ASTM D6552-06(2021)

(Practice)Standard Practice for Controlling and Characterizing Errors in Weighing Collected Aerosols

Standard Practice for Controlling and Characterizing Errors in Weighing Collected Aerosols

SIGNIFICANCE AND USE

4.1 The weighing of collected aerosol is one of the most common and purportedly simple analytical procedures in both occupational and environmental atmospheric monitoring (for example, Test Method D4532 or D4096). Problems with measurement accuracy occur when the amount of material collected is small, owing both to balance inaccuracy and variation in the weight of that part of the sampling medium that is weighed along with the sample. The procedures presented here for controlling and documenting such analytical errors will help provide the accuracy required for making well-founded decisions in identifying, characterizing, and controlling hazardous conditions.

4.2 Recommendations are given as to materials to be used. Means of controlling or correcting errors arising from instability are provided. Recommendations as to the weighing procedure are given. Finally, a method evaluation procedure for estimating weighing errors is described.

4.3 Recommendations are also provided for the reporting of weights relative to LOD (see 3.2.6) and LOQ (see 3.2.7). The quantities, LOD and LOQ, are computed as a result of the method evaluation.

SCOPE

1.1 Assessment of airborne aerosol hazards in the occupational setting entails sampling onto a collection medium followed by analysis of the collected material. The result is generally an estimated concentration of a possibly hazardous material in the air. The uncertainty in such estimates depends on several factors, one of which relates to the specific type of analysis employed. The most commonly applied method for analysis of aerosols is the weighing of the sampled material. Gravimetric analysis, though apparently simple, is subject to errors from instability in the mass of the sampling medium and other elements that must be weighed. An example is provided by aerosol samplers designed to collect particles so as to agree with the inhalable aerosol sampling convention (see ISO 7708, Guide D6062, and EN 481). For some sampler types, filter and cassette are weighed together to make estimates. Therefore, if the cassette, for example, absorbs or loses water between the weighings required for a concentration estimation, then errors may arise. This practice covers such potential errors and provides solutions for their minimization.

1.2 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D6552 − 06 (Reapproved 2021)

Standard Practice for

Controlling and Characterizing Errors in Weighing Collected

Aerosols

This standard is issued under the fixed designation D6552; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2.1 ASTM Standards:

1.1 Assessment of airborne aerosol hazards in the occupa-

D1356Terminology Relating to Sampling and Analysis of

tional setting entails sampling onto a collection medium

Atmospheres

followed by analysis of the collected material. The result is

D4096Test Method for Determination of Total Suspended

generally an estimated concentration of a possibly hazardous

ParticulateMatterintheAtmosphere(High–VolumeSam-

material in the air. The uncertainty in such estimates depends

pler Method)

on several factors, one of which relates to the specific type of

D4532Test Method for Respirable Dust in Workplace At-

analysis employed. The most commonly applied method for

mospheres Using Cyclone Samplers

analysis of aerosols is the weighing of the sampled material.

D6062GuideforPersonalSamplersofHealth-RelatedAero-

Gravimetric analysis, though apparently simple, is subject to

sol Fractions

errorsfrominstabilityinthemassofthesamplingmediumand

2.2 International Standards:

other elements that must be weighed. An example is provided

EN 481Workplace Atmospheres — Size Fraction Defini-

by aerosol samplers designed to collect particles so as to agree

tions for Measurement ofAirborne Particles in the Work-

with the inhalable aerosol sampling convention (see ISO 7708,

place

Guide D6062, and EN 481). For some sampler types, filter and

EN 13205Workplace Atmospheres — Assessment of Per-

cassette are weighed together to make estimates. Therefore, if

formance of Instruments for Measurement of Airborne

the cassette, for example, absorbs or loses water between the

Particle Concentrations

weighings required for a concentration estimation, then errors

2.3 ISO Standards:

may arise. This practice covers such potential errors and

ISO 7708Air quality — Particle size fraction definitions for

provides solutions for their minimization.

health-related sampling

ISO20581Workplaceatmospheres—Generalrequirements

1.2 The values stated in SI units are to be regarded as

for performance of procedures for the measurement of

standard. No other units of measurement are included in this

chemical agents

standard.

