ASTM D352-97(2016)

(Test Method)Standard Test Methods for Pasted Mica Used in Electrical Insulation

Standard Test Methods for Pasted Mica Used in Electrical Insulation

SIGNIFICANCE AND USE

4.1 This test determines the compressive creep under laboratory conditions or under conditions that may be encountered during manufacture of electrical equipment. It has special significance if the material to be tested is applied as commutator segment insulation. It serves as a measure under specified conditions of the ability of the material to resist deformation while under compressive load, during exposure to elevated temperature for a specified time. This test is suitable for acceptance tests and for manufacturing control.

SCOPE

1.1 These test methods cover the testing of bonded mica splittings and bonded mica paper to be used for commutator insulation, hot molding, heater plates, and other similar insulating purposes.

1.2 These test methods appear in the following sections:

Test

Sections

Compressive Creep

4 – 10

Dielectric Strength

38 – 41

Mica or Binder Content

19

Molding Test

31 – 36

Organic Binder

20 – 24

Resistivity

42 – 46

Silicone Binder

25 – 30

Stability Under Heat and Pressure

11 – 18

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 40.1 and 45.1 for specific hazard statements.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D352 − 97 (Reapproved 2016)

Standard Test Methods for

1

Pasted Mica Used in Electrical Insulation

This standard is issued under the fixed designation D352; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 These test methods cover the testing of bonded mica

3.1 Definitions:

splittings and bonded mica paper to be used for commutator

3.1.1 For definitions of terms relating to electrical

insulation, hot molding, heater plates, and other similar insu-

insulation, refer to Terminology D1711.

lating purposes.

3.2 Definitions of Terms Specific to This Standard:

1.2 These test methods appear in the following sections:

3.2.1 binder content, n, (of pasted mica)—the percent by

Test Sections weight of binder relative to the original weight of a specimen

Compressive Creep 4 – 10

as determined by procedures specified herein.

Dielectric Strength 38 – 41

Mica or Binder Content 19 3.2.1.1 Discussion—Binder content includes any residual

Molding Test 31 – 36

solvent. Pasted mica materials not fully cured (such as molding

Organic Binder 20 – 24

and flexible plates) may contain appreciable quantities of

Resistivity 42 – 46

Silicone Binder 25 – 30

solvent in the binder. This solvent is usually later removed

Stability Under Heat and Pressure 11 – 18

when the material is cured in the manufacture of electrical

1.3 The values stated in inch-pound units are to be regarded

equipment. In such cases, the binder content after cure is less

as standard. The values given in parentheses are mathematical

(by the amount of solvent removed) than would be determined

conversions to SI units that are provided for information only

by this method. To determine the binder content after cure of

and are not considered standard.

materials that are not fully cured, but subsequently will be, it is

1.4 This standard does not purport to address all of the necessary, before initially weighing the specimen, to heat the

safety concerns, if any, associated with its use. It is the specimen for a time and at a temperature that depends upon the

responsibility of the user of this standard to establish appro-

material from which the specimen is prepared.

priate safety and health practices and determine the applica-

3.2.2 compressive creep, n—the change in thickness of a

bility of regulatory limitations prior to use. See 40.1 and 45.1

bonded micaceous material resulting from exposure to elevated

for specific hazard statements.

temperature for a specified time while a specimen is under a

specified compressive load.

2. Referenced Documents

2

3.2.3 mica content, n, (of pasted mica)—the percent by

2.1 ASTM Standards:

weight of mica relative to the original weight equal to 100 %

D149 Test Method for Dielectric Breakdown Voltage and

minus the binder content as determined by procedures specified

Dielectric Strength of Solid Electrical Insulating Materials

herein.

at Commercial Power Frequencies

D257 Test Methods for DC Resistance or Conductance of

COMPRESSIVE CREEP

Insulating Materials

D1711 Terminology Relating to Electrical Insulation

4. Significance and Use

4.1 This test determines the compressive creep under labo-

1

ratory conditions or under conditions that may be encountered

These test methods are under the jurisdiction of ASTM Committee D09 on

Electrical and Electronic Insulating Materials and are the direct responsibility of during manufacture of electrical equipment. It has special

Subcommittee D09.01 on Electrical Insulating Products.

significance if the material to be tested is applied as commu-

Current edition approved May 15, 2016. Published May 2016. Originally

ε1 tator segment insulation. It serves as a measure under specified

approved in 1932. Last previous edition approved in 2008 as D352 – 97 (2008) .

DOI: 10.1520/D0352-97R16. conditions of the ability of the material to resist deformation

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

while under compressive load, during exposure to elevated

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

temperature for a specified time. This test is suitable for

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. acceptance tests and for manufacturing control.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D352 − 97 (2016)

