ASTM F2838-17

(Practice)Standard Practice for Accelerated Laboratory Aging of Radial Passenger Car and Light Truck Tires through Load Range E for the Laboratory Generation of Belt Separation

Standard Practice for Accelerated Laboratory Aging of Radial Passenger Car and Light Truck Tires through Load Range E for the Laboratory Generation of Belt Separation

SIGNIFICANCE AND USE

5.1 This standard practice establishes a method for conducting accelerated laboratory aging of radial passenger or light truck tires, or both, in an oven.

5.2 The goal of this practice is to define a scientifically valid protocol for the accelerated laboratory aging of a tire such that certain of its material properties correlate to those of in-service tires (see Appendix X1). This practice does not establish performance limits or tolerances for tire specifications.

SCOPE

1.1 This practice describes a method to laboratory age a new tire in an oven to produce changes in certain chemical and physical properties at the belt edges similar to those of tires in-service (see Appendix X1).

1.2 This practice is a precursor to conducting an ASTM standard roadwheel test method for laboratory generation of belt separation in radial passenger car and light truck tires.

1.3 This practice may not produce representative chemical and physical property changes in any part of the tire except the belt edge.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 8.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2838 − 17

Standard Practice for

Accelerated Laboratory Aging of Radial Passenger Car and

Light Truck Tires through Load Range E for the Laboratory

1

Generation of Belt Separation

This standard is issued under the fixed designation F2838; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope StandardforUseoftheInternationalSystemofUnits(SI):

The Modern Metric System

1.1 Thispracticedescribesamethodtolaboratoryageanew

F538 Terminology Relating to the Characteristics and Per-

tire in an oven to produce changes in certain chemical and

formance of Tires

physical properties at the belt edges similar to those of tires

G128 Guide for Control of Hazards and Risks in Oxygen

in-service (see Appendix X1).

Enriched Systems

1.2 This practice is a precursor to conducting an ASTM

2.2 Other Standards:

standard roadwheel test method for laboratory generation of

ANSI/ISO/IEC 17025 General requirements for the compe-

belt separation in radial passenger car and light truck tires. 3

tence of testing and calibration laboratories

Compressed Gas Association (CGA) Standard for Valve

1.3 This practice may not produce representative chemical

4

and physical property changes in any part of the tire except the Connections V-1

EIGA IGA 04/09/E Fire Hazards of Oxygen and Oxygen

belt edge.

Enriched Atmospheres

1.4 The values stated in SI units are to be regarded as the

U.S. Tire Manufacturers Association Demounting and

standard. The values given in parentheses are for information

Mounting Procedures for Passenger and LightTruckTires

only.

5

Wall Chart

6

1.5 This standard does not purport to address all of the

Tire and Rim Association (TRA) Year Book

safety concerns, if any, associated with its use. It is the

European Tyre and Rim Technical Organisation (ETRTO)

responsibility of the user of this standard to establish appro-

Standards Manual

priate safety, health, and environmental practices and deter-

Japan Automobile Tyre Manufacturers Association Inc.

mine the applicability of regulatory limitations prior to use.

(JATMA) Year Book

For specific precautionary statements, see Section 8. 7

ISO 4000 Passenger Car Tyres and Rims

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard-

3. Terminology

ization established in the Decision on Principles for the

3.1 Definitions:

Development of International Standards, Guides and Recom-

3.1.1 age, v—toapplyconditionssoastopromotechangeof

mendations issued by the World Trade Organization Technical

material properties.

Barriers to Trade (TBT) Committee.

3.1.1.1 Discussion—For a tire, this can be done on a

roadwheel, in a laboratory oven, in service, etc.

2. Referenced Documents

3.1.2 aging, accelerated laboratory (also: aging, labora-

2

2.1 ASTM Standards:

tory) , n—increasedrateoftirematerialpropertychangesunder

ASTM SI10 - 02 IEEE/ASTM SI 10 American National

3

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

1

This practice is under the jurisdiction ofASTM Committee F09 on Tires and is 4th Floor, New York, NY 10036, http://www.ansi.org.

4

the direct responsibility of Subcommittee F09.30 on Laboratory (Non-Vehicular) Available from Compressed Gas Association (CGA), 4221 Walney Rd., 5th

Testing. Floor, Chantilly, VA 20151-2923, http://www.cganet.com.

5

Current edition approved Oct. 1, 2017. Published October 2017. Originally Available from U.S. Tire Manufacturers Association, 1400 K St., NW, Suite

approved in 2010. Last previous edition approved in 2010 as F2838 – 10. DOI: 900, Washington, DC 20005, http://www.rma.org.