ISO 20988Air quality — Guidelines for estimating mea-

1.3 This standard does not purport to address all of the

surement uncertainty

safety concerns, if any, associated with its use. It is the

ISO GUMGuide to the Expression of Uncertainty in Mea-

responsibility of the user of this standard to establish appro-

surement (1998)

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3. Terminology

1.4 This international standard was developed in accor-

3.1 Definitions:

dance with internationally recognized principles on standard-

3.1.1 For definitions of terms used in this practice, refer to

ization established in the Decision on Principles for the

Terminology D1356.

Development of International Standards, Guides and Recom-

3.2 Definitions of Terms Specific to This Standard:

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

ThispracticeisunderthejurisdictionofASTMCommitteeD22onAirQuality the ASTM website.

and is the direct responsibility of Subcommittee D22.04 on WorkplaceAir Quality. Available from European Committee for Standardization (CEN), Avenue

Current edition approved Sept. 1, 2021. Published October 2021. Originally Marnix 17, B-1000, Brussels, Belgium, http://www.cen.eu.

approved in 2000. Last previous edition approved in 2016 as D6552–06 (2016). Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

DOI: 10.1520/D6552-06R21. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6552 − 06 (2021)

3.2.1 blank substrate, n—a collection medium or substrate

f = substrate index (1, ., F)

coming from the same batch as the sampling medium, but

F = number of substrates (for example, filters) in

unexposed.

each batch tested in method evaluation

γ = method evaluation error rate

3.2.2 equilibration time, n—For the purposes of this

LOD (µg) = limit of detection:3×s

w

practice, a time constant (seconds) characterizing an approxi-

LOD (µg) = LOD confidence limit

1-γ

mateexponentiallydampedapproachofthemassofanaerosol

LOQ (µg) = limit of quantitation: 10 × s

w

collection medium to a constant value. The constant can be

LOQ (µg) = LOQ confidence limit

1-γ

defined as the mean difference of the mass from equilibrium

N = number of blanks per substrate set

b

per mean mass loss or gain rate as measured over a finite time

ν = number of degrees of freedom in method

interval.

evaluation

3.2.2.1 Discussion—There may be important instances in

Φ = cumulative normal function

which several time constants are required to describe the

χ = chi-square random variable

approach to equilibrium.

χ = chi-square quantile (that is, a fixed number

γ,ν

3.2.3 estimated overall uncertainty (U), n—2 × estimated that exceeds the random variable χ at prob-

ability γ)

standard deviation of estimated mass, in the case of negligible

RH = relative humidity

uncorrectable bias (see ISO 20581).

u (µg) = uncertainty component in two balance

3.2.4 field blank, n—a blank substrate that undergoes the

readings, an estimate of σ

same handling as the sample substrate, generally including

u (µg) = weighing uncertainty, estimate of σ

w w

conditioning and loading into the samplers or transport

σ (µg) = uncorrectable (for example, by way of blank

containers, as well as transportation to the sampling site, but

correction) standard deviation in (single)

without being exposed.

mass-change measurement

3.2.4.1 Discussion—If blanks are not actually loaded into

σ (µg) = confidence limit on σ

1-γ

samplers, losses due to handling could be underestimated.

σ (µg) = standard deviation in collected mass determi-

w

3.2.5 lab blank, n—a blank substrate that undergoes the nation

U = overall uncertainty

same handling as the sample substrate in the laboratory,

including conditioning and loading into the samplers or trans-

4. Significance and Use

port containers when this is done in the laboratory.

4.1 The weighing of collected aerosol is one of the most

3.2.6 limit of detection (LOD), n—a value for which ex-

common and purportedly simple analytical procedures in both

ceedence by measured mass indicates the presence of a

occupational and environmental atmospheric monitoring (for

substance at given false-positive rate: 3 × estimated standard

example, Test Method D4532 or D4096). Problems with

deviation of the measured blank substrate mass (see Annex

measurement accuracy occur when the amount of material

A2).

collected is small, owing both to balance inaccuracy and

3.2.7 limit of quantitation (LOQ), n—a value for which

variationintheweightofthatpartofthesamplingmediumthat

exceedence by measured mass indicates the quantitation of a

is weighed along with the sample. The procedures presented

substanceatgivenaccuracy:10×estimatedstandarddeviation

here for controlling and documenting such analytical errors

of the measured blank substrate mass (see Annex A2).

will help provide the accuracy required for making well-

3.2.8 substrate, n—sampling filter, foam, and so forth to-

founded decisions in identifying, characterizing, and control-

gether with whatever mounting is weighed as a single item.

ling hazardous conditions.

