ASTM D4543-85(1991)e1

(Practice)Standard Practices for Preparing Rock Core Specimens and Determining Dimensional and Shape Tolerances

Standard Practices for Preparing Rock Core Specimens and Determining Dimensional and Shape Tolerances

SCOPE

1.1 This practice specifies procedures for determining the length and diameter of rock core specimens and the conformance of the dimensions with established standards.

1.2 Rock is a complex engineering material which can vary greatly as a function of lithology, stress history, weathering, and other natural geologic processes. As such, it is not always possible to obtain or prepare rock core specimens which satisfy the desirable criteria given in this practice. Most commonly, this situation presents itself with weaker, more porous, and poorly cemented rock types and rock types containing significant structural features. For these and other rock types which are difficult to prepare, all reasonable efforts shall be made to prepare a sample in accordance with this practice. However, when it has been determined by trial that this is not possible, prepare the rock specimen to the highest standard practicable and consider this to be the best effort and report it as such, with all appropriate size and dimensional measurements reported as in Section 6.

1.3 This practice also prescribes tolerance checks on the straightness of the elements on the cylindrical surface, the flatness of the end bearing surfaces, and the perpendicularity of the end surfaces with the axis of the core.

1.4 The requirement for specifying the moisture condition of the test specimen at the time of the test is also stated.

1.5 The values stated in inch-pound units are to be regarded as the standard. The SI units given in parentheses are for information only.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

1.7 This practice offers a set of instructions for performing one or more specific operations. This document cannot replace education or experience and should be used in conjunction with professional judgement. Not all aspects of this practice may be applicable in all circumstances. This ASTM standard is not intended to represent or replace the standard of care by which the adequacy of a given professional service must be judged, nor should this document be applied without consideration of a project's many unique aspects. The word "standard" in the title of this document means only that the document has been approved through the ASTM consensus process.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

e1

Designation: D 4543 – 85 (Reapproved 1991)

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Practice for

Preparing Rock Core Specimens and Determining

Dimensional and Shape Tolerances

This standard is issued under the fixed designation D 4543; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 7 was added editorially in December 1991.

1. Scope D 2113 Method for Diamond Core Drilling for Site Inves-

tigation

1.1 This practice specifies procedures for determining the

D 2664 Test Method for Triaxial Compressive Strength of

length and diameter of rock core specimens and the conform-

Undrained Rock Core Specimens without Pore Pressure

ance of the dimensions with established standards.

Measurements

1.2 Rock is a complex engineering material which can vary

D 2936 Test Method for Direct Tensile Strength of Intact

greatly as a function of lithology, stress history, weathering,

Rock Core Specimens

and other natural geologic processes. As such, it is not always

D 2938 Test Method for Unconfined Compressive Strength

possible to obtain or prepare rock core specimens which satisfy

of Intact Rock Core Specimens

the desirable criteria given in this practice. Most commonly,

D 3148 Test Method for Elastic Moduli of Intact Rock Core

this situation presents itself with weaker, more porous, and

Specimens in Uniaxial Compression

poorly cemented rock types and rock types containing signifi-

D 3967 Test Method for Splitting Tensile Strength of Intact

cant structural features. For these and other rock types which

Rock Core Specimens

are difficult to prepare, all reasonable efforts shall be made to

D 4341 Test Method for Creep of Cylindrical Hard Rock

prepare a sample in accordance with this practice. However,

Core Specimens in Uniaxial Compression

when it has been determined by trial that this is not possible,

D 4405 Test Method for Creep of Cylindrical Soft Rock

prepare the rock specimen to the highest standard practicable

Core Specimens in Uniaxial Compression

and consider this to be the best effort and report it as such, with

D 4406 Test Method for Creep of Cylindrical Rock Core

all appropriate size and dimensional measurements reported as

Specimens in Triaxial Compression

in Section 6.