6

10.1520/F2838-17. AvailablefromTireandRimAssociation,Inc.(TRA),175MontroseWestAve.,

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Suite 150, Copley, OH 44313, http://www.us-tra.org.

7

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from International Organization for Standardization (ISO), 1, ch. de

Standards volume information, refer to the standard’s Document Summary page on la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://

the ASTM website. www.iso.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2838 − 17

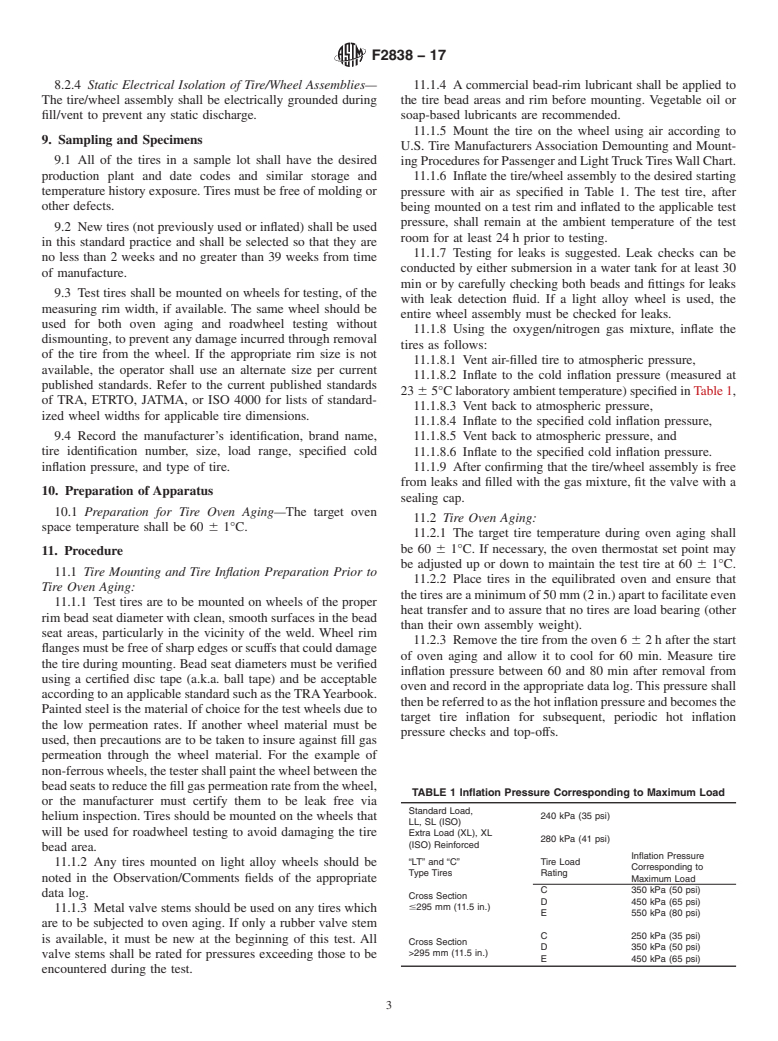

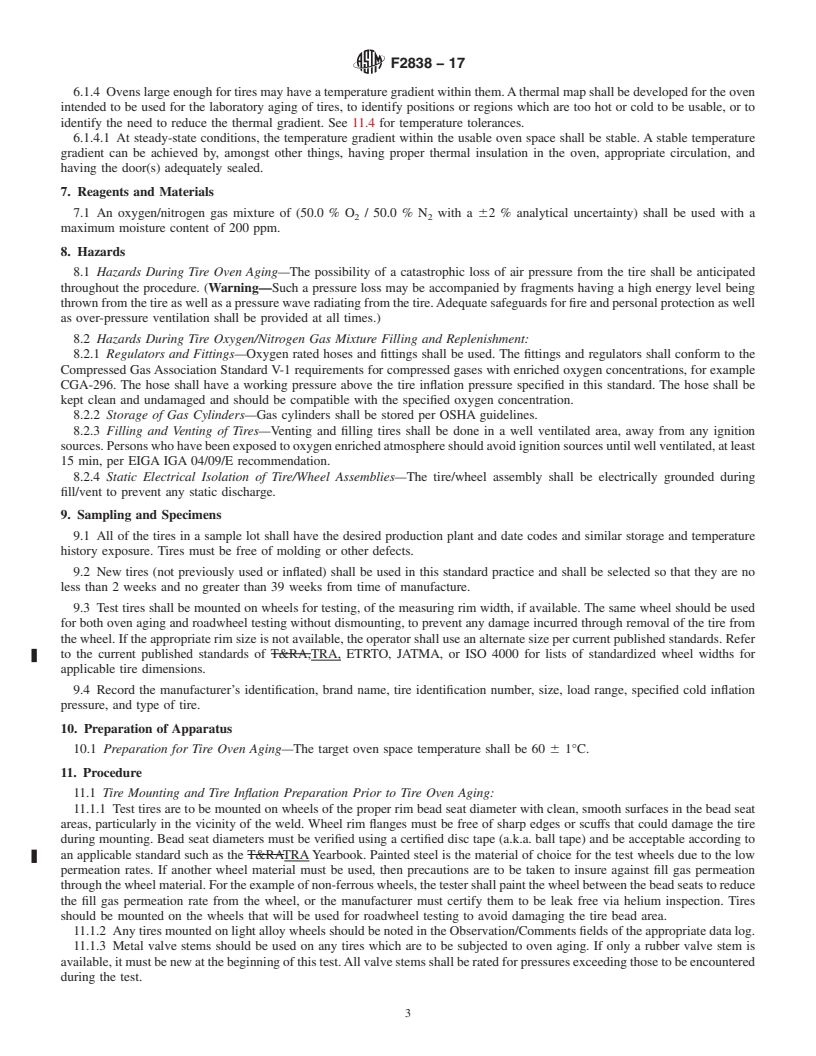

specified conditions, including temperature, inflation pressure, 6. Apparatus

oxygen concentration i

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2838 − 10 F2838 − 17

Standard Practice for

Accelerated Laboratory Aging of Radial Passenger Car and

Light Truck Tires through Load Range E for the Laboratory

1

Generation of Belt Separation

This standard is issued under the fixed designation F2838; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This practice describes a method to laboratory age a new tire in an oven to produce changes in certain chemical and physical

properties at the belt edges similar to those of tires in-service (see Appendix X1).

1.2 This practice is a precursor to conducting an ASTM standard roadwheel test method for laboratory generation of belt

separation in radial passenger car and light truck tires.

1.3 This practice may not produce representative chemical and physical property changes in any part of the tire except the belt

edge.

1.4 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use. For specific precautionary statements, see Section 8.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

ASTM SI10 - 02 IEEE/ASTM SI 10 American National Standard for Use of the International System of Units (SI): The Modern

Metric System

F538 Terminology Relating to the Characteristics and Performance of Tires

