ASTM E932-89(2007)

(Practice)Standard Practice for Describing and Measuring Performance of Dispersive Infrared Spectrometers

Standard Practice for Describing and Measuring Performance of Dispersive Infrared Spectrometers

SIGNIFICANCE AND USE

This practice is intended for all infrared spectroscopists who are using dispersive instruments for qualitative or quantitative areas of analysis.

The purpose of this practice is to set forth performance guidelines for testing instruments used in developing an analytical method. These guidelines can be used to compare an instrument in a specific application with the instrument(s) used in developing the method.

An infrared procedure must include a description of the instrumentation and of the performnace needed to duplicate the precision and accuracy of the method.

SCOPE

1.1This practice covers the necessary information to qualify dispersive infrared instruments for specific analytical applications, and especially for methods developed by ASTM International.

1.2 This practice is not to be used as a rigorous test of performance of instrumentation.

1.3 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E932 − 89 (Reapproved2007)

Standard Practice for

Describing and Measuring Performance of Dispersive

Infrared Spectrometers

This standard is issued under the fixed designation E932; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Significance and Use

4.1 This practice is intended for all infrared spectroscopists

1.1 This practice covers the necessary information to

who are using dispersive instruments for qualitative or quan-

qualify dispersive infrared instruments for specific analytical

titative areas of analysis.

applications, and especially for methods developed by ASTM

International.

4.2 The purpose of this practice is to set forth performance

guidelines for testing instruments used in developing an

1.2 This practice is not to be used as a rigorous test of

analyticalmethod.Theseguidelinescanbeusedtocomparean

performance of instrumentation.

instrumentinaspecificapplicationwiththeinstrument(s)used

1.3 This standard does not purport to address all of the

in developing the method.

safety problems, if any, associated with its use. It is the

4.3 An infrared procedure must include a description of the

responsibility of the user of this standard to establish appro-

instrumentationandoftheperformanceneededtoduplicatethe

priate safety and health practices and determine the applica-

precision and accuracy of the method.

bility of regulatory limitations prior to use.

5. Apparatus

2. Referenced Documents

5.1 For the purposes of this practice, dispersive instruments

2.1 ASTM Standards:

include those employing prisms, gratings, or filters to separate

E131Terminology Relating to Molecular Spectroscopy

infrared radiation into its component wavelengths.

E168Practices for General Techniques of Infrared Quanti-

5.2 For each new method, describe the apparatus and

tative Analysis

instrumentation both physically and mechanically, and also in

E387TestMethodforEstimatingStrayRadiantPowerRatio

terms of performance as taught in this practice. That is, the

of Dispersive Spectrophotometers by the Opaque Filter

description should give numerical values showing the fre-

Method

quency accuracy and the frequency and the photometric

E1252Practice for General Techniques for Obtaining Infra-

precision. State the spectral slit width maximum or slit width

red Spectra for Qualitative Analysis

programifoneisused.Wherepossible,statethemaximumand

minimum resolution if those data are a part of the instrument

3. Terminology

display. Show typical component spectra as produced by the

instrument to establish the needed resolution.

3.1 Definitions and Symbols—For definitions of terms and

symbols,refertoTerminologyE131and Compilation of ASTM

5.3 If a computer program is used, describe the program.

Standard Definitions.

Includetheprogramminglanguageandavailability,orwhether

the program is proprietary to a manufacturer.

6. Reference to this Practice in Standards

This practice is under the jurisdiction ofASTM Committee E13 on Molecular

Spectroscopy and Separation Science and is the direct responsibility of Subcom-

6.1 Reference to this practice should be included in all

mittee E13.03 on Infrared and Near Infrared Spectroscopy.

ASTM infrared methods. The reference should appear in the

Current edition approved Dec. 1, 2007. Published December 2007. Originally

approved in 1989. Last previous edition approved in 2002 as E932-89(2002).

section on apparatus where the particular spectrometer is

DOI: 10.1520/E0932-89R07.

described.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on 7. Parameters in Spectroscopy

the ASTM website.