1.3 This practice also prescribes tolerance checks on the

3. Significance and Use

straightness of the elements on the cylindrical surface, the

3.1 The dimensional, shape, and surface tolerances of rock

flatness of the end bearing surfaces, and the perpendicularity of

core specimens are important for determining rock properties

the end surfaces with the axis of the core.

of intact specimens. Dimensional and surface tolerance checks

1.4 The requirement for specifying the moisture condition

are required in the test methods listed in 2.1. To simplify test

of the test specimen at the time of the test is also stated.

procedures in laboratories, the parts of those procedures that

1.5 The values stated in inch-pound units are to be regarded

are common to the test methods are given in this standard.

as the standard.

1.6 This standard does not purport to address all of the

4. Specimens

safety problems, if any, associated with its use. It is the

4.1 Test specimens shall be right circular cylinders within

responsibility of the user of this standard to consult and

the tolerances specified herein.

establish appropriate safety and health practices and deter-

4.2 The specimen shall have a length-to-diameter ratio

mine the applicability of regulatory limitations prior to use.

(L/D) of 2.0 to 2.5 and a diameter of not less than 1 ⁄8 in. (47

2. Referenced Documents mm).

2.1 ASTM Standards:

NOTE 1—It is desirable that the diameter of rock test specimens be at

C 617 Practice for Capping Cylindrical Concrete Speci- least ten times the diameter of the largest mineral grain. For weak rock

types which behave more like soil (for example, weakly cemented

mens

sandstone), the specimen diameter should be at least six times the

maximum particle diameter. It is considered that the specified minimum

specimen diameter of approximately 1 ⁄8 in. (47 mm) will satisfy this

This practice is under the jurisdiction of ASTM Committee D-18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.12 on Rock Mechanics.

Current edition approved Nov. 29, 1985. Published January 1986.

2 3

Annual Book of ASTM Standards, Vol 04.02. Annual Book of ASTM Standards, Vol 04.08.

D 4543

criterion in the majority of cases. When cores of diameter smaller than the

specimen does not meet the required tolerance for straightness

specified minimum must be tested because of the unavailability of larger

of the elements. The flat test surface on which the specimen is

diameter core, as is often the case in the mining industry, suitable notation

rolled shall not depart from a plane by more than 0.0005 in. (15

of this fact shall be made in the report.

μm).

5.1.2 Procedure B—Place the cylindrical surface of the

specimen on a V-block that is laid flat on a support surface. The

V-block shall be machinist quality with all bearing faces

surface ground and with a 90° included angle. Maintain the

support surface and all bearing surfaces on the V-block flat and

smooth to within 0.0005 in. (15 μm). The length of the V-block

shall be sufficient that the specimen will not project over its

ends during movement.

5.1.2.1 Place a dial gage in contact with the top of the

specimen, as shown in Fig. 1, and observe the dial reading as

the specimen is moved from one end of the V-block to the other

along a straight line, without rotation. The sensitivity of the

dial gage shall be at least 0.001 in. (25 μm). The measurement

contact tip of the dial gage shall be round in shape.

5.1.2.2 Record the maximum and minimum readings on the

dial gage and calculate the difference, D . If the dial gage

traverses a natural cavity in the rock, readings in this region

should not be included in the determination of D . Repeat the

FIG. 1 Assembly for Determining the Straightness of Elements

same operations by rotating the specimen for every 120°, and

on the Cylindrical Surface

obtain the differences D and D . The maximum value of

120 240

these three differences shall be less than 0.020 in. (0.50 mm).

5.2 Check the flatness tolerance by a setup similar to that for

the cylindrical surface (Fig. 2) except that the dial gage shall be

mounted near the end of the V-block.

5.2.1 Move the mounting pad horizontally so that the dial

gage runs across a diameter of the specimen end surface. Take

care to make sure that one end of the mounting pad maintains

intimate contact with the end surface of the V-block during

movement. A dial gage sensitive to 0.0001 in. (2.5 μm) is

required for measurements on the end surfaces.

