be appropriate because of their

include devices or modules for supplying pure air, humidifying

absorption, adsorption, and leakage characteristics. Joints

air, supplying gases or vapors, or both, to be tested, reference

should be well-sealed using inert caulking/sealing materials.

instruments for verifying concentrations of gases and vapors,

Gaskets should be used around doors and other closable

and a chamber for placing and exposing CO detectors. The

openings to achieve a good seal when closed.

guide describes various options for each component: chamber

6.5 Air Change Rate—The air change rate of a dynamic

(Section 6), clean air supply module (Section 7), humidifica-

–1

chamber should be sufficient (for example, 1 h or higher) to

tion module (Section 8), gas/vapor delivery module (Section

overcome loss of chamber air through leakage and the deple-

9), and verification and control module (Section 10).The guide

tion of test gases and vapors due to factors, such as consump-

further provides recommendations on a minimum configura-

tion through a chemical reaction or deposition.

tion for the testing system (Section 11) and reporting results

6.6 Mixing—Toprovideauniformconcentrationfortesting,

(Section 12).

the chamber air should be well mixed. With an adequate air

–1

change rate (for example, 1 h or higher), mixing can be

5. Significance and Use

achieved through proper placement and design of inlet and

5.1 This guide provides information on testing systems and

outlet ports. The design and placement should be such that any

their components used for measuring responses of CO alarms

short-circuiting of flow from inlet to outlet ports is avoided.A

or detectors subjected to gases, vapors, and their mixtures.

better alternative to promote mixing is to use a fan that is

Components of a testing system include a chamber, clean air

appropriately sized for the chamber volume. For example,

supply module, humidification module, gas and vapor delivery

3 3

mixing within a large chamber having 23-m [800-ft ] volume

module, and verification and control instrumentation.

–1

can be achieved by an 378 l-s [800-cfm] fan. Ideally, the fan

5.2 The CO detector is tested by sequential exposure to CO

should be mounted on a shaft through the chamber wall, and

and interference gases at the specified challenge concentra-

the fan motor should be external to the chamber to prevent

tions. A properly functioning alarm/detector will sound upon

contaminationandheatloadinthechamber.Ifafanisused,the

sufficientexposuretoCObutwillnotsounduponanyexposure

sensorportsshouldbeshieldedfromdirectairimpingement.In

to interference gases consistent with applicable standards (for

addition to providing a uniform air concentration, the combi-

example, IAS 6-96 (1) , BS 7860, UL 2034).

nation of air change rate and mixing should be such that it

–1

provides sufficient face velocity (for example, over1ms or

6. Chamber

–1

3.3 ft s ) at sensor head(s) through the detector housing.

6.1 Types of Chamber—There are two types of chambers—

6.7 The chamber should be able to provide accurate control

static and dynamic. In a static chamber, air and known

of temperature and relative humidity at ambient pressure as

quantities of gases are introduced and then the chamber is

indicated in Table 1. The chamber should be airtight to

sealed. In a dynamic chamber, a characterized air-gas mixture

minimize any leakage of ambient air into or chamber air out of

is continually introduced at a rate sufficient to maintain target

the system. The range of environmental conditions cited in

concentrations.

Table 1 cover ranges specified in standards listed in 2.2 and in

6.2 Hazards—In a dynamic chamber, the air exiting cham-

the literature (1). Also, UL 2034 prescribes certain time peri-

ber will contain CO and interference gases or vapors that may

od(s) to achieve target concentrations that should be adhered to

be toxic. To avoid undue exposures of toxic gases and vapors

so that undue exposures are avoided.

to occupants of the laboratory (where the chamber is located),

6.8 Discussion—The advantage of the static chamber is that

the chamber should be properly vented to outside with an

thesetupissimple,basicallyrequiringonlyasealablebox.The

appropriate stack. For a static chamber, exposures to test gases

should be avoided in operating (for example, opening) the

chamber. TABLE 1 General Specifications for Test Chamber

Specification Control Range Control Precision

Temperature –10 to 52°C [14 to 126°F] 6 0.5°C [6 0.9°F]

Relative humidity 15 % to 95 % 6 5.0 %

The boldface numbers in parentheses refer to references at the end of this (noncondensing)

standard.

D6332 – 99 (2005)

major disadvantage of the static chamber is that the gases may bed to remove CO may not be necessary. If a catalyst bed is

be consumed or generated in the chamber, resulting in an used, use a desiccant and a downstream activated charcoal

environment that is different than originally specified. For this filter to remove water vapor and oxides of nitrogen, respec-

reason,thecompositionoftheatmosphereshouldbemonitored tively, that are generated from the catalyst bed.

continuously for CO concentrations and other related param- 7.4 Alternate Clean Air Module—Air from outdoors or

eters. The dynamic chamber requires a continuous and con- from the laboratory can be conditioned and cleaned by passing

trolled supply and exhaust of air and gases to be tested but it through particulate filters to remove suspended solid par-

provides an environment that does not undergo changes as an ticles, preheat coil and a chilled water dehumidifying coil to

artifact of testing. remove excess moisture, a desiccant dehumidifier to further

dehumidify air, a catalytic bed to remove background CO, and

7. Clean Air Supply Module

an activated carbon adsorbent bed to remove volatile organic

compounds in the air.