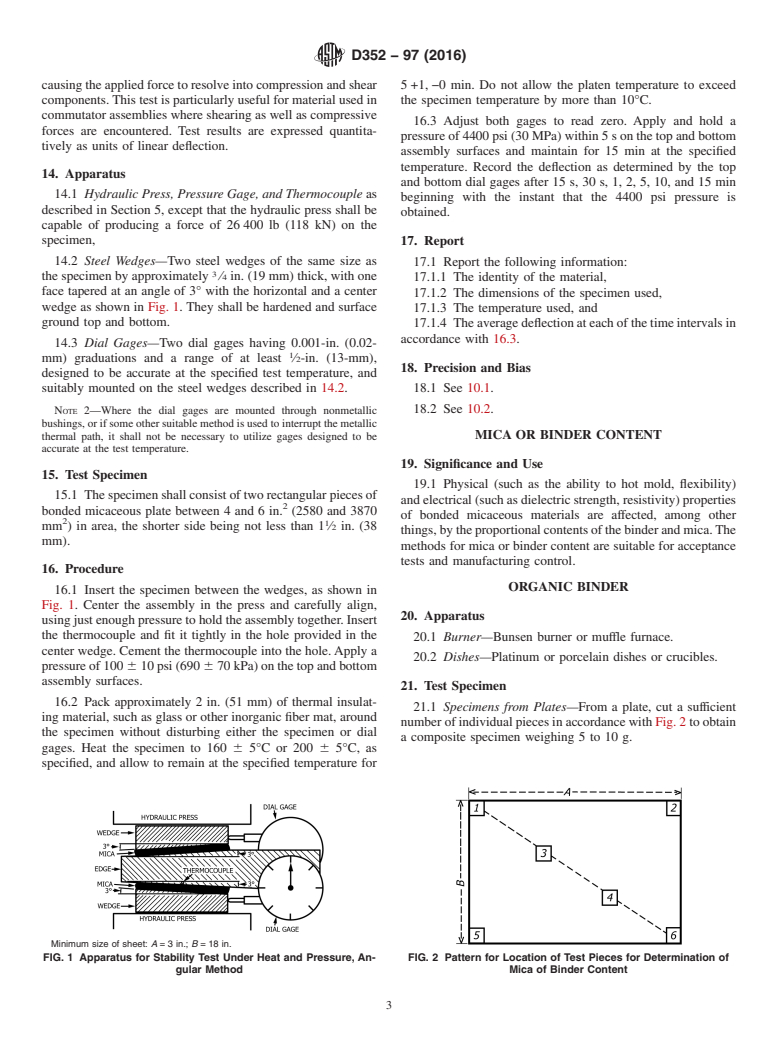

5. Apparatus 7.3 Remove the thermal insulation and, while maintaining

the pressure, allow the specimen to cool until the temper

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

´1

Designation: D352 − 97 (Reapproved 2008) D352 − 97 (Reapproved 2016)

Standard Test Methods for

1

Pasted Mica Used in Electrical Insulation

This standard is issued under the fixed designation D352; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

ε NOTE—The units statement in subsection 1.4 was corrected editorially in July 2008.

1. Scope

1.1 These test methods cover the testing of bonded mica splittings and bonded mica paper to be used for commutator insulation,

hot molding, heater plates, and other similar insulating purposes.

1.2 These test methods appear in the following sections:

Test Sections

Compressive Creep 4 – 10

Dielectric Strength 38 – 41

Mica or Binder Content 19

Molding Test 31 – 36

Organic Binder 20 – 24

Resistivity 42 – 46

Silicone Binder 25 – 30

Stability Under Heat and Pressure 11 – 18

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use. See 40.1 and 45.1 for specific hazard statements.

2. Referenced Documents

2

2.1 ASTM Standards:

D149 Test Method for Dielectric Breakdown Voltage and Dielectric Strength of Solid Electrical Insulating Materials at

Commercial Power Frequencies

D257 Test Methods for DC Resistance or Conductance of Insulating Materials

D1711 Terminology Relating to Electrical Insulation

3. Terminology

3.1 Definitions:

3.1.1 For definitions of terms relating to electrical insulation, refer to Terminology D1711.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 binder content, n, (of pasted mica)—the percent by weight of binder relative to the original weight of a specimen as

determined by procedures specified herein.

1

These test methods are under the jurisdiction of ASTM Committee D09 on Electrical and Electronic Insulating Materials and are the direct responsibility of Subcommittee

D09.19 on Dielectric Sheet and Roll Products (Disbanded 4/2016).

Current edition approved May 1, 2008May 15, 2016. Published July 2008May 2016. Originally approved in 1932. Last previous edition approved in 20032008 as

ε1

D352 – 97 (2008) (2003). DOI: 10.1520/D0352-97R08E01.10.1520/D0352-97R16.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3.2.1.1 Discussion—

Binder content includes any residual solvent. Pasted mica materials not fully cured (such as molding and flexible plates) may

contain appreciable quantities of solvent in the binder. This solvent is usually later removed when the material is cured in the

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

D352 − 97 (2016)

manufacture of electrical equipment. In such cases, the binder content after cure is less (by the amount of solvent removed) than

would be determined by this method. To determine the binder content after cure of materials that are not fully cured, but

subsequently will be, it is necessary, before initially weighing the specimen, to heat the specimen for a time and at a temperature

that depends upon the material from which the specimen is prepared.

3.2.2 compressive creep, n—the change in thickness of a bonded micaceous material resulting from exposure to elevated

temperature for a specified time while a specimen is under a specified compressive load.

3.2.3 mica content, n, (of pasted mica)—the percent by weight of mica relative to the original weight equal to 100 % minus the

binder content as determined by procedures specified herein.

COMPRESSIVE CREEP

4. Significance and Use

4.1 This test determines the compressive creep under laboratory conditions or under conditions that may be encountered during

manufacture of electrical equipment. It has special significance if the material to

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.