7.1 Dispersive infrared spectrometers have a source of

Available from ASTM International Headquarters, 100 Barr Harbor Drive,

West Conshohocken, PA 19428. quasi-monochromatic radiation together with a photometer for

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

E932 − 89 (2007)

measuring relative radiant power. Accurate spectrometry in- PRECISION AND ACCURACY

volvesalargenumberofinterrelatedfactorsthatdeterminethe

9. Definitions

quality of the radiant power passing through a sample and the

sensitivity and linearity with which this radiant power can be

9.1 wavenumber precision—ameasureofthecapabilityofa

measured. Assuming proper instrumentation and its use, the

spectrometer to return to the same spectral position as mea-

instrumental factors responsible for inaccuracies in spectrom-

sured by a well-defined absorption or emission band when the

etry are resolution, linearity (Practices E168), stray radiant

instrumentisresetorrescanned.Theindexusedinthispractice

power (Test Method E387), and cell constants (Practice

is the standard deviation.

E1252). Rigorous measurement of these factors is beyond the

9.2 wavenumber accuracy—the deviation of the average

scope of this practice, and a more practical approach is

wavenumber reading of an absorption band or emission band

described for the accessible factors.

from the known wavenumber of that band.

8. Instrument Operation

10. Nature of Test

8.1 The analyst selects the proper instrumental operating

10.1 For the purpose of calibration, most methods employ

conditions in order to get satisfactory performance (1-3).

pure compounds and known mixtures at specified analytical

Because instrument design varies, the manufacturer’s recom-

wavenumbers. The wavenumbers are either read from a dial,

mendations are usually best. A record of operating conditions

optical display, chart paper, or a computer file.

should be kept so that data can be duplicated by future users.

8.2 Inadditiontooperatingconditions,thefollowingshould

11. Reference Wavenumbers in the Infrared Region (2)

be checked and recorded:

11.1 The recommended wavenumber calibration points are

8.2.1 Ambient temperature,

the absorption maxima of a standard (98.4/0.8/0.8 by weight)

8.2.2 Pen response time,

indene/camphor/cyclohexanonemixturelistedinTable1.Suit-

8.2.3 Scanning speed,

able path lengths are 0.2 mm for the range from 3800 to 1580

−1

NOTE1—Insomeinstrumentsthesefunctionsareintegratedinthescan cm and0.03mmforthewavenumberrangefrom1600to600

-1

modes.

cm . A mixture containing equal parts by weight of indene,

camphor,andcyclohexanone(1/1/1byweight)atapathlength

8.2.4 Noise level, and

−1

of 0.1 mm may be used for the range from 600 to 300 cm .