G128 Guide for Control of Hazards and Risks in Oxygen Enriched Systems

2.2 Other Standards:

3

ANSI/ISO/IEC 17025 General requirements for the competence of testing and calibration laboratories

4

Compressed Gas Association (CGA) Standard for Valve Connections V-1

EIGA IGA 04/09/E Fire Hazards of Oxygen and Oxygen Enriched Atmospheres

RMA Volume 4 Tire Service ManualU.S. Tire Manufacturers Association Demounting and Mounting Procedures for Passenger

5

and Light Truck Tires Wall Chart

6

Tire and Rim Association (T&RA)(TRA) Year Book

European Tyre and Rim Technical Organisation (ETRTO) Standards Manual

Japan Automobile Tyre Manufacturers Association Inc. (JATMA) Year Book

7

ISO 4000 Passenger Car Tyres and Rims

1

This practice is under the jurisdiction of ASTM Committee F09 on Tires and is the direct responsibility of Subcommittee F09.30 on Laboratory (Non-Vehicular) Testing.

Current edition approved May 1, 2010Oct. 1, 2017. Published June 2010October 2017. Originally approved in 2010. Last previous edition approved in 2010 as F2838 – 10.

DOI: 10.1520/F2838-10.10.1520/F2838-17.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Available from Compressed Gas Association (CGA), 4221 Walney Rd., 5th Floor, Chantilly, VA 20151-2923, http://www.cganet.com.

5

Available from Rubber Manufacturers Association (RMA), U.S. Tire Manufacturers Association, 1400 K St., NW, Suite 900, Washington, DC 20005, http://www.rma.org.

6

Available from Tire and Rim Association, Inc. (TRA), 175 Montrose West Ave., Suite 150, Copley, OH 44313, http://www.us-tra.org.

7

Available from International Organization for Standardization (ISO), 1, ch. de la Voie-Creuse, Case postale 56, CH-1211, Geneva 20, Switzerland, http://www.iso.ch.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2838 − 17

3. Terminology

3.1 Definitions:

3.1.1 age, v—to apply conditions so as to promote change of material properties.

3.1.1.1 Discussion—

For a tire

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.