7.1 Types—There are two approaches for obtaining a clean

7.5 Discussion—The use of prepackaged clean air requires

air supply: (1) to use a prepackaged supply of clean air; and (2)

a minimal initial investment. The laboratory shall provide for

to generate clean air by processing ambient air to remove

safe storage of pressurized cylinders. Pressurized cylinders of

impurities and moisture. This second approach requires equip-

clean air that meet or exceed specifications can be purchased

ment for removing particle and gas contaminants and moisture

through commercial gas supply vendors. However, this can

from the ambient air. Clean air can be generated to meet

become costly depending on the level of use of clean air. The

specifications for different requirements of stringency. Preas-

use of a clean air module, on the other hand, requires an initial

sembled equipment for processing ambient air is also available

investment in a compressor and filtration/dehumidification

from commercial gas supply vendors. Some details on the two

equipment. The completed module supplies clean air at lower

approaches are given below.

cost if the clean air supply is used regularly. Further, proper

7.2 Packaged Clean Air—Use of packaged air involves

selection of specifications will provide adequate repeatability

purchase of pressurized cylinders of clean air or zero air with

in testing results without undue high cost. There are various

certain specifications. Recommended specifications are: less

–3

levels of clean air that can be achieved. For testing CO

than 0.5 ppm(v) (0.33 mg m of methane equivalent) of total

–3

detectors, ultra-pure air (total hydrocarbon content < 0.1

hydrocarbons, water vapor less than 3.5 ppm(v) (2.6 mg m ),

–3

–3

ppm(v) or 0.06 mg m ) is generally unnecessary. A total

and CO less than 1 ppm(v) (1.1 mg m ). Such gases are

–3

hydrocarbon content of less than 0.5 ppm(v) (0.33 mg m )is

available from commercial vendors of pure gases and gas

considered to be adequate.

mixtures.

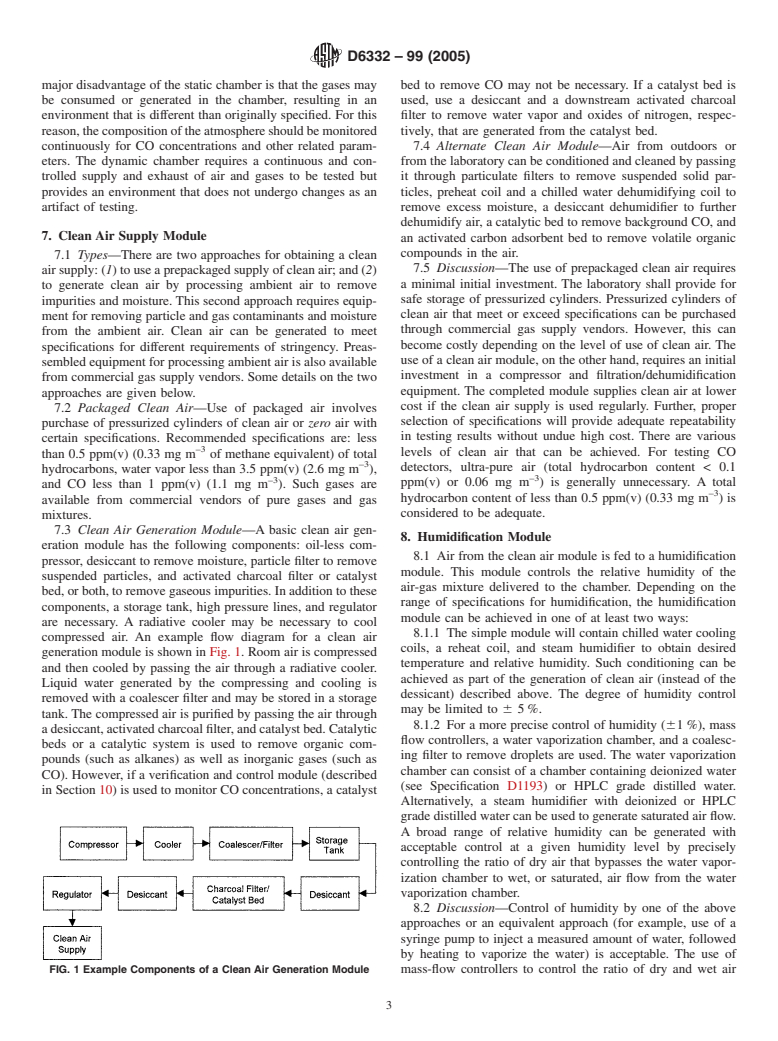

7.3 Clean Air Generation Module—A basic clean air gen-

8. Humidification Module

eration module has the following components: oil-less com-

8.1 Air from the clean air module is fed to a humidification

pressor, desiccant to remove moisture, particle filter to remove

module. This module controls the relative humidity of the

suspended particles, and activated charcoal filter or catalyst

air-gas mixture delivered to the chamber. Depending on the

bed, or both, to remove gaseous impurities. In addition to these

range of specifications for humidification, the humidification

components, a storage tank, high pressure lines, and regulator

module can be achieved in one of at least two ways:

are necessary. A radiative cooler may be necessary to cool

8.1.1 The simple module will contain chilled water cooling

compressed air. An example flow diagram for a clean air

coils, a reheat coil, and steam humidifier to obtain desired

generation module is shown in Fig. 1. Roo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.