5.2.2 Record the dial gage readings every ⁄8 in. (3 mm)

across the diameter. These readings may be recorded in tabular

FIG. 2 Assembly for Determining the Flatness and

form, or to simplify the procedure, they may be plotted directly

Perpendicularity of End Surfaces to the Specimen Axis

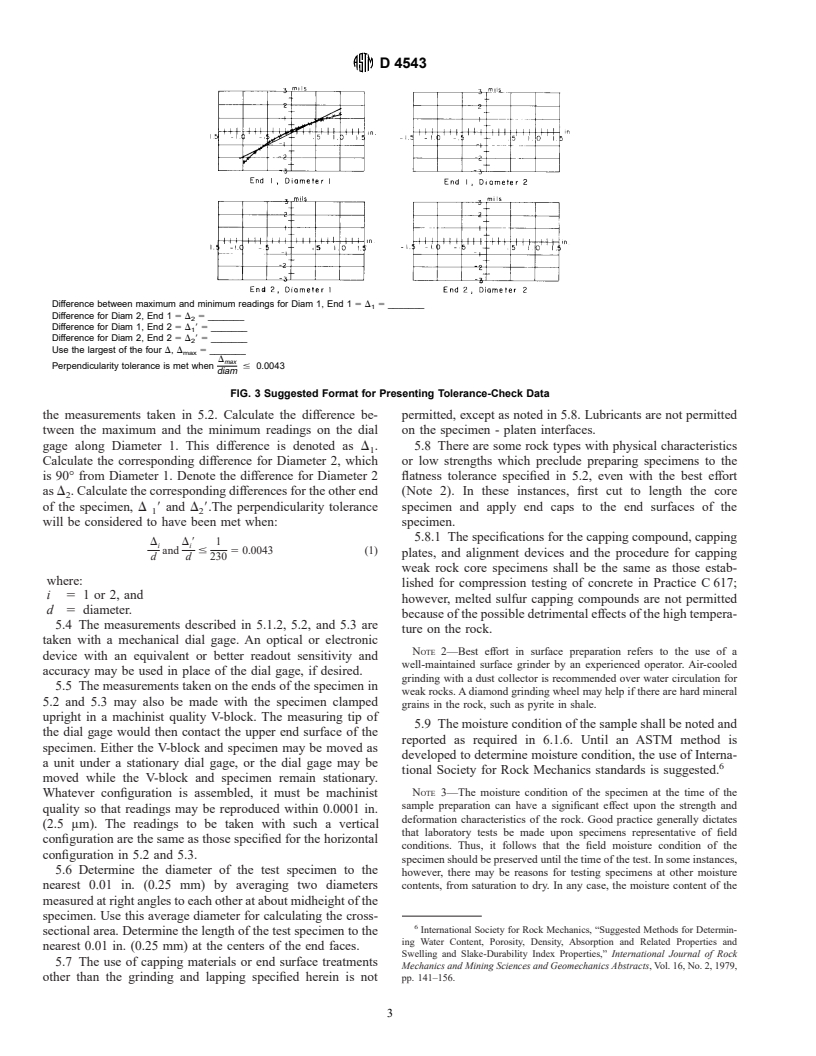

on a graph as shown for End 1, Diameter 1, in Fig. 3. Data

recording is also simplified if the dial gage is set to zero when

4.3 The sides of the specimen shall be generally smooth and

it is in contact with the center of the end face.

free of abrupt irregularities, with all the elements straight to

5.2.2.1 Plot the readings and draw a smooth curve through

within 0.020 in. (0.50 mm) over the full length of the specimen,

the points to represent the surface profile along the specified

as determined by 5.1.

diameterical plane, as shown for End 1, Diameter 1, in Fig. 3.

4.4 The ends of the specimen shall be cut parallel to each

Do not plot dial gage readings taken when the gage tip drops

other and at right angles to the longitudinal axis. The end

into a natural cavity in the rock. The flatness tolerance is met

surfaces shall be surface ground or lapped flat to a tolerance not

when the smooth curve so determined does not depart from a

to exceed 0.001 in. (25 μm), as determined by 5.2.

visual best-fit straight line by more than 0.001 in. (25 μm).

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.