3.2.8.1 Discussion—The 25 or 37-mm plastic filter cassette

4.2 Recommendations are given as to materials to be used.

often used for total dust sampling in either its closed-face or

Means of controlling or correcting errors arising from insta-

open-face version is NOTpart of the substrate in the definition

bility are provided. Recommendations as to the weighing

above, since it is not weighed.

procedure are given. Finally, a method evaluation procedure

3.3 Symbols:

for estimating weighing errors is described.

4.3 Recommendations are also provided for the reporting of

α = detection error rate

B = numberofsubstratebatchesinmethodevalu- weights relative to LOD (see 3.2.6) and LOQ (see 3.2.7). The

ation quantities, LOD and LOQ, are computed as a result of the

b = batch index (1, ., B) method evaluation.

β = mean substrate mass change during evalua-

5. Weight Instability, Causes, and Minimization

tion experiment

CV = maximum relative error acceptable in quan-

max 5.1 Weight instability of sampling substrates may be attrib-

tifying collected mass

uted to several causes. The following subclauses address the

∆m (µg) = substrate mass change

fb

more important of these.

ε (µg) = substrateweight-changerandomvariablerep-

b

5.1.1 Moisture Sorption:

resenting inter-batch variability

5.1.1.1 Moisture sorption is the most common cause of

ε (µg) = substrate weight change residual random

fb

weight instability. Water may be directly collected by the filter

variable with variance σ

or foam or other substrate material that is weighed. Water

D6552 − 06 (2021)

istheonlyformofanalysis.Preferablynonsorptivemediashouldbeused.

sorption by any part of the sampling system that is weighed

must be suspected as well. For example, the sampling cassette

5.1.4 Handling Damage—Lawless and Rodes (7) give rec-

itself,ifweighed,maybethecauseofsignificanterror (1) (see

ommendations on minimizing balance-operator effects. If fri-

also 8.2.2).

able substrates are used, procedures are needed to avoid

5.1.1.2 The effects of water sorption can be reduced by

mechanical damage during gravimetric analysis.

using nonsorptive materials. However, there may exist specific

5.1.4.1 The air sampling equipment should be designed so

sampling needs for which a hydrophobic material is not

that the substrate is not damaged during assembly and disas-

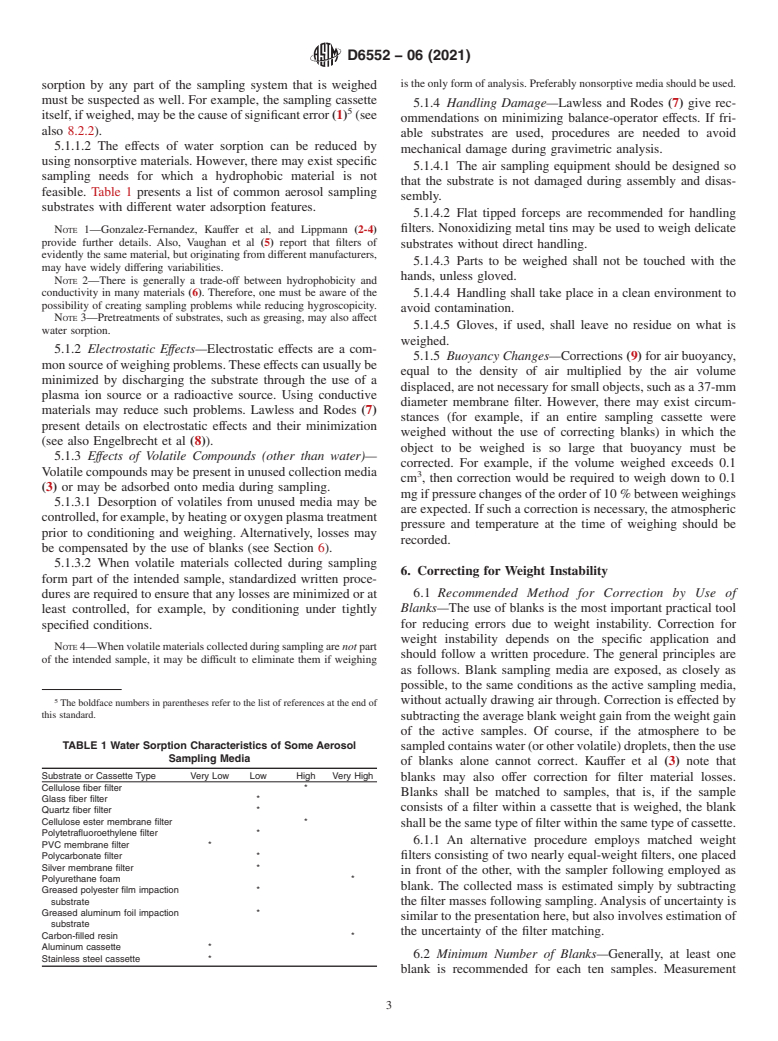

feasible. Table 1 presents a list of common aerosol sampling

sembly.

substrates with different water adsorption features.