8.2.5 Mechanical repeatability.

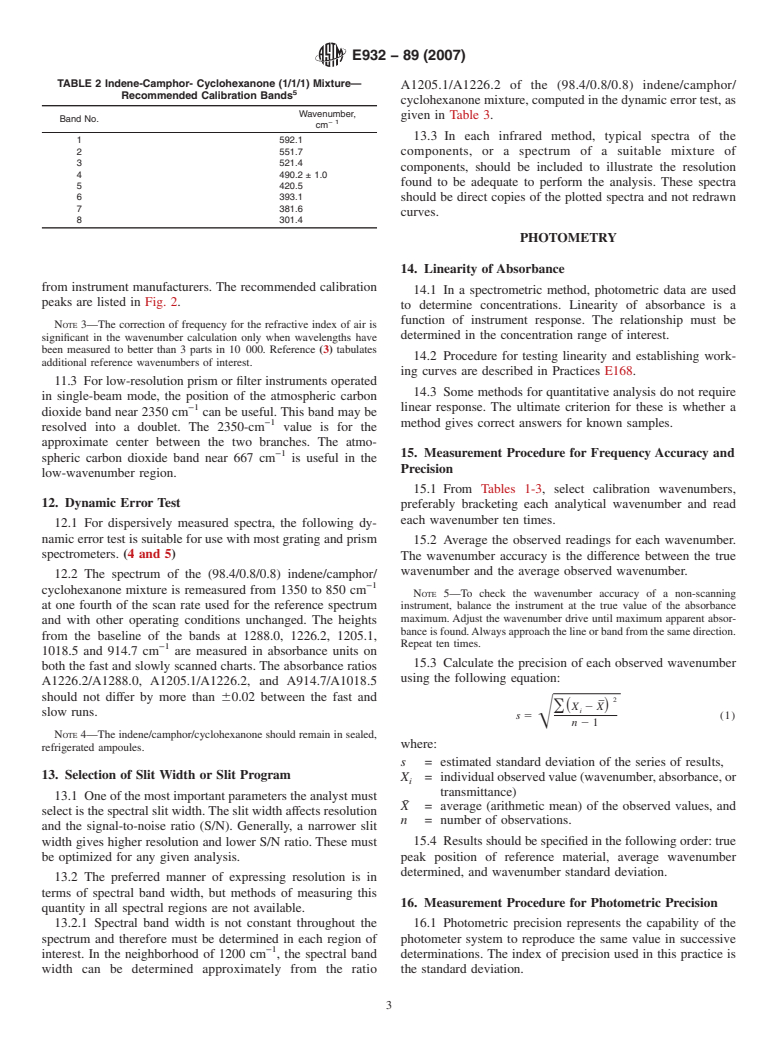

See Table 2 and Fig. 1.

8.3 Each of the above factors is important in the measure-

11.2 Polystyrene is also a convenient calibration standard

ment of analytical wavenumber and photometric data.There is

−1

forthewavenumberrangefrom4000to400cm .Polystyrene

usually some lag between the recorded reading and the correct

films, approximately 0.03 to 0.05 mm thick, can be purchased

reading. Proper selection of operating conditions and good,

reproducible, sample handling techniques minimize these ef-

fects or make the effects repeatable. For example:

8.3.1 Variation in temperature of the monochromator or

TABLE 1 Indene-Camphor-Cyclohexanone (98.4/0.8/0.8) Mixture—

sample may cause changes in wavenumber precision and

Recommended Calibration Bands

accuracy.

Band Wavenumber, Band Wavenumber,

−1 −1

8.3.2 Scanningtoofastwilldisplacetheapparentwavenum-

No. cm No. cm

ber towards the direction scanned and will decrease the peak 1 3927.2 ± 1.0 44α 1741.9

2 3901.6 44β 1713.4

absorbance reading for each band.

3 3798.9 47 1661.8

5 3660.6 ± 1.0 48 1609.8

NOTE 2—Some instruments provide for automatic monitoring and

8 3297.8 ± 1.0 49 1587.5

correction of this effect.

9 3139.5 51 1553.2

8.4 Mechanical repeatability of the monochromator and 10 3110.2 53 1457.3 ± 1.0

12 3025.4 54 1393.5

recording system as well as positioning of chart paper are

15 2887.6 55 1361.1

important in wavenumber measurement.

17 2770.9 57 1312.4

8.4.1 Chart paper should be checked for uniformity of the 19 2673.3 58 1288.0

20 2622.3 60 1226.2

printed scale length as received and rechecked at time of use,

21 2598.4 ± 1.0 61 1205.1

particularly if the paper has been subjected to pronounced

23 2525.5 62 1166.1

28 2305.1 64 1122.4

humiditychanges.Instructionsonobtainingpropermechanical

29 2271.4 66 1067.7 ± 1.0

repeatability may be given in the manufacturer’s literature.

30 2258.7 67 1018.5

33 2172.8 69 947.2

8.5 In the case of computerized dispersive instruments, any

34 2135.8 ± 1.0 70 942.4

spectrum printed from a computer file must be obtained as

35 2113.2 71 914.7

prescribed by the manufacturer and should be identical to the

36 2090.2 72 861.3

39 1943.1 73 830.5

original data.

40 1915.3 74 765.3

41 1885.1 76 718.1

42 1856.9 77 692.6 ± 1.0

The boldface numbers refer to the list of references at the end of this practice. 44 1797.7 ± 1.0

E932 − 89 (2007)

TABLE 2 Indene-Camphor- Cyclohexanone (1/1/1) Mixture—

A1205.1/A1226.2 of the (98.4/0.8/0.8) indene/camphor/

Recommended Calibration Bands

cyclohexanonemixture,computedinthedynamicerrortest,as

Wavenumber,

given in Table 3.

Band No.

−1

cm

13.3 In each infrared method, typical

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.