5.1.4.2 Flat tipped forceps are recommended for handling

filters. Nonoxidizing metal tins may be used to weigh delicate

NOTE 1—Gonzalez-Fernandez, Kauffer et al, and Lippmann (2-4)

provide further details. Also, Vaughan et al (5) report that filters of

substrates without direct handling.

evidently the same material, but originating from different manufacturers,

5.1.4.3 Parts to be weighed shall not be touched with the

may have widely differing variabilities.

hands, unless gloved.

NOTE 2—There is generally a trade-off between hydrophobicity and

conductivity in many materials (6). Therefore, one must be aware of the

5.1.4.4 Handling shall take place in a clean environment to

possibility of creating sampling problems while reducing hygroscopicity.

avoid contamination.

NOTE 3—Pretreatments of substrates, such as greasing, may also affect

5.1.4.5 Gloves, if used, shall leave no residue on what is

water sorption.

weighed.

5.1.2 Electrostatic Effects—Electrostatic effects are a com-

5.1.5 Buoyancy Changes—Corrections (9) for air buoyancy,

monsourceofweighingproblems.Theseeffectscanusuallybe

equal to the density of air multiplied by the air volume

minimized by discharging the substrate through the use of a

displaced,arenotnecessaryforsmallobjects,suchasa37-mm

plasma ion source or a radioactive source. Using conductive

diameter membrane filter. However, there may exist circum-

materials may reduce such problems. Lawless and Rodes (7)

stances (for example, if an entire sampling cassette were

present details on electrostatic effects and their minimization

weighed without the use of correcting blanks) in which the

(see also Engelbrecht et al (8)).

object to be weighed is so large that buoyancy must be

5.1.3 Effects of Volatile Compounds (other than water)—

corrected. For example, if the volume weighed exceeds 0.1

Volatilecompoundsmaybepresentinunusedcollectionmedia

cm , then correction would be required to weigh down to 0.1

(3) or may be adsorbed onto media during sampling.

mgifpressurechangesoftheorderof10%betweenweighings

5.1.3.1 Desorption of volatiles from unused media may be

are expected. If such a correction is necessary, the atmospheric

controlled,forexample,byheatingoroxygenplasmatreatment

pressure and temperature at the time of weighing should be

prior to conditioning and weighing. Alternatively, losses may

recorded.

be compensated by the use of blanks (see Section 6).

5.1.3.2 When volatile materials collected during sampling

6. Correcting for Weight Instability

form part of the intended sample, standardized written proce-

duresarerequiredtoensurethatanylossesareminimizedorat 6.1 Recommended Method for Correction by Use of

Blanks—The use of blanks is the most important practical tool

least controlled, for example, by conditioning under tightly

specified conditions. for reducing errors due to weight instability. Correction for

weight instability depends on the specific application and

NOTE4—Whenvolatilematerialscollectedduringsamplingarenotpart

should follow a written procedure. The general principles are

of the intended sample, it may be difficult to eliminate them if weighing

as follows. Blank sampling media are exposed, as closely as

possible, to the same conditions as the active sampling media,

without actually drawing air through. Correction is effected by

The boldface numbers in parentheses refer to the list of references at the end of

this standard.

subtractingtheaverageblankweightgainfromtheweightgain

of the active samples. Of course, if the atmosphere to be

TABLE 1 Water Sorption Characteristics of Some Aerosol

sampledcontainswater(orothervolatile)droplets,thentheuse

Sampling Media

of blanks alone cannot correct. Kauffer et al (3) note that

Substrate or Cassette Type Very Low Low High Very High

blanks may also offer correction for filter material losses.

Cellulose fiber filter *

Blanks shall be matched to samples, that is, if the sample

Glass fiber filter *

consists of a filter within a cassette

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.